SOP Operation

-

Upload

pamela-bradley -

Category

Documents

-

view

175 -

download

2

description

Transcript of SOP Operation

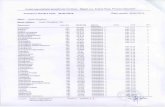

AMENDMENT RECORD SHEET

Sl. No. Page No. Issue/ Revision Number SummaryOld Date New Date of Change

1 All Pages - - 0 25.02.2012 New for Operation of Boiler & Turbine

2 1 & 3 0 25.02.2012 1-Jan 04.05.2012 New Key Performance Indicators has been introduced.

3 All Pages 1/0 04.05.2012 2/0 20.06.2013 New format of has been introduced & entire reviewed.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 1 of 6

1.0 1.0 Objective: This procedure is used as work instruction for boiler operator, turbine operator, desk

Engineer, shift in charge.

2.0 Scope: This is applicable for operation of boiler and turbine by adapting operational parameter.

3.0 Key Performance Indicator:

a) Plant Load Factor b) Auxiliary Power Consumption c) Specific Oil Consumption d) Reportable accident

4.0 Responsibility: HOD, Operation

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 2 of 6

5.0 Procedure:

This standard operating procedure shall comprise of the following Standard Operation Procedures (’s), describing the operation methods for the process equipments.

INDEX:-

1: OPERATION OF LDO STORAGE & HANDLING SYSTEM

2: OPERATION OF CW & ACW PUMP

3: OPERATION OF AIR COMPRESSOR

4: OPERATION OF DMCCW SYSTEM

5: OPERATION OF ID FAN

6: OPERATION OF HIGH PRESSURE FLUIDIZING SYSTEM

7: OPERATION OF SECONDARY AIR FAN

8: OPERATION OF PRIMARY AIR FAN

9: OPERATION FOR COLD START UP OF BOILER

10: OPERATION OF SOOT BLOWER

11: OPERATION OF OIL SYSTEM OF TURBINE

12: OPERATION OF EH OIL SYSTEM

13: OPERATION OF CONDENSATE EXTRACTION PUMP

14: OPERATION OF CONDENSATE WATER SYSTEM

15: OPERATION OF VACUUM PUMP

16: OPERATION OF BOILER FEED PUMP

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 3 of 6

17: OPERATION OF FEED WATER SYSTEM

18: OPERATION OF CT FANS

19: OPERATION FOR COLD START UP OF TURBINE

20 : OPERATION OF LP DRIP PUMP

21: OPERATION FOR SHUT-DOWN OF UNIT

22 : ISSUING WORK PERMIT (PTW)

23 : OPERATION OF DG SET

24 : OPERATION FOR BLACK OUT CONDITION

25 : OPERATION OF BED ASH COOLER

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 4 of 6

5.1 1: OPERATION OF LDO STORAGE & HANDLING SYSTEM

PRE OPERATION CHECK

1) All work permits related to this system closed after job completion.2) Check that all related instrument & fitting are properly mounted3) Confirm that L .D.O tank is filled well above the suction level of the pump.4) Open the valves of the pump supply lines and headers (coming from F.O tank) so that Inlet header of the

pumps is charged.5) Check for any leakage in the line joints and instruments.6) Open the suction & the discharge valve of the F .O Transfer Pumps to be started and check for any

leakage.7) Partially open all possible venting points in the entire fuel oil line up to boiler to remove air and

arrangements made to avoid any loss of oil. (Only to be done for first time startup) 8) Open Short recirculation bypass valve & its header valve going to LDO tank also open.9) Discharge header valve full closed for going to boiler.

10) Bearing Cooling water inlet & out valve open and its pressure up to 4 kg/sqcm should be maintained.

START UP

1. Check power supply to the pumps for healthiness.2. Check the filter vent nozzle by opening it so that oil comes freely without air.3. Start one pump with discharge valve open and short recirculation throttled condition. After normal start,

open the recirculation valve as per pressure requirement.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 5 of 6

4. Oil DP should be maintained 30%-50% (max)

5.2 2: OPERATION OF CW & ACW PUMP

PRE START UP CHECK

1. All pending PTW closed2. Check all the air release isolation valves in discharge line and ensure it to be in open

condition.3. Check the discharge valve to be in close condition.4. Open the water flow regulating valves for TBH cooling.5. Check the oil level of TBH >60 %.6. Check the pressure gauge and transmitters for healthy condition.7. Check for any foreign material in the sump.8. Check the water flow path up to cooling tower is through.9. Check the Condenser vent valve is in open condition.10. Check for SUMP Level is normal.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 6 of 6

11.Check CT Make-up sump level is normal and CT-makeup pump is available.

START PERMISSIVES

1. Sump level not low.2. Water path healthy either condenser inlet and outlet valve or recirculation valve is in

open condition.3. Pump is in remote Position.4. Discharge valve 100 % close condition and close limit switch is healthy.5. Motor DE & NDE bearing temperature are not high.6. Motor winding temperature is not high.7. Pump breaker is in service position and not fault relays are acted.8. Discharge valve is in remote position and no fault condition.

START UP

1 Give “START” command to pump and check if discharge valve starts opening. If it doesn’t then instruct field operator to open the valve from field.

2 Check the CW Discharge pressure 2.5 kg/cm2.3 Check for the bearing temperature, vibration, noise, and any leakages.

4 Select the pump to keep in standby mode selection tile in DCS. Put the valve and pump in auto start mode.

5 If the recirculation valve is open ensure the condenser valves are open and if required close the recirculation valve.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 7 of 6

CW & ACW STOP

1. Get clearance from CCR to stop the pump.2. Uncheck selection of stand by pump and put in manual mode.3. Give close command to discharge valve as soon as it goes below 80% give stop

command to the pump.4. Put the pump in Auto start mode and select it for standby selection.5. Press the emergency stop button, if the pump is going for the maintenance activity.

5.3 3: OPERATION OF AIR COMPRESSOR

PRE START UP CHECK

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 8 of 6

1. All pending PTW closed2. Check the oil temperature > 32 ˚C (89.60 ˚F);3. Check the oil level.4. Open the air Discharge valve.5. Open the ACW water inlet valve and outlet valve for the Intercoolers and Oil coolers.6. If these conditions are not fulfilled, the compressor will not start and the alarm LED (1)

will light up after the permissive start time (30 seconds).7. Close the condensate drain valves.

START UP

1. Press start button on the control panel. The compressor starts running in unloaded

condition.

2. Immediately after pressing the start button, the oil pressure must exceed 0.2 bar (e) (2.9 Psig).

3. Automatic operation LED on the control panel will light up. Auxiliary oil pump should automatically turn off after the compressor has reached full operating speed.

4. After 20 seconds (programmable), the compressor starts running loaded.5. At load condition check the Blow-off valve should be in close condition.6. Check for Gear oil-Box temperature, Intercooler temperature, current and suction

DP.

Check on Panel for:

• The compressor outlet pressure• The percentage of open position of inlet guide vanes (IGV) (2)• The compressor operation status

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 9 of 6

STOP:-

1. Get clearance from CCR to stop the Compressor.

2. Take compressor to unloaded condition.

3. Press “STOP” command.

4. Check the Blow-off valve to be open and Discharge valve closed position.5. Make it On AUTO Stand By position.6. Press Emergency push button if the compressor is going for Maintenance activity.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 10 of 6

5.4 4: OPERATION OF DMCCW SYSTEM

DMCCW WATER CIRCUIT :

DMCCW TANK→PUMP

PRE STARTUP CHECKING:

1. All PTW is in closed condition.2. All equipment, piping and valve of DMCCW pump have been pre-checked & should be OK.3. DMCCW tank level is normal.4. Check ACW pressure is available at PHE of DMCCW waterline.5. Check the basket strainer inlet & Outlet is open condition with proper venting.6. Electrical power is available for the pump.7. All Instrument and pressure gauge is available.8. Check all the interlock and protection in service.9. Check the oil level in the pump.10. DMCCW tank makeup valve and closed loop water makeup valve is in open condition.11. Suction valve is in open condition, discharge is in closed condition with proper venting.12. Check the Emergency push button should be in release condition.

START:

1. Check on DCS for pump start permissive:a) NO fault.b) Pump Remote service position.

2. Give “START” command to pump.3. Check the Discharge pressure >4.2 Kg/cm2, and current < 194 amps.4. Check pump packing temperature is normal, cooling water flow normal5. Check there is no friction, vibration, noise, motor temperature is normal.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

Boiler

Turbine

Bed ash cooler, IDF, HPBF, SAF, PAF, SWAS Panel

BFP, CEP, Vacuum pump, LP Drip pump, EH Oil pump, TG Pedestal cooling, All GV Block cooling

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 11 of 6

6. Check the availability of Stand by DMCCW pump and take the interlock in service.

STOP:

1. Check the clearance from the Control room.2. Standby start interlock of standby pump should be released.3. Give “STOP” command to pump.4. If the pump is in stand by condition then make the stand by interlock in service.5. If the pump is going for the maintenance purpose then press emergency push button.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 12 of 6

5.5 5: OPERATION OF ID FAN

PRE START UP CHECK (FIELD)

1. All pending PTW should be closed.

2. Check All the Manholes of boiler and ESP Should be Closed.

3. All equipment, piping and valve of ID Fan set has been pre checked. & should be OK.

4. Confirm that all the inspection work related to Chimney, ESP, furnace & Flue Duct are completed.

5. Check DMCCW cooling water valve and ACW PHE valve of ID FAN is in open condition.

6. Check the Oil level in the Bearing & Hydraulic Coupling of ID Fan.

7. Confirm the operation of Dampers, IGV, Scoop from DCS and Local is ok.

8. Check the IGV & Discharge valve of the fan is in closed and remote condition.

START PERMISSIVE:

1. There is no Fault on the DCS.

2. ID Fan is in Remote condition.

3. ID Fan is in Service position (6.6 KV power available).

4. All Bearing Temperature and Vibration Transmitter in service.

5. ID Fan Discharge & suction IGV & Damper have close feedback.

6. NO priority stops on DCS.

START UP

1. The start permissive of the ID FAN in DCS should be healthy.

2. Give “START” command to ID Fan.

3. After ID Fan is started, check the time for the speed and current to be stable.

4. Check I/L Dampers (04 Nos.) & the discharge dampers (02 Nos.) are fully opened automatically.

5. Check ID Fan noise, bearing temperature and vibration are normal.

6. Check the hydro-coupling Oil pressure is more than (>0.045 Mpa)

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 13 of 6

7. Check “NO” Alarm or abnormality in parameters of Fan.

8. As the ID fan is normal, maintain the Furnace Pressure ( <125 Pa ) by controlling the IGV &

Scoop Position.

STOP

1. To stop the ID Fan, release Auto switch first, & ensure that all the PA Fan , SA Fan & HPFB

are in stopped condition.

2. Reduce the speed of the fan by reducing the Hyd. Coup. Position with respect to the Furnace Pressure.

3. Give “STOP” command to ID Fan.

4. After Stopping the ID Fan, It should be ensured that the I/L & O/L dampers are fully closed

automatically.

5. The Local Push Button should be pressed.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 14 of 6

5.6 6: OPERATION OF HIGH PRESSURE FLUIDIZING SYSTEM

PRE START UP CHECK (FIELD)

1. All pending PTW closed.

2. Check all the Manholes of Boiler should be closed.

3. All equipment, piping and valve of HPFB set has been pre checked. & should be OK.

4. Confirm that all the inspection work related to Seal Pot, Cyclone is completed

5. Check DMCCW pump is in running condition and cooling water valve of HPFB is in open condition.

6. Check the Oil level in the Bearing and Gear-box of HPFB should be Normal.

7. Check the Discharge damper of the Fan is in closed condition & Vent is in Open condition and remote

position.

8. Check the Seal pot A & B all Dampers are in Open Condition and remote position.

9. Ensure the Open/Close operation of Valves & Dampers are OK.

10. Local push button should be released.

START PERMISSIVE:

1. There is no Fault on the DCS.

2. HPFB is in Remote condition.

3. HPFB is in Service position (6.6 KV Power available).

4. All Bearing Temperature and Vibration Transmitter in service.

5. HPFB Discharge damper & Vent have close & open feedback respectively.

6. HPFB discharge to Seal Pot Dampers should be in fully open condition.

7. NO priority stops on DCS.

START UP

1. The start permissive of the HPFB in DCS should be healthy.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 15 of 6

2. Any ID Fan Is in Running Condition.

3. Give “START” command to HPFB.

4. After HPFB started, check the current to be stable, fully auto open O/L Valve & the vent

to be fully auto closed.

5. Check HPFB Set noise, Bearing temperature and vibration, Discharge Flow are normal.

6. As the HPFB is normal, check the availability of stand by HPFB and put the interlock in service.

STOP

1. To stop the HPFB, release interlock switch first, & ensure that all the PA Fan & SA Fan

are in stopped condition.

2. Give “STOP” command to HPFB.

3. After Stopping the HPFB, It should be ensured that the O/L Valve is fully auto closed & the vent is fully

auto opened, if not, open/close manually & The Local Push Button should be pressed

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 16 of 6

5.7 7: OPERATION OF SECONDARY AIR FAN

PRE START UP CHECK

1. All pending PTW closed.

2. Check All the Manholes of Boiler should be Closed.

3. All equipment, piping and valve of SA Fan set has been pre checked. & should be OK.

4. Check DMCCW pump is in running condition and cooling water valve of SA FAN is in open

condition.

5. Check the Oil level in the Bearing of SA Fan Set.

6. Check the Discharge damper & IGV of the Fan is in closed condition

7. All the Auxiliary Dampers of Furnace (18 Nos) are in >30 % open condition

8. Local push button should be released.

START PERMISSIVE:

1. There is no Fault on the DCS.

2. SA Fan is in Remote condition.

3. SA Fan is in Service position (6.6 KV power Available).

4. Any HPFB should be in running condition.

5. All Bearing Temperature and Vibration Transmitter in service.

6. SA Fan Discharge damper & IGV has close feedback.

7. NO priority stops on DCS.

START UP

1. The start permissive of the SA Fan in DCS should be healthy.

2. Any HPFB should be in running condition.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 17 of 6

3. Give “START” command to SA Fan.

4. After SA Fan started, checks the auto open of O/L damper & current to be stable.

5. Check SA Fan Set noise, Bearing temperature and vibration are normal.

6. As the SA Fan is normal, increase the flow as per requirement by maintaining the Furnace

Pressure.

7. Start the Standby SA Fan as per the requirement of Air Flow.

STOP

1. To stop the SA Fan, ensure that all the PA Fan Are in stopped condition.

2. Give “STOP” command to SA Fan.

3. After Stopping the SA Fan, It should be ensured that the O/L damper is fully auto closed

if not, close manually.

4. As the SA fan Stops Local Push Button should be pressed.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 18 of 6

5.8 8: OPERATION OF PRIMARY AIR FAN

PRE START UP CHECK

1. All pending PTW closed.

2. Check All the Manholes of Boilers & ESP should be closed and free from foreign materials.

3. All equipment, piping and valve of PA Fan set has been pre checked. & should be OK.

4. Check DMCCW pump is in running condition and cooling water valve of SA FAN is in open

condition

5. Check the Oil level in the oil station & Bearing of PA Fan.

6. Ensure the availability of AOP of PA fan, and keep on stand-by.

7. Check the Oil Pressure, temp. & oil DP In oil station.

8. Check the Discharge damper & IGV of the Fan is in closed & Remote condition

9. PA to wind Box Regulating Valve (02 Nos.) are in fully open condition.

10. Local push button should be released.

START PERMISSIVE:

1. Any SA Fan is in running condition.

2. There is no Fault on the DCS.

3. PA Fan is in Remote condition.

4. PA Fan is in Service position (6.6 KV power available).

5. PA lube oil Station should be normal.

6. All Bearing Temperature and Vibration Transmitter in service.

7. PA Fan Discharge damper & IGV has close feedback.

8. NO priority stops on DCS.

START UP

1. The start permissive of the PA Fan in DCS should be healthy.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 19 of 6

2. One of the lube oil pumps should be running

3. Give “START” command to PA Fan.

4. After PA Fan started, check full auto open of O/L damper & the current to be stable.

5. Check PA Fan Set noise, temperature and vibration are normal.

6. As the PA Fan is normal, increase the flow as per requirement maintaining the Furnace Pressure.

7. Start the Standby PA Fan as per the requirement of Air Flow.

STOP

1. Slowly reduce the IGV by maintaining the furnace pressure.

2. Give “STOP” command to PA Fan.

3. After Stopping the PA Fan, It should be ensured that the O/L damper is fully auto closed

if not, close manually.

4. As the PA fan Stops Local Push Button should be pressed.

5. After stopping the PA Fan as the bearing temp. Becomes <50oC, Stop the lube oil pump in the oil station.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 20 of 6

5.9 9: OPERATION FOR COLD START UP OF BOILER

1. All pending permit to work should be closed.

2. Check no person is working inside the boiler or with any equipment and all temporary facility must be removed.

3. All manholes in furnace, air heater, ducts & fans are in closed condition.(i.e. all 1st pass and 2nd pass man hole

should be closed )

4. AC & DC Power is in Available Condition.

5. Unit Critical Power is in Available Condition.

6. All HT & LT drive megger value is OK.

7. Ensure the Sand silo level; bunker level, LDO Tank level and DM Tank level should be normal.

8. Ensure that the ACW and DMCCW line for all the drives is charged.

9. DMCCW starting procedure as per following:

Tank level should be normal (1600 – 2600mm).

Check suction make up v/v opened & the suction pressure to 2.0 Kg/cm2.

After ensuring all pump start condition, give the START command to DMCCW pump.

Check the Discharge pressure and the parameters of pump.

10.Ensure that hot well Makeup Pump is running, Dm water for DMCCW tank & for makeup purpose is available.

11.Put ESP Insulator Heater in service 8 hrs. Before Boiler Lit-up.

12.Start the LDO Pump & ensure that LDO pressure is available at around 1.80 MPa in DCS

13.Ensure that the Air Compressor is running & Instrument air pressure is available at 0.6 – 0.7 MPa.

14.Ensure that HP and LP Dosing Pump should be available.

15.The furnace bed height should be normal & free from any foreign material. (Bed Height – 760mm)

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 21 of 6

16.All fire protection system is in operational condition.

17.Hydrostatic plugs or test tags are removed from safety valves.

18.All Pressure & temperature gauges and Transmitters are in service.

19.All Expansion indicators in different area are normal and indicator pin is free from Jam.

20.Check fully opening & closing of the discharge damper of PA, SA, ID fans & High pressure blowers.

21.Opening and closing of ID fan Suction & scoop operation, Also the IGV operation of SA & PA Fan

22.Check operation of all control valves and motorized valves.

23.Ensure boiler and fan-Set safety interlock, Protection and annunciation OK.

24.Ensure the following valves are in closed condition before cold start up.

Feed water station drain valve, economizer drain valve, and economizer recirculation drain valve, all

the attemperation water drain valves and all the drain valves of furnace lower headers,CBD,EBD

should be in closed condition.( i.e. all water side drain valve should be closed and steam side drain

valve should be open)

25.Ensure the boiler main steam stop valve should be in closed condition

25. Ensure opening of Drum, CRH, HRH and SH air vent and start up vent valve.

26. Ensure the opening of SH, CRH, HRH and main steam line drain valve.

27. Take water in drum up to normal (-50 mm to -100 mm) level through cold filling line, Then open economizer

Recirculation valve.

28. Ensure 2nd pass RH and SH regulating damper should be 50%.

Ensure that Scanner Air Fan is running & another one is available & also in Standby.

29. Start One ID Fan and maintain the furnace pressure to (< -125 Pa).

30. Start High Pressure Fluidizing Blower and check the seal pot pressure and Flow of HP Blower. Also put

Second HP-Blower in Stand-by condition.

31. Start Secondary Air fan A (SA fan B start as per requirement) respectively supervising the furnace pressure

and increase the SA Flow.

33. Start Primary Air fan A & B, Slowly open PA fan IGV for increasing the flow looking on furnace pressure.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 22 of 6

34. After starting PA and SA Fan maintain the total air flow more than (>25 %) 114200 Nm3/hr. Also maintain the

Primary Air flow is over the Critical fluidizing air flow (>25%). Then purge the boiler.

35. After Purge complete, put one start-up oil gun into operation at minimum combustion rate. Regulating related

air flow, check if the combustion condition is good. Then put opposite start-up oil gun into operation at the same

Manner, After 30 min. changeover another two opposite oil guns based on the principle of changeover.

36. Boiler heating-up and boosting pressure should be slowly and uniform, must control all the gas side

temperature

(Including bed temperature change rate not more than 135⁰C/hr, also control the saturated temperature rising

Speed 93⁰C/hr and Drum metal temperature change rate 55⁰C/hr, and Drum upper & lower metal temperature

difference 50⁰C/hr.

37. After achieving the drum pressure 0.1 ~ 0.3 MPa, close the drum vent, and purge water level gauge and

check

Water level, also at 0.5 MPa closes the superheater vent.

38. As the drum Pressure reaches 0.5 ~ 1.0 MPa, inform chemical section to test the steam & water quality.

39. According to the drum wall temperature difference, open periodic blow down valve as per requirement, making Uniform heating up of different part and establish good water circulation.

40. The Expansion reading of the Boiler to be taken periodically as the boiler loading increases.

.41. As the furnace temperature increase, must control the temperature difference between material return device

and

Furnace outlet within 38⁰C, when the temperature at material return device is lower than furnace outlet

temperature

38 ⁰C or more, primary air flow must be increased in order to reduce temperature difference.

42. As the drum pressure reaches 1.0 – 1.2 MPa as well as according to the drum level condition, starts the feed

Water pump, and takes the feed water from (30 %) control valve. (Close economizer recirculation valve).

43. After getting all the permissive for the HP/LP bypass, start the steam dumping and close the start-up vent

valve.

43. As steam pressure increased to 1.8 ~2.0 MPa, superheated steam temperature reaches to 360⁰C & the

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 23 of 6

temperature difference between superheated steam and reheated steam is not more than 40⁰C, and temperature

difference between right and left side of SH & RH is not bigger than 20⁰C, Also supervise drum upper/down wall

temperature difference 50 ⁰C, connect with turbine section for rolling the turbine. Meanwhile, keep on observing

the steam temperature and steam pressure.

44. During turbine rolling, regulate bypass to meet the requirement of steam pressure and temperature for turbine

rolling.

45. After synchronization, unit immediately carries 5% rated load.

46. As the furnace bed temperature reaches above 6000C coal feeding can be proceeded.

47. Start coal feeder at minimum coal feed rate & observe bed temperature and oxygen change and

accordingly

Feed coal continuously.

48. After feeding coal, supervise & regulate, the change of bed DP, bed temperature, flue gas temperature &

wall Temperature.

49. As the furnace temperature increases flow rate of the oil gun can be gradually decreased down to minimum,

and

Then oil gun can be cut off one by one. At the same time, feeding coal can be gradually increased.

50. According to bed DP take Bed material feeding or Bed Ash conveying system into operation.

51. Gradually increase the coal feeding & supervise the Main steam pressure and Temperature with respect to bed

Temperature rising as per the Turbine load requirement.

52. According to Loads the main steam and Re heater temperature to be controlled by taking attemperation system in

Service. Also regulate the RH/SH flue gas regulating damper into operation as per requirement.

53. As the ESP I/L temperature reaches to 120⁰C, put ESP field in operation.

54. Gradually increase the load and regulate air flow based on combustion condition (Maintain Oxygen level 3 ~ 4

%).

55. According to start-up curve, gradually increase load to rated value, and inspect the entire boiler from top to

Bottom for any abnormality.

56. Also note down all the parameters of Boiler at the desk and at field as per the normal values.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 24 of 6

5.10 10: OPERATION OF SOOT BLOWER

SOOT BLOWER ARRANGEMENT:

1) There are altogether 42 sets retractable soot blowers for this boiler arranged in the back-pass SH area, RH area, economizer and air pre-heater area. Steam source is taken from cold end platen SH outlet pipe, before first stage spray water attemperator, then the steam pressure reduce to design value through pressure reduction station and transmit to each soot blower.

2) Steam parameters for soot blower are: temperature ≥ 260°C, pressure ≥ 18 MPa.

SOOT BLOWER OPERATION:

1. Check before soot blower put into operation: 2. Soot blower system screen has no alarm signal; 3. Soot blower proper is in good condition, connection pipe no leakage; 4. Soot blower returned to original position, steam inlet valve closed; 5. All the control electric source and power electric source of soot blower system have been

energized; 6. All the manual valves of soot blower system opened already.

CONDITION OF SOOT BLOWING:

1. No boiler MFT signal; 2. Power electric source normal; 3. Control device under “remote” control state.

MANUAL SOOT BLOWER

1. Soot blower manual operation conditions:

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 25 of 6

2. Soot blower steam pressure normal;3. Piping warm up finished;4. Power electric source normal;5. No boiler MFT signal;6. No soot blower program operation;7. Control device under “remote” control state.8. No soot blower operation on same side.

5.11 11: OPERATION OF OIL SYSTEM OF TURBINE

PRE START UP CHECK

1. All pending PTW closed.2. Main oil tank level is normal.

3. All equipment, piping and valve of Lube oil should be pre checked & should be OK.

4. Main oil tank temperature is higher than 21°c.

5. Check the Oil sample result for the NAS value within the permissible limit.

6. Check the ACW water header pressure and inlet & outlet valve for lube oil PHE.

7. Check the Lube oil & JOP filter available with proper venting.

8. Take trial run of Lube oil pump, Jacking oil pump, and put all the interlock in service.9. Check the lube oil pressure transmitter, gauge and pressure switch in service.

On DCS check:-

a) LP AC/DC oil pump NO Fault.

b) LPAC/DC Oil pump Remote Service position.

For Starting of JOP:-

a) JOP AC/DC Oil pump NO Fault.

b) JOP AC/DC Remote Service position.

c) Any Lube oil pump running condition.START UP

1. Start oil vapor extraction fan.

2. START AC lube oil pump, check lube oil pressure is >0.088mpa.

3. Check the availability of DC oil pump and put AC/DC lube oil pump interlock switch in service.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 26 of 6

4. Check thoroughly lube oil system has no leakage.

5. Check the Lube oil filter DP.

For JOP:-

1. Open the inlet valves of Both jacking oil pump and confirm pump inlet oil Pressure

>0.039mpa

2. START jacking oil pump.

3. Check outlet pressure in range of 10 to 12 MPA.

4. Confirm shaft journal should be lifted 0.03 to 0.05 mm.

5. Check all bearing return oil is normal and note down individual bearing oil pressures.

6. Check the JOP filter DP.

For Turning Gear operation:-

1. Check the power supply on the Turning gear panel, and all the permissive (Compressed air

availability>0.06 Mpa, Motor cooling fan running condition, JOP pressure available).

2. Before starting the Turning gear turn the Rotor 180 Degree.

3. Turning gear on AUTO Mode: - as it senses ZERO rpm signal, and remote condition, it starts

automatically.

Turning gear on Semi-automatic mode: - when speed reaches zero, push button “START” initiating this mode.

Turning gear on Inching mode: - maintenance use, inching button “START”, shaft turning some angle. Turning gear on Manual Mode:- when failure of air supply, pull out pin, turning shaft manually.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 27 of 6

5.12 12: OPERATION OF EH OIL SYSTEM

PRE START UP CHECK

1. All pending PTW closed.

2. All equipment, piping and valve of EH Oil system should be pre checked & should be OK.

3. EH oil tank level normal (> 500 mm).

4. Check the Oil sample result for the NAS value within the permissible limit.

5. DMCCW pump is running condition.

6. Check all valves of the system are in open condition (Suction & discharge valve of main oil

pump, filter pump and Cooling pump, also to the individual governing valve).

7. Oil Tank temperature> 20 °C.

8. Check the power supply available for the EH main oil pump, Cooling pump and Filter pump.

On DCS check

a) EH oil pump NO fault.

b) EH oil level Normal.

START UP

1. Start the EH oil filter pump.

2. Start the EH oil Cooling pump, and check the flow.

3. Start the EH oil Main pump.

4. Check the pressure 14±0.5 Mpa.

5. Check for any abnormal sound, and for any leakages.

EH OIL PUMP STOP:

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 28 of 6

1. Turbine is in inoperative condition.

2. HP /LP bypass is not in operational condition.

3. STOP the EH oil pump.

4. Stop the EH oil cooling pump

5. Stop the EH oil filter pump.

5.13 13: OPERATION OF CONDENSATE EXTRACTION PUMP

PRE START UP CHECK:

1. All pending PTW closed.

2. All equipment, piping and valve of CEP should be pre checked & should be OK.

3. Adjust cooling water of condensate pump packing, sealing water pressure is Normal (0.25 to 0.4mpa)

4. Check the CEP Bearing Oil Level normal.

5. Check the Suction valve is open condition.

6. Check the balancing line is open condition.

7. Check the Discharge valve of the pump is in closed & in remote condition.

8. Check the Recirculation valve of CEP full open condition.

9. Ensure the Hotwell level on the level gauge glass and in DCS.

10. CST to Hotwell make-up water valve is in open condition, also check the CEP to CST valve.

11. Check GSC and all LP heater is in service condition.

12. All Bearing Temperature and Vibration Transmitter in service.

13. CEP to CST valve is in closed condition.

START PERMISSIVE :

1. There is no Fault on the DCS.

2. CEP is in Remote condition.

3. CEP is in Service position.

4. Condenser level normal > 650 mm

5. CEP Discharge valve close feedback.

6. CEP Recirculation valve open feedback >95%

7. NO priority stops on DCS.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 29 of 6

START UP :

1. Give “START” command to CEP.

2. After CEP started, check the time for the speed and current to be stable, auto opening of

discharge Valve (Delay 10seconds)

3. Adjust condensate re-circulating valve, keeping outlet pressure normal.

4. Check CEP noise, bearing temperature and vibration are normal, also check the operating

parameters and any abnormality at the field.

5. Check the availability of Stand by CEP and put the interlock in service

CEP STOP

1. Interlock to be removed from service before Stop the CEP.

2. When condensate pump flow is<140t/h, check condensate re-circulating Valve is open

3. Give “STOP” command to condensate pump which is in operation.

4. After the CEP stopped, the Hotwell Make up & the Local Push Button should be pressed.

5. If the Stopped CEP in Standby condition then put the interlock in service.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 30 of 6

5.14 14: OPERATION OF CONDENSATE WATER SYSTEM

CONDENSATE SYSTEM FLOW PATH :-

HOTWELL →CONDENSATE PUMP→GLAND SEALING COOLER→NO.7 LP HEATER→NO.6 LP HEATER→NO.5 LP HEATER→NO.4 LP HEATER→DEAERATOR

PRE START UP CHECK

1. All pending PTW is closed.

2. Check all condensate system maintenance work had finished, equipment and site is clean, no obstacles around, system and equipment are complete.

3. Check condensate system valves according to “valve check list.

4. Coordinate I&C person to supply power for instrument, motor valve and protection device, check meter is complete, indication is correct

5. Supply circulating water to condenser.6. Check condensate level is normal, normal value will be in 650 mm. Condenser make up

water system is normal.

7. Power supply is available in CEP & LP Drip Pump.

8. Check start permissive for the CEP & LP Drip pump.

9. Start the CEP and check all the operating parameters and put stand by CEP interlock in-service.

10. Check the condensate flow through the LP heaters.

11. Check the DUMP valve is in closed condition. (If taking condensate water in closed cycle).

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 31 of 6

LP HEATERS IN OPERATION :

a) Before starting, check LP heater system, all valves and instrument are good.

b) Check the LP Heater Local Level Gauge glass in service.

c) Close steam side drain valve, confirm the drain valves upstream and downstream of extracting check valve had opened.

d) Confirm the operated LP heater’s water side drain valve and vent valve had opened.

e) Open slowly the operated LP heater water side inlet valve filling water, after water flows out from vent valve, close it, open water side inlet valve gradually, close condensate bypass valve.

f) Open operated LP heater’s air vent valve slowly, attention vacuum change.

g) Open operated LP heater’s steam inlet valve slightly, warm the heater, 2 °C/min temperature raise rate, the maximum is 3 °C/min.

h) Close related drain valves upstream and downstream of extracting check valve.

i) Open operated LP heater’s steam inlet valve gradually according to the temperature raise condition.

j) Put the LP Heater protection interlock in service.

12. Check the Flow and pressure of Condensate system after LP heater to Deaerator13. After the Turbine load increased > 60 MW start the LP Drip pump and maintain the heater level.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 32 of 6

5.15 15: OPERATION OF VACCUM PUMP

PRE START UP CHECK

1. All pending PTW Tag Removed.

2. All equipment and piping and valve of Vacuum pump have been pre-checked. & should be OK.

3. Open all the suction isolation valve for vacuum pump.

4. Check the oil level in the Circulation water pump.

5. Check the cooling water make-up valve (before solenoid valve) is in open condition.

6. Check the PHE cooling water valve is open condition.

7. Check the Emergency push button release condition.

8. Vacuum breaker valve should be in closed condition.

On DCS check:-

a) There is no Fault on the DCS.

b) Remote service position

c) Circulating pump running.

START UP

Before starting the Vacuum pump check the permissive of cooling water recirculation pump,

There is no fault on the pump.

Pump is in Remote service condition.

1. Now start the Cooling water recirculation pump and check the make-up solenoid valve auto open

close operation according to the separator level.

2. Now after satisfying the vacuum pulling condition (sealing of the Turbine with gland sealing

Condenser) and closing the vacuum breaker valve, The Vacuum Pump should be started.

3. Give “START” command to Vacuum Pump.

4. After starting the vacuum pump check the inlet solenoid valve auto open condition.

5. Now check for the abnormality in the vacuum pump like vibration, bearing temperature, sound in

the field.

6. Now start the 2nd Vacuum pump’s cooling water recirculation pump and put the vacuum pump on

the stand-by condition.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 33 of 6

VACUUM PUMP STOP:

1. For stopping the vacuum pump the give “STOP” command to the vacuum pump and check the inlet

solenoid valve auto closing.

2. Then stop the cooling water recirculation pump and check the make-up solenoid valve auto closing.

3. Then press the Emergency push button on the field.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 34 of 6

5.16 16: OPERATION OF BOILER FEED PUMP

PRE START UP CHECK

1. All pending PTW closed.

2. All equipment, piping and valve of BFP have been pre checked. & should be OK.

3. All cooling & sealing water line is charged for the Booster Pump.

4. Open the Cooling & Sealing water valve for the Mechanical Sealing.

5. Oil level > 40 %

6. All drains are in closed condition.

7. Confirm booster pump inlet valve full open.

8. Confirm BFP outlet motorized valve is closed, BFP re-circulating Valve is 100% opened.

9. Confirm hydraulic coupling scoop is in 0% position (20% in local), auxiliary oil pump is in

running condition.

10. Put working oil cooler and lube oil cooler in service with proper venting, check cooling water

flow & pressure.

11. Open the ACW cooling water valve for the Motor Air Cooler.

START UP

1. The start permissive of the BFP in DCS as below :

a) Deaerator level normal >1950mm

b) Check the Booster pump suction pressure.

c) Recirculation Valve open >95%

d) Discharge MOV fully closed

e) Lube oil Pressure Normal >0.16 MPa ( AOP should be running)

f) Scoop Position <5% ( 20 % in local)

g) Hydraulic Coupling Oil I/L & O/L temp. Should be normal.

h) Electrical 6.6 KV supply normalized and selector is in remote condition.

2. Start AOP and check the lube oil header pressure (> 0.21 MPA), and the filer DP.

3. Give “START” command to BFP

4. After BFP started, check the time for the speed and current to be stable, auto open Discharge

Valve (delay 10 seconds) & the Suction Flow should not be less than 100 T/Hr for a time of 60 sec

to avoid tripping.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 35 of 6

5. Check thoroughly BFP for noise, bearing temperature, vibration, leakage at field is normal, if any

abnormality found then inform to Control-room and stop the pump if required.

6. After lube oil header pressure >0.25 MPa, auxiliary oil pump should be auto stopped.

7. After AOP stop check lube oil pressure and working oil pressure should be normal.

8. Check that the lube oil and working oil temperature is in normal range.

9. Put the recirculation valve in Auto giving the Low flow set point of >150t/h, so it can adjust the flow

accordingly.

10. BFP Middle Tap MOV should be opened as per the requirement of SH & RH Spray.

11. Put interlock switch in service if the availability of the Standby Start the BFP – AOP & check the lube

oil pressure & Filter ∆P, oil level

BFP STOP

1. Check that auxiliary oil pump is healthy & sealing water and cooling water is Normal.

2. Release BFP interlock & start decreasing BFP speed as per the requirement of the system

(maintaining the drum level).

3. When BFP feed water flow is <150 t/h, BFP re-circulating valve will be Opened 100 %

automatically, if not, open it manually.

4. Decrease speed to minimum, scoop position adjusted to ≤20%.

5. Give “STOP” command to BFP & check discharge valve closed & also the local push button

should be pressed.

6. As the BFP is stopped, check that the AOP is auto started. After 30 min, the AOP will be auto

stopped.

7. When lube oil temperature decreased to 40°c, close lube oil cooler cooling water valve.

8. When working oil temperature decreased to 50°c, close working Oil cooler cooling water valve.

9. In change over condition, the BFP interlock switch, BFP discharge valve, lube oil and working oil

cooler cooling water inlet valve and re-circulating valve of Stand by BFP should be opened.

10. If maintenance work will be done after BFP stopping, the auxiliary oil pump will be kept operating

30 min. After BFP stopping to cool the BFP.

11. After pump casing temperature decreased <80°c, drain water from casing and stopping cooling

water supply will be permitted.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 36 of 6

5.17 17: OPERATION OF FEED WATER SYSTEM

FEED WATER SYSTEM FLOW PATH:-

DEAERATOR →BOILER FEED PUMP→NO.2 HP HEATER→NO.1 HP HEATER → BOILER DRUM

PRE START UP CHECK

1. All pending PTW is closed.2. Confirm deaerator and system maintenance work had finished, equipment and site is clean,

no obstacles around, system and equipment are complete. 3. Check feed water deaerating system valves according to “valve check list”. 4. Coordinate I&C person to supply power for instrument, motor valve, level meter and

protection device, check meter is complete, indication is correct. 5. Confirm deaerator water level and pressure high /low signal alarm & Interlock in service,

motor valve and control valve moving smoothly, switch action direction is correct. 6. Check the Level gauge glass availability of HP Heaters.7. Coordinate chemical group, prepare enough DM water, start DM water pump, DM water

quality analysis is accepted. 8. Check proper venting of the deaerator. 9. Start the Boiler fill pump and gradually fill the deaerator up to normal level (2350 mm).10. Supply steam into station steam header, before supply steam, it will be warmed and

drained. 11. Open both side steam inlet valves slowly for initial heating of storage tank. And maintain

the deaerator pressure 0.19MPa and temperature >100°C12. When extraction-3 steam pressure is >0.19MPa, it will be used as heating steam source,

closing both side initial heating steam supply valves. 13. Deaerator pressure increased following the turbine load increasing, after reaching full load

operation, check deaerator thoroughly.14. Adjust the deaerator vent valve as per requirement.15. Check all the permissive for starting of BFP.16. Start the BFP as per , and take the HP Heater in service.17. After checking all the parameters of deaerator are condensate water system in auto control

mode.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 37 of 6

HP HEATER IN OPERATION :

1. Confirm HP heater water inlet and outlet valve are in close condition, feed water flows through bypass piping, filling water valve is close tightly, open water side vent valve.

2. Open HP heater filling water valve, and close the vent valve after proper venting,3. When HP heater pressure is equal to the feed water pressure, open HP heater motor outlet valve

first then open motor inlet (3 way) valve, check the bypass valve is closed and steam side water level is zero to confirm no leakage.

4. Open HP heater-1 & 2 shell side vent valve and vent to deaerator.5. Open extraction 1 & 2 check valves ensuring its upstream and downstream drain valves open.6. Open extraction 1 and 2 MOV slowly (increasing rate is not more than 1.83°C/min.i.e.110°C/h),

keeping pressure 0.05-0.1MPa to warm heaters, close drain valves upstream and downstream of extraction 1 & 2 check valves.

7. Close HP heater 1 & 2 shell side vent valve, keep vent to deaerator vent open condition.8. Pay attention to HP heater water level, when its steam side pressure is 0.3MPa higher than that of

deaerator, close the HP heater-2 to LP heater-4 drip valve and take the Drip to deaerator in-service and also check HP heater water level is normal.

9. Check the Feed water Flow, pressure and temperature after HP Heater.10. Check the LP and HP dosing system operation for maintaining the water quality of Deaerator and Drum.11. Take the water to the Drum as per requirement through the feed control station.12. When water is not taken through the Feed control station maintain the circulation through Eco-

recirculation valve.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 38 of 6

5.18 OF CT FAN SYSTEM

PRE START UP CHECK

1. All Pending PTW closed.2. All the pipe line work is completed and clear.3. All the motor valves, Riser valves and alarm signal inside system should be checked.4. All the motor and MOV, power supply available.5. Sump level is Normal.6. CT make-up water pump is available.7. CT nozzles, V-Bar, Drift eliminator are properly fixed.8. Check the Gear Box Oil level of Cooling Tower Fan.9. Check the Vibration switch is properly fixed.

CHARGING OF COOLING TOWER :

1. Check the Cooling Tower Sump level is Normal.2. Check the Riser valve of running unit is open condition.3. Start one CW or ACW pump as per .4. Check for any water leakages at the System.5. Check the proper circulation through the Riser valve.6. Now Start One Cooling Tower Fan.7. Check the Vibration, Abnormality in sound of Cooling Tower Fan.8. Check the Current of Cooling Tower Fan.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 39 of 6

5.19 19: OPERATION FOR COLD START UP OF TURBINE

1. All pending PTW should be closed.

2. All Equipment and its area should be clean from foreign materials.

3. Following Level to be check for the process healthiness:-

a) Lube oil & EH Oil tank level.

b) Cooling tower sump level.

c) Deaerator level.

d) Hot well level.

e) CST level.

f) DMCCW tank level.

g) DM Tank level.

4. Check the analysis report of DM water, Hotwell, Lube oil and EH Oil for the acceptable range.

5. Check and Confirm Electrical Power supply is available for all the motors and valves.

6. Check the stand by interlock of all the equipments and the operation of all MOV & CV.

7. Check that Cooling Tower Sump Water Level Is Normal. Start the ACW Pump with proper venting &

maintain O/L header pressure as 5.2 Kg/cm2

8. Start CW (Circulating water) pump supplying water to the condenser, open both side water outlet

valve and vent valves, after proper air venting open both side inlet valve slightly and maintain the O/L

header pressure as 2.5 Kg/cm2

9. Start the Instrument Air Compressor and conform the availability of Stand by Compressor. (01 out of

04 nos.)

10. Open Inlet/Outlet Valves Of Oil Cooler And Filter, Cooling Water Will Be Adjusted According To The

Oil Temperature.

11. The Oil Inlet Valve Of HP Oil Pump And LP AC/DC Oil Pump Will Be Opened.

12. Coordinate with C&I to check DEH, ETS, TSI device are normal. And test the following protection:

a) C & I signal and sound/light alarm.b) All oil pump low pressure auto start and turning gear device test.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 40 of 6

c) Manual emergency trip device test d) ETS solenoid valve protection test

e) Extracting check valve protection test.f) OPC protection test g) LP casing hood water spray test.h) HP heater water level protection test.i) Bypass system interlock protection test j) Drainage pot high/low level protection test.k) Deaerator high/low level alarm test l) BFP without power supply test

BFP electric interlock test.

Feed water header pressure low interlock test.

BFP lube oil pressure low protection test

m) Oil vapor extraction fan operating test.

13. Start-up Procedure:-

`

i) Check all oil pumps.ii) Start oil vapor extraction fan.

iii) Start AC lube oil pump, filling oil into system and venting air, check no leakage, oil return is normal

iv) Start HP oil pump, check system and equipment no leakage.

v) Check the pressure of all parts is normal

vi) Start jacking oil pump, check outlet pressure will be 10.0 to 13.0 mpa,confirming rotor had Lifted.

vii) Turning gear should be started around 4 hrs. Prior to the turbine rolling, Also check the turning gear interlock in service.

viii) Check there is no noise and friction in turbine rotation part.

ix) Confirm rotor eccentricity is inacceptable range, and the bearing lube oil temperature before turbine

start is 21-27°c.

x) Ensure that all the drains & vents of the turbine side should be in opened condition. (All

extractions, CRH, HRH, MS, GSC Header, Aux. PRDS header, D/A vent, HP/LP By Pass)

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 41 of 6

xi) Deaerator Will Be In a Normal Level. Warming Auxiliary Steam Header With Station Back Up Steam

Source, keeping Its Pressure, 0.6 TO 0.7Mpa, Temperature, 150°C TO 250°C. Open Deaerator

Auxiliary Steam Supply Valve Heating Storage Tank Water To 90°C TO100°C.

xii) Ensure the DMCCW pump is running and the DMCCW water valve for Turbine and other equipment are

open condition.

xiii) Check the level of condenser and the no.6, no.5, no.4 LP heater is normal.

xiv) Start one CEP, and check there is no leakage in the condensate circuit, and keep stand by pump

interlock in service.

xv) When the boiler drum pressure reaches 0.7 MPa & MS temperature reaches 300⁰C, the Aux. PRDS

should be charged slowly through Drum to Aux PRDS line with proper drain and vent open,

‘OR’ if the other unit is running condition charge the APRDS of start-up unit from the APRDS line of

Running unit with proper drain & vent open condition.

xvi) After the APRDS temperature & pressure reaches 160 - 180⁰C & 0.6 MPa,Start the GSC Fan &

slowly charge the Gland Steam Header (0.03 MPA & 120 – 150 ⁰C) and check there should be no

leakage and adjust drain valve between multistage “ U ” tube type siphon and maintain the gland

steam cooler level.

xvii) Start one Cooling tower fan.

xviii) Start one Vacuum pump and simultaneously close the vacuum breaker valve and check the

healthiness of the pump and observe the rate of increasing trend of the vacuum, if necessary take

another vacuum pump in service. And keeping vacuum at (>-65 KPA).

xix) Start EH Oil Pump, EH Oil Cooling & Filter pump, check current is normal and fluid pressure increasing

slowly to specified value. (If fluid temperature is lower than 10°C, EH pump start is prohibited, if

fluid temperature is lower than 21°C, system can not be circulated. When fluid temperature

reaches 43°C,control fluid cooler cooling water to maintain fluid temperature in 43-54°C range,

then EH system can be circulated.)

xx) Open Bypass stage I & II (HP-Bypass & LP- Bypass) based on requirement, observe the main

steam and Re-heat steam temperature, full-fill the requirement by paying attention to condenser

vacuum.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 42 of 6

xxi) When By-pass temperature reaches the value- HP-bypass 360 ⁰C & LP-bypass 180 ⁰C start spray

water for maintaining temperature and the III-stage spray will auto open based on the LP steam

Exhaust temperature.

14. After pressure established in boiler, based on operation mode, check the tightness of TV, RSV, GV,

IV and HP exhaust check valve, prevent it from casing metal temperature change due to steam

leakage.

15. When Main Steam Pressure 1.5 To1.6mpa. Main Steam Temperature 360°C, Reheat steam

Temperature >300°C, The Difference Between Main Steam And Reheat Steam Temperature Of Both Side

Will Be Not More Than17°C, Condenser Vacuum > (-65kpa) (G), Outlet Oil Temperature Of Oil

Cooler Will Be 35 To45 °C, Rotor Eccentricity Will Not Be More Than 0.076 Mm, Regulating Oil Pressure

Will Be 1.17mpa, Lube Oil Pressure Will Be 0.147 MPa, All Bearing Return Oil Is Normal value are

Reached Rolling Can Be Started.

16. Push protection reset button first then turn on main protection switch, inform C & I Person to turn on Hp Expansion difference, Axial displacement, bearing temperature, bearing oil pressure, over speed protection and bearing vibration protection switches.

17. Finally go through the Prerequisite before turbine rolling if it satisfy then Go to “DEH OVERVIEW”

display and put DEH-control system to “OPERATOR AUTO” mode, click LIMIT SET to set “ VALVE

LIMIT “ and conform valve position 100 % and click “ LATCH “ button, Turbine Latched ,TV & RSV full

open.

18. Starting time period in various conditions:

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 43 of 6

Item Warm Start Hot Start Remark

HP Stationary Blade Very Hot Start

Retain Ring Lower Part 200--320°C More Than 320 °C Same As Hot

Main Steam Temperature

50°C At Least Higher Than HP Stationary Blade Retain Ring Lower Part Temperature

50°C At Least Higher Than HP Stationary Blade Retain Ring Lower Part Temperature

With More Than 50°C Superheat

Reheat Steam

Temperature30°C At Least Higher Than Reheat Lower Flange Metal Temperature

30°C At Least Higher Than Reheat Lower Flange Metal Temperature

With More Than

50°C Superheat

Maximum Speed Increasing Rate 70-100 R/Min

450 Rpm,Not More Than 500 Rpm

Time From Rolling To 3000 Rpm. 40- 50 Min 10 Min

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 44 of 6

19. Give the target speed to 500 RPM with the speed rate of 100 RPM/min & click “GO” button for the rolling.

20. GV, IV Opening gradually, Speed increase gradually, turning gear disengage automatically, if not then trip the

turbine, and check for the reason.

21. After reaching 500 RPM hold up for the primary warm-up period (15 min).

22. In speed-up period check HP Exhaust check valve opening condition, drain of turbine proper and other

related piping will be good, there is no water hammer and vibration existed.

23. Pay attention to main steam and Reheater steam parameter change condition, the deviation with start-

up curve will not more.

24. Now increase the Target speed to 1100 RPM with a rate of 100 RPM/min. The warm-up time will be

maintained at 1100 RPM for 45 minutes and check all important parameters of turbine,

Rotor eccentricity (<0.076 mm), Rotor vibration, axial displacement ((+/-) 1), casing absolute

expansion,

HP/IP Upper & Lower casing temperature difference (<50⁰C), Bearing Temperature- (Journal <90⁰C,

Thrust <85⁰C), Return oil temperature < 65⁰C.

25. After completion of the warm-up period increase the target speed to 2950 RPM with a rate of 200

RPM/min.

26. Check JOP Auto Stop at 1250 RPM, if not Stop it manually.

27. The turbine critical Bands of turbine are: 1st Band :- 1580 – 1890 RPM

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 45 of 6

RPM Hold Timing Rate of Increase500 15 min 100 rpm/min

1100 45 min 100 rpm/min2950 10 min 200 rpm/min

2nd Band : - 2220 – 2390 RPM

3rd Band : - 2630 – 2810 RPM

28. Within the critical bands the increasing speed rate will be automatically change to 500 RPM/min.

supervises the Turbine vibration with this critical band. After reaching at 2950 RPM with normal

parameters increase the target speed to 3000 RPM. Within the range of 2950 to 3000 RPM the Rate of

Speed will automatically change to 50 RPM/min.

29. Now unit will be warm up at 3000 RPM, check the system thoroughly (Both on DCS & Field).

30. Check mail oil pump outlet press 1.17 MPa and Inlet Pressure 0.098 MPa, conform lube oil pressure and

oil temperature. After this STOP HP oil pump and put its interlock switch in service.

31. Now Turbine will thoroughly check normal then the Electrical & C&I personnel should be co-ordinate for

synchronization with grid.

32. For synchronization process, go to DEH panel & take “AUTO SYNC” in service.

Now on DCS panel (Excitation System)

CLOSE the Field Breaker.

START the AVR channel A & B.

START the excitation system & wait for the Excitation voltage & PMG Voltage to be developed

to 25 Volts & 330 Volts resp.

33. As the above parameters are satisfied then go to the DEH panel & click on “PREPARE FOR AUTO

SYNC” if the required permissive are OK.

34. Check the unit synchronization conditions are fulfilled then SYNCHRONIZATION with Grid making

turbine operated with 5 % rated load immediately.

Now check and maintain primary load warm-up period with,

Turbine vibration, Differential Expansion (HP/LP),casing expansion, Axial displacement,

Bearing metal temperature, Return oil temperature, Lube oil pressure, upper & lower casing

temperature difference, Generator core temperature, winding temperature, air temperature are

normal.

35. Now increase the Turbine loading as per requirement and increase Boiler pressure and temperature

according to start-up curve.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 46 of 6

36. Conform all Turbine side drain had close condition at 10 % of rated load, When load reaches to 15 %,

check LP water spray had closed automatically (if not close manually).Also close the By-pass system as

per unit requirement.

37. Now increase the load as per unit requirement and take all extraction with respective heaters in service,

Also take changeover of Auxiliary PRDS steam with 3rd extraction of turbine. Also the LP-drip pump

should be started as per the requirement to maintain the LP-heaters level.

38. After the UNIT reaches the full load of 135 MW, if required then put the operation of the unit in CCS

(Coordinate control system) mode. And observe and maintain the turbine parameters within specified

limit.

** Coordinate control system (CCS) is a critical one in full power plant automatic control system.

The function of Coordinate Control System is boiler and turbine receive the load command, coordinated together to satisfy the load requirement of net work and guarantee the power plant safe operating. It consists of master control system, boiler fuel control system, boiler air flow control system, feed water control system and steam temperature control system, in turbine aspect DEH system.

Generally speaking, the function of CCS will composed with as follows:

Load change rating limitation Generally speaking, the outside load command is to change the electric power, it is a step signal, the load change rate should not be more than the specified unit load change ability, normally it will be 3-5% rated load/min.

Maximum load limitation Load command cannot be more than the maximum permitted unit load, so, in load command handing device, a calculating circuit which calculates the maximum permitted unit load based on the related auxiliaries operating condition will be provided.

Run back protection When some auxiliaries damaged, regardless the outside load requirement, unit load should decreased to a specified level to guarantee unit operating safely and continuously, the run back rate will be limited according to the damage condition.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 47 of 6

Turbine follow control mode (pressure control by turbine) At turbine follow control mode, main steam pressure is controlled automatically by turbine control loop, and the boiler load is control manually by operator.

Unit actual output holding function When some unit auxiliaries operated in a limited condition or some major mass flow (such as fuel flow, feed water flow and air flow) are not matched with load command, The unit actual load command is confined by the high limit and low limit of unit load command, If reason of malfunction is not clear, “holding load” will be taken to avoid accident developed.

5.20 20: OPERATION OF LP DRIP PUMP

PRE START UP CHECK

1. All pending PTW closed.

2. All equipment and piping and valve of LP DRIP pump have been pre-checked. & should be OK.3. Check the condensate level in the LP heater-6.4. Check the Oil level in the DE & NDE side of the Drip pump.5. Check all the suction & discharge valve of the Drip pump.6. Check the DMCCW pump is in running condition.7. Check cooling and sealing water line for the drip pump.

8. Check the Emergency push button release condition.

PRE START UP CHECK

1. LP Heater drip pump no fault.2. LP Heater drip pump remote service.3. LP Heater in Service position.

START UP

1. Check the discharge Control valve is in close condition.

2. START the Drip pump.

3. Now check for the abnormality in the vacuum pump like vibration, bearing temperature, sound in the field.

4. Open the Control valve as per the requirement looking on to the level of LP Heater-6.

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 48 of 6

STOP

1. Reduce the Discharge Control valve position looking on to the LP Heater-6 level, and after reducing loading of pump give the STOP command.

2. Press Emergency Push Button on the field.3. If no maintenance work will be taken in this pump then put the stand by interlock in service.

5.21 21: OPERATION FOR SHUT-DOWN OF UNIT

PREPARATION BEFORE SHUT DOWN:-

1. Inform to all concerning department about the unit shutdown.2. Coordinate electric group to measure the insulation of motors of AC/DC oil pump, jacking oil

pump, turning gear, confirm they are acceptable, putting in interlock switch. 3. Coordinate with C & I group to check DEH, ETS, TSI device are normal.4. Turbine bypass system is in hot stand by condition.

SHUT DOWN IN SLIDE PRESSURE MODE

1. CCS is the basic control mode 2. DEH, valve control mode changes over from “SEQUANTIAL” to “SINGLE” mode under

operator “AUTO” control mode.3. Coordinate with Boiler group during load sliding down maintaining the following parameters:

a) Fluidized air quantity should always more than critical fluidized air quantity.b) For reducing load of unit, gradually reduce the pressure & temperature

maintaining the load curve.c) Coordinate with boiler for reducing coal and air flow maintaining the oxygen

and furnace temperature.d) Temperature deviation between main steam and reheat steam 20℃, not

allow to exceed >40℃. Temperature difference between two side of main steam or reheat steam line is <20℃.

e) Take boiler expansion reading periodically.f) Temperature difference between drum upper and lower wall 50℃.g) Bed temperature cooling rate should not exceed 135℃/h.h) Switchover automatic regulation to manual as per requirement, and maintain

drum

Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 49 of 6

water within normal level range.i) Regulate or close primary and secondary stage attempter water gradually in

terms of steam temperature sliding, and regulate or close reheater attempter flue gas damper

4. Open GV gradually keeping load 100 MW for 10 to 20 min. Casing temperature should be checked every 15 min during this period.

5. Reduce the TG load set point, observing the main steam pressure and temperature.

Following regulations should be followed during shut down period:

i) Avoid ETS over speed test.ii) Maintain differential expansion in the range of +8 to -3mm, if not, inform boiler group

to control parameter stable, pay attention to negative expansion difference.iii) After process is stable, main steam temperature will be 10°C to 20°C lower than

regulating stage metal temperature.iv) In low load condition, pay attention to heaters water level and maintain lube oil

temperature.v) when load decreased to 30% rated load, open HP/LP bypass system, according

to boiler requirement, pay attention to condenser vacuum and turbine exhaust temperature.

vi) Stop all coal feeding into furnace while load slide down to 30%, to generate power by using of residual heat.

vii) When load decreased to 25% rated load, check Gland sealing steam source change over from extraction-3 or auxiliary steam header from boiler drum or from other unit and maintain the gland sealing temperature and pressure.

viii) When load decreased to 20% rated load, Stop Drip pump according to No.6 LP heater water level.

ix) Stop CT fan according to load, observing the vacuum and cooling water I/L & O/L temp. Of condenser.

x) HP heater-2 drip will be changed from deaerator to LP heater-4 when HP Heater-2 pressure is lower than the deaerator.

xi) All extractions taken out of service according to the load reduction curve.xii) When main steam parameter decreased to < 3.0 MPa and 470°C, boiler

pressure/temperature decreasing period finished, for avoiding negative expansion difference to make turbine trip.

xiii)Keep on ventilating into furnace after shutdown, pay attention to each part of refractory temperature fluctuation within regulated range. When bed temperature slide down to 400°C, after purging 30 minutes to Boiler, if boiler not cooling down rapidly, stop primary air fan, secondary air fan, high pressure fluidized fan and induce draft fan running sequentially.

SHUT DOWN

i) Release boiler main protection and water level protection.Prepared by: DM & SM Approved by: HEAD (POWER PLANT)

Reviewed by: HOD (OPERATION) Issued by: MR

STANDARD OPERATING PROCEDUREFOR OPERATION OF BOILER , TURBINE &

BOP

Ref No: CPP-OPR-SOP-1-01 Issue No: 02 Rev No: 00Eff. Date: 20/06/2014PAGE : 50 of 6

ii) Start AC lube oil pump, release HP start oil pump low oil pressure interlock. iii) Steps out generator, the operating time in this period will not exceed 15 min., speed