SPK, SPS, SPL SERIES HYDROPHORE · SPK-SPS-SPL SERIES HYDROPHORES Definition SPK-SPS-SPL Series...

Transcript of SPK, SPS, SPL SERIES HYDROPHORE · SPK-SPS-SPL SERIES HYDROPHORES Definition SPK-SPS-SPL Series...

SPK, SPS, SPL SERIES HYDROPHORE

ENGLISH INTRODUCTION AND USER MANUAL

TABLE OF CONTENTS

Warranty and Service 3

General Properties 4

Usage Instructions 5

Hydrophore Definition 7

Hydrophore Code System 8

Carrying, Shipment and Storage 9

Rules Which Should Be Obeyed During Installation 11

Other Installation Conditions 14

Properties of Used Liquid 15

Electrical Connections 16

Putting Hydrophore Group Into Service 18

Putting Hydrophore Group Out Of Service 19

Pressure Balancing Tank 20

Technical Properties of Membranes 23

Pressure Switch 24

Dismounting, Maintenance and Installation of Hydrophore 25

Protection Against operation without water 25

Hydrophore cross sectional drawing 26

Possible Failures and Troubleshooting 27

Certificates 21

Dear Valued Customer; Firstly we thank for you to select SEMPOMP trademark. This manual includes maintenance and user information about SEMPOMP trademark SPK, SPS, SPL Series Hydrophores . Our products are produced according to total quality principals of Sempa Ltd. Şti. Please carefully read our manual completely for operating our hydrophores economically and with high efficiency within our total quality understanding. Performers of operations which are contrary with recommendations and instructions in this manual and out of information which are defined in this manual; will be liable with results of operations. Authorized seller and services will provide necessary information about usage and maintenance of this pump after pump is put into service. You can contact with SEMPOMP authorized seller and services for getting detailed information about submersible pumps.

-2-

WARRANTY AND SERVICE This manual is valid for all types of SPK, SPS, SPL series hydrophores SEMPOMP motor water pumps are under warranty for 2(two) years against material and manufacturing failures provided that conditions and principals that are mentioned in this manual and related standards are obeyed. P rovisions related with warranty conditions which are appropriate with provisions which are mentioned in related law provisions are explained over Warranty Certificate which is given with hydrophore Product warranty certificate will be filled and sealed by authorized SEMPOMP seller where you had purchased product One part of warranty certificate will be delivered to you after hydrophore has been installed into well by authorized SEMPOMP service personnel and other part will be sent to SEMPOMP customer services.

Warranty processes are just valid for operations that are

performed by SEMPOMP authorized services. Therefore call SEMPOMP authorized services in probable hydrohore failures.

Usage lifetime of pumps which determined by related Ministry is

10 (ten )years. According to related law, Producer and Seller Companies commit to provide service and spare parts for the hydrophore within this period.

Failures which may occur because of inappropriateness of cable type and cross section are evaluated as out of scope of warranty. You can get detailed information about hydrophore by contacting with SEMPOMP Customer Services General Directorate or by email from [email protected]

GENERAL PROPERTIES Main objective of hydrophores is to keep pressurized water always ready in an installation for usage. There are mainly 3 parts in a hydrophore unit. -Hydrophore+Motor (Motopomp) -Control Equipments -Pressure Balancing Tank (It is externally supplied) Motopump: It provides the water get pressure energy. In hydrophores, SPK series is monophase type and SPS and SPL series are triphase type. All series are in vertical condition. Control equipments: Pressure changes in installation are equipments which automatically put hydrophore into service according to presence of water. Pressure Tank: Its aim is to balance pressure changes in water installation and optimizing the pump start stops (number of switching) to a suitable number. Figure 1: Sİngle Hydrophore Scheme

-4-

USAGE INSTRUCTIONS

Operate the hydrophore according to conditions which are only written in this user manual.

Cricks and weight which occur in hydrophore pipe system should never reach the pump.

Electrical connections related with hydrohpore and auxiliary elements in hydrohphore should absolutely be done according to rules and by authorized personnel.

Operations should never be done over hydrophore without completely stopping the hydrphore unit.

Before making operation over waste hydrophore unit, you should be sure that electricity power of motor is disconnected and will not connect again until operation ends.

Operations to be done over hydrophore should always be done by at least two personnel.

Clothes of personnel who will work over hydrophore unit should be suitable with work to be done and necessary safety precautions should be taken.

Operations should not be done over pump while hydrophore is hot.

Waste water should not be installed or uninstalled into drainage pits by hanging from its control cable. Operations should never be done over hydrophore when hydrophore and its connections are pressurized.

Uninstalled guards and protective parts should absolutely be installed in their place after operations over hydrophore is completed.

-5-

USER MANUAL

Hydrophores should never operate in reverse direction.

Hands should not be inserted into holes and spaces over hydrophore.

You should never walk over hydrophore and/or pipes which are fixed to the hydrophore unit.

Precautions should be taken for preventing water to freeze because of frost hazard.

Cable attachment should be done by expert personnel, according to measurements of voltage at the ends not according to color.

Control panels should be controlled by expert personnel in every six months and parts having failure or do not function properly should be replaced.

Power supply should not be made from control panels to any other devices out of hydrophore.

Hydrophores should never operate without water.

Hydrophore installation should be made by experienced technical personnel.

-6-

SPK-SPS-SPL SERIES HYDROPHORES

Definition

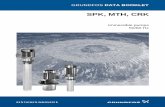

SPK-SPS-SPL Series Hydrophores have vertical shaft, are multistaged, have closed impeller and diffuser.

Application Areas

SPK-SPS-SPL series hydrophores are suitable for discharging clean or very less polluted liquids which are low viscose and fluid temperature is up to 600C. (max 20 mg(dm3). In addition to others; main application areas are:

Water supply, watering and sprinkling systems.

Pressurized water supply and hydrophore systems.

Boiler supply and condense

Heating and air conditioning systems

Industrial applications

Fire extinguishing systems.

Power stationsT

Technical information

Speed : Up to 3600 rpm

Discharge Flange :DN32 …DN 65 mm

Operational Temperature :0ºC…60ºC cooled soft gasket

Ambient Temperature (Maximum) :+40ºC

Body Pressure :16 bar-(25 Bar)

Isolation Class :F

Protection Class :IP55

Electrical Connection :1 Phase-220 V-50 Hz 3 Phases-380V-50Hz

Motor Options(Optional) : Special Voltage Special Frequency and Exproof

-7-

HYDROPHORE CODE SYSTEM

Coding system which is used in hydrophore groups are given below as following. Please use this code number for determining your hydrophore.

Hydrophore group: SPK,SPS, SPL

SPK 80-08 x1

Single Hydrophore Number of Stages Motor body type Hydrophore type

-8-

PROPERTIES TO BE CARED DURING CARRYING, SHIPPING AND STORAGE

Rules which are mentioned in user manual should strictly be obeyed for not causing accidents.

Protective gloves, shoes and helmet should be used during shipment and carrying.

Crane and lifting ropes which are suitable with hydrophore volume and weight and structure should be used.

Following aspects should be considered before lifting hydrophore or hydrophpre or motor group over frame.

- Total weight and center of gravity

- Maximum external dimension

-Locations of lifting points

Capacity of machines etc objects should be suitable with weight of hydrophore and hydrophore group.

Hydrophore or hydrophore group should always be lifted vertically.

You should never stay near under or close to pump during hydrophore lifting.

Lifting operations of hydrophores should be short as possible.

Accelerating and braking operations during lifting should be performed such that it will not cause any harm for the personnel working for this operation.

-9-

Hydrophore should be protected against contracts and hard impacts while they are loading to transportation vehicles.

Necessary fixing and anchoring materials should be used for the machines which are loaded to transportation vehicles for preventing crashes and contacts.

Hydrophore nameplates should absolutely be controlled while they are being received.

Figure 1a. Only Hydrophore Figure 1b. Common Hydrophore and Motor over frame

Hydrophores should be lifted as it is shown in drawings Figure 1.a and Figure 1.b for not causing any danger and deformation during transportation.

The area where hydrophore will be stored should be clean, dry and should not include frost hazard and ambient temperature should not change so frequently.

Necessary precautions should be taken for preventing hydrophore against dust, dirt and foreign objects.

Shaft should be rotated in definite time intervals for preventing pitting in hydrophore shaft and bearings.

-10-

RULES WHICH SHOULD BE OBEYED IN HYDROPHORE INSTALLATION

WORKING PLACE:

Hydrophores should be carried over a flat and robust ground.

Working places of hydrophores should be closed such that they will not be effect from environmental conditions such as rain, frost.

Hydrophores should not be effected from temperatures of other equipments and machines around them.

Required space should be adjusted around hydrophore for maintenance and repair operations.

If hydrophore is supplied from a tank, there should be maximum 10 mt distance between tank and hydrophore.

SUCTION INSTALLATION:

Supply in hydrophores should be done by water tank. Waterworks should not be used directly.

Suction pipe should be short as possible.

A filter having quality and property which will permit the water passing with internal diameter area of suction pipe should be selected.

Filter with backwater valve and auxiliary parts should be connected to suction pipe provided that they will not take air and have water impermeability and suction pipe should be connected to hydrophore after bending and having a wide angle as possible.

-11-

Water tank and hydrophore connection should be in same plane. So there will always be water in hydrophore suction.

Suction should never be performed from lower levels of hydrohore plane. Damages which may be caused from such applications are not included within warranty.

Impermeability should be provided in suction lines of hydrophores, air should not enter into suction line.

As hydrohphores are designed for ready water suction, suction should not be performed by hydrophores. Water suction should be one fold greater in single hydrophores and should be equal to collector diameter in two or more hydrophores system.

If hydrophore is supplied from a tank whose level is higher than hydrophore, an isolation valve whose axis should be horizontal with suction pipe should be used. This valve should always be in open position while hydrophore is operating and should never be used as adjustment valve.

Closing valve may cause hydrophore operate with cavitations.

If suction pipe is plastic pipe, pipe whose diameter is suitable with galvanized pipe should be selected since the diameters of plastic pipes are narrower than galvanized pipes.

If there is the necessity of cross section change in a horizontal suction pipe, an eccentric conical part whose flat part is at upper side should be used.

Suction pipe should absolutely be impermeable and arranged to prevent the formation air peripheries. So if hydrophore is supplied from a tank whose level is higher suction pipe should have a slope which slightly decrease towards hydrophore and if it is supplied from a tank whose level is lower, suction pipes should have a slope which slightly increase towards hydrophore.

-12-

For minimizing the pipe friction losses as possible, sharp curves should not be used, and sudden direction and section changes should be avoided. If there is the necessity of section change in a horizontal pipe and eccentric intermediate part whose flat side will be at upper side should be used.

DISCHARGE INSTALLATION:

A control valve is connected to discharge pipe line, in a level which is very close to hydrophore as possible for adjusting flow rate and discharge height.

If discharge height of hydrophore is more than 10 mt or discharge line is very long, a check valve should be connected over discharge pipe line between hydrophore and isolation valve for preventing motor against water impacts and reverse flow during hydrphore stopping.

Installation of suction and discharge line is given below as schematics.

1- Hydrophore 2- Float Valve 3- Valve 4- Check Valve 5- Drain 6- Discharge 7- Dirt retainer 8- Console Tap 8- Level FLoater

-13-

OTHER INSTALLATION CONDITIONS:

Backwater valve should be installed at suction part of hydrophores. This will prevent the entrance of solid particles to hydrophore and its parts during suction.

Silt traps which are used at the end of suction pipe should be cleaned periodically. Otherwise foreign objects which ma come to hydrophore suction may clog the suction and prevent water entry to hydrophore suction.

Valve should be installed in hydrophore inlet and valve and check valve should be installed at hydrophore outlet. By means of this application separation of hydrophore from installation will be possible during repair and maintenance operations.

Curves which are used in suction and discharge lines should have wide angles as possible.

Pipe connections should be made by flanges. Flange seals should be made from suitable materials and should have proper sizes. Flange seals should be centered as they will not prevent flow.

Connection of hydrophore to installation by means of flexible hoses should be preferred. So loads which may be caused by installation will not reflected to hydrophore. Also vibration and sound of hydrophore will not pass to the installation.

Hydrophore should be fixed to ground by bolts during operation. So sound which may occur during operation is almost prevented.

In case that suction and discharge lines are long, bedding should absolutely be done in bearings. Otherwise it will cause shocks and vibrations.

-14-

PROPERTIES OF USED LIQUIDS:

Water is used as fluid in hydrophores. Clean water should not include particles. Liquid temperature should be between 0-350C

Ambient temperature should be maximum 400C

Water inside hydrophore should be protected from frost hazard. Damages which may be caused by frost are out of warranty.

PRECAUTIONS WHICH SHOULD BE TAKEN FOR ELONGATING THE USAGE TIME OF MECHANICAL SEAL

Mechanical seals are one of the weakest part of hydrophores. Incorrect installation and usage may cause rapid breakdowns. Operational life time of mechanical seal is 8000 hours in waters which does not include particles in

normal operational period. As an operational principle; it forms a film layer between carbon and ceramic or stainless surface and ensures contact of those surfaces without friction. Water also has cooling function. However, if water film does not form and mechanical seal surface runs for few minutes without water, this cause burn of mechanical seal and break down in 3-5 minutes.

PRECAUTIONS WHICH SHOULD BE TAKEN FOR HEALTHY OPERATION OF MECHANICAL SEAL

Hydrophore should not make suction from low levels.

Check valves should not be used in hydrophore connections whose suction level is same with tank. Check valve makes flow difficult. Also filter which locates in suction part should frequently be cleaned for preventing clogging.

Sand which presents in water may tear water film and provides break down in impermeability.

-15-

ELECTRICAL CONNECTIONS

Electrical connections should only be done by authorized service personnel.

Current national regulations and instructions of motor manufacturer should be obeyed in hydrophore installation.

Precautions which are mentioned in "USAGE PRINCIPALS" should be obeyed. All electrical connections should be disconnected before making any operations over hydrophore.

Installation of power cables should be performed such that they will not have contact with pipe, hydrophore and motor part.

Voltage, frequency and ampere values which are written in nameplate should be checked whether they are suitable with line values.

Circuit breakers and fuses should be used for preventing motor operate overloaded.

Pump shaft should be checked whether it rotates easily before giving power to motor.

Motor electrical connections should be done according to Electricity Regulations and grounding should strictly be done.

Motor connection scheme is included in user manual and motor connection box.

Motor connection types are given in Table 1 and Figure 2.a,2.b, 2.c In cases that electrical connections are incorrect and failures which are caused by power supply unit will make pump unit become out of warranty.

-16-

TABLE 1

Start Type Motor Power

PN<4kW

Motor Power

PN >4kW

Mains Power

3~400V

Mains Power

3~400V

Direct Y-connection (1b) Δ-connection (1a)

Y/ Δ Star Delta Impossible Remove Jumpers (1c)

Figure 2a- Δ-Connection Figure 2- bΔ-Connection Figure 2a- Y/Δ-Connection

Transition time from star to delta should be very short in star/delta connected motors. Otherwise this may cause damage in pumps.

Rotate the hydrophore rotor manually for few turns after abovementioned operations are completed for being sure that it rotates easily.

All guards are installed in their places before hydrophore starts to run. Motor should not absolutely be started before guards are placed into their places.

Cables coming from electricity unit to pump are isolated and protected.

Pumps and cable connections should not be contacted out of expert pr responsible personnel and without switching off power from main circuit breaker; For preventing the damages which may be caused by electrical leakages which may occur pump connection an cables.

-17-

PUTTING HYDROPHORE GROUP INTO SERVICE

SEMPA LTD .ŞTİ. authorized services are responsible for performing first start operations.

Grounding of hydrophore system should be done.

Electrical leakage control should be done.

Line voltage should be measured.

Check whether there is sufficient water inside tank.

Thermal protection adjustments should be controlled.

Be sure that installation of membrane tank is correct and control the appropriateness of preliminary pressure.

Completely open the valve in hydrophore suction part.

Slightly loosen the air take plug of hydrophore. If the water level in water tank is higher than this level, water will leak from the plug for a while. If hydrphore will operate with suction, fill water from this part and tightly close the plug.

Run the hydrophore or hydrophores for a short while. Check whether hydrophore shaft rotates in correct direction. If hydrophore rotates in reverse direction change the places of electrical connection terminals.

Check whether hydrophore or hydrophores in requested pressure interval.

Check rotation is performed in every operation in hydrophores having multi-pumps.

PUTTING HYDROPHORE INTO SERVICE OPERATION HAS FINISHED

-18-

PUTTING HYDROPHORE GROUP OUT OF SERVICE

Slowly close the discharge valve

If there is equipment for preventing and impulse is not in dangerous, you can directly stop hydrophore without closing the discharge valve for preventing water hammer.

Stop the pump. Control the motor stop whether it has stopped regularly.

Control whether there is water leakage from mechanical seal after hydrophores have put out of service.

If hydrophore will be out of service for a long time close the suction valve and other auxiliary pumps.

If there is frost risk in the environment where hydrophore locates, water inside pump should absolutely be discharged and necessary precautions should be taken.

CONTROLS WHICH ARE NECESSARY TO BE DONE IN WATER PUMPS DURING OPERATION

Hydrophore should operate regularly, silent and without vibration.

Hydrophores should never be operated without water.

Pumps should not operate in completely closed valve condition for a long time.

Take care that all valves belonging to auxiliary systems are open during hysrophore operation.

Hydrophore will not need any maintenance if it is operated with mechanical seal. Leaked water is so low that it can not be seen. Increase in drops from mechanical seal means that surfaces are abraded and needs to be changed. Lifetime for mechanical seal usage depends on cleanness of water.

-19-

Control the clutch materials between motor and hydrophore periodically. If there are abraded materials replace them with newer ones.

Periodically control the motor current. If motor current is less than occasional values stop the motor. There may be jamming in motor and hydrophore accessories. Run the hydrophore after making necessary repair and maintenance operations and according to necessary safety precautions.

Hydrophores which are used as spare should be run at least once a week and systems related with this should be controlled.

No Operation should be done over hydrophpres while hydrophores are operating. Centrifugal Hydrophores should not be started in particular when guards and protective materials are not installed.

PRESSURE BALANCING TANK (MEMBRANE TANK)

There are different applications pressure tanks that are used in hydrophores depending on size and tonnage of hydrophores.

User should use membrane tank with hydrphore in SPK, SPS and SPL series. Selection of membrane tank, installation and pressurizing is explained below.

-20-

VOLUME CALCULATION OF MEMBRANE TANK

Total volume calculation for replaceable expansion membrane tank which is used in hydrophore system is calculated as following.

VE=0,33 X Qmax(PA+1) (m3) ΔP(A.E)vXS Qmax= Maximum flow rate of hydrophore (m/h) PA= Upper pressure of Hydrophore operation (Bar) P(A-E)=Hydrophore operational interval (Difference between upper pressure and lower pressure) Bar S=Number of switching (Number of starts and stops of Hysrophore in one hour)

Minimum usage pressure of tank is found after calculations. There is no problem if operational pressure is calculated high. On the contrary following benefits may occur as the tank volume increases.

Pressure fluctuations in water decrease.

Lifetime of motor becomes longer.

Energy costs decrease.

Sound of motopump start stop decreases as the number of hydrophore switching number will decrease.

Notice: As it is defined by the general instructions which is published by Ministry of Public Works:

Number of switching up to power max 1.1 kW motor power is 180 times/hour

Number of switching up to power more than 1.1 kW motor power is 40 times/hour

Notice: Maximum operational pressure of membrane tank should be higher than maximum operational pressure of hydrophore. CONNECTION OF MEMBRANE TANK Aim of pressure membrane tank is to decrease the number of start and stops in one hour. There will not be necessity of motopump for usages in low amounts. Therefore the greater tank the less number of switching.

-21-

Connection of membrane tank to hydrophore unit is performed in two ways. 1- Collector Connection There is tank connection outlet over hydrophore discharge collector. Pressurized tank can be connected here by means of steel cord flexible hose, galvanized or plastic pipes. Pipe installation having minimum diameter of outlet of membrane tank should be used at hydrophore discharging pipe. Otherwise water transmission speed between tank and installation decreases. This may cause decrease in efficiency of tank and may cause problems in hydrophore operation. 2-Connection to Installation

It is possible to connect pressure tank directly to installation. If hydrophore is directly connected to installation, end of membrane tank in collector should be closed. Distance of pressure tank to hydrophore group should not exceed 5(five) meters. If distance increases sense of pressure switch is delayed and there may be irregularities in operation. PRELIMINARY GAS PRESSURE ADJUSTMENT OF PRESSURE TANK Hydrophore unit is not absolutely used without tank. Tanks with membranes are used for this purpose provided that they are suitable with operational pressure. There is a little air inside tanks with membrane during transportation and shipment. Air pressures of membrane tanks should be adjusted according to usage conditions. Tank pressure is practically calculated as following. Pö=Pst-0.5(Bar) Pö=Hydrophore preliminary pressure Pst=Tank Pressure

MEMBRANE TECHNICAL PROPERTIES

VOLUME OPERATIONAL PRESSURE

HEIGHT H (MM)

MIN-MAX OPERATIONAL TEMPERATURE

(0C)

CONNECTION PROPERTY

8-12 LT 10-16 190 mm -10/+100 85 mm EPDM

18-24 LT 10-16 200 mm -10/+100 85 mm EPDM

35-60 LT 10-16 320 mm -10/+100 85 mm EPDM

80-100 LT 10-16 700 mm -10/+100 85 mm EPDM

200-300 LT 10-16 900 mm -10/+100 150 mm EPDM

500-750 LT 10-16 1300 mm -10/+100 150 mm EPDM

1000-1500 LT

10-16 1950 mm -10/+100 205 mm EPDM

2000 LT 10-16 1950 mm -10/+100 205 mm EPDM

2000 LT 8 2100 mm -10/+70 150 mm BUTYL

2500 LT 8 2300 mm -10/+70 150 mm BUTYL

3000 LT 8 2350 mm -10/+70 200 mm BUTYL

3500 LT 8 2400 mm -10/+70 250 mm BUTYL

5000 LT 8 3285 mm -10/+70 250 mm BUTYL

10000 LT 8 5500 mm -10/+70 320 mm BUTYL

Connection of hydrophore with installation should not be disconnected during air injection and if there is water inside hydrophore it should be discharged.

Using galvanized tanks which has direct contact with air is inconvenient for usage as hydrophore tank. As air inside tank dissolves in water leaks to outside with air. Therefore air inside tank finishes and as a result of this number of motor switching over increases.

Air inside membrane tank should periodically be controlled. If the pressure inside tank decreases, number of hydrophore switching will increase therefore sound and water fluctuation will increase.

-23-

PRESSURE SWITCH

Pressure switches are used for adjusting operational pressures and stop pressure

PRESSURE SWITCH ADJUSTMENT

There are two pieces of spring screws in pressure switches. Longer one is used for pressure adjustment and shorter one is used for adjusting stop pressure.

1- Loosen the shorter screw till the end.

2- Adjust the hydrophore start pressure by longer screw.

3- As a final operation tighten the shorter screw the shorter screw up to your preferred stop pressure.

There is approximately 3 seconds of delay in two or more hydrophore systems for preventing water hammer. This property should be considered during adjustment in hydrophores

Pressure should not be increased so much in hydrophore while making pressure switch adjustment.

-24-

PROTECTION AGAINST OPERATION WITHOUT WATER

Float valve system is used to take precautions for preventing hydrophore operate without water. Hydrophore makes suction as the float valve is suspended in water. If water inside tank finishes, float valve will fall down and suction will not occur.

Float valve system should absolutely be used in hydrophore systems with tank for preventing pump operate without water. Otherwise, if there is not water in tank, pump will operate without

water . Pump unit will be out of warranty if is works without water.

DISMOUNTING OF HYDROPHORE; REPAIR AND MAINTENANCE

DISMOUNTING OF HYDROPHORE

Switch the main circuit breaker off which is at energy inlet of motopump.

Uninstall electrical cables and be sure that they will not mistakenly be connected.

Switch off the fuse in pump panel which is related with hydrophore.

Remove the hydrophore motor connections.

Close the isolation valve which are in discharge and suction line.

Uninstall the clutch and other safety guards

Close the valve which is at water inlet and separate pump from flange.

If there are pumps more than one in system each operations are repeated for the hydrophore to be unintalled. And system should be powered on after this operations are completed.

-25-

HYDRPPHORE CROSS SECTIONAL DRAWING

PART LIST

01- Body 07-Guide Bearing 13- Stud Bold Nut

02- Receiver Body 08- Fan 14- Set Screw

03- Stage 09- Shaft 15- Coupling Pin

04- Diffuser 10-Special Bearing Bushing 16- Mechanical Seal

05- Special Flange 11- Rigit Coupling 17- O-ring

06- Connection Stud Bolt 12- Air Plug 18- Flange Seal

-26-

In this chapter failures which can be seen in ARS type pumps, possible reasons (Table 3) and trouble shooting methods (Table 4) are given.

ATTENTION! Control the accuracy of all measurement gauges before starting to eliminate the failure operation.

Table 3

NO Possible Reason Correction Methods

1 Electricity Check whether there is electricity

2 Tank Control whether there is enough water in tank. If there is not enough water protection against working without water is active and switch electricity off. It will operate when the tank is full again.

3 Thermal Relay Thermal Relay may trip. Contact with service

4 There may be air in hydrophore and/or suction line

Fill hydrophore or suction pipe completely with liquid. Control whether there is water in tank which supplies the hydrophore. Repeat the start process

5 Air is absorbed from seal, suction pipe, or connections. Pump absorbs liquid which is mixed with air

Control all connections in suction pipe. Check seals.

6 Air pocket in suction pipe Control the slope of suction pipe and whether there are suitable places for formation of air pockets, if any make necessary corrections.

7

There is air in liquid Swirls occur since depth of submersion pipe is not enough and there fore air is absorbed. Control the liquid level in suction tank and increase the depth of bottom/suction pipe back water valve.

FAILURES POSSIBLE REASONS

Hydrophore does not work 1-2-3

Started Hydrohore disccharges no water 4-8-10-13-14-16

Flow decreases or no water is discharged 5-6-11-17

Motor is overloaded 12-15-20-29

Hydrophore starts and stops so frequently 25-26-27-28

Bearings have over temperature 21

There is vibration in hydrophore 18-19-22-23

Noise level is high 7-9-24

8 Suction depth is very much Performing suction to hydrophore is not suitable . If there is no obstacle which may cause clogging control the friction losses of suction line. If necessary use a suction pipe having larger diameter. If

9 Hydrophore operates with cavitations

NPSH of plant is very low. Check the water level in suction tank. Check whether there are over friction losses in suction line. Check whether isolation valve in suction line is completely open. If necessary place the pump in low levels and increase the load of pump at suction side

10 Hydrophore discharge height is insufficient

Actual discharge height of plant is higher than given values. Check the total static height and friction losses of discharge pipe. Using pipes having greater diameter may be solution. Check whether valves are completely opened.

11 Increase in discharge height Check whether valves are completely open. Check whether there is an obstacle which may cause clogging in discharge pipe.

12 Hydrophore is operating at lower discharge height

Discharge height of plant is lower than given values. Lathe the impellor diameter according to manufacturer suggestions

13 Hydrophore rotates reverse Check rotation direction of motor whether it is same with the direction which is indicated in pump body or nameplate

14 Speed very low Check the voltage and frequency of line and check whether phase is missing in motor.

15 Speed very much Decrease the motor revolution if possible or Lathe the impellor diameter according to manufacturer suggestions

16 Impellor, check valve or filter clogged

Clean Impellor, check valve or filter

17 Impellor, check valve or filter clogged

Clean Impellor, check valve or filter

18 Impellor partially clogged Clean the impellor

19 Worn or malfunctioned impellor

Replace the impellor

20 Mechanical friction in hydrophore

Check whether there are any obstacle or bend in hydrophore rotor

21 Flow rate is less than pumps necessary flow rate

Increase the flow rate, use by pass valve or line if necessary

22 Shaft is bend Check the shaft and replace if necessary

23 Imbalanced rotating parts Adjust the balance of rotating parts

24 Pump operates out of its operation region

Check the operational region values

25 Membrane with hole Remove the cover of plastic relief valve over tank. Press the pressure relief valve, if water comes it means that membrane is slitted and does not function properly. Membrane should be replaced and operational pressure should be adjusted as 0,9 bars.

26 Low pressured tank Air or gas pressure in membrane tank may be low. Contact with service.

27 Over Pressured Tank Air or gas pressure in membrane tank may be high. Contact with service. Gas pressure in tank should be 0,5 bar less than hydrophore operational pressure.

28 Pressure switch adjustment may be incorrect

Please contact with service for pressure switch adjsutment

29 Motor Fault Check the motor. Motor is not suitable with air conditioning.

-29-

LIST DISPLAYING THE SERVICE STATIONS

MANUFACTURER COMPANY'S

Title : SEMPA ELK.MOT.SAT.POMPA İMLT.DEMİR

TİC.İTH.İHRC.SAN.TİC.LTD.ŞTİ.

Address : Büsan Özel Organize San.Bölgesi 4.Sk. İlerisi

No:43-45-47 Karatay / KONYA

Phone&Fax : 0 332 345 32 90 & 345 32 95

Service Scope: Pumps (Waste, clean, water, oil, fuel oil, Lpg, Cng)

NO TITLE ADDRESS NAME OF OFFICIAL

TEL&FAX

1 SEMPA LTD.ŞTİ.

Büsan Org.San.Böl. 4.Sk. İlerisi No:43-45-47 Karatay / KONYA

SEYİT MEHMET FERAHKAYA

0 332 345 32 90 0 332 345 32 95

MANUFACTURER COMPANY

SEMPA ELK.MOT.SAT.POMPA İML.DEMİR TİC.İTH.İHRC.SAN.TİC.LTD.ŞTİ.

Factort :Büsan Org.San.Böl.4.Sk.İlerisi No:43-45-47 Karatay/KONYA/TÜRKİYE Tel : +90 (332) 345 32 90 (4Hat) Fax: + 90 (332) 345 32 95 Store:Horozluhan Mah.Çakırlı Cad.No:23 Selçuklu / KONYA Tel : +90 (332) 237 03 31 Fax: +90 332 235 43 64 Web :www.sempaltd.com E-mail : [email protected]

WARRANTY CONDITIONS 1-) Warranty period starts with delivery of goods and it is for 2(two) years. 2-) Complete of good including all parts under warranty of our company. 3-) In case that good had a failure within warranty period, duration which passes through warranty is added to warranty period. Repair time for good can not exceed 20 days. In case that there is not service station related with failure of good, this duration starts with the informing the seller, distributor, agency, importer, exporter or producer. It is possible for consumer to make failure notification by telephone, fax, e-mail, certified mail and similar ways. However proof liability belongs to consumer in dispute cases. If the failure of good can not be eliminated within 10 days; manufacturer, produces or importer is liable to deliver a similar product until repair has been completed. 4-) In case that product has failure because of labor or material failure, its repair will be performed without charging any amount regardless with labor costs, or replaced part prices. 5-) Although the repair right of product is used by consumer; - Provided that remaining in defined warranty period after the date of delivery to consumer; , , in case that maximum four times in a year or more than six time in warranty period defined by manufacturer-producer and/or importer it has a failure, and besides this if those failure prevents usage, - exceeding the maximum time which is determined for repair; - Provided that there is not any service station, by means of a report issued by seller, distributor, agency, representation, importer or manufacturer or produced indicating that repair is impossible; consumer may request the replacement free od charge, refunding or price deduction with same amount. 6-) Warranties which are caused by contrary usafe of product with user manual are not covered by warranty. 7-) Consumer may apply to CUSTOMS AND COMMERCE MINISTRY PROTECTION OF CONSUMER AND MARKET SUPERVISION GENERAL DIRECTORATE for the problems which may be related with warranty certificate.

MANUFACTURER COMPANY SEMPA ELK.MOT.SAT.POMPA İML.DEMİR TİC.İTH.İHRC.SAN.TİC.LTD.ŞTİ.

Factory :Büsan Org.San.Böl.4.Sk.İlerisi No:43-45-47 Karatay/KONYA/TÜRKİYE Tel : +90 (332) 345 32 90 (4Hat) Fax: + 90 (332) 345 32 95

e-mail:[email protected] web:www.sempaltd.com

DISTRIBUTOR SEAL

In addition that this guarantee does not cover the failures which may be caused by abnormal usage of pump also is not valid for following cases.

Changes and repairs which are made by unauthorized service.

Damages and failures which may be caused by using contrary with aspects that are written in user manual

Damages and failures which may be caused by faults in suction and discharge lines of pump

Damages and failures which may be caused by improper pump selection.

Damages and failures caused by abrasives which may be found in water

Especially the damages and faults which may be caused by liquids having different properties which are mentioned in user manual.

Damages and failures which occur after delivery of product to consumer in loading, unloading, carrying, transportation and storage conditions.

Low or high voltage, erroneous electrical installation and control cabinet, wrong connection of cable ends, and usage of pump out of voltage values which are written in pump nameplate.

Damages and failures which may be caused by using cables with cross sections which are not suitable with pump power.

Damages and failures which may be caused by fire, lighting and freezing.

Failures which may occur because of abovementioned events are repaired in return of charge.

Responsibility of filling warranty certificate and delivery to customer belongs to seller, agency or distributor where product is purchased.

Warranty will be void in cases that alteration is made over warranty, original series number over product is removed or altered.

WARRATY CERTIFICATE

MANUFACTURER OF IMPORTER COMPANY Title: SEMPA LTD Address: Büsan Özel Org. San. 4.Sk. İlerisi Elit San Sir. No:43-45-47 Tel: : 0 332 345 3290 (4 lines) Fax: 0 332 345 32 95 Invoice Date: Invoice No: Certificate nı:108981 Company Official Signature and Seal

Products' Type: Trademark: Model: Serial No: Delivery Date and Place Seller Company Title: Address Phone: Invoice Date Invoice No: Sales Date Seal Signature This certificate is issued according to permission of Customs and Commerce Ministry Protection of Consumers and Market Supervision General Directorate

Customer Name: Address: Phone Fax: Products' Type: Trademark: Model: Serial No: Delivery Date and Place Seller Company Title:

Address Phone: Invoice Date Invoice No: Sales Date Seal Signature This part will be delivered to SEMPA LTD ŞTİ by agency, seller or distributor.

![GRUNDFOS PRODUCT GUIDE...1 SPK, CRK 6 Product range TM05 3480 1412 TM05 3481 1412 Description SPK 1 SPK 2 SPK 4 SPK 8 CRK 2 CRK 4 Range 60 Hz Nominal flow [gpm] 5 11 18 40 13 28 Flow](https://static.fdocuments.us/doc/165x107/5fe15c8b642fe875f13fc7e5/grundfos-product-guide-1-spk-crk-6-product-range-tm05-3480-1412-tm05-3481-1412.jpg)