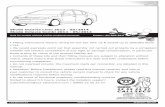

SKODA OCTAVIA (1U2) 1.6, 75 KW

Transcript of SKODA OCTAVIA (1U2) 1.6, 75 KW

As a system specialist for engines and chassis, we have the right repair solution in OE quality on stock for all standard European and Asian cars. Why would this be any different for the chassis components of the Skoda Octavia (1U2) 1.6, 75 KW? Please always comply with the general and specific procedures for the respective compo-nents when carrying out repairs.

Vehicle-specific installation instructions:

The specific assembly information needs to be observed for some chassis components in the Skoda Octavia (1U2) 1.6., 75 KW. These are described in more detail below. The affected items are marked in grey in the table.

Basic installation instructions:

The wheel bearing may not be put under pressure when the double hexagon head nut is loose. Under a full load, the wheel bearing suffers preliminary damage caused by the deadweight of the vehicle. In turn, this reduces the service life of the wheel bearing

If vehicles whose cardan shafts have been removed are moved, an outer joint needs to be fitted in place of the cardan shaft and tightened to 50 Nm; otherwise the wheel bearing might be damaged

Before dismantling, the screws of the supporting joint on the control arm need to be marked. Otherwise, the axle geometry needs to be tested and set

When pushing out the cardan shaft, ensure there is enough space When pushing out the cardan shaft, ensure it does not hang down. The inner joint will otherwise be damaged due to over-bending

Always use new screws

Every new model or series entails new installation specifications for the chassis. RUVILLE passes on all the latest know-how to the garages. You can find out more about our training courses at www.ruville.de or directly from our technical instructor Remo Schönsee on e-mail: [email protected]

WE prOvidE hAndS-On, prACTiCAL TrAininG

GEnErAL inSTrUCTiOnS ALL rUviLLE ChASSiS COMpOnEnTS fOr ThE SKOdA OCTAviA (1U2) 1.6, 75 KW

KNOW-HOW IN DETAIL CAN ALSO BE DOWNLOADED

OFF THE INTERNET AT

WWW.rUviLLE.dE ➜ SErviCE ➜

dOWnLOAdS ➜ TEChniCAL infO

➜ SKOdA OCTAviA (1U2) 1.6, 75 KW ChASSiS

inSTrUCTiOnS fOr SpECifiC COMpOnEnTS

SKODA OCTAVIA (1U2) 1.6, 75 KW

Article no description

75414S Joint kit, drive shaft, wheel-side

75418S Joint kit, drive shaft, wheel-side

75457S Joint kit, drive shaft, gearbox-side

755439 Bellow kit, drive shaft, wheel-side

755441 Bellow kit, drive shaft, wheel-side

755753 Bellow kit, drive shaft, gearbox-side

75414 Joint, drive shaft, wheel-side

75418 Joint, drive shaft, wheel-side

75457 Joint, drive shaft, gearbox-side

SKOdA OCTAviA (1U2) 1.6, 75 KW

ChASSiS

KnOW-hOW in dETAiL pAGE 1

Article: 75414S | Joint kit, drive shaft, wheel-side 75418S | Joint kit, drive shaft, wheel-side 755439 | Bellow kit, drive shaft, wheel-side 755441 | Bellow kit, drive shaft, wheel-side 75414 | Joint, drive shaft, wheel-side 75418 | Joint, drive shaft, wheel-side

Check the outside of the constant-velocity joint: The joint must be dismantled when the lubricant is changed, when it is heavily soiled, and also if the running surfaces of the balls need to be checked for wear and damage.

Dismantling: The position of the ball hub in rela-tion to the ball cage and the casing needs to be marked with an electric engraver or honing stone before dismantling (arrow A). Swivel the ball hub and ball cage and remove the balls one after another. Turn the cage until the two square cage windows (arrow B) face the joint piece. Lift out the cage with the hub. Swivel the segment of the hub into the square window of the cage. Then swivel the hub out of the cage.

Note: The 6 balls for each joint belong to a tolerance group. Check the kingpin, hub, cage and balls for small dents (pitting = spot corrosion) and seizing marks. Audible thumping is the result if there is too much radial clearance in the joint. In these cases, the joint needs to be replaced. Flat-tened or scored balls are no reason to replace the joint; check the cage for cracks.

Install: Inject the required amount of lubricant into the joint piece; please note the lubricant type and quantity. Then insert the cage with the hub into the joint piece.

Note: The cage needs to be inserted laterally. Then press in the balls on the opposite side one after another. The old position of the ball hub in relation to the ball cage and joint piece must be reinstated. Place the new locking ring into the groove in the shaft and then distribute the rest of the grease inside the protective joint cover.

Check the inside of the constant-velocity joint: Here again, the ball hub and joint piece are paired and need to be marked before being dismantled so that the track assignment is not con-fused.

it is dismantled in the same sequence and the outer constant- velocity joints!

Install: Place the ball hub into the ball cage over the two bevels. The installation position is not de-fined. Now press the balls into the cage and then place the hub and the cage and balls upright into the joint piece. Note: When inserting, ensure that the wide clear-ance (a) on the joint piece lies together with the narrow clearance (b) on the hub after swivelling (arrow). The bevel on the inner diameter of the ball hub (cogging) must point toward the larger diameter of the joint piece.

Swivel the hub as far out of the cage as possible (arrow) so that the balls have the same clear-ance as the tracks.

SKOdA OCTAviA (1U2)

1.6, 75 KW ChASSiS

Article: 75414 | Joint, drive shaft, wheel-side 75414S | Joint kit, drive shaft, wheel-side

Check the installation position of the protective joint cover for the outside constant-velocity joint Ø 90 mm on the left shaft.

The sealing surface of the protective joint cover must be positioned up to the end of the edge of the shaft.

Article: 75457 | Joint, drive shaft, gearbox-side 75457S | Joint kit, drive shaft, gearbox-side

Check the installation position of the protective joint cover for the inside constant-velocity joint Ø 94 mm on the right shaft.

1 to 1½ of the groove on the drive shaft must be visible. Before fitting the cardan shaft, remove any corrosion inside the thread / cogging of the outer joint and wet the cogging of the wheel hub with oil. Then insert the cardan shaft and insert the outer joint into the cogging of the wheel hub as far as it will go. Screw the axle joint and the axle guide with new screws to the old imprint of the transverse link.

The contact surface of the double hexagon head nut and the cogging and thread should be wet with oil and the new double hexagon head nut screwed on as far as possible.

Now pull the outer joint into the wheel hub until the outer joint makes contact inside the wheel bearing; then attach the wheel. Then lower the vehicle. Ensure that the wheels do not yet touch the floor. If the wheel bearing is loaded with the vehicle deadweight, it will suffer initial damage and this will in turn reduce its service life. Now press the brake pedal (a second techni-cian is required for this step) and tighten the new double hexagon head nut to 225 Nm and then half-twist back. Continue turning the wheel hub for at least 90° and tighten the double hexagon head nut.

Tightening torque: 50 Nm and 60° continue tightening.

Note: To tighten the double hexagon head nut, we recommend using e.g. the angle-control wrench - V.A. G 1756 -.

(picture 1) Press the cage hard (arrows) and then swivel in the hub with the balls. (picture 2) After fitting the piece together, check the function of the constant-velocity joint: The constant-velocity joint is correctly assembled when the ball hub in the joint piece can be slid manually backwards and forwards over the entire length adjustment piece. Then add the cardan shaft. After the joint has been adequately lubri-cated, attach the clip and the protective joint cover.

Picture 1

Picture 2

A

B

ab

KnOW-hOW in dETAiL pAGE 2