Soap Basic Batch 3

-

Upload

sid-deshotel -

Category

Documents

-

view

13 -

download

3

Transcript of Soap Basic Batch 3

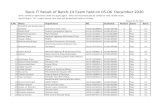

Fat Sodium Hydroxide Potassium Hydroxide Iodine ValueNaOH KOH Low High Dr. Bob's INS Est. INS INS Other Names

Almond, Sweet 0.1360 0.1904 93 105 97 92 97Apricot Kernel 0.1350 0.1890 92 108 91 89 91Arachis 0.1360 0.1904 93 93 99 98 99 peanutAvocado 0.1330 0.1862 82 90 99 101 99Avocado Butter 0.1339 0.1875 60 90 113 113Babassu, brazil nut 0.1750 0.2450 10 20 230 230 230Beef Hoof 0.1410 0.1974 72 72 124 126 124 neat's footBeeswax 0.0690 0.0966 8 11 84 88 84Borage 0.1357 0.1900 130 150 50 50Brazil Nut 0.1750 0.2450 10 20 230 230 230Butterfat, Cow 0.1619 0.2266 30 30 191 197 191Butterfat, Goat 0.1672 0.2340 30 30 204 204Camelina 0.1333 0.1870 140 160 37 37Camellia 0.1362 0.1910 78 88 108 108Candelilla Wax 0.0381 0.0535 19 24 32 32Canola 0.1324 0.1856 110 126 56 68 56Carnauba Wax 0.0611 0.0856 7 14 76 76Castor 0.1286 0.1800 82 90 95 94 95Chicken Fat 0.1389 0.1944 130 130Chinese Bean 0.1350 0.1890 124 132 61 61 61 soybeanCocoa Butter 0.1370 0.1918 33 44 157 154 157

0.1900 0.2660 10 10 258 256 258Cod-liver 0.1326 0.1856 181 181 29 5 29Colza 0.1240 0.1736 105 120 56 62 56 rapeseedCorn 0.1360 0.1904 103 130 69 74 69Cottonseed 0.1386 0.1940 112 112 89 82 89Earthnut 0.1360 0.1904 93 93 99 98 99 peanutEmu 0.1359 0.1906 40 80 128 131 128Evening Primrose 0.1357 0.1900 150 170 30 30Flaxseed 0.1357 0.1899 205 205 -6 -16 -6Goose Fat 0.1369 0.1916 130 130Grapeseed 0.1265 0.1771 125 137 66 47 66Hazelnut 0.1356 0.1898 90 103 94 94Hemp Seed 0.1345 0.1883 160 170 39 24 39Illipe Butter 0.1385 0.1940 43 55 145 145Java Cotton 0.1461 0.2049 85 110 108 108 kapokJojoba 0.0690 0.0966 80 85 11 15 11Kapok 0.1461 0.2049 85 110 108 108Karite Butter (Shea) 0.1280 0.1792 55 71 116 117 116Katchung 0.1360 0.1904 93 93 99 98 99 peanutKokum Butter 0.1357 0.1900 32 40 154 154Kukui Nut 0.1350 0.1890 160 175 24 22 24Lanolin 0.0741 0.1037 18 36 83 77 83Lard 0.1380 0.1932 60 60 139 134 139Linseed 0.1357 0.1899 205 205 -6 -16 -6 flaxseedMacadamia 0.1390 0.1946 73 79 119 119Maize 0.1360 0.1904 103 130 69 74 69 cornMango 0.1280 0.1792 55 65 120 120Mango Butter 0.1371 0.1920 43 50 146 146Meadowfoam 0.1207 0.1690 92 92 77 77Mink 0.1400 0.1960 45 65 141 141Mustard 0.1241 0.1737 105 120 56 62 56 rapeseedNeat's foot 0.1359 0.1902 72 72 124 119 124Neem 0.1387 0.1941 84 94 124 106 124Nutmeg Butter 0.1160 0.1624

0.1340 0.1876 79 95 109 101 109Ostrich 0.1390 0.1946 90 103 128 99 128Palm 0.1410 0.1974 45 57 145 147 145Palm Butter 0.1560 0.2184 37 42 183 179 183Palm Kernel 0.1560 0.2184 37 42 183 179 183Palm, Stearic 0.1410 0.1974 37 45 157 157Peach Kernel 0.1370 0.1920 108 118 96 79 96Peanut 0.1360 0.1904 93 93 99 98 99Perilla 0.1369 0.1916 185 208 -5 -5Pistachio Nut 0.1328 0.1863 93 96 92 92Poppyseed 0.1383 0.1936 140 140 54 54Pumpkinseed 0.1331 0.1863 110 130 67 67Ramic 0.1240 0.1736 105 120 56 62 56 rapeseedRape 0.1240 0.1736 105 120 56 62 56 rapeseedRapeseed 0.1240 0.1736 105 120 56 62 56Rice Bran 0.1280 0.1792 110 110 70 70Ricinus 0.1286 0.1800 82 90 95 94 95 castorRose Hip Seed 0.1378 0.1930 170 185 16 16Safflower 0.1360 0.1904 150 150 47 41 47Sal Butter 0.1306 0.1832 35 43 145 145Sesame Seed 0.1330 0.1862 105 115 81 77 81Shea Butter 0.1280 0.1792 55 71 116 117 116Shortening (veg.) 0.1360 0.1904 90 95 115 98 115Soybean 0.1350 0.1890 124 132 61 61 61Sunflower Seed 0.1340 0.1876 136 136 63 52 63Sweet Oil 0.1340 0.1876 79 95 109 101 109 oliveTallow, bear 0.1390 0.1946Tallow, beef 0.1405 0.1967 43 47 147 152 147Tallow, chinese vegetable 0.1345 0.1883Tallow, deer 0.1379 0.1930 166 166Tallow, goat 0.1383 0.1936 156 156Tallow, sheep 0.1383 0.1936 156 156Tamanu 0.1357 0.1900 108 108 82 82Theobroma 0.1370 0.1918 33 44 157 154 157 cocoa butterTung 0.1377 0.1927 163 173 25 25Walnut 0.1353 0.1894 140 150 45 45

0.1310 0.1834 115 140 58 56 58

Coconut

Olive

Wheatgerm

Recipe Name: BASIC BATCH 3

Alkali: NaOH (Bar Soap)

Estimated INS Value: 150

Oil Weight in Oz % of Oils INS SAP Oz NaOH Super-fatting Oil Weight in Oz15.026 49.8% 109 0.1340 2.013484 Castor 1.59 0.1286 0.204474

7.94 26.3% 258 0.1900 1.5086Shortening (veg.) 7.19 23.8% 115 0.1360 0.97784

Total: 30.156 100.0% 4.499924 Total: 1.59 0.204474

Lye discount: 0.0% Total Effective Lye Discount: 6.5%

Total Oz Pounds Ounces Notes:Oils 31.7 1 15.7Lye 4.4 0 4.4Water 10.0 0 10.0Total 46.1 2 14.1After Cure (15% water) 37.6 2 5.6

Bar Size (Oz) 4.0Number of Bars 9

Olive Coconut

MIXED OILS AND LYE AT 120 DEGREES USED 200 GRAMS OF ICE AND 97 GRAMS OF WATER TO KEEP LYE MIX AT LOW TEMP. I GOT 3 BATCHES OUT OF A 31.5 OZ CAN OF COCONUT OIL AND STILL HAVE SOME LEFT OVER, ALSO HAVE A DAB OF CASTOR OIL LEFT OVER FROM A 6 OZ JAR. HAVE USED 2-25.5 BOTTLES OF OLIVE AND MAYBE HALF OF A CAN OF CRISCO.

Recipe Name: BASIC BATCH 3

Alkali: NaOH (Bar Soap) Scale To:or

Scale Factor: 1.76 or

Oil Weight in Oz % of Oils SAP Oz NaOH26.45 49.8% 0.1340 3.544313.97 26.3% 0.1900 2.6543

Shortening (veg.) 12.65 23.8% 0.1360 1.7204

Total: 53.07 100.0% 7.919

Lye discount: 0.0% Total Effective Lye Discount:

Total Oz Pounds OuncesOils 55.9 3 7.9Lye 7.9 0 7.9Water 17.6 1 1.6Total 81.4 5 1.4After Cure (15% water) 66.4 4 2.4

Bar Size (Oz) 4.0Number of Bars 16

Olive Coconut

BASIC BATCH 3

Total Weight (Oz)Weight After Cure (Oz)Number of Bars

Super-fatting Oil Weight in OzCastor 2.8 0.1286 0.36008

Total: 2.8 0.36008

Total Effective Lye Discount: 4.6%

Notes:

MIXED OILS AND LYE AT 120 DEGREES USED 200 GRAMS OF ICE AND 97 GRAMS OF WATER TO KEEP LYE MIX AT LOW TEMP. I GOT 3 BATCHES OUT OF A 31.5 OZ CAN OF COCONUT OIL AND STILL HAVE SOME LEFT OVER, ALSO HAVE A DAB OF CASTOR OIL LEFT OVER FROM A 6 OZ JAR. HAVE USED 2-25.5 BOTTLES OF OLIVE AND MAYBE HALF OF A CAN OF CRISCO.

Hi, just a few notes about this template, how to use the workbooks created from it, and the methods used for certain operations. There's a short FAQ at the very end of this document.

Installation------------(These instructions are based on installing the template for use by MSExcel97, on a machine running MSWindows95/98/ME/NT.)

The best place to keep this template is in your Templates folder. Your Templates folder should be in the folder in which you installed Microsoft Office or Microsoft Excel. For example: on my machine the Templates folder is 'C:\Program Files\Microsoft Office\Templates'.

Basic usage-----------Once you have saved the template to your Templates folder, here's how to create new workbooks from it:1) Start Excel2) Click 'New' on the 'File' menu, which opens up the 'New' dialog box.3) On the 'General' tab of the 'New' dialog, pick 'soapsheet.xlt'.4) Click the OK button.5) A new workbook called soapsheet1 should appear in Excel.

There are only two worksheets in this workbook that you need to be concerned with when you play with your soap recipes. They are the sheets labeled "Recipe Worksheet" (the one you're on by default when you create a new workbook from the template) and "Scaled Version". The fields that may be changed on the Recipe worksheet are:

- Recipe Name- Alkali (NaOH for bar soap recipes, KOH for liquid soap recipes)- fields under the "Oil" heading- fields under the "Super-fatting Oil" heading- fields under the "Weight in Oz" headings for oils and super-fatting oils- Lye discount- Bar Size (Oz)- Notes

Entering a recipe is as easy as picking oils from the drop-down list attached to the Oil fields and entering the amount of each you want to use. Then, if you want, enter super-fatting oils the same way, enter a lye discount, and perhaps change the bar size. That's it. Everything else will be calculated for you.

The Scaled Version sheet allows you to take the recipe entered on the Recipe sheet and scale it to whatever batch size you want. It shows everything from the Recipe sheet except INS values, and includes the additional field "Scale Factor". Scale Factor is the only field that may be changed on the Scaled Version sheet, and is used as follows: to scale a recipe down to one half of its original size, enter a Scale Factor of .5. To double a recipe, enter a Scale Factor of 2. Enter whatever factor you want, 2 and .5 are just examples. You get the idea.

New feature on Scaled Version worksheet: there are now three new fields thatallow the recipe to be scaled either to a total batch size in ounces, a totalbatch size in ounces after cure, or a total number of bars based on the usersettable bar size. To use these, enter a number in any one of the threefields (after typing the number hit return or select another cell to completeyour change), then click on the button next to the field. This will cause Excelto automatically change the scale factor to achieve the batch size or numberof bars you specify. Please note that this "goal seeking" feature of Excel isnot perfect, sometimes it will not be able to properly scale to the number youspecify. If that happens, try fractionally changing the number in onedirection or another and then hit the button again. For example, if Excel ishaving trouble scaling your recipe to a 64 ounce batch, try scaling to 64.1 or63.9 ounces instead. If it still doesn't work, try changing the number alittle more. Also note that scaling to a batch size after cure or to anumber of bars is disabled when the alkali is set to KOH (liquid soap).

Bar Soap (NaOH) versus Liquid Soap (KOH) Recipes------------------------------------------------The alkali for a recipe is set to NaOH by default. If you change it to KOH for a liquidsoap recipe, several things change:

1) The SAP values used change to those for KOH.2) The water calculation changes to one suitable for liquid soap recipes.3) The INS values and the INS calculation disappear, since the are not appli- cable to liquid soap.4) Other fields/calculations that are not applicable to liquid soap (e.g. weight after cure, bar size, and yield in bars) also disappear.

SAP Values----------The SAP values used in calculating the lye are looked up from the SAP Values worksheet. If you disagree with any of the values, please feel free to change them. You may also change the names of any of the oils, just make sure you change any references on the Recipe worksheet from the old name to the new name. You may also add new oils, as long as you don't change the format of the SAP Values worksheet (this is very important, as the lookup from the Recipe worksheet depends upon the oil names and SAP values being in specific columns, and within a certain range of rows). If you do add new oils, you can either insert them into the list where you want or put them at the end; order is not important, just don't go past row 200 or so. Note too that the oils in the drop down list on the Recipe sheet appear in the same order as on the SAP Values sheet, so if you don't insert new oils in alphabetical order, they won't appear that way in the list either. To save any changes/additions you make to the SAP Values worksheet, so that any new workbooks you create will include them, see "Changing the template" below.

INS Values of Recipes---------------------The concept of INS values is borrowed from Dr Robert McDaniel's book, "Essentially Soap." He in turn borrowed it from an unattributed source. In any event, what he says is that an oil's INS value is based on its SAP value and iodine value, and that a soap's INS is the weighted average of the INS values of its constituent oils. What does that mean to you? Probably not much. The important thing is that (as related by Dr Bob) the 'ideal' INS value to shoot for when formulating a soap recipe is 160. Now remember: 160 is only the ideal. Most recipes, even really excellent ones, won't be at an INS of 160. The majority of the ones I've looked at are in the mid 140's or low 150's. The INS value's real utility is as a sort of rough gauge of how well your recipe is balanced. In other words, if your recipe's INS is much above or way below 160, you might want to take another look at things. Note that the INS calculation isnot done for liquid soap recipes.

INS Values of Individual Oils-----------------------------Many of the INS values for individual oils are borrowed from Dr Bob. Specifically, the sheet calculates its own INS values based on the best SAP and iodine values I could find, but where Dr Bob had a value, I defer to him. You may note that a few of the oils listed have no INS. That's because Dr Bob didn't list them, and I couldn't find iodine value numbers for them either. You can still use those oils in your recipes, but they will be ignored in the INS calculation for the recipe as a whole.

Canola versus Rapeseed oil--------------------------All canola oil is rapeseed oil, but not all rapeseed oil is canola. The reason for this is that rapeseed oil normally has an erucic acid content of up to fifty percent, while in order for an oil to be called canola, it may have an erucic acid content of no more than two percent. In other words, canola is low erucic acid rapeseed oil. What does this mean to you? Well, the erucic acid of regular rapeseed is largely replaced by oleic and linoleic acids in canola, which CHANGES THE SAP VALUE. I have yet to see a saponification chart, either published or on the web, which takes this into account. Every one of them treats rape and canola interchangeably, and lists the SAP of regular rape, even though the availability of regular rapeseed oil to the average North American consumer is limited at best. Is this dangerous? Since the SAP of rape is lower than that of canola, no, not really. It just means you're building an additional lye discount into any soap that uses canola. Which isn't much of a problem unless your recipe is already at the extreme of superfatting, or you're trying to make transparent soap. Bottom line: use canola for canola, and any of the other names (ramic/rape/rapeseed) for regular rapeseed oil.

Lye calculation and rounding----------------------------Because most people don't have a way to accurately measure amounts smaller than .1 ounces (well, I don't), the calculated amounts for lye and water are rounded DOWN to the nearest .1 ounce. If you must round, rounding down is the only safe way to go for lye, and unless you are making very small batches, a difference of less than one tenth of an ounce should have very little effect. Note that you may still enter amounts of oil to any level of precision you want, you just won't ever get more than one decimal place of precision for the lye and water.

Water calculation-----------------The amount of water required for bar soaps is calculated based on the rule ofthumb of one pound of water for every three pounds of oils. There are otherrules of thumb out there, e.g. six ounces of water per pound of oils, ala theMMS calculator, but I prefer the 1:3 rule. For liquid soap recipes the amountof water is three times the total weight of the KOH.

After Cure calculation----------------------The After Cure weight is an estimate of the total yield of soap after most of the water has cured out of your bars. It is based on the rule of thumb that when your soap is done curing it will have about 15% of its original water content remaining.

Default values--------------Every new soapsheet workbook will have a default alkali of NaOH (bar soap), a lyediscount of 0%, bar size of 4 ounces, and scale factor of 1. Any of these may bechanged. To save your changes for future workbooks, see "Changing the template"below.

Changing the template---------------------Here's how to change the template:

1) Create a new soapsheet workbook.2) Make your changes/additions to SAP Values, bar size, lye discount, and/or scale factor.3) From the File menu, click Save As.4) In the 'Save as type' drop-down list box on the 'Save As' dialog, choose 'Template (*.xlt)'. This choice should automatically change the 'Save in' directory to your Templates directory.5) In the 'File name' box of the 'Save As' dialog enter 'soapsheet' (the original name), or whatever name you would like to use for the new version of the template.6) If you are replacing the template you started with in step one, you will be prompted whether or not to overwrite the original. Click 'Yes'.7) You're done.

FAQ's-----

1) What the heck is a '.xlt' file?

The .xlt, versus .xls, indicates that it is an Excel spreadsheet _template_, not actually a spreadsheet. Every time you open it, it will create a new workbook in Excel that you will be asked to name when you save (i.e. it's hitting the `New' button to create a new workbook, but instead of being blank, it's got all of this stuff from the template in it already). Normally templates are kept in the Templates directory under the directory where Microsoft Office was installed. For me, under WindowsNT 4.0, that defaults to c:\program files\microsoft office\templates. Once the template is installed in the templates directory, picking File>New off of Excel's menu will pop up a dialog for choosing a template or wizard for the new workbook. Just pick 'soapsheet.xlt' from the General tab, and you are good to go.

2) Why is the total effective lye discount greater than my lye discount, even though I specified no superfatting oils?

3) Why is the total effective lye discount different for the scaled version of my recipe?

The answer to these two questions has to do with the fact that lye amounts are rounded down to the nearest tenth of an ounce, as detailed in "Lye calculation and rounding" above. To answer the first question, by way of example: if you specify a lye discount of 5%, which puts the lye amount at, for example, 7.39 ounces, the number 7.39 will be rounded down to 7.3, giving you a total effective lye discount of almost 6.2%. That's a 1.2% higher discount, all because you lost .09 ounces of lye to rounding. Are you with me so far? Now on to question two... The reason why the total effective lye discount may be a different value on the scaled version worksheet than the recipe worksheet is that the amount being rounded off of the lye amount will almost certainly change, and it will be a different proportion to the lye amount than in the unscaled version. For example: say I have a recipe with a 5% lye discount, which puts the lye amount at 8.66 ounces, which rounds down to 8.6, giving me a total effective lye discount of around 5.7%. Then I go to the scaled version worksheet and double the batch size. Now my 5% discount puts the lye amount at 17.32 ounces, which rounds down to 17.3, giving me a total effective lye discount of only about 5.2%. This effect can work the opposite way too, with the total effective lye discount going up when you change the batch size. It is even more pronounced when you scale down to smaller batch sizes, because even a small amount rounded off is a proportionately larger change than in a large batch. I hope that makes sense to everyone. There's no way around this without taking a smaller lye discount than what you originally entered.

Hi, just a few notes about this template, how to use the workbooks created from it, and the methods used for certain operations. There's a short FAQ at the very end of this document.

Installation------------(These instructions are based on installing the template for use by MSExcel97, on a machine running MSWindows95/98/ME/NT.)

The best place to keep this template is in your Templates folder. Your Templates folder should be in the folder in which you installed Microsoft Office or Microsoft Excel. For example: on my machine the Templates folder is 'C:\Program Files\Microsoft Office\Templates'.

Basic usage-----------Once you have saved the template to your Templates folder, here's how to create new workbooks from it:1) Start Excel2) Click 'New' on the 'File' menu, which opens up the 'New' dialog box.3) On the 'General' tab of the 'New' dialog, pick 'soapsheet.xlt'.4) Click the OK button.5) A new workbook called soapsheet1 should appear in Excel.

There are only two worksheets in this workbook that you need to be concerned with when you play with your soap recipes. They are the sheets labeled "Recipe Worksheet" (the one you're on by default when you create a new workbook from the template) and "Scaled Version". The fields that may be changed on the Recipe worksheet are:

- Recipe Name- Alkali (NaOH for bar soap recipes, KOH for liquid soap recipes)- fields under the "Oil" heading- fields under the "Super-fatting Oil" heading- fields under the "Weight in Oz" headings for oils and super-fatting oils- Lye discount- Bar Size (Oz)- Notes

Entering a recipe is as easy as picking oils from the drop-down list attached to the Oil fields and entering the amount of each you want to use. Then, if you want, enter super-fatting oils the same way, enter a lye discount, and perhaps change the bar size. That's it. Everything else will be calculated for you.

The Scaled Version sheet allows you to take the recipe entered on the Recipe sheet and scale it to whatever batch size you want. It shows everything from the Recipe sheet except INS values, and includes the additional field "Scale Factor". Scale Factor is the only field that may be changed on the Scaled Version sheet, and is used as follows: to scale a recipe down to one half of its original size, enter a Scale Factor of .5. To double a recipe, enter a Scale Factor of 2. Enter whatever factor you want, 2 and .5 are just examples. You get the idea.

New feature on Scaled Version worksheet: there are now three new fields thatallow the recipe to be scaled either to a total batch size in ounces, a totalbatch size in ounces after cure, or a total number of bars based on the usersettable bar size. To use these, enter a number in any one of the threefields (after typing the number hit return or select another cell to completeyour change), then click on the button next to the field. This will cause Excelto automatically change the scale factor to achieve the batch size or numberof bars you specify. Please note that this "goal seeking" feature of Excel isnot perfect, sometimes it will not be able to properly scale to the number youspecify. If that happens, try fractionally changing the number in onedirection or another and then hit the button again. For example, if Excel ishaving trouble scaling your recipe to a 64 ounce batch, try scaling to 64.1 or63.9 ounces instead. If it still doesn't work, try changing the number alittle more. Also note that scaling to a batch size after cure or to anumber of bars is disabled when the alkali is set to KOH (liquid soap).

Bar Soap (NaOH) versus Liquid Soap (KOH) Recipes------------------------------------------------The alkali for a recipe is set to NaOH by default. If you change it to KOH for a liquidsoap recipe, several things change:

1) The SAP values used change to those for KOH.2) The water calculation changes to one suitable for liquid soap recipes.3) The INS values and the INS calculation disappear, since the are not appli- cable to liquid soap.4) Other fields/calculations that are not applicable to liquid soap (e.g. weight after cure, bar size, and yield in bars) also disappear.

SAP Values----------The SAP values used in calculating the lye are looked up from the SAP Values worksheet. If you disagree with any of the values, please feel free to change them. You may also change the names of any of the oils, just make sure you change any references on the Recipe worksheet from the old name to the new name. You may also add new oils, as long as you don't change the format of the SAP Values worksheet (this is very important, as the lookup from the Recipe worksheet depends upon the oil names and SAP values being in specific columns, and within a certain range of rows). If you do add new oils, you can either insert them into the list where you want or put them at the end; order is not important, just don't go past row 200 or so. Note too that the oils in the drop down list on the Recipe sheet appear in the same order as on the SAP Values sheet, so if you don't insert new oils in alphabetical order, they won't appear that way in the list either. To save any changes/additions you make to the SAP Values worksheet, so that any new workbooks you create will include them, see "Changing the template" below.

INS Values of Recipes---------------------The concept of INS values is borrowed from Dr Robert McDaniel's book, "Essentially Soap." He in turn borrowed it from an unattributed source. In any event, what he says is that an oil's INS value is based on its SAP value and iodine value, and that a soap's INS is the weighted average of the INS values of its constituent oils. What does that mean to you? Probably not much. The important thing is that (as related by Dr Bob) the 'ideal' INS value to shoot for when formulating a soap recipe is 160. Now remember: 160 is only the ideal. Most recipes, even really excellent ones, won't be at an INS of 160. The majority of the ones I've looked at are in the mid 140's or low 150's. The INS value's real utility is as a sort of rough gauge of how well your recipe is balanced. In other words, if your recipe's INS is much above or way below 160, you might want to take another look at things. Note that the INS calculation isnot done for liquid soap recipes.

INS Values of Individual Oils-----------------------------Many of the INS values for individual oils are borrowed from Dr Bob. Specifically, the sheet calculates its own INS values based on the best SAP and iodine values I could find, but where Dr Bob had a value, I defer to him. You may note that a few of the oils listed have no INS. That's because Dr Bob didn't list them, and I couldn't find iodine value numbers for them either. You can still use those oils in your recipes, but they will be ignored in the INS calculation for the recipe as a whole.

Canola versus Rapeseed oil--------------------------All canola oil is rapeseed oil, but not all rapeseed oil is canola. The reason for this is that rapeseed oil normally has an erucic acid content of up to fifty percent, while in order for an oil to be called canola, it may have an erucic acid content of no more than two percent. In other words, canola is low erucic acid rapeseed oil. What does this mean to you? Well, the erucic acid of regular rapeseed is largely replaced by oleic and linoleic acids in canola, which CHANGES THE SAP VALUE. I have yet to see a saponification chart, either published or on the web, which takes this into account. Every one of them treats rape and canola interchangeably, and lists the SAP of regular rape, even though the availability of regular rapeseed oil to the average North American consumer is limited at best. Is this dangerous? Since the SAP of rape is lower than that of canola, no, not really. It just means you're building an additional lye discount into any soap that uses canola. Which isn't much of a problem unless your recipe is already at the extreme of superfatting, or you're trying to make transparent soap. Bottom line: use canola for canola, and any of the other names (ramic/rape/rapeseed) for regular rapeseed oil.

Lye calculation and rounding----------------------------Because most people don't have a way to accurately measure amounts smaller than .1 ounces (well, I don't), the calculated amounts for lye and water are rounded DOWN to the nearest .1 ounce. If you must round, rounding down is the only safe way to go for lye, and unless you are making very small batches, a difference of less than one tenth of an ounce should have very little effect. Note that you may still enter amounts of oil to any level of precision you want, you just won't ever get more than one decimal place of precision for the lye and water.

Water calculation-----------------The amount of water required for bar soaps is calculated based on the rule ofthumb of one pound of water for every three pounds of oils. There are otherrules of thumb out there, e.g. six ounces of water per pound of oils, ala theMMS calculator, but I prefer the 1:3 rule. For liquid soap recipes the amountof water is three times the total weight of the KOH.

After Cure calculation----------------------The After Cure weight is an estimate of the total yield of soap after most of the water has cured out of your bars. It is based on the rule of thumb that when your soap is done curing it will have about 15% of its original water content remaining.

Default values--------------Every new soapsheet workbook will have a default alkali of NaOH (bar soap), a lyediscount of 0%, bar size of 4 ounces, and scale factor of 1. Any of these may bechanged. To save your changes for future workbooks, see "Changing the template"below.

Changing the template---------------------Here's how to change the template:

1) Create a new soapsheet workbook.2) Make your changes/additions to SAP Values, bar size, lye discount, and/or scale factor.3) From the File menu, click Save As.4) In the 'Save as type' drop-down list box on the 'Save As' dialog, choose 'Template (*.xlt)'. This choice should automatically change the 'Save in' directory to your Templates directory.5) In the 'File name' box of the 'Save As' dialog enter 'soapsheet' (the original name), or whatever name you would like to use for the new version of the template.6) If you are replacing the template you started with in step one, you will be prompted whether or not to overwrite the original. Click 'Yes'.7) You're done.

FAQ's-----

1) What the heck is a '.xlt' file?

The .xlt, versus .xls, indicates that it is an Excel spreadsheet _template_, not actually a spreadsheet. Every time you open it, it will create a new workbook in Excel that you will be asked to name when you save (i.e. it's hitting the `New' button to create a new workbook, but instead of being blank, it's got all of this stuff from the template in it already). Normally templates are kept in the Templates directory under the directory where Microsoft Office was installed. For me, under WindowsNT 4.0, that defaults to c:\program files\microsoft office\templates. Once the template is installed in the templates directory, picking File>New off of Excel's menu will pop up a dialog for choosing a template or wizard for the new workbook. Just pick 'soapsheet.xlt' from the General tab, and you are good to go.

2) Why is the total effective lye discount greater than my lye discount, even though I specified no superfatting oils?

3) Why is the total effective lye discount different for the scaled version of my recipe?

The answer to these two questions has to do with the fact that lye amounts are rounded down to the nearest tenth of an ounce, as detailed in "Lye calculation and rounding" above. To answer the first question, by way of example: if you specify a lye discount of 5%, which puts the lye amount at, for example, 7.39 ounces, the number 7.39 will be rounded down to 7.3, giving you a total effective lye discount of almost 6.2%. That's a 1.2% higher discount, all because you lost .09 ounces of lye to rounding. Are you with me so far? Now on to question two... The reason why the total effective lye discount may be a different value on the scaled version worksheet than the recipe worksheet is that the amount being rounded off of the lye amount will almost certainly change, and it will be a different proportion to the lye amount than in the unscaled version. For example: say I have a recipe with a 5% lye discount, which puts the lye amount at 8.66 ounces, which rounds down to 8.6, giving me a total effective lye discount of around 5.7%. Then I go to the scaled version worksheet and double the batch size. Now my 5% discount puts the lye amount at 17.32 ounces, which rounds down to 17.3, giving me a total effective lye discount of only about 5.2%. This effect can work the opposite way too, with the total effective lye discount going up when you change the batch size. It is even more pronounced when you scale down to smaller batch sizes, because even a small amount rounded off is a proportionately larger change than in a large batch. I hope that makes sense to everyone. There's no way around this without taking a smaller lye discount than what you originally entered.

Hi, just a few notes about this template, how to use the workbooks created from it, and the methods used for certain operations. There's a short FAQ at the very end of this document.

Installation------------(These instructions are based on installing the template for use by MSExcel97, on a machine running MSWindows95/98/ME/NT.)

The best place to keep this template is in your Templates folder. Your Templates folder should be in the folder in which you installed Microsoft Office or Microsoft Excel. For example: on my machine the Templates folder is 'C:\Program Files\Microsoft Office\Templates'.

Basic usage-----------Once you have saved the template to your Templates folder, here's how to create new workbooks from it:1) Start Excel2) Click 'New' on the 'File' menu, which opens up the 'New' dialog box.3) On the 'General' tab of the 'New' dialog, pick 'soapsheet.xlt'.4) Click the OK button.5) A new workbook called soapsheet1 should appear in Excel.

There are only two worksheets in this workbook that you need to be concerned with when you play with your soap recipes. They are the sheets labeled "Recipe Worksheet" (the one you're on by default when you create a new workbook from the template) and "Scaled Version". The fields that may be changed on the Recipe worksheet are:

- Recipe Name- Alkali (NaOH for bar soap recipes, KOH for liquid soap recipes)- fields under the "Oil" heading- fields under the "Super-fatting Oil" heading- fields under the "Weight in Oz" headings for oils and super-fatting oils- Lye discount- Bar Size (Oz)- Notes

Entering a recipe is as easy as picking oils from the drop-down list attached to the Oil fields and entering the amount of each you want to use. Then, if you want, enter super-fatting oils the same way, enter a lye discount, and perhaps change the bar size. That's it. Everything else will be calculated for you.

The Scaled Version sheet allows you to take the recipe entered on the Recipe sheet and scale it to whatever batch size you want. It shows everything from the Recipe sheet except INS values, and includes the additional field "Scale Factor". Scale Factor is the only field that may be changed on the Scaled Version sheet, and is used as follows: to scale a recipe down to one half of its original size, enter a Scale Factor of .5. To double a recipe, enter a Scale Factor of 2. Enter whatever factor you want, 2 and .5 are just examples. You get the idea.

New feature on Scaled Version worksheet: there are now three new fields thatallow the recipe to be scaled either to a total batch size in ounces, a totalbatch size in ounces after cure, or a total number of bars based on the usersettable bar size. To use these, enter a number in any one of the threefields (after typing the number hit return or select another cell to completeyour change), then click on the button next to the field. This will cause Excelto automatically change the scale factor to achieve the batch size or numberof bars you specify. Please note that this "goal seeking" feature of Excel isnot perfect, sometimes it will not be able to properly scale to the number youspecify. If that happens, try fractionally changing the number in onedirection or another and then hit the button again. For example, if Excel ishaving trouble scaling your recipe to a 64 ounce batch, try scaling to 64.1 or63.9 ounces instead. If it still doesn't work, try changing the number alittle more. Also note that scaling to a batch size after cure or to anumber of bars is disabled when the alkali is set to KOH (liquid soap).

Bar Soap (NaOH) versus Liquid Soap (KOH) Recipes------------------------------------------------The alkali for a recipe is set to NaOH by default. If you change it to KOH for a liquidsoap recipe, several things change:

1) The SAP values used change to those for KOH.2) The water calculation changes to one suitable for liquid soap recipes.3) The INS values and the INS calculation disappear, since the are not appli- cable to liquid soap.4) Other fields/calculations that are not applicable to liquid soap (e.g. weight after cure, bar size, and yield in bars) also disappear.

SAP Values----------The SAP values used in calculating the lye are looked up from the SAP Values worksheet. If you disagree with any of the values, please feel free to change them. You may also change the names of any of the oils, just make sure you change any references on the Recipe worksheet from the old name to the new name. You may also add new oils, as long as you don't change the format of the SAP Values worksheet (this is very important, as the lookup from the Recipe worksheet depends upon the oil names and SAP values being in specific columns, and within a certain range of rows). If you do add new oils, you can either insert them into the list where you want or put them at the end; order is not important, just don't go past row 200 or so. Note too that the oils in the drop down list on the Recipe sheet appear in the same order as on the SAP Values sheet, so if you don't insert new oils in alphabetical order, they won't appear that way in the list either. To save any changes/additions you make to the SAP Values worksheet, so that any new workbooks you create will include them, see "Changing the template" below.

INS Values of Recipes---------------------The concept of INS values is borrowed from Dr Robert McDaniel's book, "Essentially Soap." He in turn borrowed it from an unattributed source. In any event, what he says is that an oil's INS value is based on its SAP value and iodine value, and that a soap's INS is the weighted average of the INS values of its constituent oils. What does that mean to you? Probably not much. The important thing is that (as related by Dr Bob) the 'ideal' INS value to shoot for when formulating a soap recipe is 160. Now remember: 160 is only the ideal. Most recipes, even really excellent ones, won't be at an INS of 160. The majority of the ones I've looked at are in the mid 140's or low 150's. The INS value's real utility is as a sort of rough gauge of how well your recipe is balanced. In other words, if your recipe's INS is much above or way below 160, you might want to take another look at things. Note that the INS calculation isnot done for liquid soap recipes.

INS Values of Individual Oils-----------------------------Many of the INS values for individual oils are borrowed from Dr Bob. Specifically, the sheet calculates its own INS values based on the best SAP and iodine values I could find, but where Dr Bob had a value, I defer to him. You may note that a few of the oils listed have no INS. That's because Dr Bob didn't list them, and I couldn't find iodine value numbers for them either. You can still use those oils in your recipes, but they will be ignored in the INS calculation for the recipe as a whole.

Canola versus Rapeseed oil--------------------------All canola oil is rapeseed oil, but not all rapeseed oil is canola. The reason for this is that rapeseed oil normally has an erucic acid content of up to fifty percent, while in order for an oil to be called canola, it may have an erucic acid content of no more than two percent. In other words, canola is low erucic acid rapeseed oil. What does this mean to you? Well, the erucic acid of regular rapeseed is largely replaced by oleic and linoleic acids in canola, which CHANGES THE SAP VALUE. I have yet to see a saponification chart, either published or on the web, which takes this into account. Every one of them treats rape and canola interchangeably, and lists the SAP of regular rape, even though the availability of regular rapeseed oil to the average North American consumer is limited at best. Is this dangerous? Since the SAP of rape is lower than that of canola, no, not really. It just means you're building an additional lye discount into any soap that uses canola. Which isn't much of a problem unless your recipe is already at the extreme of superfatting, or you're trying to make transparent soap. Bottom line: use canola for canola, and any of the other names (ramic/rape/rapeseed) for regular rapeseed oil.

Lye calculation and rounding----------------------------Because most people don't have a way to accurately measure amounts smaller than .1 ounces (well, I don't), the calculated amounts for lye and water are rounded DOWN to the nearest .1 ounce. If you must round, rounding down is the only safe way to go for lye, and unless you are making very small batches, a difference of less than one tenth of an ounce should have very little effect. Note that you may still enter amounts of oil to any level of precision you want, you just won't ever get more than one decimal place of precision for the lye and water.

Water calculation-----------------The amount of water required for bar soaps is calculated based on the rule ofthumb of one pound of water for every three pounds of oils. There are otherrules of thumb out there, e.g. six ounces of water per pound of oils, ala theMMS calculator, but I prefer the 1:3 rule. For liquid soap recipes the amountof water is three times the total weight of the KOH.

After Cure calculation----------------------The After Cure weight is an estimate of the total yield of soap after most of the water has cured out of your bars. It is based on the rule of thumb that when your soap is done curing it will have about 15% of its original water content remaining.

Default values--------------Every new soapsheet workbook will have a default alkali of NaOH (bar soap), a lyediscount of 0%, bar size of 4 ounces, and scale factor of 1. Any of these may bechanged. To save your changes for future workbooks, see "Changing the template"below.

Changing the template---------------------Here's how to change the template:

1) Create a new soapsheet workbook.2) Make your changes/additions to SAP Values, bar size, lye discount, and/or scale factor.3) From the File menu, click Save As.4) In the 'Save as type' drop-down list box on the 'Save As' dialog, choose 'Template (*.xlt)'. This choice should automatically change the 'Save in' directory to your Templates directory.5) In the 'File name' box of the 'Save As' dialog enter 'soapsheet' (the original name), or whatever name you would like to use for the new version of the template.6) If you are replacing the template you started with in step one, you will be prompted whether or not to overwrite the original. Click 'Yes'.7) You're done.

FAQ's-----

1) What the heck is a '.xlt' file?

The .xlt, versus .xls, indicates that it is an Excel spreadsheet _template_, not actually a spreadsheet. Every time you open it, it will create a new workbook in Excel that you will be asked to name when you save (i.e. it's hitting the `New' button to create a new workbook, but instead of being blank, it's got all of this stuff from the template in it already). Normally templates are kept in the Templates directory under the directory where Microsoft Office was installed. For me, under WindowsNT 4.0, that defaults to c:\program files\microsoft office\templates. Once the template is installed in the templates directory, picking File>New off of Excel's menu will pop up a dialog for choosing a template or wizard for the new workbook. Just pick 'soapsheet.xlt' from the General tab, and you are good to go.

2) Why is the total effective lye discount greater than my lye discount, even though I specified no superfatting oils?

3) Why is the total effective lye discount different for the scaled version of my recipe?

The answer to these two questions has to do with the fact that lye amounts are rounded down to the nearest tenth of an ounce, as detailed in "Lye calculation and rounding" above. To answer the first question, by way of example: if you specify a lye discount of 5%, which puts the lye amount at, for example, 7.39 ounces, the number 7.39 will be rounded down to 7.3, giving you a total effective lye discount of almost 6.2%. That's a 1.2% higher discount, all because you lost .09 ounces of lye to rounding. Are you with me so far? Now on to question two... The reason why the total effective lye discount may be a different value on the scaled version worksheet than the recipe worksheet is that the amount being rounded off of the lye amount will almost certainly change, and it will be a different proportion to the lye amount than in the unscaled version. For example: say I have a recipe with a 5% lye discount, which puts the lye amount at 8.66 ounces, which rounds down to 8.6, giving me a total effective lye discount of around 5.7%. Then I go to the scaled version worksheet and double the batch size. Now my 5% discount puts the lye amount at 17.32 ounces, which rounds down to 17.3, giving me a total effective lye discount of only about 5.2%. This effect can work the opposite way too, with the total effective lye discount going up when you change the batch size. It is even more pronounced when you scale down to smaller batch sizes, because even a small amount rounded off is a proportionately larger change than in a large batch. I hope that makes sense to everyone. There's no way around this without taking a smaller lye discount than what you originally entered.

Hi, just a few notes about this template, how to use the workbooks created from it, and the methods used for certain operations. There's a short FAQ at the very end of this document.

Installation------------(These instructions are based on installing the template for use by MSExcel97, on a machine running MSWindows95/98/ME/NT.)

The best place to keep this template is in your Templates folder. Your Templates folder should be in the folder in which you installed Microsoft Office or Microsoft Excel. For example: on my machine the Templates folder is 'C:\Program Files\Microsoft Office\Templates'.

Basic usage-----------Once you have saved the template to your Templates folder, here's how to create new workbooks from it:1) Start Excel2) Click 'New' on the 'File' menu, which opens up the 'New' dialog box.3) On the 'General' tab of the 'New' dialog, pick 'soapsheet.xlt'.4) Click the OK button.5) A new workbook called soapsheet1 should appear in Excel.

There are only two worksheets in this workbook that you need to be concerned with when you play with your soap recipes. They are the sheets labeled "Recipe Worksheet" (the one you're on by default when you create a new workbook from the template) and "Scaled Version". The fields that may be changed on the Recipe worksheet are:

- Recipe Name- Alkali (NaOH for bar soap recipes, KOH for liquid soap recipes)- fields under the "Oil" heading- fields under the "Super-fatting Oil" heading- fields under the "Weight in Oz" headings for oils and super-fatting oils- Lye discount- Bar Size (Oz)- Notes

Entering a recipe is as easy as picking oils from the drop-down list attached to the Oil fields and entering the amount of each you want to use. Then, if you want, enter super-fatting oils the same way, enter a lye discount, and perhaps change the bar size. That's it. Everything else will be calculated for you.

The Scaled Version sheet allows you to take the recipe entered on the Recipe sheet and scale it to whatever batch size you want. It shows everything from the Recipe sheet except INS values, and includes the additional field "Scale Factor". Scale Factor is the only field that may be changed on the Scaled Version sheet, and is used as follows: to scale a recipe down to one half of its original size, enter a Scale Factor of .5. To double a recipe, enter a Scale Factor of 2. Enter whatever factor you want, 2 and .5 are just examples. You get the idea.

New feature on Scaled Version worksheet: there are now three new fields thatallow the recipe to be scaled either to a total batch size in ounces, a totalbatch size in ounces after cure, or a total number of bars based on the usersettable bar size. To use these, enter a number in any one of the threefields (after typing the number hit return or select another cell to completeyour change), then click on the button next to the field. This will cause Excelto automatically change the scale factor to achieve the batch size or numberof bars you specify. Please note that this "goal seeking" feature of Excel isnot perfect, sometimes it will not be able to properly scale to the number youspecify. If that happens, try fractionally changing the number in onedirection or another and then hit the button again. For example, if Excel ishaving trouble scaling your recipe to a 64 ounce batch, try scaling to 64.1 or63.9 ounces instead. If it still doesn't work, try changing the number alittle more. Also note that scaling to a batch size after cure or to anumber of bars is disabled when the alkali is set to KOH (liquid soap).

Bar Soap (NaOH) versus Liquid Soap (KOH) Recipes------------------------------------------------The alkali for a recipe is set to NaOH by default. If you change it to KOH for a liquidsoap recipe, several things change:

1) The SAP values used change to those for KOH.2) The water calculation changes to one suitable for liquid soap recipes.3) The INS values and the INS calculation disappear, since the are not appli- cable to liquid soap.4) Other fields/calculations that are not applicable to liquid soap (e.g. weight after cure, bar size, and yield in bars) also disappear.

SAP Values----------The SAP values used in calculating the lye are looked up from the SAP Values worksheet. If you disagree with any of the values, please feel free to change them. You may also change the names of any of the oils, just make sure you change any references on the Recipe worksheet from the old name to the new name. You may also add new oils, as long as you don't change the format of the SAP Values worksheet (this is very important, as the lookup from the Recipe worksheet depends upon the oil names and SAP values being in specific columns, and within a certain range of rows). If you do add new oils, you can either insert them into the list where you want or put them at the end; order is not important, just don't go past row 200 or so. Note too that the oils in the drop down list on the Recipe sheet appear in the same order as on the SAP Values sheet, so if you don't insert new oils in alphabetical order, they won't appear that way in the list either. To save any changes/additions you make to the SAP Values worksheet, so that any new workbooks you create will include them, see "Changing the template" below.

INS Values of Recipes---------------------The concept of INS values is borrowed from Dr Robert McDaniel's book, "Essentially Soap." He in turn borrowed it from an unattributed source. In any event, what he says is that an oil's INS value is based on its SAP value and iodine value, and that a soap's INS is the weighted average of the INS values of its constituent oils. What does that mean to you? Probably not much. The important thing is that (as related by Dr Bob) the 'ideal' INS value to shoot for when formulating a soap recipe is 160. Now remember: 160 is only the ideal. Most recipes, even really excellent ones, won't be at an INS of 160. The majority of the ones I've looked at are in the mid 140's or low 150's. The INS value's real utility is as a sort of rough gauge of how well your recipe is balanced. In other words, if your recipe's INS is much above or way below 160, you might want to take another look at things. Note that the INS calculation isnot done for liquid soap recipes.

INS Values of Individual Oils-----------------------------Many of the INS values for individual oils are borrowed from Dr Bob. Specifically, the sheet calculates its own INS values based on the best SAP and iodine values I could find, but where Dr Bob had a value, I defer to him. You may note that a few of the oils listed have no INS. That's because Dr Bob didn't list them, and I couldn't find iodine value numbers for them either. You can still use those oils in your recipes, but they will be ignored in the INS calculation for the recipe as a whole.

Canola versus Rapeseed oil--------------------------All canola oil is rapeseed oil, but not all rapeseed oil is canola. The reason for this is that rapeseed oil normally has an erucic acid content of up to fifty percent, while in order for an oil to be called canola, it may have an erucic acid content of no more than two percent. In other words, canola is low erucic acid rapeseed oil. What does this mean to you? Well, the erucic acid of regular rapeseed is largely replaced by oleic and linoleic acids in canola, which CHANGES THE SAP VALUE. I have yet to see a saponification chart, either published or on the web, which takes this into account. Every one of them treats rape and canola interchangeably, and lists the SAP of regular rape, even though the availability of regular rapeseed oil to the average North American consumer is limited at best. Is this dangerous? Since the SAP of rape is lower than that of canola, no, not really. It just means you're building an additional lye discount into any soap that uses canola. Which isn't much of a problem unless your recipe is already at the extreme of superfatting, or you're trying to make transparent soap. Bottom line: use canola for canola, and any of the other names (ramic/rape/rapeseed) for regular rapeseed oil.

Lye calculation and rounding----------------------------Because most people don't have a way to accurately measure amounts smaller than .1 ounces (well, I don't), the calculated amounts for lye and water are rounded DOWN to the nearest .1 ounce. If you must round, rounding down is the only safe way to go for lye, and unless you are making very small batches, a difference of less than one tenth of an ounce should have very little effect. Note that you may still enter amounts of oil to any level of precision you want, you just won't ever get more than one decimal place of precision for the lye and water.

Water calculation-----------------The amount of water required for bar soaps is calculated based on the rule ofthumb of one pound of water for every three pounds of oils. There are otherrules of thumb out there, e.g. six ounces of water per pound of oils, ala theMMS calculator, but I prefer the 1:3 rule. For liquid soap recipes the amountof water is three times the total weight of the KOH.

After Cure calculation----------------------The After Cure weight is an estimate of the total yield of soap after most of the water has cured out of your bars. It is based on the rule of thumb that when your soap is done curing it will have about 15% of its original water content remaining.

Default values--------------Every new soapsheet workbook will have a default alkali of NaOH (bar soap), a lyediscount of 0%, bar size of 4 ounces, and scale factor of 1. Any of these may bechanged. To save your changes for future workbooks, see "Changing the template"below.

Changing the template---------------------Here's how to change the template:

1) Create a new soapsheet workbook.2) Make your changes/additions to SAP Values, bar size, lye discount, and/or scale factor.3) From the File menu, click Save As.4) In the 'Save as type' drop-down list box on the 'Save As' dialog, choose 'Template (*.xlt)'. This choice should automatically change the 'Save in' directory to your Templates directory.5) In the 'File name' box of the 'Save As' dialog enter 'soapsheet' (the original name), or whatever name you would like to use for the new version of the template.6) If you are replacing the template you started with in step one, you will be prompted whether or not to overwrite the original. Click 'Yes'.7) You're done.

FAQ's-----

1) What the heck is a '.xlt' file?

The .xlt, versus .xls, indicates that it is an Excel spreadsheet _template_, not actually a spreadsheet. Every time you open it, it will create a new workbook in Excel that you will be asked to name when you save (i.e. it's hitting the `New' button to create a new workbook, but instead of being blank, it's got all of this stuff from the template in it already). Normally templates are kept in the Templates directory under the directory where Microsoft Office was installed. For me, under WindowsNT 4.0, that defaults to c:\program files\microsoft office\templates. Once the template is installed in the templates directory, picking File>New off of Excel's menu will pop up a dialog for choosing a template or wizard for the new workbook. Just pick 'soapsheet.xlt' from the General tab, and you are good to go.

2) Why is the total effective lye discount greater than my lye discount, even though I specified no superfatting oils?

3) Why is the total effective lye discount different for the scaled version of my recipe?

The answer to these two questions has to do with the fact that lye amounts are rounded down to the nearest tenth of an ounce, as detailed in "Lye calculation and rounding" above. To answer the first question, by way of example: if you specify a lye discount of 5%, which puts the lye amount at, for example, 7.39 ounces, the number 7.39 will be rounded down to 7.3, giving you a total effective lye discount of almost 6.2%. That's a 1.2% higher discount, all because you lost .09 ounces of lye to rounding. Are you with me so far? Now on to question two... The reason why the total effective lye discount may be a different value on the scaled version worksheet than the recipe worksheet is that the amount being rounded off of the lye amount will almost certainly change, and it will be a different proportion to the lye amount than in the unscaled version. For example: say I have a recipe with a 5% lye discount, which puts the lye amount at 8.66 ounces, which rounds down to 8.6, giving me a total effective lye discount of around 5.7%. Then I go to the scaled version worksheet and double the batch size. Now my 5% discount puts the lye amount at 17.32 ounces, which rounds down to 17.3, giving me a total effective lye discount of only about 5.2%. This effect can work the opposite way too, with the total effective lye discount going up when you change the batch size. It is even more pronounced when you scale down to smaller batch sizes, because even a small amount rounded off is a proportionately larger change than in a large batch. I hope that makes sense to everyone. There's no way around this without taking a smaller lye discount than what you originally entered.

Hi, just a few notes about this template, how to use the workbooks created from it, and the methods used for certain operations. There's a short FAQ at the very end of this document.

Installation------------(These instructions are based on installing the template for use by MSExcel97, on a machine running MSWindows95/98/ME/NT.)

The best place to keep this template is in your Templates folder. Your Templates folder should be in the folder in which you installed Microsoft Office or Microsoft Excel. For example: on my machine the Templates folder is 'C:\Program Files\Microsoft Office\Templates'.

Basic usage-----------Once you have saved the template to your Templates folder, here's how to create new workbooks from it:1) Start Excel2) Click 'New' on the 'File' menu, which opens up the 'New' dialog box.3) On the 'General' tab of the 'New' dialog, pick 'soapsheet.xlt'.4) Click the OK button.5) A new workbook called soapsheet1 should appear in Excel.

There are only two worksheets in this workbook that you need to be concerned with when you play with your soap recipes. They are the sheets labeled "Recipe Worksheet" (the one you're on by default when you create a new workbook from the template) and "Scaled Version". The fields that may be changed on the Recipe worksheet are:

- Recipe Name- Alkali (NaOH for bar soap recipes, KOH for liquid soap recipes)- fields under the "Oil" heading- fields under the "Super-fatting Oil" heading- fields under the "Weight in Oz" headings for oils and super-fatting oils- Lye discount- Bar Size (Oz)- Notes

Entering a recipe is as easy as picking oils from the drop-down list attached to the Oil fields and entering the amount of each you want to use. Then, if you want, enter super-fatting oils the same way, enter a lye discount, and perhaps change the bar size. That's it. Everything else will be calculated for you.

The Scaled Version sheet allows you to take the recipe entered on the Recipe sheet and scale it to whatever batch size you want. It shows everything from the Recipe sheet except INS values, and includes the additional field "Scale Factor". Scale Factor is the only field that may be changed on the Scaled Version sheet, and is used as follows: to scale a recipe down to one half of its original size, enter a Scale Factor of .5. To double a recipe, enter a Scale Factor of 2. Enter whatever factor you want, 2 and .5 are just examples. You get the idea.

New feature on Scaled Version worksheet: there are now three new fields thatallow the recipe to be scaled either to a total batch size in ounces, a totalbatch size in ounces after cure, or a total number of bars based on the usersettable bar size. To use these, enter a number in any one of the threefields (after typing the number hit return or select another cell to completeyour change), then click on the button next to the field. This will cause Excelto automatically change the scale factor to achieve the batch size or numberof bars you specify. Please note that this "goal seeking" feature of Excel isnot perfect, sometimes it will not be able to properly scale to the number youspecify. If that happens, try fractionally changing the number in onedirection or another and then hit the button again. For example, if Excel ishaving trouble scaling your recipe to a 64 ounce batch, try scaling to 64.1 or63.9 ounces instead. If it still doesn't work, try changing the number alittle more. Also note that scaling to a batch size after cure or to anumber of bars is disabled when the alkali is set to KOH (liquid soap).

Bar Soap (NaOH) versus Liquid Soap (KOH) Recipes------------------------------------------------The alkali for a recipe is set to NaOH by default. If you change it to KOH for a liquidsoap recipe, several things change:

1) The SAP values used change to those for KOH.2) The water calculation changes to one suitable for liquid soap recipes.3) The INS values and the INS calculation disappear, since the are not appli- cable to liquid soap.4) Other fields/calculations that are not applicable to liquid soap (e.g. weight after cure, bar size, and yield in bars) also disappear.

SAP Values----------The SAP values used in calculating the lye are looked up from the SAP Values worksheet. If you disagree with any of the values, please feel free to change them. You may also change the names of any of the oils, just make sure you change any references on the Recipe worksheet from the old name to the new name. You may also add new oils, as long as you don't change the format of the SAP Values worksheet (this is very important, as the lookup from the Recipe worksheet depends upon the oil names and SAP values being in specific columns, and within a certain range of rows). If you do add new oils, you can either insert them into the list where you want or put them at the end; order is not important, just don't go past row 200 or so. Note too that the oils in the drop down list on the Recipe sheet appear in the same order as on the SAP Values sheet, so if you don't insert new oils in alphabetical order, they won't appear that way in the list either. To save any changes/additions you make to the SAP Values worksheet, so that any new workbooks you create will include them, see "Changing the template" below.

INS Values of Recipes---------------------The concept of INS values is borrowed from Dr Robert McDaniel's book, "Essentially Soap." He in turn borrowed it from an unattributed source. In any event, what he says is that an oil's INS value is based on its SAP value and iodine value, and that a soap's INS is the weighted average of the INS values of its constituent oils. What does that mean to you? Probably not much. The important thing is that (as related by Dr Bob) the 'ideal' INS value to shoot for when formulating a soap recipe is 160. Now remember: 160 is only the ideal. Most recipes, even really excellent ones, won't be at an INS of 160. The majority of the ones I've looked at are in the mid 140's or low 150's. The INS value's real utility is as a sort of rough gauge of how well your recipe is balanced. In other words, if your recipe's INS is much above or way below 160, you might want to take another look at things. Note that the INS calculation isnot done for liquid soap recipes.

INS Values of Individual Oils-----------------------------Many of the INS values for individual oils are borrowed from Dr Bob. Specifically, the sheet calculates its own INS values based on the best SAP and iodine values I could find, but where Dr Bob had a value, I defer to him. You may note that a few of the oils listed have no INS. That's because Dr Bob didn't list them, and I couldn't find iodine value numbers for them either. You can still use those oils in your recipes, but they will be ignored in the INS calculation for the recipe as a whole.

Canola versus Rapeseed oil--------------------------All canola oil is rapeseed oil, but not all rapeseed oil is canola. The reason for this is that rapeseed oil normally has an erucic acid content of up to fifty percent, while in order for an oil to be called canola, it may have an erucic acid content of no more than two percent. In other words, canola is low erucic acid rapeseed oil. What does this mean to you? Well, the erucic acid of regular rapeseed is largely replaced by oleic and linoleic acids in canola, which CHANGES THE SAP VALUE. I have yet to see a saponification chart, either published or on the web, which takes this into account. Every one of them treats rape and canola interchangeably, and lists the SAP of regular rape, even though the availability of regular rapeseed oil to the average North American consumer is limited at best. Is this dangerous? Since the SAP of rape is lower than that of canola, no, not really. It just means you're building an additional lye discount into any soap that uses canola. Which isn't much of a problem unless your recipe is already at the extreme of superfatting, or you're trying to make transparent soap. Bottom line: use canola for canola, and any of the other names (ramic/rape/rapeseed) for regular rapeseed oil.

Lye calculation and rounding----------------------------Because most people don't have a way to accurately measure amounts smaller than .1 ounces (well, I don't), the calculated amounts for lye and water are rounded DOWN to the nearest .1 ounce. If you must round, rounding down is the only safe way to go for lye, and unless you are making very small batches, a difference of less than one tenth of an ounce should have very little effect. Note that you may still enter amounts of oil to any level of precision you want, you just won't ever get more than one decimal place of precision for the lye and water.

Water calculation-----------------The amount of water required for bar soaps is calculated based on the rule ofthumb of one pound of water for every three pounds of oils. There are otherrules of thumb out there, e.g. six ounces of water per pound of oils, ala theMMS calculator, but I prefer the 1:3 rule. For liquid soap recipes the amountof water is three times the total weight of the KOH.

After Cure calculation----------------------The After Cure weight is an estimate of the total yield of soap after most of the water has cured out of your bars. It is based on the rule of thumb that when your soap is done curing it will have about 15% of its original water content remaining.

Default values--------------Every new soapsheet workbook will have a default alkali of NaOH (bar soap), a lyediscount of 0%, bar size of 4 ounces, and scale factor of 1. Any of these may bechanged. To save your changes for future workbooks, see "Changing the template"below.

Changing the template---------------------Here's how to change the template:

1) Create a new soapsheet workbook.2) Make your changes/additions to SAP Values, bar size, lye discount, and/or scale factor.3) From the File menu, click Save As.4) In the 'Save as type' drop-down list box on the 'Save As' dialog, choose 'Template (*.xlt)'. This choice should automatically change the 'Save in' directory to your Templates directory.5) In the 'File name' box of the 'Save As' dialog enter 'soapsheet' (the original name), or whatever name you would like to use for the new version of the template.6) If you are replacing the template you started with in step one, you will be prompted whether or not to overwrite the original. Click 'Yes'.7) You're done.

FAQ's-----

1) What the heck is a '.xlt' file?

The .xlt, versus .xls, indicates that it is an Excel spreadsheet _template_, not actually a spreadsheet. Every time you open it, it will create a new workbook in Excel that you will be asked to name when you save (i.e. it's hitting the `New' button to create a new workbook, but instead of being blank, it's got all of this stuff from the template in it already). Normally templates are kept in the Templates directory under the directory where Microsoft Office was installed. For me, under WindowsNT 4.0, that defaults to c:\program files\microsoft office\templates. Once the template is installed in the templates directory, picking File>New off of Excel's menu will pop up a dialog for choosing a template or wizard for the new workbook. Just pick 'soapsheet.xlt' from the General tab, and you are good to go.

2) Why is the total effective lye discount greater than my lye discount, even though I specified no superfatting oils?

3) Why is the total effective lye discount different for the scaled version of my recipe?

The answer to these two questions has to do with the fact that lye amounts are rounded down to the nearest tenth of an ounce, as detailed in "Lye calculation and rounding" above. To answer the first question, by way of example: if you specify a lye discount of 5%, which puts the lye amount at, for example, 7.39 ounces, the number 7.39 will be rounded down to 7.3, giving you a total effective lye discount of almost 6.2%. That's a 1.2% higher discount, all because you lost .09 ounces of lye to rounding. Are you with me so far? Now on to question two... The reason why the total effective lye discount may be a different value on the scaled version worksheet than the recipe worksheet is that the amount being rounded off of the lye amount will almost certainly change, and it will be a different proportion to the lye amount than in the unscaled version. For example: say I have a recipe with a 5% lye discount, which puts the lye amount at 8.66 ounces, which rounds down to 8.6, giving me a total effective lye discount of around 5.7%. Then I go to the scaled version worksheet and double the batch size. Now my 5% discount puts the lye amount at 17.32 ounces, which rounds down to 17.3, giving me a total effective lye discount of only about 5.2%. This effect can work the opposite way too, with the total effective lye discount going up when you change the batch size. It is even more pronounced when you scale down to smaller batch sizes, because even a small amount rounded off is a proportionately larger change than in a large batch. I hope that makes sense to everyone. There's no way around this without taking a smaller lye discount than what you originally entered.

Hi, just a few notes about this template, how to use the workbooks created from it, and the methods used for certain operations. There's a short FAQ at the very end of this document.

Installation------------(These instructions are based on installing the template for use by MSExcel97, on a machine running MSWindows95/98/ME/NT.)

The best place to keep this template is in your Templates folder. Your Templates folder should be in the folder in which you installed Microsoft Office or Microsoft Excel. For example: on my machine the Templates folder is 'C:\Program Files\Microsoft Office\Templates'.

Basic usage-----------Once you have saved the template to your Templates folder, here's how to create new workbooks from it:1) Start Excel2) Click 'New' on the 'File' menu, which opens up the 'New' dialog box.3) On the 'General' tab of the 'New' dialog, pick 'soapsheet.xlt'.4) Click the OK button.5) A new workbook called soapsheet1 should appear in Excel.

There are only two worksheets in this workbook that you need to be concerned with when you play with your soap recipes. They are the sheets labeled "Recipe Worksheet" (the one you're on by default when you create a new workbook from the template) and "Scaled Version". The fields that may be changed on the Recipe worksheet are:

- Recipe Name- Alkali (NaOH for bar soap recipes, KOH for liquid soap recipes)- fields under the "Oil" heading- fields under the "Super-fatting Oil" heading- fields under the "Weight in Oz" headings for oils and super-fatting oils- Lye discount- Bar Size (Oz)- Notes

Entering a recipe is as easy as picking oils from the drop-down list attached to the Oil fields and entering the amount of each you want to use. Then, if you want, enter super-fatting oils the same way, enter a lye discount, and perhaps change the bar size. That's it. Everything else will be calculated for you.

The Scaled Version sheet allows you to take the recipe entered on the Recipe sheet and scale it to whatever batch size you want. It shows everything from the Recipe sheet except INS values, and includes the additional field "Scale Factor". Scale Factor is the only field that may be changed on the Scaled Version sheet, and is used as follows: to scale a recipe down to one half of its original size, enter a Scale Factor of .5. To double a recipe, enter a Scale Factor of 2. Enter whatever factor you want, 2 and .5 are just examples. You get the idea.

New feature on Scaled Version worksheet: there are now three new fields thatallow the recipe to be scaled either to a total batch size in ounces, a totalbatch size in ounces after cure, or a total number of bars based on the usersettable bar size. To use these, enter a number in any one of the threefields (after typing the number hit return or select another cell to completeyour change), then click on the button next to the field. This will cause Excelto automatically change the scale factor to achieve the batch size or numberof bars you specify. Please note that this "goal seeking" feature of Excel isnot perfect, sometimes it will not be able to properly scale to the number youspecify. If that happens, try fractionally changing the number in onedirection or another and then hit the button again. For example, if Excel ishaving trouble scaling your recipe to a 64 ounce batch, try scaling to 64.1 or63.9 ounces instead. If it still doesn't work, try changing the number alittle more. Also note that scaling to a batch size after cure or to anumber of bars is disabled when the alkali is set to KOH (liquid soap).

Bar Soap (NaOH) versus Liquid Soap (KOH) Recipes------------------------------------------------The alkali for a recipe is set to NaOH by default. If you change it to KOH for a liquidsoap recipe, several things change:

1) The SAP values used change to those for KOH.2) The water calculation changes to one suitable for liquid soap recipes.3) The INS values and the INS calculation disappear, since the are not appli- cable to liquid soap.4) Other fields/calculations that are not applicable to liquid soap (e.g. weight after cure, bar size, and yield in bars) also disappear.

SAP Values----------The SAP values used in calculating the lye are looked up from the SAP Values worksheet. If you disagree with any of the values, please feel free to change them. You may also change the names of any of the oils, just make sure you change any references on the Recipe worksheet from the old name to the new name. You may also add new oils, as long as you don't change the format of the SAP Values worksheet (this is very important, as the lookup from the Recipe worksheet depends upon the oil names and SAP values being in specific columns, and within a certain range of rows). If you do add new oils, you can either insert them into the list where you want or put them at the end; order is not important, just don't go past row 200 or so. Note too that the oils in the drop down list on the Recipe sheet appear in the same order as on the SAP Values sheet, so if you don't insert new oils in alphabetical order, they won't appear that way in the list either. To save any changes/additions you make to the SAP Values worksheet, so that any new workbooks you create will include them, see "Changing the template" below.

INS Values of Recipes---------------------The concept of INS values is borrowed from Dr Robert McDaniel's book, "Essentially Soap." He in turn borrowed it from an unattributed source. In any event, what he says is that an oil's INS value is based on its SAP value and iodine value, and that a soap's INS is the weighted average of the INS values of its constituent oils. What does that mean to you? Probably not much. The important thing is that (as related by Dr Bob) the 'ideal' INS value to shoot for when formulating a soap recipe is 160. Now remember: 160 is only the ideal. Most recipes, even really excellent ones, won't be at an INS of 160. The majority of the ones I've looked at are in the mid 140's or low 150's. The INS value's real utility is as a sort of rough gauge of how well your recipe is balanced. In other words, if your recipe's INS is much above or way below 160, you might want to take another look at things. Note that the INS calculation isnot done for liquid soap recipes.

INS Values of Individual Oils-----------------------------Many of the INS values for individual oils are borrowed from Dr Bob. Specifically, the sheet calculates its own INS values based on the best SAP and iodine values I could find, but where Dr Bob had a value, I defer to him. You may note that a few of the oils listed have no INS. That's because Dr Bob didn't list them, and I couldn't find iodine value numbers for them either. You can still use those oils in your recipes, but they will be ignored in the INS calculation for the recipe as a whole.