SMART MATERIALS AND SENSORS.doc

-

Upload

ammayi9845930467904 -

Category

Documents

-

view

219 -

download

0

Transcript of SMART MATERIALS AND SENSORS.doc

7/27/2019 SMART MATERIALS AND SENSORS.doc

http://slidepdf.com/reader/full/smart-materials-and-sensorsdoc 1/13

MART MATERIAL AND EN OR

ABSTRACT

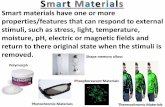

Now days, smart materials have found an important place in the

modern engineering applications. Smart materials or intelligent materials

system include integration of sensors, actuators and control with a material

or structural component possesses intelligent and life features .The

development of smart material is inspired by the biological structure

systems and their basic characteristics of functionality, efficiency, precision,

self - repair and durability. Smart materials are not only singular materialsbut also Hybrid composites or integrated systems of materials.

Shape Memory Alloys are one of the maor categories of smart

materials which after being strained at certain temperature revert bac! to

the original shape because of uni"ue properties such as Shape Memory

effect, Pseudo elasticity and high damping capacity . These properties in

smart hybrid composites provide them the tremendous potential for creating

new paradigms for material-structural interactions and demonstrate various

successes in engineering applications li!e Aeronautical engineering, in

medical fields li!e Vascular stents and Osteosynthesis etc., and in

commercial fields also.

The main advantages of shape memory alloys are, they are Bio-

compatible, strong and good corrosion resistant . They generally have high

power to weight ratio and can withstand large amount of recoverable strain

and when heated above transition temperature, they can e#ert high recovery

stresses of 700MPa which can be used to perform wor!.

7/27/2019 SMART MATERIALS AND SENSORS.doc

http://slidepdf.com/reader/full/smart-materials-and-sensorsdoc 2/13

$n this paper, we are presenting one of the maor categories of smart

materials, SMAs, their properties, different types of SMAs and their

applications in various fields

.

HAPE MEMORY ALLOY

INTRODUCTION:

Shape memory alloys are metals that, after being strained, at a certain temperature

revert back to their original shape. A change in their crystal structure above their

transformatations temperature causes them to return to their original shape.

SMAs enable large forces (generated when encountering any resistance during theirtransformation) and large movements’ actuation, as they can recover large strains.

SMAs ehibit two very uni!ue properties pseudo-elasticity and the shape memory

effect. "ypical Alloys which ehibit these properties are #i$"i alloy, %ron base SMA

alloy, &opper base SMA alloy, Super 'lastic glasses etc.,

SHAPE EOR! E""ECT:

"he ability of SMAs to return to their original shape after heating to their

transformation temperature after having been deformed is termed as #shape memory

e$$ect%& "his is due to the change in the crystalline structure during the transition from

7/27/2019 SMART MATERIALS AND SENSORS.doc

http://slidepdf.com/reader/full/smart-materials-and-sensorsdoc 3/13

martensitic phase to austenitic phase.

Martensite is the relatively soft and easily deformed phase of shape memory alloys,

which eists at lower temperatures. "he molecular structure in this phase is twinned as

shown in the middle of figure. pon deformation this phase takes on the second form

shown in figure, on the right. Austenite, the stronger phase of shape memory alloys,

occurs at higher temperatures. "he shape of the Austenite structure is cubic, shown on the

left side of figure."he un$deformed Martensite phase is the same si*e and shape as the

cubic Austenite phase on a macroscopic scale, so that no change is visible in shape

memory alloys until the Martensite is deformed.

"he Shape Memory effect is observed when the temperature of SMA is cooled to

below the temperature Mf. At this stage the alloy is completely composed of Martensite

which can be easily deformed. "he original shape of SMA can be recovered simply by

7/27/2019 SMART MATERIALS AND SENSORS.doc

http://slidepdf.com/reader/full/smart-materials-and-sensorsdoc 4/13

heating the SMA above the temperature Af.

"he shape memory effect is currently being implemented in+

Co$$eepots

The Space Shuttle

Thermostats

'ascular Ste(ts

Hydraulic "itti() *$or Airpla(es+

PSEUDO-E,ASTICIT!+

7/27/2019 SMART MATERIALS AND SENSORS.doc

http://slidepdf.com/reader/full/smart-materials-and-sensorsdoc 5/13

Pseudo-elasticity occurs i( SAs he( the alloy is completely composed o$

Auste(ite. %t occurs without change in temperature. "he load on the SMA is increased

until the Austenite becomes transformed into Martensite due to the loading (as shown).

7/27/2019 SMART MATERIALS AND SENSORS.doc

http://slidepdf.com/reader/full/smart-materials-and-sensorsdoc 6/13

"he loading is absorbed by the softer

Martensite, but as soon as loading is decreased the Martensite begins to transform back to

Austenite since the temperature of the SMAs is still above Af, and the wire springs back to

its original shape.

Some Applications of pseudo$elasticity is used are+

Eye)lass "rames

edical tools

Cellular pho(e A(te((a

Orthodo(tic Arches

"E. SHAPE EOR! A,,O!S+

!"#$%-&!&A!'M A%%O()

#i$"i alloys are the most used SMA. %t is an e!uiatomic compound of #i$"i, whose

transformation temperature can range between -/00 1 //0C& %t has great shape$memory

strain (up to 23+4is thermally stable and has ecellent corrosion resistance. ecause of

the reactivity of "i, all melting of it must be done in a vacuum.

"OPP$* BAS$ SMA A%%O( +"u-n-Al "u-Al-i.)

&u$-n$Al and &u$Al$#i alloys are commercially available SMAs. "heir

transformation temperature ranges between -/20 1 500C a(d -/60 1 /00 C

respectively. "hey are cheaper than #i$"i alloys can be melted in air with ease and have a

shape$memory strain up to 6-73& ot work in air is well suitable, while cold work is

suitable only for low Al content alloys *893 t+&

S'P$* $%AS&!" /%ASS$S +

"hese glasses are made from a super elastic metal alloy. "herefore, they

can be bended !uite drastically without permanent damage. The )lasses

utilie the super elastic property o$ Ni-Ti alloys.

!*O BAS$ SMA A%%O(S)

7/27/2019 SMART MATERIALS AND SENSORS.doc

http://slidepdf.com/reader/full/smart-materials-and-sensorsdoc 7/13

"he most important %ron based shape memory alloy is "e-(-Si. "hey base shape$

memory effect on a different physical principle than conventional SMAs. "hey can

recover only less tha( 63 strai(&

APP,ICATIONS:

"he pseudo elasticity and Shape memory effect are being applied to a wide variety

of applications in a number of different fields. Some of them are+

Aero(autical E()i(eeri()

edical Applicatio(s

Commercial applicatio(s

AERONAUTICS:

Aircraft maneuverability depends heavily of flaps found at the rear or trailing edges

of the wings.Aircrafts at present operate these flaps using etensive hydraulic systems. %n

order to maintain reliability of operation, multiple hydraulic lines must be run to each set

of flaps. "his comple system is often relatively difficult and costly to maintain. Some of

the most promising alternatives to this comple system are+

Pieoelectric $i;res

Electrostricti<e ceramics

Shape emory Alloys

/Smart0wings, which incorporate shape memory alloys, are shown.

7/27/2019 SMART MATERIALS AND SENSORS.doc

http://slidepdf.com/reader/full/smart-materials-and-sensorsdoc 8/13

"his system is much more compact and efficient, in that the shape memory wires

only re!uire an electric current for movement.

"he shape memory wire is used to manipulate a fleible wing surface. "he wire on

the bottom of the wing is shortened through the Shape Memory 'ffect, while the top wire

is stretched bending the edge downwards, the opposite occurs when the wing must be

bent upwards. "he shape memory effect is induced in the wires simply by heating them

with an electric current, which is easily supplied through electrical wiring, eliminating the

need for large hydraulic lines.

y removing the hydraulic system, aircraft weight, maintenance costs and repair

time are all reduced. "he smart wing system is currently being developed cooperatively

through the efense Ad1anced *esearch Pro2ect Agency (1A23A, a branch of the

nited States 1epartment of 1efense) and oeing.

7/27/2019 SMART MATERIALS AND SENSORS.doc

http://slidepdf.com/reader/full/smart-materials-and-sensorsdoc 9/13

EDICA, APP,ICATIONS:

S'*/!"A% &OO%S)

one plates are surgical tools, which are used to assist in the healing of broken and

fractured bones. "hey are often applied to fractures occurring to facial areas such as nose,

4aw or eye sockets. 2epair like this fall into an area of medicine known as

Osteosynthesis3

Curre(tly osteotemy e=uipme(t is made primarily o$ tita(ium a(d stai(less

steel. "he broken bones are first surgically reset into their proper position. "hen a plate is

screwed onto the broken bones to hold them in place, while the bone heals back together.

The dra;ac> o$ this process is a$ter i(itially paci() the plate o the ;rea> or

$racture the ;o(es are compressed to)ether a(d held u(der some sli)ht pressure

hich helps to speed up the heali() process o$ the ;o(e& U($ortu(ately4 a$ter o(ly a

couple o$ days the te(sio( pro<ided ;y the steel plate is lost a(d the ;rea> or

7/27/2019 SMART MATERIALS AND SENSORS.doc

http://slidepdf.com/reader/full/smart-materials-and-sensorsdoc 10/13

$racture is (o lo()er u(der compressio(4 sloi() do( the heali() process. f

"he bone plates can also be fabricated using SMAs, in particular #i$"i alloys. sing

a bone plate made out of #i$"i, which has a transformation temperature of around Af

much greater than /7 C& the #i$"i plates are first cooled to well below their

transformation temperature, then they are placed on the set break 4ust like "i plates.

owever when the body heats the plate upto the body temperature the #i$"i attempts to

contract applying sustained pressure on the break or fracture for far longer than stainless

steel or "itanium. "his steady pressure assists the healing process and reduces recovery

7/27/2019 SMART MATERIALS AND SENSORS.doc

http://slidepdf.com/reader/full/smart-materials-and-sensorsdoc 11/13

time.

VAS"'%A* S&$&S)

A vascular stent is a device which is implanted in a blood vessel (veins and

arteries) to provide structural reinforcements of the vessel wall. "he introduction of SMA

to stent manufacture allows greater recovery strains for use in wider vessels, or stronger

recovery force in narrower vessels.

COERCIA, APP,ICATIONS:

7/27/2019 SMART MATERIALS AND SENSORS.doc

http://slidepdf.com/reader/full/smart-materials-and-sensorsdoc 12/13

A&!S"A%$ $V!"$S)

asically an etension which fits between the shower head and the water pipe,

containing a "i$based SMA element which epands if water becomes too hot, choking off

the flow. A very cheap, easy and effective alternative to more epensive technologies."O$"&!/ *!/S)

2ings and cylinders of SMA which are austenite at ambient temperature can provide

significant constraining force around their inner circumference, ensuring a strong 4oint

which can be released by cooling couplings.

"O44$$PO& &5$*MOS&A&)

A #i$"i spring in coffeepots marketed in 5apan is trained to open a valve and

release hot water at the proper temperature to brew a perfect pot of coffee.4AS&$!/ 4'"&!OS)

Shape Memory 'ffect 'lements (SM''), in a variety of shapes can be used for

fastening and coupling purposes, e&)& ;uildi() e()i(eeri()4 aero(autics a(d i(

assem;ly operatio(s. y epanding or shrinking at preset temperatures 4 SEE ca(

per$orm hi)h $orces a(d assure ti)ht $aste(i()4 either perma(e(t or temporary. %n

temporary fastening, the fiation can be released by means of the two$way$memory

effect.

RO?OTICS APP,ICATIONS:

S&$& 4O* V$!S)

"he stent is used for reinforcing weak vein walls and for widening narrow veins.

"he chilled stent is brought into position through a probe, and epands to its original si*e

when warmed up to body temperature. "he stent replaces similar steel stents that are

epanded with a little balloon.

AD'ANTA@ES O" SHAPE EOR! A,,O!S: Some of the main advantages of shape memory alloys include+

?io-compati;ility

Di<erse "ields o$ Applicatio(

@ood echa(ical Properties *stro()4 corrosio( resista(t+

7/27/2019 SMART MATERIALS AND SENSORS.doc

http://slidepdf.com/reader/full/smart-materials-and-sensorsdoc 13/13

Hi)h Poer to .ei)ht Ratio

I( marte(site phase they ca( ithsta(d lar)e amou(ts o$ reco<era;le strai(

*upto 23+

.he( heated a;o<e the tra(sitio( temperature they ca( eert hi)h reco<ery

stress o$ B00Pa&

CONC,USION:

"hus, the shape memory Alloys are etensively used in Aeronautics, 6steosynthesis and

in some commercial products. Still they have got some drawbacks(7ess efficient,

epensive etc,). 8e can hope that the ongoing researches in SMAs will rectify these

drawbacks so that they will emerge as a universally accessible one.

?I?,IO@RAPH!:

9. 'ngineering Aspects of Shape Memory Alloys$1uerig ".8., Melton :.#.,

Stoeckel 1, 8ayman &.M.

. 'ngineering Aspects of Shape Memory Alloys$1.'. odgson, M.. 8u, and 2.5.

iermann.

;. "itanium$#ickel Shape Memory Alloys$ 1uerig ".8., A.2. 1elton.

.E?SITES:

9. Shape Memory Applications %nc.,

. #itinol devices and components %nc.,