SolidWorks Miscellaneous Procedures - SOP ATAMI Standard ...SolidWorks Miscellaneous Procedures -...

Transcript of SolidWorks Miscellaneous Procedures - SOP ATAMI Standard ...SolidWorks Miscellaneous Procedures -...

SolidWorks Miscellaneous Procedures - SOP

Page 1 of 9 (back to contents)

ATAMI Standard Operating Procedure

SolidWorks Miscellaneous Procedures

Last saved by Randy Greb on 9/13/2020 11:48 AM

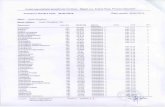

Revision Date Description/Change Curator

0 9/13/2020 New document Randy Greb

SolidWorks Miscellaneous Procedures - SOP

Page 2 of 9 (back to contents)

Contents

Scope: ............................................................................................................................................................ 3

Procedures .................................................................................................................................................... 3

Using Equations in Solidworks: ................................................................................................................. 3

Re-sizable drawing for ASTM E8 Sub-size Specimen: ............................................................................... 3

Place holes on a curved surface (edge of flange): .................................................................................... 5

Links/References: .......................................................................................................................................... 9

Youtube links:............................................................................................................................................ 9

Dogbone video ...................................................................................................................................... 9

Holes on a curved surface ..................................................................................................................... 9

How to Dimension Using Equations ...................................................................................................... 9

SolidWorks Miscellaneous Procedures - SOP

Page 3 of 9 (back to contents)

Scope:

This SOP contains procedures that may be useful for Solidworks drawing.

Procedures

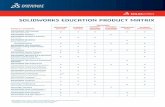

Using Equations in Solidworks:

Global variables and functions under the equations menue are extremely useful for setting up relations

between various dimensions in a part. Setting up dimensions variables and functions can be extremely

useful in allowing scaling of drawings and sub-features to different sizes based on a reference size.

For example, the test structure below can easily be scaled just by changing the spacing and border

variables. If variables are not used, each set of test holes would have to be sized individually each time

you save a drawing.

Re-sizable drawing for ASTM E8 Sub-size Specimen:

This procedure shows how to use a re-sizable drawing to create an ASTM E8 sub-size specimen of

varying lengths.

SolidWorks Miscellaneous Procedures - SOP

Page 4 of 9 (back to contents)

Step Action Notes

1 Open the reference sketch in Solidworks.

2 Be sure to save the drawing to a new name.

3 Adjust the length to the desired value. The various features of the dogbone (B, C, R,..) will scale correspondingly.

4 Select the lower right curve and then choose mirror entities from the Solidworks menu.

5 Then choose both lower arcs and mirror around the horizontal center line.

SolidWorks Miscellaneous Procedures - SOP

Page 5 of 9 (back to contents)

6 Then use trim entities to trim the various internal lines that are not part of the dogbone. This will need to be done for both the top and bottom of the dogbone.

To:

7 The use boss extrude to define the thickness of the

dogbone. A 3 mm thick, 100mm long dogbone is included here.

Place holes on a curved surface (edge of flange):

1. Make a new plane. 2. Draw a 2D sketch in that plane with the lines that locate the holes. Then line should end

at the edge. 3. Use the hole

SolidWorks Miscellaneous Procedures - SOP

Page 6 of 9 (back to contents)

4. Make the center of the hole coincident with the point at the end of the line.

Step Action Notes

8 Orient the part to the plane of interest (front typically?) and then select the menu item: “Reference Geometry->Plane”

9 Pick the surface of the extruded boss that you

want the plane to parallel.

10 Set the offset to that the plane is within the ring. You may have top check flip offset to get it to go in the right direction. Then click the check mark to save it.

Then you’ll see that the new plane is parallel to the plane of the extruded boss surface and offset:

11 Go back to front orientation using ctrl-1.

12 Create a new 2D sketch in the new plane and draw 3 lines from the center out. If you anchor one of the lines, you can then use smart-dimension to set the angle of the other lines relative to the anchored line, as shown in the right.

You can move the part to verify that the lines are on the new plane:

SolidWorks Miscellaneous Procedures - SOP

Page 7 of 9 (back to contents)

13 Set the length of the line so that they end right at the surface where you want the holes. Then exit sketch.

14 Go to features and open the hole wizard. Pick the size and style of hole, and use blind, with a small number for the end condition.

15 Then pick the surface for the holes, and place them close to where you want them. They don’t need to be exact. To the right they are placed on the boss extrude curved surface (not plane 1). Then be sure to click the check mark to save them.

16 Then select the 3D sketch for the hole and open it for editing.

SolidWorks Miscellaneous Procedures - SOP

Page 8 of 9 (back to contents)

17 Then select the end point of the hole and the end of the line that you want to use for positioning the hole and use “Add relation” to make then coincident. Then click the check to save the relationship. Unclick 3D sketch under the sketch menu and you’ll see that the hole and the line, line up.

SolidWorks Miscellaneous Procedures - SOP

Page 9 of 9 (back to contents)

18 You can then change the position of the plane and the line to align the hole to the position you need in the edge. You can change the hole properties to get the depth and type.

19 You can repeat this for each custom hole of interest. Including different holes that can line up exactly over top of the previous ones.

20 If you want to run this pattern around the object in a repeatable fashion, you can use the circular pattern tool.

Links/References:

Youtube links:

Youtube has an amazing number of useful tutorials for Solidworks.

Dogbone video

Holes on a curved surface

How to Dimension Using Equations