Smart Nanotextiles- A Review of Materials and Applications

Transcript of Smart Nanotextiles- A Review of Materials and Applications

Smart Nanotextiles:A Review ofMaterials andApplications

Shirley Coyle, Yanzhe Wu, King-Tong Lau,Danilo De Rossi, Gordon Wallace,

and Dermot Diamond

ing garments that maintain the wearer’sbody temperature.

Therefore, the fundamental compo-nents within smart textiles are sensors,actuators, and control units. The sensingelements, data transmission, and process-ing must be integrated into the textilewhile retaining the usual tactile, flexible,and comfort properties of clothing inorder for the smart textile to be practical.Much work in the field of smart clothingfeatures conventional electronics overlaidonto a textile substrate, and the problemsof connections, bulkiness, wearability, andwashability are well documented.3,4

A means of seamless integration isrequired to develop true textile sensors.This is why nanotechnology is key to thesmart textiles industry, enabling the incor-poration of new functionalities at variousproduction stages—at the fiber-spinninglevel, during yarn/fabric formation, or atthe finishing stage. This article describescurrent materials developments for smartnanotextiles and some of the many appli-cations where these innovative textiles areof great benefit.

Materials ResearchThe earliest textile developments

involved the use of natural materials suchas cotton, wool, and flax. More recently,synthetic fibers were developed: Lycra®, asegmented polyurethane-urea, has excep-tional elastic properties, and Kevlar®,poly-para-phenylene terephthalamide, hasultrahigh-strength properties and is usedin bulletproof vests. Today, needs for per-sonal mobility, healthcare, or rehabilitationrequire that novel functions in sensing andactuating be integrated into textiles. Thefundamental challenge in system-on-textile design is that the drapability andmanufacturability of textiles and clothingmust remain largely unaffected. Materialssuitable for the development of smartnanotextiles include inherently conductingpolymers (ICPs), carbon nanotubes(CNTs), and a number of other materials inthe forms of nanoparticles or nanofibers.

Inherently Conducting PolymersDiscovered in 1977, inherently conduct-

ing polymers (ICPs) conduct electricityand have the ability to sense and actuate.5Actuators based on ICPs can generatemuch higher stresses with a strain compa-rable to natural skeletal muscle,6,7 and sen-sors based on ICPs can change theirresistivity or generate an electrical signalin response to external stimuli.8,9 ICP-based intelligent polymer systems havethe ability to sense, process information,and actuate. Chart 1 depicts chemicalstructures of some commonly used ICPs.

434 MRS BULLETIN • VOLUME 32 • MAY 2007 • www/mrs.org/bulletin

AbstractThe development of smart nanotextiles has the potential to revolutionize the

functionality of our clothing and the fabrics in our surroundings. Nanoscale manipulationresults in new functionalities for intelligent textiles, including self-cleaning, sensing,actuating, and communicating. This is made possible by such developments as newmaterials, fibers, and finishings; inherently conducting polymers; carbon nanotubes; andantimicrobial nanocoatings. These additional functionalities have numerous applications,encompassing healthcare, sports, military applications, and fashion. The wearer and thesurrounding environment may be monitored in an innocuous manner, giving continuousupdates of individual health status or environmental hazards. More generally, smarttextiles become a critical part of the emerging area of body sensor networksincorporating sensing, actuation, control, and wireless data transmission. This articlereviews current research in nanotechnology application to textiles, from fibermanipulation and development to end uses of smart nanotextiles.

IntroductionTechnology is becoming increasingly

prominent in our daily lives, in many waysalleviating and in other ways fueling thedemands of modern living. Huge opportu-nities exist in the textile market to extendthe functionality and performance of tex-tiles to meet these demands. The advent ofsmart nanotextiles will revolutionize theclothes we wear, the furnishings in ourhomes, and the materials used in industry.This coming revolution has heightenedthe expectations of textile performance,and there is a great demand for “smart fab-rics” that are more perceptive of the sur-rounding environment. Technical andfunctional textiles may be enlisted in awealth of applications ranging from mili-tary and security to personalized health-care, hygiene, and entertainment.

Advancing the current functionalities oftextiles while maintaining the look and

feel of the fabric is where nanotechnologyis having a huge impact on the textileindustry. The market for textiles usingnanotechnologies is predicted to reach$13.6 billion in 2007 and climb dramati-cally to $115 billion by 2012.1

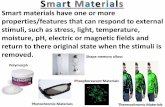

Textiles, being a pervasive and univer-sal interface, are an ideal substrate forintegrating sensors to monitor the wearerand the environment. Textiles offer aversatile framework for incorporatingsensing, monitoring, and informationprocessing devices. Smart textiles cansense and react to environmental condi-tions or stimuli, for example, frommechanical, thermal, chemical, electrical,or magnetic sources.2 Some are termed“passive smart textiles,” capable of sens-ing environmental conditions, whereas“active smart textiles” contain both actua-tors and sensors, such as thermoregulat-

MRSBull_May07_Coyle_Final.qxd 5/7/07 6:14 PM Page 434

Smart Nanotextiles: A Review of Materials and Applications

MRS BULLETIN • VOLUME 32 • MAY 2007 • www/mrs.org/bulletin 435

Most ICPs are prepared via chemical orelectrochemical oxidation of the monomerin solution or in the vapor phase,10 andincorporation of a range of dopants ispossible, resulting in ICPs with varyingproperties. Among the available ICPs,polypyrrole (PPy) is attractive because ithas high mechanical strength, is rela-tively stable in air, and is electroactive inboth organic and aqueous solutions.Polyacetylene is unstable in air, limiting itsuse. Polyaniline (PANi) is one of the mostwidely studied ICPs, with relatively goodenvironmental stability and good electri-cal conductivity. PANi has three possibleconfigurations: leucoemeraldine base(fully reduced), emeraldine base (partlyoxidized), and pernigraniline base (fullyoxidized). When oxidized in aqueousprotonic acids, PANi increases its con-ductivity by 9–10 orders of magnitude.Polythiophene and its derivatives haveboth p- and n-type electronic forms, whichhave been researched to construct poly-mer field-effect transistors for flexiblelogic circuits.11 Moreover, extensiveresearch has also been devoted to its usein polymer solar cells,12 where its manyadvantages, such as low production costs,flexibility, and light weight, make it suit-able for integration into textile fibers.13

The unusual electrical conduction inICPs is achieved through a charged p-conjugated system, which is a truly nano-structured charge pathway via a longmolecular chain. This pathway is stabi-lized by a negatively charged dopantincorporated in close vicinity; that is, allcharged dopants, such as iodide, triiodide,and perchlorate, are spatially removedfrom the quasi-one-dimensional conduc-tion pathway.14,15 The resistive backscat-tering of electrons is reduced, and this

leads to a theoretical conductivity of up to2 ¥ 107 S cm-1, which is much higher thanmetal conductors.16 However, the com-monly used bulk synthesis methodinevitably results in a shorter molecularchain and introduces conjugation defects,with interchain charge hopping reducingthe electrical conductivity of ICPs to lessthan 1000 S cm-1.17

Textiles made from ICPs may be real-ized by continuous wet spinning to pro-duce ICP-based textile fibers, which canbe manufactured into yarns and a rangeof fabric structures.18 The conductivitychanges in response to external deforma-tion are exploited in the production oftextile-based mechanical sensors such asthe flexible strain gauge.19 Particularly,PPy coated on nylon and Lycra by anin situ chemical polymerization processhas been applied to biofeedback devicesfor sports training and rehabilitation.20,21

The actuation property of ICPs resultsfrom the volume change of ICPs(Reaction 1). An applied positive potentialleads to the removal of electrons from thepolymer backbone and the incorporationof dopant ions (A-) to maintain electricalneutrality. The positive charges on thepolymer backbone provide coulombicrepulsion forces between polymerchains. Together with the incorporation ofdopants, the overall volume can be varied,and this process can be reversed in acontrolled fashion to produce usablemechanical work.6 ICP-based mechanicalactuators can achieve average stresses ~10to 20 times those generated from naturalmuscle,22 realize strains (>20%) compara-ble to natural muscle,23 and achieve fastfreestanding beam actuation with an oper-ational frequency of up to 40 Hz.24

Recently, more than one million redoxcycles were reported using an ionic liquid1-butyl-3-methylimidazolium tetrafluo-roborate (BMI-BF4)/PANi fiber actuatorsystem, with a minimal decrease in actua-tion strain.25

Films of ICP nanofibers have been usedas sensors to detect chemical vapors thatinteract with ICPs and change their con-ductivity. This application exploits the ben-efit of high surface area resulting from thesmall diameter of the nanofibers. Thin filmsmade of PANi/CSA nanofibers with diam-eters between 30 and 50 nm (Figure 1) havebeen used as a chemical sensor with supe-rior performance to vapors of acid (HCl)and base (NH3).

8

Moreover, by incorporating CNTs, theelectrical and mechanical properties ofICPs can also be improved. For example,a PANi–CNT composite fiber was pro-duced recently26 using a wet spinning tech-nique where the ultimate tensile strengthand elastic modulus of composite fiberincreased by 50% to 120% with an elec-tronic conductivity of up to ~750 S cm-1.The unique properties of high strength,robustness, good conductivity, and pro-nounced electroactivity of CNTs in thenano domain make these composite fiberspotentially useful in electronic textile appli-cations, such as the enhanced force genera-tion when incorporated into fabric as anactuator and the improved conductionwhen used as the connection wire. Figure 2shows the morphology of a PANi– SWNT(single-wall nanotube) composite fiber.

Nanoparticles: Composite Fibersand Finishings

Nanostructured composite fibers areone area where nanotechnology is alreadyhaving a huge impact within the textileindustry. Composite fibers employ nano-sized components such as nanoparticles,graphite nanofibers, and CNTs to improvephysical properties such as conductivityand antistatic behavior. Table I lists someof the nano-sized species that are used toimprove the performance of textiles.27

These nanoparticles may be used todevelop composite fibers as nanoscalefillers or through a foam-forming processand may also be applied as finishings to

Chart 1. Chemical structures ofselected inherently conductingpolymers (ICPs) in the undoped form.

Reaction 1. Incorporation and exclusion of the dopant ions in electrochemical actuation ofinherently conducting polymers (ICPs), for which polypyrrole (PPy) doped with a mobileanion is shown as an example. The incorporation of dopant ions results in an increase inthe total volume of polymer, while the exclusion of dopant ions results in a volumedecrease. A– represents anions incorporated into the PPy during synthesis, n is the numberof pyrrole units for each A– incorporated, and n ¥ m is the number of PPy repeat units thatdetermines the molecular weight of the polymer.

MRSBull_May07_Coyle_Final.qxd 5/7/07 6:14 PM Page 435

Smart Nanotextiles: A Review of Materials and Applications

436 MRS BULLETIN • VOLUME 32 • MAY 2007 • www/mrs.org/bulletin

the textile, for example, spray-coatingTiO2 for biological protective materials.

ApplicationsSports

The sports industry has driven muchresearch within the textile industry to helpimprove athletic performance, personalcomfort, and protection from the elements.Synthetics that were once thought to beinferior to natural fabrics now boast high-performance characteristics. Numerousproducts designed to improve the comfortof the wearer are commercially available;for instance, there are breathable water-proof fabrics such as Gore-Tex® andmoisture-management textiles that wickmoisture away from the skin such asCoolmax®. Gore-Tex® fabric uses a mem-

brane of expanded poly(tetrafluoroethyl-ene) (PTFE) that has pores of less than 1 mmin diameter, allowing water vapor to pene-trate the material, but preventing the pas-sage of liquid. To maintain the wearer’scomfort, it is important that sweat isallowed to evaporate, maintaining thebody’s natural thermoregulatory function.High-performance moisture-wicking fab-rics worn next to the skin transport perspi-ration away from the body to the outside ofthe garment where it can more quicklyevaporate. This is achieved using synthetic

microfibers that, unlike natural fibers, donot absorb moisture, but rather pass itthrough by a wicking effect that makesthem more comfortable to wear. It is evenpossible to maintain constant body tem-perature using phase-change technologysuch as Outlast Adaptive Comfort®. Phase-changing materials (PCMs) absorb, store,and release heat as the material changesphase from solid to liquid and back tosolid. A microencapsulation process isused to capture small amounts of phase-change material in a polymer shell so thatit is permanently enclosed and protected.These microencapsulated PCMs, devel-oped by Outlast Technologies Inc. andcalled Thermocules®, can then be appliedas a finishing on fabrics or infused intofibers during the manufacturing process.

Through the use of nanotextiles, clothesare adapting to their wearers, meetingtheir needs, and maintaining their com-fort. The adidas_1 running shoe usessensors, a microprocessor, and a motorto adjust its shock-absorbing characteris-tics to the individual runner’s style,pace, body weight, and running surface.28

Nike has also released a smart runningshoe containing a wireless sensor thatconnects to an iPod with various playliststo match the type of workout whilealso tracking distance, time, pace, andcalories burned.29 Textiles are engineeredto improve performance; for example,nanotech swimsuits for Olympic swim-mers have been developed to reduce drag

Figure 1. (a) Transmission electron microscopy images of polyaniline/camphor sulfonic acid(PANi/CSA) nanofibers cast from suspension after dialysis. Inset shows a twisted fiber.(b) Scanning electron microscopy (SEM) secondary electron images of a thin film ofPANi/CSA deposited on glass from suspension. Inset shows a cross-sectional view of thefilm on the glass substrate.8

Figure 2. Cross-sectional SEM imageof polyaniline–single-walled nanotubecomposite fiber.

Table I: Properties and Applications of Nanoscale Materials Used to ImproveTextile Performance.

Nano-Filler Properties/Applications

Carbon nanofibers Increased tensile strengthHigh chemical resistanceElectrical conductivity

Carbon black nanoparticles Improved abrasion resistance and toughnessHigh chemical resistanceElectrical conductivity

Clay nanoparticles Electrical, heat, and chemical resistanceBlock UV lightFlame retardant, anticorrosive

Metal oxide nanoparticles Photocatalytic ability(TiO2, Al2O3, ZnO, MgO) Electrical conductivity

UV absorptionPhoto-oxidizing capacity against chemical and

biological speciesAntimicrobial/self-sterilization

Carbon nanotubes 100¥ tensile strength of steel at one-sixth the weightElectrical conductivity similar to copperGood thermal conductivity

MRSBull_May07_Coyle_Final.qxd 5/7/07 6:14 PM Page 436

by using a biometric knitted constructionof nylon/elastane with v-shaped ridgesthat emulate a shark’s skin.30 The latestdevelopments integrate sensing capabili-ties to provide instantaneous awarenessof the physiological condition of the ath-lete, thus providing valuable informationabout the athlete’s physical abilities, train-ing status, athletic potential, andresponses to various training regimens.There is a great demand for wearable sen-sors to be used in the field for kinematicanalysis, monitoring of vital signs, andbiochemical analysis.31

Strain sensors made from piezoelectricmaterials may be used in biomechani-cal analysis to provide wearable kines-thetic interfaces able to detect posture,improve movement performance, andreduce injuries.32 The conductivity ofthese textiles is affected by stress andstrain applied to the fabric, which can beused to assess physiological movementsthat impose strain or pressure on thematerial. Garments integrating piezoresis-tive ICPs and conductor-loaded rubberswith strain-sensing capabilities offer con-tinuous monitoring of body kinematicsand vital signs.21,33–35 The advantage ofthis approach is that the tactile and flexibleproperties of the textile are maintained,providing truly wearable fabrics.

Such devices may be used to teachathletes the correct way to perform move-ment skills by providing real-time feed-back about limb orientation. Examples ofsuch devices are shown in Figure 3. Figure3a shows a carbon-loaded elastomer-sensorized garment developed at theUniversity of Pisa. The piezoresistive sen-sors are fabricated on a Lycra®/cotton tex-tile by masked smearing of the conductingmixture, which consists of a siliconematrix filled with carbon black powder.The same polymer/conductor compositeis also used as material for the connectiontracks between sensors and an acquisitionelectronic unit, avoiding the stiffness ofconventional metal wires. Figure 3bshows the Intelligent Knee Sleeve, devel-oped through a collaboration between theIntelligent Polymer Research Institute andBiomedical Science at the University ofWollongong and CSIRO Textile and FiberTechnology. It is a biofeedback deviceusing PPy sensors that monitors thewearer’s knee joint motion during jump-ing and landing to reinforce the correctlanding technique.34 The PPy-coatedfabric acts as a strain gauge, with awide dynamic range, and is connectedto a microcontroller that emits an audiotone when the knee bends beyond apre-set angle. The device was developedfor sports where jumping-related knee

injuries are common and may also beused as a rehabilitation device followinginjury.

In addition to their application as straingauges, conducting polymers have beendemonstrated to function as pressure

Smart Nanotextiles: A Review of Materials and Applications

MRS BULLETIN • VOLUME 32 • MAY 2007 • www/mrs.org/bulletin 437

Figure 3. (a) Carbon-loaded elastomer-sensorized garment for kinesthetic monitoringdeveloped at the University of Pisa. (b) The Intelligent Knee Sleeve is a biofeedback deviceusing PPy sensors that monitors the wearer’s knee joint motion. (Courtesy of CSIRO Textileand Fiber Technology.)

MRSBull_May07_Coyle_Final.qxd 5/7/07 6:14 PM Page 437

sensors by combining them with com-pressible textiles. Polyurethane (PU) foamcoated with PPy sensors was developedat Dublin City University. The sensorremains soft, compressible, versatile, and,in contrast to conventional coated textiles,is sensitive to forces from all three dimen-sions. The PPy-coated PU foam has beenused for developing a breathing monitor,whereby the foam sample is incorporatedinto a harness to wrap around the ribcagearea. The movement of the ribcage duringbreathing exerts pressure on the conduct-ing foam, causing an increase in conduc-tivity of the material. It has also beenintegrated into the armhole of a shirt todetect joint movements of the upperlimbs, and smart insoles monitoring plan-tar pressure have been demonstrated forgait analysis applications.36,37

A new area of research that will have amajor impact for sports performanceinvolves integrating chemical sensors intotextiles. The aim of the European Union(EU)–supported BIOTEX (bio-sensing tex-tile for health management) project38 is toperform real-time analysis of the variousconstituents in sweat. Research in this areais unfortunately lacking, because of theoverwhelming focus on blood-based diag-nostics. The approach being taken is tointegrate electrochemical and optical sen-sors within a textile substrate, enabling thedirect collection of sweat from a large bodysurface area. The target analytes includesodium, chloride, pH, sweat rate, andsweat conductivity in addition to monitor-ing cardiac and respiratory functions.38

This is of particular interest in sports appli-cations where rehydration strategy plays acritical role in the recovery process afterexercise. It is important not only to replacevolume losses due to sweat, but also elec-trolytes. These factors are highly variableamong individuals, and current tech-niques are impractical, involving sweatpatches that must be sent to a laboratoryfor analysis. BIOTEX is developing a wear-able system incorporating a fluid handlingplatform based on moisture-wicking fab-rics and nonwoven superabsorbent tex-tiles. The sensing elements are integratedwithin the fabric’s fluidic channels to mon-itor the sweat composition. Control elec-tronics and wireless data transmissionallow real-time analysis of the signal andgive feedback to the wearers regardingtheir well-being, making individuals moreaware of their personal healthcare needs.

HealthcareThe interest in smart textiles for health-

care arises from the need to monitorpatients for extensive periods because ofrehabilitation or chronic illness. The prob-

lem with conventional clinical visits inthese cases is that they can only provide abrief window on the physiology of thepatient;39 wearable devices offer the possi-bility to monitor physiological signalscontinuously in a realistic setting. This isvital for the future of the healthcare sys-tem, given the global aging population.There is a need to shift the focus of health-care expenditures from treatment to pre-vention and wellness promotion.40

The EU has funded a number of inter-related, specifically targeted researchprojects in this area. The WEALTHY(Wearable Health Care System) andMyHeart projects involve wearable textileinterfaces integrating sensors, electrodes,and connections realized with conductiveand piezoresistive yarns41,42 to tackle car-diovascular diseases, which are the leadingcause of death in the Western world. TheWEALTHY system is made up of a sen-sorized cotton/Lycra® shirt that integratescarbon-loaded elastomer strain sensorsand fabric bioelectrodes, enabling the mon-itoring of respiration, electrocardiogram(ECG), electromyogram (EMG), body pos-ture, and movement. Electrodes, to detectECG and EMG signals, are knitted usingstainless steel–based yarns, and a hydrogelmembrane is applied to improve contactand match impedance with the skin. Newproducts coming onto the market for simi-lar applications include the SmartShirt bySensatex™ and the Life Shirt® system byVivoMetrics®, offering continuous ambula-tory monitoring systems.

There is also potential for monitoringemotional, sensory, and cognitive activi-ties, as demonstrated by the MARSIANsystem (Modular Autonomous RecorderSystem for the measurement of Auto-nomic Nervous system). The systemincludes a smart glove with sensors forthe detection of the activity of the auto-nomic nervous system, which is respon-sible for the body’s involuntary vitalfunctions. The glove contains noninvasivesensors to measure physiological parame-ters such as skin temperature, skin electri-cal conductance, and skin potential.A microsensor (0.45 mm) is integrated intothe glove to monitor skin temperature,and electrodes measure the skin’s electri-cal activity. The initial approach to elec-trode integration was to embroidercommercially available silver/silver chlo-ride electrodes into a hairnet glove, whilea recent prototype uses a 3D structuremade of Kapton® copper foil (150 mmthick) with electrodes covered in silver.43

One of the more recent endeavorswithin the EU roadmap is the ProeTEXproject (advanced e-textiles for firefightersand civilian victims) to perform on-

body biochemical sensing within a textile.While BIOTEX fabrics, as discussed pre-viously, monitor the wearer’s health,44

ProeTEX fabrics monitor the surround-ing environment to detect any potentialrisks. The project plans to develop a fullsystem for firefighters and civil protectionworkers plus a limited system for injuredcivilians. The wearable sensing and trans-mission systems will be able to monitorhealth, activity, position, and environ-ment, with information relayed both tothe individual and also to a central moni-toring unit.

ICPs used for kinesthetic and physio-logical monitoring, as discussed previ-ously for assessing sports performance,may also be used in the area of patientrehabilitation.45 These electroactive poly-mers, typically PANi and PPy, are used assensing devices and may also be config-ured as actuators. For this purpose, theyare used as electrodes properly configuredwithin an electrochemical cell. By apply-ing a potential, the ICP electrode changesits dimension and works as a mechanicalactuator. Integration of such actuatorswithin textiles would enable fabrics tohave motor functions, opening a new fieldof applications, particularly in the devel-opment of artificial muscles. For example,ICP actuators have been developed toassist the insertion of cochlear implantelectrodes, in which a prototype actuatormade of a bilayer PPy actuator is able tosteer or bend the electrode in a control-lable manner.46 Although the current actu-ation force and mechanical energy densityof electroactive polymers are relativelylow, there is potential to develop rehabili-tative aids and orthotic limbs.46,47

Textiles have acted as a second skin forprotection and appearance, whereas smarttextiles have the potential to emulate andaugment the sensory system of the skin bysensing external stimuli such as proximity,touch, pressure, temperature, and chemi-cal/biological substances. Lumelsky et al.describe a large-area, flexible array of skin-like sensors with data processing capabili-ties that can be used to cover the entiresurface of a machine, such as a robotic sys-tem or even part of a human body.48 Forconditions such as diabetes mellitus,where the patient loses sensation in thelimbs, or for bedridden patients, pressure-sensitive fabrics may aid in assessmentand warning to reduce the occurrence ofpressure ulcers. PPy foam pressure sen-sors have been demonstrated for this pur-pose.9 With nanotechnologies, smarttextiles may provide a haptic interface, thatis, a touch-sensitive alternative to skin.

Novel functionalities in textiles are ofcourse not limited to personal apparel.

Smart Nanotextiles: A Review of Materials and Applications

438 MRS BULLETIN • VOLUME 32 • MAY 2007 • www/mrs.org/bulletin

MRSBull_May07_Coyle_Final.qxd 5/7/07 6:14 PM Page 438

Smart Nanotextiles: A Review of Materials and Applications

MRS BULLETIN • VOLUME 32 • MAY 2007 • www/mrs.org/bulletin 439

Home furnishings may be enlisted intoubiquitous sensing within smart homesfor telemonitoring elderly, convalescent,or isolated individuals.49,50 This alignswith the “continuity of care” concept thatwearable technologies bring throughmonitoring patients at home in comfort-able surroundings.

Military/SecurityThere is a need for real-time infor-

mation technology to increase the protec-tion and survivability of people workingin extreme environmental conditionsand hazardous situations. Performanceimprovements and additional capabilitieswould be of immense benefit to defenseforces and emergency response personnel.The SmartShirt by Sensatex™ was initiallydeveloped by the Georgia Tech ResearchCorporation and for military applications.The T-shirt functions like a computer bymeans of optical and conductive fibersintegrated into the garment. The opticalfibers are used to detect bullet wounds,pinpointing their exact location, and vari-ous sensors are used to monitor the body’svital signs during combat conditions.51

The Institute for Soldier Nanotech-nologies (ISN) is an interdepartmentalresearch center at the MassachusettsInstitute of Technology. The ISN’s researchmission is to use nanotechnology to dra-matically improve soldier survival. Theintention is to secure a lighter, faster, moreagile force with a heightened awareness ofits environment and potential threats.Wireless networking enables medics tomonitor the health status of the soldier.The ultimate vision of the battlesuit of thefuture is a bulletproof jumpsuit, no thickerthan ordinary spandex, that monitorshealth, eases injuries, transmits data auto-matically, and enables medics to conductremote triage of combat casualties to helpthem respond more rapidly and safely.52

The chemical-sensing properties of con-ductive polymers coated onto woven fab-ric materials were investigated to detecthazards that may endanger the health ofthe wearer. Low-ppm detection limitswere demonstrated for toxic gases such asammonia and nitrogen dioxide as well asthe chemical warfare simulant dimethylmethylphosphonate (DMMP).53 Fiber-optic sensors with modified claddingmaterials are suitable for detecting haz-ards on the battlefield and may be easilyintegrated into soldiers’ uniforms. Theoriginal cladding material is replaced witha chemical agent or environmentally sen-sitive material on a small section of thefiber. The modified cladding material maybe sensitive to different environmentalconditions, causing a change in the refrac-

tive index. This affects the propagation ofthe transmitted light signal, which can bemeasured using optical detection tech-niques. El-Sherif et al. demonstrated thisusing a thermochromic agent, segmentedpolyurethane-diacetylene copolymer, anda photochemical polymer, PANi, ascladding agents.54

Fashion/LifestyleThe development of high-tech advanced

textiles for specific applications, such asextreme sports, eventually finds itsway to street fashion, where designersare allowed the creativity of experiment-ing with these new emerging materials.Microfibers, for example, were initiallydeveloped for space and military applica-tions, and are now used in sportswear,interior fabrics, and fashion.55

We have become exceedingly reliant ontechnology; for instance, at any one time,the typical person may be carrying anMP3 player, a laptop computer, a mobilephone, a computational wristwatch, and adigital camera. The components of thesedevices are being continually miniatur-ized and, with methods such as thin-filmtechnology, the electronics are becomingmore flexible. Such advancements areenabling the technology to integrate moreeasily into our lives and onto our clothes.Eleksen has developed fabric touch padsintegrated into jackets for more accessible

control of MP3 players. The initial applica-tion was for snowboarding jackets toprovide ease of access to the control but-tons. Eleksen has also developed a fabrickeyboard for personal digital assistants(PDAs) that can be rolled out, easilystored, and transported (Figure 4).Another producer of electronic textiles,Textronics, develops fabrics that canwarm, illuminate, conduct, and sense.One of their recent developments is theNuMetrex heart rate monitoring sportsbra, which incorporates conductive knit-ted sensors that link wirelessly to a heart-rate-monitoring watch.

Nanocoatings now offer advanced pro-tection to improve hygiene and clean-liness. To add antibacterial properties,nano-sized silver, titanium dioxide, andzinc oxide12 are used. Metallic ions andmetallic compounds display a certaindegree of sterilizing behavior. It is consid-ered that part of the oxygen in the air orwater is turned into active oxygen bymeans of catalysis with the metallic ion,thereby dissolving the organic substanceto create this sterilizing effect. By usingnano-sized particles, the number of parti-cles per unit area is increased, and thus,antibacterial effects can be maximized.Antimicrobial coatings are widely appliedto socks in order to prohibit the growth ofbacteria, but their uses also extend fromwound dressings to home furnishings,

Figure 4. Elektex fabric-based keyboard (30 ¥ 11 cm; weight, 65 g). (Courtesy of Eleksen.)

MRSBull_May07_Coyle_Final.qxd 5/7/07 6:14 PM Page 439

Smart Nanotextiles: A Review of Materials and Applications

440 MRS BULLETIN • VOLUME 32 • MAY 2007 • www/mrs.org/bulletin

carpets, and clothing.56 Another innova-tion for such purposes is superhydropho-bic self-cleaning surfaces. This was firstinspired by the natural cleanness of plantleaves such as the lotus leaf. Water comingin contact with a superhydrophobic sur-face (contact angle, >150∞) forms nearlyspherical droplets. Contaminants, eitherinorganic or organic, adhere to the waterdroplets and are removed from the sur-face when the water rolls off. Nano-Texhas a range of products using such coat-ings to resist spills, repel and releasestains, and resist static.57 These textileenhancements become inherent to the fab-ric, improving the performance and dura-bility of everyday apparel and interiorfurnishings.

Although technology may be hiddenthrough invisible coatings and advancedfibers, it can also be used to dramaticallychange the appearance of the textile,giving new and dazzling effects. Luminex®

is a fabric with fiber-optic strands woveninto it, which are then illuminated usinglight-emitting diodes (LEDs). Luminex®

has been incorporated into glowingclothes, safety garments, handbags, furni-ture, and even a wedding dress. Anotherrecent development is the Lumalive fabricfrom Philips, featuring flexible arrays ofcolored LEDs fully integrated within thefabric (Figure 5). These light-emitting tex-tiles can carry dynamic messages, graph-ics, or multicolored images. Based onconcepts of color and light therapy, bright-ness and the color appearance of light58

are thought to affect mood; these textilesare designed to enhance the observer’smood and positively influence his or herbehavior.59

ConclusionsDevelopments in smart nanotextiles

may affect many aspects of our daily livesand produce clothing that is contextuallyaware. New materials integrating noveltechnologies enable passive, noninvasivesensing of wearers and their environs.A major problem in wearable computingat present is the interconnections, withconventional silicon and metal compo-nents being highly incompatible with thesoft textile substrate. By integrating tech-nology at the nanoscale, the tactile andmechanical properties of the textile maybe preserved, retaining the necessarywearable and flexible characteristics thatwe expect from our clothing. Smart tex-tiles must be flexible enough to be wornfor long periods of time without causingany discomfort in order to become aviable and practical product.

Smart textiles have a large range ofapplications, often starting as a highly

specialized application before becoming amore generally available consumer prod-uct. The topics covered here show that thisis an area of interdisciplinary research thatmust involve materials research, sensortechnologies, engineering, wireless net-working, and computer applications.Creating a wearable garment integratestextile and fashion design with input fromthe end users, such as healthcare workers,defense forces, and sports physicians.Market trends suggest great opportunitiesfor nanotechnology within the textile mar-ket; given the current pace of develop-ment, smart nanotextiles will form aubiquitous part of our lifestyle. Our cloth-

ing is becoming contextually aware and islearning to adjust to suit the individualneeds of the user.

References1. “Nanotechnologies for the Textile Market”(Cientifica, London, April 2006).2. S. Lam Po Tang, G.K. Stylios, Int. J. ClothingSci. Technol. 18, 108 (2006).3. S. Wagner, E. Bonderover, W.B. Jordan, J.C.Sturm, Int. J. High-Speed Electron. Sys. 12, 391(2002).4. E.R. Post, M. Orth, P.R. Russo, N.Gershenfield, IBM Sys. J. 39, 840 (2000).5. C.K. Chiang et al., Phys. Rev. Lett. 39, 1098(1977).6. R.H. Baughman, Synth. Met. 78, 339 (1996).

Figure 5. Lumalive textile garment from Philips features flexible arrays of colored light-emitting diodes fully integrated into the fabric. (Courtesy of Philips.)

MRSBull_May07_Coyle_Final.qxd 5/7/07 6:14 PM Page 440

Smart Nanotextiles: A Review of Materials and Applications

MRS BULLETIN • VOLUME 32 • MAY 2007 • www/mrs.org/bulletin 441

7. T.F. Otero, in Handbook of Organic ConductiveMolecules and Polymers, H.S. Nalwa, Ed. (Wiley,Chichester, UK, 1997) p. 549.8. J. Huang, S. Virji, B.H. Weiller, B.H. Kaner,J. Am. Chem. Soc. 125, 314 (2003).9. S. Brady, D. Diamond, K.T. Lau, Sens.Actuators, A 119, 398 (2005).10. G.G. Wallace et al., Conductive ElectroactivePolymers: Intelligent Materials Systems (CRCPress, Boca Raton, FL, ed. 2, 2002).11. A. Knobloch, A. Manuelli, A. Bernds,W. Clemens, J. Appl. Phys. 96, 2286 (2004).12. J. Chen et al., Electrochim. Acta 49, 329 (2004).13. R.R. Mather, J. Wilson, in Intelligent Textilesand Clothing, H.R. Mattila, Ed. (Woodhead,Cambridge, UK, 2006) p. 2.14. J.P. Pouget et al., Mol. Crys. Liq. Cryst. 117,75 (1985).15. R.H. Baughman, B.E. Kohler, I.J. Levy, C.Spangler, Synth. Met. 11, 37 (1985).16. S. Kivelson, A.J. Heeger, Synth. Met. 22, 371(1988).17. S. Roth, Hopping Transport in Solids (ElsevierScience, 1991).18. D. Bowman, B.M. Mattes, Synth. Met. 154,29 (2005).19. A. Mazzoldi, A.D. Santa, D.D. Rossi, inPolymer Sensors and Actuators, Y. Osada, Ed.(Springer, 2000) pp. 207–244.20. J. Wu, D. Zhou, C.O. Doo, G.G. Wallace,Synth. Met. 155, 698 (2005).21. S. Brady, S. Coyle, D. Diamond, in Mater.Res. Soc. Symp. Proc. 920, X. Tao, G. Tröster, D.Diamond, Eds. (Materials Research Society,Warrendale, PA, 2006) pp. 85–90.22. A. Della Santa, D.D. Rossi, A. Mazzoldi,Smart Mater. Struct. 6, 23 (1997).23. S. Hara, T. Zama, W. Takashima, K. Kaneto,Polym. J. 36, 933 (2004).24. Y. Wu, G. Alici, G.M. Spinks, G.G. Wallace,Synth. Met. 156, 1017 (2006).25. W. Lu, B.R. Mattes, Synth. Met. 152, 53 (2005).26. V. Mottaghitalab, G.M. Spinks, G.G.Wallace, Polym. J. 47, 4996 (2006).27. L. Qian, J.P. Hinestroza, J. Text. Apparel,Technol. Manage. 4, 1 (2004).28. Adidas Innovation Zone Web site, www.adidas.com/innovation zone (accessed April2007).29. Nike Plus Products Web site, www.nike.com/nikeplus/ (accessed April 2007).30. M. O’Mahony, S. Braddock, Sportstech:Revolutionary Fabrics, Fashion, and Design(Thames & Hudson, London, 2002).31. R. Shishoo, Textiles in Sport (Woodhead,Cambridge, UK, 2005).32. G. Pigos, Sport J. 9, 1 (2006).33. F. Carpi, D. De Rossi, IEEE Trans. Inf.Technol. Biomed. 9, 295 (2005).34. B.J. Munro, J.R. Steele, T.E. Campbell, G.G.Wallace, Stud. Health Technol. Informatics 108,271 (2004).35. P. Xue, X. Tao, M. Leung, H. Zhang, inWearable Electronics and Photonics, X. Tao, Ed.(CRC Press, Boca Raton, FL, 2005) pp. 81–104.36. L.E. Dunne, P. Walsh, B. Smyth, B. Caulfield, in Proc. 10th IEEE Int. Symp.Wearable Computers (IEEE Computer Society,Los Alamitos, CA, 2006) pp. 65–68.

37. S. Brady et al., in Body Sensor Networks 2006,J.A. Paradiso, G.-Z. Yang, Eds. (IEEE ComputerSociety, Los Alamitos, CA, 2006) pp. 31–34.38. BIOTEX Web site, http://www.biotex-eu.com (accessed April 2007).39. M. Engin, A. Demirel, E.Z. Engin, M.Fedakar, Measurement 37, 173 (2005).40. F. Axisa et al., IEEE Trans. Inf. Technol.Biomed. 9, 325 (2005).41. R. Paradiso, G. Loriga, N. Taccini, IEEETrans. Inf. Technol. Biomed. 9, 337 (2005).42. R. Paradiso, C. Belloc, G. Loriga, N. Taccini,in Personalised Health Management Systems, C.Nugent, P.J. McCullagh, E. McAdams, A.Lymberis, Eds. (IOS Press, Amsterdam, 2005)pp. 9–16.43. F. Axisa et al., in Proc. 26th Annu. Int. Conf.IEEE EMBS (IEEE Engineering in Medicine andBiology Society, Piscataway, NJ, 2004) pp.2161–2164.44. J.-C. Bouvier et al., BIOTEX Project, “Useand technical requirements for all applications,”www.biotex-eu.com/pdf/Biotex_wp2_del2_1_v1d_public.pdf (accessed April 2007).45. A. Tognetti et al., J. Neuroeng. Rehabil. 2, 8(2005).46. D. Zhou et al., Synth. Met. 135, 39 (2003).47. Y. Bar-Cohen, “Electroactive Polymers asArtificial Muscles: Capabilities, Potentials, andChallenges,” in Robotics 2000 and Space 2000,W.C. Stone, Ed. (American Society of CivilEngineers, Reston, VA, 2000) pp. 188–196.48. V.J. Lumelsky, M.S. Shur, S. Wagner, IEEESensors J. 1, 41 (2001).49. G. Demiris et al., Stud. Health Technol. Inf.124, 45 (2006).50. B. Allen, Med. Eng. Phys. 18, 203 (1996).51. B. Firoozbakhsh, N. Jayant, S. Park,S. Jayaraman, in Proc. IEEE Int. Conf. Multimediaand Expo (IEEE Signal Processing Society,Piscataway, NJ, 2000) pp. 1253–1256.52. Institute for Soldier NanotechnologiesWeb site, http://web.mit.edu/isn/index.html(accessed April 2007).53. G.E. Collins, L.J. Buckley, Synth. Met. 78, 93(1996).54. M.A. El-Sherif, J. Yuan, A. MacDiarmid,J. Intelligent Mater. Sys. Struct. 11, 407 (2000).55. S. Braddock, M. O’Mahony, Techno Textiles2: Revolutionary Fabrics for Fashion and Design(Thames & Hudson, London, 2005).56. T. Ramachandran, K. Rajendrakumar, R.Rajendran, Text. Eng. 84, 42 (2004).57. Nano-Tex press release, “Nano-Tex UnveilsAnti-Static, Stain Release, Moisture-WickingFabric Enhancements,” www.nano-tex.com/news&media/Feb16_2005.pdf (February 16,2005, accessed April 2007).58. H. Juslén, “Improving Health andHealthcare with Light,” Business Briefing:Hospital Engineering and Facilities Management(Touch Briefings, London, 2005) pp. 1–2.59. Philips Research press release, “Philipsilluminates IFA2006 with production-ready Lumalive textile garments,” www.research.philips.com/newscenter/archive/2006/060901-lumalive.html (accessed April2007).

Shirley Coyle receivedher BEng degree in elec-tronic engineering in 2000from Dublin City Univer-sity, Ireland. She thenworked in the Informa-tion and CommunicationsDivision at Siemens Ltd.for two years before start-

ing her PhD studies in the field of biomedicalengineering. The focus of this research was todevelop a brain–computer interface using opti-cal brain imaging techniques. She received herPhD from the National University of IrelandMaynooth in 2005.

Since 2002, Coyle has been studying for adiploma in fashion design at the GraftonAcademy of Dress Designing. Her currentresearch interests combine her biomedical engi-neering background with a long-standinginterest in apparel design to develop wearablesensors and smart textiles for healthcare man-agement. She is now a full-time researcher atDublin City University, working on theEuropean Union’s BIOTEX Project, aEuropean-wide multi-partner research effort tomerge sensing capabilities with fabrics andtextiles.

Coyle can be reached at the AdaptiveSensors Group, National Centre for SensorResearch, School of Chemistry, Dublin CityUniversity, Glasnevin, Dublin 9, Ireland; tel.353-1-700-7657, fax 353-1-700-8021, and e-mail [email protected].

Yanzhe Wu graduatedwith a degree in biochem-istry from the Universityof Anhui, China, in 1998,and received his master’sdegree in information andcommunication technol-ogy from the University ofWollongong, Australia, in

2001. Wu recently earned his PhD degreeunder Gordon Wallace at the University ofWollongong, where he worked on inherentlyconducting polymers to develop sensors andactuators for cochlear implants. He is now afull-time researcher at Dublin City University,working on the European Union’s BIOTEXProject.

Wu can be reached at the Adaptive SensorsGroup, National Centre for Sensor Research,School of Chemistry, Dublin City University,Glasnevin, Dublin 9, Ireland; tel. 353-1-700-5670, fax 353-1-700-8021, and [email protected].

MRSBull_May07_Coyle_Final.qxd 5/7/07 6:14 PM Page 441

Smart Nanotextiles: A Review of Materials and Applications

442 MRS BULLETIN • VOLUME 32 • MAY 2007 • www/mrs.org/bulletin

King-Tong Lau is cur-rently a senior researchchemist in the NationalCentre for Sensor Researchat Dublin City University,Ireland. He received hisPhD degree from theUniversity of London in2001 on electrochemical

biosensor development. His research interest isin the area of molecular recognition and thedevelopment of low-cost, deployable sensordevices for chemical, environmental, and food-quality monitoring.

Lau can be reached at the Adaptive SensorsGroup, National Centre for Sensor Research,School of Chemistry, Dublin City University,Glasnevin, Dublin 9, Ireland; tel. 353-1-700-7926, fax 353-1-700-5503, and [email protected].

Danilo De Rossi gradu-ated with a degree in chem-ical engineering from theUniversity of Genoa in1976. From 1976 to 1981,he was a researcher atthe Institute of ClinicalPhysiology of the ItalianNational Research Council

(CNR) in Pisa, Italy. Since 1982, he has beenworking in the School of Engineering at theUniversity of Pisa, where he is a full professor ofbioengineering and president of the BiomedicalEngineering Teaching Track. Since 1999, he hasalso been an adjunct professor of materials sci-ence at the University of Wollongong,Australia. His scientific activities are related tothe physics of organic and polymeric materialsand the design of sensors and actuators for bio-engineering and robotics. He is the author ofmore than 150 technical and scientific publica-tions and co-author of seven books.

De Rossi can be reached at InterdepartmentalResearch, Center “E. Piaggio,” University ofPisa, Via Diotisalvi, 2, 56100 Pisa, Italy; tel. 39-050-2217053, fax 39-050-2217051, and e-mail [email protected].

Gordon Wallace has beena professor at the Univer-sity of Wollongong, Aus-tralia, since 1990. He haspublished more than 380refereed publications andtwo editions of a mono-graph on inherently con-ducting polymers for

intelligent materials systems. He has super-vised 47 PhD students to completion of theirdegrees. Wallace currently serves as the execu-tive research director of the new AustralianResearch Council (ARC) Centre of Excellencefor Electromaterials Science. He holds a DScdegree from Deakin University (2000).

Wallace is a fellow of the Royal AustralianChemical Institute (RACI) and received theinaugural Polymer Science and TechnologyAward from RACI in 1992. Wallace has beenhonored with an ARC QEII Fellowship (1991),an ARC Senior Research Fellowship (1995),and an ARC Professorial Fellowship (2002).He was awarded an ETS Walton Fellowship byScience Foundation Ireland in 2003 and in thesame year was elected fellow of the AustralianAcademy of Technological Sciences andEngineering. He received the RACI StokesMedal for Research in Electrochemistry andwas elected fellow of the Institute of Physics(U.K.) in 2004. In 2006, he was awarded anARC Federation Fellowship.

Wallace can be reached at the IntelligentPolymer Research Institute and ARC Centreof Excellence for Electromaterials Science,University of Wollongong, Northfields Ave.,New South Wales 2522, Australia; tel. 61-2-

4221-3127, fax 61-2-4221-3114, and [email protected].

Dermot Diamond holds aPhD degree from Queen’sUniversity Belfast and wasvice president for researchat Dublin City University,Ireland, from 2002 to2004. He has publishedmore than 140 peer-reviewed papers in inter-

national science journals, is a named inventoron 12 patents, and is co-author and editor oftwo books, Spreadsheet Applications inChemistry Using Microsoft Excel (1997)and Principles of Chemical and BiologicalSensors (1998), both published by Wiley. Hisresearch interests range from molecular recog-nition, host–guest chemistry, ligand designand synthesis, electrochemical and opticalchemical sensors and biosensors, to lab-on-a-chip devices; sensor applications in envi-ronmental, clinical, food quality, and processmonitoring; the development of fullyautonomous sensing devices; wireless sensors;and sensor networks. He has numerous inter-national collaborations in Europe, the UnitedStates, and Australia, and is particularlyinterested in developing the potential of ana-lytical devices and sensors as informationproviders for wireless networked systems.

Diamond can be reached at the AdaptiveSensors Group, National Centre for SensorResearch, School of Chemistry, Dublin CityUniversity, Glasnevin, Dublin 9, Ireland; tel.353-1-700-5404, fax 353-1-600-7995, and e-mail [email protected].

MRSBull_May07_Coyle_Final.qxd 5/7/07 6:14 PM Page 442