soyabeans oil production chart

-

Upload

borode-adeola -

Category

Documents

-

view

216 -

download

0

Transcript of soyabeans oil production chart

8/7/2019 soyabeans oil production chart

http://slidepdf.com/reader/full/soyabeans-oil-production-chart 1/8

iwan Turnkey-Project Information> -Edible Oil Making Plant http://turnkey. tai wantrade. com tw/en!Content. aspx?ID= 37

I Home I Espanol I

Taiwan Tu rnkey -P ro jec t In fo rmat ion Search

Edible Oil Making Plant

Home> Food Making Plant

Edible Oil Making Plant

l-----------------_j (Continuous Type Expeller Extraction and Refining Plant)

Food Making Plant

Beverage Making Plant

Textile Machinery Making Plant

Garment Machinery Making Plant

Leather Products Machinery Making

Plant

Wood Products Machinery Plant

Paper Milling Machinery Making Plant

Printing Machinery Making Plant

Rubber Products Making Plant

Plastic Products Making Plant

Chemical, Refined Petroleum and Coal

Products Plant

Non-metallic Mineral Plant

Steal Material Making Plant

Non-Ferrous Metal Making Plant

Electrical Machine and Apparatus

Making Plant

Electronic Products Making Plant

Public Utilities and Services

Other Industrial Accessories /

Components

1 Introduction

Fats and oils, like proteins and carbohydrates, are necessary life

sustaining ingredients in man's diet. Food use accounts for more

than two-thirds of total world consumption of oil.

Refining of vegetable and animal oils improves their keeping

quality. The separation of oils and fats from oil-bearing animals and

vegetables constitutes a distinctive and specialized branch of food

processing technology. Crude oils and fats are 90% make up of

esterstriglycerides and triglycerols. These esters, called neutral oils,

are purified during the edible oil refining process. There is, however, a significant amount of

nonglyceride impurities such as free fatty acids, tocopherols, sterols, phosphatides, hydrocarbons,

pigments, oxides, waxes, moisture, proteins, carbohydrates, dirt, bagging fiber, cellular tissue, gum

and resins that need to be removed during processing. These impurities generally find their way into

the oil during the refining process. They produce the dark-color and cause oil to foam, smoke or

precipitate when heated. Subsequent processing might result in an unpleasant taste and odor when

the oil is exposed to atmospheric conditions.

Fats and oils are not only essential to the diet of man and animals but also play an important role in

the manufacture of numerous products, such as paints, varnishes, soap, cosmetics hardened fats,

textiles, leather, paper, pharmaceuticals and lubricants. They are also often used or converted into

edible medicinal.

The widely different characteristics of oil-bearing materials from diverse resources have given rise to

different extraction and refining processes. But the system most commonly used in the refinement of

edible oils today consists of neutralization, washing, bleaching, deodorization of other processes for

special purposes or which produce new products to meet changing market demands. However, to

choose the best process for an oil extraction and refinement plant, some common objectives must be

considered. These include the need to obtain uninjured fats and oils, which are as free as possible from

undesirable impurities, to obtain the fats and oils in as high a yield consistent with economical

processing, and to produce an oil cake residue (by-product) of the highest value.

In the current world industrial situation of energy resource shortage, rising wages, demand for higher

quality from consumers and stiffer competition, investors must tread carefully in making their

investment plans in and management of a whole plant business. How to make an economical

investment, save labor expenses and energy resources, and how to produce high value products and

by-products are points, which must be considered when investing in an edible oil plant. The investor

must consider that there are many inherent disadvantages to processing edible oil by the solvent

extraction method. These include the large amount of investment and energy costs, the complex and

dangerous processing, difficult maintenance and repair of machinery and equipment, large solvent

leakage during the manufacturing process, and high personnel expenses for high-tech engineers, all of

which make the cost of solvent-extracted products at least twice higher than the alternative continuous

type oil expeller-extraction method (although the former extracts about 2-5%more oil). Today unlike

the low oil content materials such as soybeans, oil from rice bran must be extracted using the solvent

extraction process. Contrarily, for other high oil content materials such as peanuts, copra, palm kernel,

rapeseed, etc., the continuous type oil expeller process is used to extract oil, so that the management

and profitability of the plant will be much more efficient and competitive.

Among all kinds of oil extraction plants, the continuous type oil expeller-extraction and refining process

is the most economical investment because:

1.1 The manufacturing process is easy.Itis easy to manage and control, and there is a

minimal need for high-tech engineering personnel

1.2 The cost of machinery and equipment and the occupation of the plant are not very high.

1.3 The production capacity is stable, and there is less likelihood of unit equipment failure

and job interruption.

1.4 Due to simple machinery design, it is easier to repair

1.5 There is lower leakage and loss of raw materials, Products, and energy during

2110212011 13 :09

8/7/2019 soyabeans oil production chart

http://slidepdf.com/reader/full/soyabeans-oil-production-chart 2/8

iwan Turnkey-Project Information> -Edible Oil Making Plant http://turnkey. tai wantrade. com tw/en!Content. aspx?ID= 37

manufacturing

1.6 Because of the low content of gum and wax, it is easy to refine crude oil from the

continuous type oil expeller-extraction process, and

1.7 It is easy and safe to operate the plant because no volatile materials are involved.

2 General Processing Information

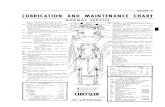

2.1 Flow Chart

2.1.1 Expeller Extraction Section

2.1.1.1 The Process for Peanut, Rapeseed, Cotton Seed, and corn palm kernel, copra, Sunflower Seed,

etc., Material.

2.1.1.2 The Process For Palm Kernel Material

2.1.1.3 The Process For Copra Material

2.1.2 Refining Section

2.1.2.1 The Process of physical Refining System:

2.1.2.2 The Process of Batch Type Refining System

2.1.2.3 The Process of Semi-Continuous Refining System

2.2 Process Description:

2.2.1 Pressing

2.2.1.1 Any raw material such as peanut, rapeseed, cotton seed, corn, palm kernel, copra, or sunflower

seed that is stored in the warehouse in bulk form is loaded by using wheel loaders and dumped into

the receiving hopper where labor will push the raw seed grain through the static screen into the

receiving hopper.

2.2.1.2 Through vibrating feeders, the raw seed grain is fed into the bucket elevator and transported to

the vibrating screen which magnetically removing part of the dehulling equipment.

2.2.1.3 After being crushed, the dehulled seeds are separated from the hulls by a screening device. The

hulls thus removed are sent to storage for eventual use as roughing in animal feeds.

2.2.1.4 The seeds are rolled into thin flakes to make them easily permeable to steam in the cooking

operation and are next cooked or conditioned in a 5-stage automatic steam kettle at 1200( for 20

minutes before pressing to rupture the oil lands and to coagulate the proteins.

2.2.1.5 The conditioned vegetable seeds are then places in an oil pressure expeller, which remove the

oil from the seeds. The oil removed by the presses is screened, cooled, filtered and stored for refining.

2.2.1.6 The expressed meal cake extruded from the expellers consists of approximately 8-10%

vegetable oil, which could be recovered through a secondary mechanical pressure expeller, which

recovers up to 95%-98%of oil from the raw vegetable seed. The cake residue could eventually be

consumed as animal feed.

2.2.2 Refining: The overall refining process of crude vegetable oil usually involves neutralization, water

washing and drying, bleaching, and deodorization.

2.2.2.1 Neutralization is carried out to remove the free fatty acid present in the oil. This is the most

delicate and difficult stage in the refining cycle because this is the stage with the highest loss of

neutral oil. In this process, the oil is heated in jacketed kettle fitted with a heating cell set at a

temperature of 500(-600( and agitated. Sodium hydroxide solution is added to the oil in excess of

stoichiometric requirements. Agitation is continued when the soap flocks are well flocculated. Soap

stock or foots is settled, and then pumped to the holding tank.

2.2.2.2 The soap stock is then steamed with phosphoric acid, the fatty acids and the neutral oil thus

liberated rise to the surface. A thorough washing is required to remove the traces of soap, which always

remain in the oil. After washing, the surface of the oil mass and water are settled and drained off

separately.

2.2.2.3 The dehydrated oil is brought into intimate contact with the bleaching materials. The mixture is

then heated by steam while the contents are maintained under vacuum by the barometric condenser

and vacuum pump. When the required temperature is reached, the moisture present in the oil is

completely removed upon completion of bleaching; The oil-bleached suspension is pumped to the

filtration section where the two component are separated. Neutralization, bleaching and filtration

remove coarse suspened free acids and coloring matter from the extruded oil.

2.2.2.4 The purpose of deodorization is to remove unpleasant odor and flavour to oils. The operation

should be operated at lower temperatures. The deodorizer is fitted with heating coils, and a vacuum is

applied. Measured amounts of oil are charged into it, and the oil is heated to the desired temperature

at which deodorization is carried out. Steam is injected in the operating coils. At the end of this

operation, oil is dumped by gravity into a cooling tank, which is maintained at the same pressure as

the deodorizer. After this final step of refining, the odorless, transparent and neutralized oil is ready for

packaging.

3 Plant Description

2110212011 13 :09

8/7/2019 soyabeans oil production chart

http://slidepdf.com/reader/full/soyabeans-oil-production-chart 3/8

iwan Turnkey-Project Information> -Edible Oil Making Plant http://turnkey. tai wantrade. com tw/en!Content. aspx?ID= 37

3.1 Production capacity:

The plant equipped with the machinery and equipment outlined in section 3.4 of this proposal,

operating 24 hours (3 shifts) a day, 25 days a month, is capable of producing 1500-5000 tons of high

quality vegetable oil per month.

3.2 Raw Materials:

Copra, seasame seed, palm fruit, ground nut (peanut), rapeseed, sunflower seed, safflower seed,

corngern,cotton and soybean.

The oil content of the oil-bearing vegetable materials is as follows:

I Oil Bearing Material I Oil content 10/0

ICol2ra 65-68

ISeasame Seed 50-55

IPaim Kernel 45-50

IGroundnut (Peanut) 45-50

IRal2eseed 40-45

ISunflower seed 35-45

Icorngern 35-45

ICotton Seed 18-20

3.3 Manpower Required:

IRaw Material

I

Input Capacity Persons/Shift(Tone/24hrs) O~erator I Engineer I Total

I 50 5 I 1 I 6

Palm Kernel100 6 1 I 7

150 8 1 I 9

200 10 1 11

~P,"

I 50 8 1 I 9

100 10 1 11

150 12 1 13

200 14 1 15

Peanut Cotton Seed 100 10 1 11

Sunflower Seed150 12 1 13

Castor nut

Rapeseed 200 14 1 15

3.4 Machinery & Equipment:

I Item I Set

IBucket Elevator

IVibrating Screen 2

IVeqetable seed Crusher 1

15-Staqe Automatic Steam Kettle 1-2

ICrude Cake or Residue Cooker 1

IScrew Convel'or 6

ID!:l(Run Bin 1

IFloat Level Control Puml2 1

IFeed Puml2 1

IWater SUl2l2ll' and Drainage Facilitl' 1

ICooling Tower 1

IHeating Sl'stem 1

IHot Water Tank 2IAgitator and Motor 3

IBeit Convel'or 2

IElectroaqnetic Discharqe Belt 1

INeutralization Tank 1

ICentrifugal Sel2arator 1

ICentrifugal Sel2arator 1

INeutralized Oil Tank 1

ISoalLWashiD_gTank - 1 -

2110212011 13 :09

8/7/2019 soyabeans oil production chart

http://slidepdf.com/reader/full/soyabeans-oil-production-chart 4/8

iwan Turnkey-Project Information> -Edible Oil Making Plant http://turnkey. tai wantrade. com tw/en!Content. aspx?ID= 37

I Item I Set

IWashed Oil Tank 1

Ivacuum S::,'stem 1

IBleaching Tank 1

IFilter Press 2

IBleached Oil Tank 2

IDeaerator Tank 1

IDeodorization Vessel

ISlurl}' Tank 1

IDirt::,'Oil::,'Tank 1

IDeodorized Oil Tank 1

IAcid Oil Storaqe Tank 1

3.5 Information Required for the Set Up of An Oil & Fat

Expelling and Refining Processing Plant:

3.5.1 Raw material quality analysis information

3.5.2 The plant civil structure design drawing.

3.5.3 The flow chart design of manufacturing process.

3.5.4 The flow chart and storage layout for raw material and finished products.

3.5.5 The layout of whole plant equipment.

3.5.6 The electricity supply and installation diagram.

3.5.7 The foundation diagram of equipment.

3.5.8 The operation frame mechanism design.

3.5.9 The water supply and piping system installation diagram.

3.5.10 The steam boiler and system and installation diagram.

3.5.11 The manpower arrangement information.

3.5.12 The electricity power arrangement information.

3.5.13 The investment and cost analysis information.

3.5.14 The market analysis information.

3.5.15 The operation instruction and trouble shooting in processing and technical information.

3.5.16 The maintenance technical information.

3.5.17 To be visited the production plant to understand the actual practice.

3.6 Plant Site Planning:

The location of the plant can have a crucial effect on the profitability of the project and the scope for

future expansion. Many factors must be considered when selecting a suitable site. The principle ones to

consider are:

3.6.1 Proximity of material supply market and product consumer market.

3.6.2 Transportation facilities.

3.6.3 Availability of utilit ies: Water, fuel, electric power

3.6.4 Availability of labor

3.6.5 Location not too close to metro area.

For the purpose of economical investment, the plant should be built with steel frame or with concrete

but be ready for reconditioning for future development. The height between every two stairs should

consider piping engineering and air flow system and should be at least 4.5M. In order for the future

development, the area of the oil refining plant should have enough unoccupied area for development of

twice of the capacity. The plant should have good drainage system to avoid contamination of water,

good air flow system to avoid wetting and a suitable width of aisle space for convenient processing.

3.7 Electricity Power Requirement:

2110212011 13 :09

8/7/2019 soyabeans oil production chart

http://slidepdf.com/reader/full/soyabeans-oil-production-chart 5/8

iwan Turnkey-Project Information> -Edible Oil Making Plant http://turnkey. tai wantrade. com tw/en!Content. aspx?ID= 37

IRaw Material

Input Capacity

IElectricity Power (Kw)

(Tons/24hrs)

I " , m Kernel

50 I 405

100 I 703

I 150 I 974

200 I 1381

r ' "I 50 I 463

100 I 974

I 150 I 1320

200 I 1800

Peanut, Cotton seed 100 I 913

Sunflower seed,150

I1267

Castor nutRapeseed 200 I 1725

3.8 Layout for the Package Plant

f8 2110212011 13 :09

8/7/2019 soyabeans oil production chart

http://slidepdf.com/reader/full/soyabeans-oil-production-chart 6/8

iwan Turnkey-Project Information> -Edible Oil Making Plant http://turnkey. tai wantrade. com tw/en!Content. aspx?ID= 37

H' ;PO.

'To F'ackgo

2110212011 13 :09

8/7/2019 soyabeans oil production chart

http://slidepdf.com/reader/full/soyabeans-oil-production-chart 7/8

iwan Turnkey-Project Information> -Edible Oil Making Plant http://turnkey. tai wantrade. com tw/en!Content. aspx?ID= 37

4 Suppliers Information

Shanq Jer Industries Co.. Ltd

Taiepe World Trade Center

RM.3C16,No.S, Sec.S, Hsinyi Rd.,

Taiepei, Taiwan., R.O.C.

Tel:886-02-27234300, 886-2-87809087

Fax:886-2-88622723

E-Mail:[email protected]

http://www.shang-jer.com.tw

2110212011 13 :09

8/7/2019 soyabeans oil production chart

http://slidepdf.com/reader/full/soyabeans-oil-production-chart 8/8

iwan Turnkey-Project Information> -Edible Oil Making Plant http://turnkey. tai wantrade. com tw/en!Content. aspx?ID= 37

Back to Top

Sponsored by the Bureau of Foreign Trade (80FT) Administered by the Taiwan External Trade Development Council (TAITRA)

333 Keelung Rd., Section 1, 5-7 Fl., Taipei 11003, Taiwan ROC

Tel: +886 (2) 2725-5200 Fax: +886 (2) 2757-6245 E-mail: [email protected]

You are the IEguest.