Site Visit Report - Environmental Protection Agency · Sulphur Dioxide FTIR by MKS MG2030 Nitrous...

Transcript of Site Visit Report - Environmental Protection Agency · Sulphur Dioxide FTIR by MKS MG2030 Nitrous...

Site Visit Report

The site visit process is a sample on a particular day of an installation's compliance with some of its licence conditions. Where non-compliance against a particular condition has not been reported, this should not be construed to mean that there is full compliance with that condition of the licence.

Instructions and actions arising from the visit shall be addressed, or where applicable noted, by the licensee in order to ensure compliance, to improve the environmental performance of the installation and to provide clarification on certain issues.

The licensee shall take the actions specified to close out the non-compliances and observations raised in this Site Visit Report.

Licensee

Name of Installation Edenderry Power Limited

Licensee Edenderry Power Limited

Licence Register No. P0482-04

CRO Number 278071

Site Address Ballykilleen, Edenderry, Offaly

Site Visit Reference No. SV08119

Report Detail

Issue Date 03/01/2017

Prepared By David Matthews

Site Visit Detail

Date Of Inspection 28/09/2016 Announced No

Time In 13:00 Time Out 14:00

Visited by on behalf of the EPA Exova Ltd.

Licensee Personnel and Role See report.

Photo Taken No Samples Taken Yes Video Taken No

Site Visit Report - SV08119 - Edenderry Power Limited Page 1 of 42

Scope

This is a report on monitoring of emissions to atmosphere at this site. Please find the detailed technical report attached.

Media

Air.

Site Areas Inspected

See report.

Documents Inspected

See report.

Site Visit Report - SV08119 - Edenderry Power Limited Page 2 of 42

ISO/IEC 17025 Accredited Legal Entity, UKAS Accredited Testing Laboratory No. 4279Exova (UK) Ltd trading as Exova Catalyst & Exova Catalyst Ireland

Unit C5, Emery Court, The Embankment Business Park, Stockport, SK4 3GL

Exova Catalyst Ireland, Unit D8 North City Business Park, North Road, Finglas, Dublin 11T: +353 86 853 8247

E: [email protected] Exova Catalyst Ireland Contact: Nick Kenny (+353 86 853 8247)

EdenderryBallykillen

Edenderry Power Ltd

Co. Offaly

EPA Office of Environmental Enforcement

A1-1 Main Boiler

EMISSIONS REPORT(Prepared on behalf of the EPA by Exova Catalyst - EPA Contract No. OEE-14-DS)

-

-

EPA AIR EMISSIONS COMPLIANCE MONITORING

Stack Reference

Industrial Emissions Licence: P0482-04

Stack Emissions Testing Report Commissioned by

Installation Name & Address

Signature of Report Approver

Version 2

Donal O Faogain

3rd January 2017Report Date

TE1 TE2 TE3 TE4

Version

Team Leader

Deputy Regional Manager

TE1 TE2 TE3 TE4MM08 922

MCERTS Level 2

Patrick O'BrienReport Approved by

MM13 1259MCERTS Level 2

28th - 29th September 2016

Job Reference NumberP0482-04CAR-16-01

Dates of the Monitoring Campaign

Report Written by

Site Visit Report - SV08119 - Edenderry Power Limited Page 4 of 42

TITLE PAGE

CONTENTS

Summary of Sampling Deviations

EXECUTIVE SUMMARY

Monitoring Objectives

Monitoring Results

Monitoring Dates & Times

Process Details

Monitoring & Analytical Methods

Sampling Location

Plant Photos / Sample Points

APPENDIX 1 - Monitoring Personnel & List of Equipment

APPENDIX 2 - Raw Data, Sampling Equations & Charts

Opinions and interpretations expressed herein are outside the scope of Exova Catalyst Ireland's ISO 17025 accreditation.

9

3

5

6

8

4

2

7

CONTENTS

The testing performed fully meets the technical requirements in Irish EPA Guidance Note, AG2.

This test report shall not be reproduced, except in full, without the written approval of Exova Catalyst Ireland.

This version of the test report supersedes the previous version of the test report. Please destroy all previous versions to ensure no confusion arises from having multiple test reports in existence.

CAT-RT (Version BP)Page 2 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 5 of 42

Overall Aim of the Monitoring Campaign

Special Requirements

Target Parameters

Total Particulate Matter | Oxides of Nitrogen (as NO₂) | Nitrous Oxide | Sulphur Dioxide |

MONITORING OBJECTIVES

Executive Summary

Exova Catalyst Ireland were commissioned by EPA Office of Environmental Enforcement to carry out stack emissions testing at Edenderry Power Ltd on the A1-1 Main Boiler at Edenderry.

The aim of the monitoring campaign was to demonstrate compliance with a set of emission limit values (ELVs) as specified in the Site's Permit.

There were no special requirements.

A1-1 Main Boiler28th - 29th September 2016

(Page 1 of 7)

Edenderry Power Ltd, Edenderry

CAT-RT (Version BP)Page 3 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 6 of 42

where MU = Measurement Uncertainty associated with the Result

Parameter

Total Particulate Matter ¹

Oxides of Nitrogen (as NO₂) ¹ - -Nitrous Oxide ¹ - -Sulphur Dioxide ¹ - -Oxygen Dry

Water Vapour Stack Gas TemperatureStack Gas Velocity

¹

- -NOTE: VOLUMETRIC FLOW RATE & VELOCITY DATA TAKEN FROM THE PRELIMINARY VELOCITY TRAVERSE.

¹ Reference Conditions (REF) are: 273K, 101.3kPa, dry gas, 6% oxygen.

Limit485000

-

g/hr

g/hr

19135m³/hr

Limit+/-

Units

mg/m³mg/m³

8982-

0.18

% v/v

23.7

73.16

m/s

0.91163.1

0.95mg/m³mg/m³

4.5160015.29

325g/hr0.18

Edenderry Power Ltd, Edenderry

`

g/hr 151248.10+/-

Units Result

Concentration

MU

(Page 2 of 7)

-

200.0

% v/v21.3

417210

0.38

774532m³/hr

20067

Result LimitMU

A1-1 Main Boiler

-

Executive Summary

Mass Emission

50

Volumetric Flow Rate (REF)

398.4 -

2.88

MONITORING RESULTS

137893

9.42 -

°C

Volumetric Flow Rate (ACTUAL)

83449 5486

330.5

35523

CAT-RT (Version BP)Page 4 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 7 of 42

Parameter

R1 - -R1 -R1 - -R1 - -R1 - -R1 -R1

All results are expressed at the respective reference conditions.

Date(s)Mass Emission

g/hr

08:25 - 08:4523.0

Velocity & Volumetric Flow Rate

MONITORING DATE(S) & TIMES

mins

08:50 - 09:4929/09/201629/09/2016

% v/v

g/hr

200.0

08:48 - 09:48

A1-1 Main Boiler28th - 29th September 2016

Executive Summary

SamplingTimes

Concentration

29/09/2016

Sampling

20067

Units

Edenderry Power Ltd, Edenderry

60

(Page 3 of 7)

Water Vapour

mg/m³

60

DurationUnits

Total Particulate Matter 48.1mg/m³

% v/v60

08:50 - 09:49

4.51

60

8344973.2 60

Oxides of Nitrogen (as NO₂)Nitrous Oxide

08:50 - 09:49

08:50 - 09:49

29/09/201629/09/2016

Sulphur Dioxide 330.5

6008:50 - 09:490.18

g/hrg/hr

mg/m³ 29/09/2016

Oxygen

137893

mg/m³29/09/2016

CAT-RT (Version BP)Page 5 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 8 of 42

Standard Operating Conditions

Value

Feedstock (if applicable)

Edenderry Power Ltd, Edenderry

Power GenerationCapacity (of 100%) and Tonnes / HourContinuous or Batch Process

Solid FuelOn

Continuous

Abatement SystemAbatement System Running Status

Plume Appearance

Electrostatic Precipitator

Parameter

A1-1 Main Boiler28th - 29th September 2016

Normal operating conditions

Peat and biomass

FuelVisible

(Page 4 of 7)Executive Summary

PROCESS DETAILS

Process Status

CAT-RT (Version BP)Page 6 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 9 of 42

2.68 mg/m³

CAT

Yes

Yes

CAT-TP-05 0.1 % v/vCAT-TP-05 YesEN 14790EN 14789 CAT-TP-21 Yes

TGN M22 FTIR by Gasmet Technologies Oy DX4000

Dry Zirconia Cell by Horiba PG-250

CAT

0.15 mg/m³

CAT-TP-22(b)

CATOxygen

FTIR by MKS MG2030Sulphur DioxideNitrous Oxide

YesTGN M22

Water VapourYes 1.2 m/s

0.1 %

CAT

ANALYSIS LABORATORIES

TGN M22FTIR by MKS MG2030

YesYes

(with short name reference as appears in the table above)

Exova Catalyst (CAT)

FTIR by MKS MG2030

YesCAT Yes

CATYesCAT-TP-22(b)

CAT

ISO 17025 Accreditation Number: 4279

CATCAT-TP-22(b)

Yes

Yes

CAT-TP-22(b)

0.02 %

CAT-TP-41

(Average)

Yes

Analytical

GravimetricWater Vapour

Yes

Velocity & Vol. Flow Rate

TGN M22

(Page 5 of 7)

Testing ISOStandard

CAT-TP-01 Gravimetric

MCERTS17025

Testing

0.09 mg/m³Yes

Analytical LOD

Edenderry Power Ltd, Edenderry

Analysis

Total Particulate Matter EN 13284-1

Lab

Yes

ISOLab

Technical

CAT-TP-03

A1-1 Main Boiler

0.51 mg/m³

28th - 29th September 2016

Analysis17025

Analysis

Monitoring

CAT

ParameterProcedure

Oxides of Nitrogen (as NO₂)

TechniqueProcedure

Executive Summary

Testing

CAT

EN 16911-1 (MID)

MONITORING & ANALYTICAL METHODS

Pitot Tube and ThermocoupleYes

SUMMARY OF SAMPLING DEVIATIONS

1Total Particulate Matter

Deviation

Due to the restricted access, it was not possible to sample at all of the sample points on the available sampling lines.

SUMMARY OF SAMPLING DEVIATIONS

Parameter Run

CAT-RT (Version BP)Page 7 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 10 of 42

Duct Characteristics Location of Sampling Platform

Platform Details

Sampling Location / Platform Improvement Recommendations

-

-

Sufficient working area to manipulate probe and operate the measuring instruments

Type3.40

Parameter

There are no obstructions present which hamper insertion of sampling equipment

(Page 6 of 7)

Permanent

Safe Access Available

Value

Platform has 2 levels of handrails (approx. 0.5m & 1.0m high)

Executive Summary

cm

Inside / Outside

Yes

-

Units

Sample Port Size

Circular

Value

Vertical

Yes

Width

All platforms should be designed in accordance with the requirements in EPA Guidance Note AG1 and EN 15259.

General Platform Information

Permanent / Temporary Platform

-

m²m

Yes

9

Platform has vertical base boards (approx. 0.25m high)YesYes

SUITABILITY OF SAMPLING LOCATION

Outside

Irish EPA Technical Guidance Note AG1 / EN 15259 Platform Requirements

Port Depth

YesYes

Platform has chains / self closing gates at top of ladders

Value

m

9.08

Orientation of Duct

Area

4" BSP

Easy Access Available

Depth

EN 15259 Homogeneity Test Requirements

Sampling Plane Validation Criteria (from EN 15259)

-

-

-

-

-

--m/s

Maximum Angle of Swirl Yes

--Units

-

-

-

No Local Negative Flow

Mean Velocity> 5 Pa Yes

- --8 -°

--

There is no requirement to perform a EN 15259 Homogeneity Test on this Stack.

267.0

- Compliant

Yes

All platforms should be designed in accordance with the requirements in EPA Guidance Note AG1 and EN 15259.

Criteria in EN 15259

0.001.10

-

Ratio of Above : 1 Yes< 15°

-

-

< 3 : 10.00

--

Traverse 1

m/s-

Lowest Gas Velocitym/s

-

22.64-

-

Required

--23.69

Pa

-

Yes

Highest Gas Velocity

--

Lowest Differential Pressure

24.82

--

0.00

-

0.00

CAT-RT (Version BP)Page 8 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 11 of 42

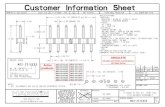

Photo 2

PLANT PHOTOS

(Page 7 of 7)

Photo 1

Photo 4Photo 3

Executive Summary

SAMPLE POINTS

where = isokinetic point sampled at

= isokinetic point not sampled at

= combustion gases sample point= non-isokinetic sample point

Line B

Line A

B1

A1

B2

B3

B4

B5

B6

A2A3A4A5

A6

CAT-RT (Version BP)Page 9 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 12 of 42

APPENDIX 1 - Stack Emissions Monitoring Personnel, List of Equipment & Methods and Technical Procedures Used

APPENDIX 2 - Summaries, Calculations, Raw Data and Charts

APPENDIX CONTENTS

APPENDICES

CAT-RT (Version BP)Page 10 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 13 of 42

Bioaerosols Temperature Logger -Electronic Refrigerator -

StopwatchServomex 4900

-CAT 19.1

Position

CAT 3.27SELECT Horiba Model (2)

MM13 1259 TE1 TE2 TE3 TE4Technician James Magann MCERTS Level 2 MM13 1330 TE1

-

Digital Manometer (2)

Box Thermocouples (2)Box Thermocouples (1)

-

Equipment Type

-

-

-

MKS MG2030

CAT 21S.46

CAT 7.15

Miscellaneous Items

Digital Temperature Meter

Heated Probe (3) -CAT 6.44

Eco Physics CLD 822Mh

Stack Thermocouple (1)

Gasmet Sampling SystemCAT 5.13Heated Probe (2)

500g / 1Kg Check WeightsLast Impinger ArmCallipers

- 20m Heated Line (1)

Bernath 3006 FID --

- 1m Heated Line (2)

CAT 11.53SELECT Logger 2 -

Dual Channel Heater Controller -CAT 17.1-

ABB AO2020-URAS26

MCERTS Number

Equipment Type

Control Box DGM (2)

-

Donal O Faogain MCERTS Level 2

Mass Flow Controller (2) CAT 6.45 -

Stack Thermocouple (3)Stack Thermocouple (2)

Equipment I.D.

STACK EMISSIONS MONITORING PERSONNEL

APPENDIX 1

15m Heated Line (1)

JCT JCC P1 Cooler

CAT 13.22

Mass Flow Controller (1)

Extractive Sampling

LIST OF EQUIPMENT

-

-

Umbilical (2) Servomex 5200MP

-

CAT 17.1 CAT 25.12

Tubes Kit Thermocouple -

CAT 20.124

Heated Probe (1)

--

-

CAT 3.62-

Mass View (2)

CAT 12.66

CAT 19.9-

M&C PSS

BarometerUmbilical (1)

Hioki 5031 (mA)

Technical Endorsements

Team Leader

Equipment Type

CAT 4.695

5m Heated Line (1) -

Site BalanceMass View (1) CAT 25.11

20m Heated Line (2)

Oven Box (1)

CAT 20.124

-

S-Pitot (1)

L-Pitot-

Equipment I.D.Digital Manometer (1)Horiba PG-250

MCERTS Accreditation

Single Channel Heater ControllerLaboratory Balance CAT 1.18 / 1.18aTape Measure CAT 16.94

Equipment I.D.

1m Heated Line (3)

Control Box DGM (1)

CAT 23.3

Instrumental Analysers

S-Pitot (2) -

-

CAT 14.53

Name

CAT 3.27

Oven Box (2)CAT 19.4 1m Heated Line (1)

METHODS & TECHNICAL PROCEDURES USED

Velocity & Vol. Flow Rate

Nitrous Oxide CAT-TP-22(b)CAT-TP-22(b)

CAT-TP-21

EN 16911-1 (MID) CAT-TP-41

CAT-TP-22(b)CAT-TP-22(b)

Oxides of Nitrogen (as NO₂)

EN 14790EN 14789

Water VapourSulphur Dioxide

Parameter

Total Particulate MatterWater VapourOxygen

EN 13284-1

Technical ProcedureStandard

CAT-TP-01

TGN M22TGN M22TGN M22TGN M22

CAT-TP-05

CAT-RT (Version BP)Page 11 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 14 of 42

General Stack Details

Stack Gas Composition & Molecular Weights

CO₂ (Estimated)

O₂

Moisture (H₂O)

Where: p = M / 22.41

pi = r x p

Calculation of Stack Gas Densities

Stack Diameter / Depth, D

0.84

Value

3.40

101.2

Average Stack Gas Temperature, Ta

-0.414

-

Units

Pa

m²

PRELIMINARY STACK SURVEY: CALCULATIONS

°C

Average Stack Static Pressure, Pstatic

Stack Area, A

292.5

9.08mStack Width, W

163.1

Average Barometric Pressure, Pb

m

Stack Details (from Traverse)

APPENDIX 2

0.05

Average Stack Gas Pressure

21.3395.43

-

Volume

Average Pitot Tube Calibration Coefficient, Cp

ppm kg/m³Conc

0.06438-0.9543 28.01

1.9635

kg/m³

kPakPa

0.00118

Conc

MWet

r% v/vFraction

DensityDry

0.17145

4.51 32.00

Conc

0.2133

3.550.06

N₂1.4277

Molar Conc

1.1927375.0718.02

0.0006

p pi

MassComponent

--

0.0451-

0.8037

% v/v

44.01

-1.2498

Calculation of Stack Gas Densities

Where: P STD = sum of component concentrations, kg/m³ (not including water vapour)

P STW = sum of all wet concentrations / 100 x density, kg/m³ (including water vapour)

P Actual = P STD x (TSTP / (PSTP)) x ((Pstatic + Pb) / Ta)

P ActualW (at each sampling point) = P STW x (Ts / Ps) x (Pa / Ta)

Calculation of Stack Gas Volumetric Flowrate, Q

Gas Volumetric Flowrate (from Traverse)

Average Wet Density (Actual), P ActualW

kg/m³

ResultUnits

kg/m³

m³/hr

Total Pressure

kg/m³

kPa

1.258Dry Density (STP), P STD

Determinand

417210

kg/m³

m³/hr

Result

°C

m³/hr

REF ¹

Oxygen (Dry)

0.723

Dry Density (Actual), P Actual

m³/hrGas Volumetric Flowrate (STP, Dry)

21.33

Units

Gas Volumetric Flowrate (Actual)

-0.0

Actual

4.5

101.3163.1100.8

Temperature

%

Units

0.00

0.784

Wet Density (STP), P STW

Gas Volumetric Flowrate REF ¹

%

Gas Volumetric Flowrate (STP, Wet)

Moisture

379499

Duct gas flow conditions

482402774532

1.161

6.0

CAT-RT (Version BP)Page 12 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 15 of 42

Parameter Parameter

Date of Survey Initial Pitot Leak CheckTime of Survey Final Pitot Leak CheckAtmospheric Pressure Orientation of DuctAverage Stack Static Pressure Pitot Tube, Cp

Result of Pitot Stagnation Test Number of Lines AvailableAre Water Droplets Present? Number of Lines UsedDevice Used

0.725

279.0

Wet Density

Pa 0.84

S-Type Pitot with KIMO MP 200 (500Pa)

-414 -22

29/09/2016

Value

-

Units

-

(1 of 1)

Depth

-

Velocity

Units

APPENDIX 2

∆P Temp°

162.0

48.0

288.02.1

0.723

-

-

Traverse

0.723

101.2

Pass

∆P

-

Sampling Line A

0.7235163.0163.0

-418.0

2.0

0.723

0.723

287.0

2.90

4.0293.0

24.00

23.570.09

23.72

1

0.723163.00.50

163.0 1.0

0.723

kg/m³Point

162.0

24.20

282.0

304.023.72

23.17

2.63

20.725

0.77

Temp

5.0

°C

299.0

2.0

°

282.0279.0

m/s°C-409.0

162.0

305.0

Mean

0.28

163.0

4.03

163.1

23.4924.20

23.24

0.723

PRELIMINARY STACK SURVEY: VELOCITY TRAVERSE TO EN 16911-1 (MID)

Swirl

Vertical

Pass

0.725

m/sPa

0.725

m

23.966.0

kg/m³STATIC (Units: Pa)

Value

6.0

Sampling Line B

Pa

163.0300.0

83.12

-

0.722

2.0

08:25 - 08:45

4.0

23.3823.82

163.0 0.723

5.09 23.1724.30 4.0 164.0

24.8224.16

23.47

284.0

163.0

10

0.723

24.07

164.0

2.246

164.03.0

295.0 164.0

301.0 0.7220.722

0.7220.722

5.0

71.0

164.0

5.0267.0

307.0279.0

164.00.722

321.0 163.04.0293.0

3.31

22.64

305.0

289.4 163.1

0.723

295.6

Pass

1.16

23.2423.82

3.0

0.72323.12

163.0

162.0

kPa

-

Wet Density

-

VelocitySwirl

No

- - --

--

- ----

-

-

---

-

-

-

-

-

-

--

-

-

-- --

- -

-- - ---

--

--

--

-

-

--

-

-

- -

-

---

-

----

-

----

-------

--

CAT-RT (Version BP)Page 13 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 16 of 42

3.548- 0.047

u(φO₂,d) 0.138

u(φCO₂,w) 0.002

5.667

(1 of 1)

Standard uncertainty associated with the local velocities

u(Cf)

u(cal) 8.908

u(φO₂,w)

-Pa

m/s

-

u(φCO₂,d) 0.002

-u(M) 0.00011

0.241u(v)

APPENDIX 2

u(φH₂O) 1.088

-

u(ρ) 0.00390

Standard Uncertainty on the coefficient of the Pitot Tube

PRELIMINARY STACK SURVEY: VELOCITY TRAVERSE TO EN 16911-1 (MID) - MEASUREMENT UNCERTAINTY

Performance characteristics (Uncertainty Components)

Standard uncertainty associated with the stack temperature

Standard uncertainty associated with the mean velocity

- Resolution- Calibration

- Water Vapour- Oxygen, wet- Carbon Dioxide, wet

- φCO₂,w- Oxygen, dry- Carbon Dioxide, dry

u(fit) 22.118

Standard Uncertainty associated with the mean local dynamic pressures u(∆pi)

Standard uncertainty associated with the mean velocity (95% Confidence) m/sUc,rel(v) 0.74

0.175

UnitsValueUncertainty

- Atmospheric Pressure

u(drift) 0.083

Ku(pc) 175.738

0.119

u(Tc) 2.225

u(k) 0.005Pa

u(res) 0.00087

31.111

0.089Uc(v)

Standard uncertainty associated with the mean velocity (95% Confidence), relative

Standard uncertainty associated with the absolute pressure in the duct

- Drift- Lack of Fit- Overall corrections to dynamic measurementsStandard uncertainty associated with the molar mass of the gas- φO₂,w

%

- Static PressureStandard uncertainty associated with the density in the duct

u(vi)

Pau(patm) 175.692u(pstat) 4.007

- u²(a)/a²- u²(qV,w)/q²V,w

-35523.0 m³/hr

- u²(qV,w)

Uc,rel(v) 0.74Standard uncertainty associated with the volume flow rate (95% Confidence)Standard uncertainty associated with the mean velocity (95% Confidence), relative

- u(qV,w)Standard uncertainty associated with the volume flow rate (95% Confidence), relative

0.00053-

Uc(qV,w)

0.00055- 328479425- 18124.0

Uc,rel(qV,w) 4.59

%

%

CAT-RT (Version BP)Page 14 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 17 of 42

Sample Runs

- -

- -

- -

- -

- -

- -

- -

- -

Blank Runs

- -

APPENDIX 2

20067.5

mg/m³ 48.10

Run 1

Maximum

Mean

1512.2

1.03 1.03±% v/v

Parameter Units

Run 1

Water Vapour

Concentration

Mass Emission

19.62% v/v

g/hr 20067.5

1512.2

Parameter Units

Uncertainty ±g/hr

Edenderry Power Ltd, Edenderry

Mean

19.62

TOTAL PARTICULATE MATTER: RESULTS SUMMARY

A1-1 Main Boiler

Parameter

48.10

Blank 1

Uncertainty

Uncertainty ±mg/m³ 2.88 2.88

Units

- -

General Sampling Information

FORMAT: Number Used / Number Required

FORMAT: Number Used / Number Required

Reference Conditions

Reference Conditions are: 273K, 101.3kPa, dry gas, 6% oxygen.

mg/m³ 0.09

A1, A2, A3, A4, A5, A6, B1, B2, B3, B4, B5, & B6

2 / 2Number of Sampling Points Used 10 / 10

TitaniumFilter Housing Material TitaniumProbe Material

Standard

NOTE: Where the Balance Uncertainty / Limit of Detection is higher than the Blank concentration, the Balance Uncertainty / Limit of Detection concentration has been reported.

47mm Glass Fibre

0.09

Parameter

EN 13284-1

Sample Point I.D.'s

Number of Sampling Lines Used

CAT-TP-01

Value

Filter Size and MaterialIn Stack

Technical Procedure

Concentration

Positioning of Filter

CAT-RT (Version BP)Page 15 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 18 of 42

Absolute pressure of stack gas, Ps

Volume of water vapour collected, Vwstd

Volume of gas metered dry, Vmstd

Moisture content, Bwo & Rwv

Bwo as a percentageReported Water Vapour, checked with Tables in EN 14790, RwvVolume of gas metered wet, Vmstw

Volume of gas metered at Oxygen Reference Conditions, Vmstd@X%O₂ & Vmstw@X%O₂

755.9

- 0.91

NoIED & Incinerates Hazardous Material? (Yes = no positive O₂ correction)

Bwo = Vwstd / (Vmstd + Vwstd) 0.1962

3.56

0.86

m³

m³

Average pressure drop across orifice, ∆H

Total mass collected in impingers (silica trap)

mmHg

g

759.0mmHg

62.5

Run 1

-1.6189

g

TOTAL PARTICULATE MATTER: ISOKINETIC SAMPLING CALCULATIONS

Test Units

Total mass collected in impingers (liquid trap)104.7

Stack static pressure, Pstatic

Ps = (Pb + (Pstatic / 13.6)

Barometric pressure, Pb

282.1

mmH₂O

0.3515

Volume of gas sample through gas meter, Vm m³Gas meter correction factor, Yd

177.4g

% v/v

1.7916

-

Vmstw = (Vmstd)(100/(100 - Rwv))

% wet oxygen measured in gas stream, ACT%O₂w

% v/v 6.00% dry oxygen measured in gas stream, ACT%O₂d

O₂ Reference Factor dry (O₂REFd) = (21 - REF%O₂) / (21 - ACT%O₂d)V = (V ) / (O₂ ) m³ 2.0834

-

APPENDIX 2

mmH₂O

% oxygen reference condition, REF%O₂

1.4401

0.935015.3

Vwstd = (0.001246)(Vlc)

Average dry gas meter temperature, Tm °C

Total mass of liquid collected, Vlc

% v/v% v/v

m³

Vmstd = ((0.3592)(Vm)(Pb + (∆H/13.6))(Yd)) / (Tm + 273)

-41.7

m³

% v/v

O₂ Reference Factor wet (O₂REFw) = (21 - REF%O₂) / (21 - ACT%O₂w)

19.6219.62

4.52

Molecular weight of dry gas stream, Md

CO₂ (Estimated)

O₂

Molecular weight of stack gas (wet), Ms

Total flow of stack gas: Actual (Qa), Wet (Qstw), Dry (Qstd), Wet@O₂REF (QstwO₂), Dry@O₂REF (QstdO₂)

Percent isokinetic, %I

g/gmol 28.19N₂

Pitot tube velocity constant, Kp

-34.97

0.3592

m³

g/gmol 26.19

-

0.06

15199.7

°C

Ms = Md(1 - (Rwv/100)) + 18(Rwv/100)

Average stack gas temperature, Ts

m³/min

Average square root of velocity heads, √∆P

m³/min

103.0

m/s

Area of stack, As m²

5.97

Qstw = ((Qa)(Ps)(Cf)) / ((Ts) + 273)Conversion factor (K/mm.Hg), Cf

Vs = ((Kp)(Cp)(√∆P)(√Ts + 273)) / (√(Ms)(Ps)) 27.90

mm

min 60%

Average of velocity heads, ∆Pavg mmH₂O

Total sampling time, q

9.08

m³/min 7557.010932.2

QstdO₂ = ((Qa)(Ps)(Cf)(1 - (Rwv/100))) / ((Ts) + 273) / (O₂REFd)

m³/minQa = (60)(As)(Vs)

4.52

Velocity of stack gas, Vs

Velocity pressure coefficient, Cp

41.676.45

28.00

166.0

-

Nozzle diameter, Dn

% v/v 4.58

0.83

Vmstw@X%oxygen = (Vmstw) / (O₂REFw) m³ 2.0834

% v/vMd = 0.44(%CO₂)+0.32(%O₂)+0.28(%N₂)

% v/v

1.5820Vmstd@X%oxygen = (Vmstd) / (O₂REFd)

QstwO₂ = ((Qa)(Ps)(Cf)) / ((Ts) + 273) / (O₂REFw)

%I = (4.6398E⁶)(Ts+273)(Vmstd) / (Ps)(Vs)(An)(q)(1 - (Rwv/100))

% v/v

mm²

Qstd = ((Qa)(Ps)(Cf)(1 - (Rwv/100))) / ((Ts) + 273)

95.42

√mmH₂O

Nozzle area, An

m³/min

Total

8301.4

9401.4

CAT-RT (Version BP)Page 16 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 19 of 42

Sample Runs

Filter I.D. Number

Probe Rinse I.D. Number

Where: ISO stands for Manual Isokinetic Sampling Train

Blank Runs

Start Probe Rinse Mass

0.00534

Sampling Device

47-36467

Sampling Times

Average Volume Sampled (REF)

Total Mass on Filter

mg/m³0.09

Units

PR-47-36467g

g

1.5820

0.07075-

ISO

TOTAL PARTICULATE MATTER: SAMPLING DETAILS

2.980592.97525

76.09

-

End Probe Rinse Mass

48.10

Blank Dates

Balance Uncertainty / LODCalculated Concentration

29/09/2016

1.5820

Start Filter Mass

Run 1

Parameter Units

End Filter Mass

-

Parameter

Blank 1

Total Mass Collected

-

mg/m³

m³

Sampling Dates

g0.148970.21972

Total Mass in Probe Rinse

08:48 - 09:48

APPENDIX 2

-

gg

-Volume Sampled (REF) m³

mg

g

29/09/2016

Filter I.D. Number

Probe Rinse I.D. Number

0.14688Total Mass on Filter

Average Volume Sampled (REF)-

3.09039

mg -0.10

0.09Calculated Concentration

1.5820

g

Balance Uncertainty / LOD

Start Filter Mass

-0.06

0.14699

-g

47-36466

PR-47-36466

mg/m³

m³

gEnd Filter Mass

mg/m³

Total Mass in Probe Rinse

Start Probe Rinse Mass

g

End Probe Rinse Mass

-0.00011

0.00001g

3.09038

Total Mass Collectedg

CAT-RT (Version BP)Page 17 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 20 of 42

Sample Runs

MU Acceptable

95 - 115

Post-Sampling Leak Rate

Leak Test Results

Yes

Isokinetic Variation

Yes

Run 1

TOTAL PARTICULATE MATTER: QUALITY ASSURANCE

Run 1

%

l/min 0.13

Are Water Droplets Present

l/minLeak Test Acceptable -Allowable Leak Rate

Units Run 1

Mean Sampling Rate l/min 25.23

Measurement Uncertainty (MU)

Silica Gel (Concurrent Water Vapour) Units

Allowable Isokinetic Range %

Allowable MU

(PAGE 1 OF 2)

%

103.0

- No

- Yes

Water Droplets

%

Units

%

5.2

0.50

%

Isokineticity Acceptable

20

APPENDIX 2

Isokinetic Criterion Compliance

Units

Pre-Sampling Leak Rate l/min 0.11

Run 1

Less than 50% Faded

Units

Yes

Run 1

MU (Concurrent Water Vapour)

Test Conditions Units

Allowable Weighing Uncertainty

180

0.25

Weighing Uncertainty Criteria

160Post-Conditioning Temperature

Run 1

± mg/m³

Weighing Uncertainty Acceptable

Yes

ELV [Daily ELV for IED] mg/m³ 50.00

Ambient Temperature Recorded? -

0.16

166

-

Units

Yes

Units Run 1

Run 1

°C

mg/m³ 2.50

Filter Temperatures

°C

Overall Weighing Uncertainty± mg

Pre-Conditioning Temperature °C

Overall Weighing Uncertainty

Maximum Filter Temperature

CAT-RT (Version BP)Page 18 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 21 of 42

Blank Runs

Method Deviations

1

wx

- - - - -

Units Blank 1

APPENDIX 2

mg/l

Run Number

Post-Sampling Leak Rate l/min 0.12

Yes0.50

Validity of Blank vs ELV

Leak Test Acceptable

TOTAL PARTICULATE MATTER: QUALITY ASSURANCE

Due to the restricted access, it was not possible to sample at all of the sample points on the available sampling lines.

0.12

- Yes

Blank 1

-

Leak Test Results

(PAGE 2 OF 2)

Units

Allowable Blank

l/minExpected Sampling Rate

5.0

Acetone / Water Rinse Value

mg/m³

(x = deviation applies to the associated run, wx = deviation also applies to the concurrent water vapour run)

2.7

Pre-Sampling Leak Rate

10

Allowable Leak Rate

Nature of Deviation

Acetone / Water Rinse Blank Units Blank

l/min

25.00

Allowable Blank

mg/l

-

YesBlank Acceptable

Blank Acceptable

l/min

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

CAT-RT (Version BP)Page 19 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 22 of 42

Sampled Volume (Actual)Sampled Gas TemperatureSampled Gas PressureSampled Gas HumidityLeakMass of ParticulateUncollected Mass

Sampled Volume (Actual)Sampled Gas TemperatureSampled Gas PressureSampled Gas HumidityLeakMass of ParticulateUncollected Mass

Sampled Volume (STP)LeakMass of Particulate

0.143

Measured Quantities

-

0.50≤1%

Measured Quantities Symbol

288.3

uVm m³

L 0.520.0

≤2%0.52

Symbol UnitsUncertainty in Measurement Units Sensitivity Coefficient

%

76.093

kPaHm

mg

APPENDIX 2

TOTAL PARTICULATE MATTER: MEASUREMENT UNCERTAINTY CALCULATIONS

Value Standard uncertainty

0.0324

UCM

0.5ρm 100.8

%

m

1.0

33.40

um

Run 1

76.09

Symbol

%

K 2.01.6189

mg/m³

-uL %

1.4401

-

Run 1 Requirement of Standard

Run 1

2.00 ≤2%0.69

%

Measured Quantities

Units Run 1

uTm

Uncertainty as a Percentage

%

uHm

uUCM mg -

Units

Run 1

Vm

% v/v

uρm

% 0.18

Lr mg

m³

<5% of ELV

Tm

L

Vm

0.63

≤1%% 1.00

0.14

1.00

≤1%

-0.10

Mass of ParticulateUncollected Mass

Sampled Volume (STP)LeakMass of ParticulateUncollected Mass

O₂ Correction FactorStack Gas O₂ ContentMU for O₂ Correction

Combined uncertainty

Expanded uncertainty (95% confidence), without Oxygen CorrectionExpanded uncertainty (95% confidence), with Oxygen CorrectionExpanded uncertainty (95% confidence), estimated with Method DeviationsReported Uncertainty

Expanded uncertainty (95% confidence), without Oxygen CorrectionExpanded uncertainty (95% confidence), with Oxygen CorrectionExpanded uncertainty (95% confidence), estimated with Method DeviationsReported Uncertainty

Measured Quantities

% v/v 4.52-

mg

2.88

Oxygen Correction Part of MU Budget

-0.0365

Run 1

Units

- 0.91

mg/m³

76.093

Units Run 1

mg/m³

3.03

mg/m³

Parameter Units

0.03%

mg/m³

0.0885

mg/m³ 1.253

2.88mg/m³

% 6.06.0

Overall MU For O₂ Measurement

5.2

0.63

%

%

-0.06

Lr mg

2.48

2.88

Measured Quantities

0.1431

mg/m³

UCM

Run 1

0.63

Uncertainty in Result

mg/m³ 1.26

% 6.0

mg/m³

CAT-RT (Version BP)Page 20 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 23 of 42

Sample Runs

- -

- -

- -

General Sampling Information

NOTE: Dilution performed to achieve correct span value

Span Gas Type Synthetic Air (5 Grade)

Run 1

Value

Standard EN 14789Technical Procedure CAT-TP-21

Probe Material Stainless SteelFiltration Type / Size

Parameter

Span Gas Expiry Date 14/09/2021Span Gas Start Pressure (bar) 100Gas Cylinder Concentration (% v/v) 21.22

Parameter

Span Gas Reference Number

Span Gas Uncertainty (%) 2

180°C

MeanUnits

11.0256

Uncertainty ±% v/v 0.38 0.38

0.1µm Glass Fibre

Concentration % v/v 4.51 4.51

Heated Line TemperatureHeated Head Filter Used Yes

Edenderry Power Ltd, EdenderryA1-1 Main Boiler

APPENDIX 2

OXYGEN: RESULTS SUMMARY

FORMAT: Number Used / Number Required

FORMAT: Number Used / Number Required

Span Gas Uncertainty (%) 2Zero Gas Type

Number of Sampling Lines Used 1 / 1

Nitrogen (5 Grade)

Number of Sampling Points Used 1 / 1

Sample Point I.D.'s A2

CAT-RT (Version BP)Page 21 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 24 of 42

Graphical Trend of Data

OXYGEN: DATA TREND

APPENDIX 2

COVER ME WITH CHART/S

0.0

1.0

2.0

3.0

4.0

5.0

6.0

08:5

0

08:5

2

08:5

4

08:5

6

08:5

8

09:0

0

09:0

2

09:0

4

09:0

6

09:0

8

09:1

0

09:1

2

09:1

4

09:1

6

09:1

8

09:2

0

09:2

2

09:2

4

09:2

6

09:2

8

09:3

0

09:3

2

09:3

4

09:3

6

09:3

8

09:4

0

09:4

2

09:4

4

09:4

6

09:4

8

Conc

entr

atio

n (%

v/v

)

Oxygen Oxygen

- Run 1

CAT-RT (Version BP)Page 22 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 25 of 42

Sampling Details

Quality Assurance

Zero Drift 0 0 0

Zero Drift 0 0 0

Zero Drift 0 0 0

Zero Down Sampling Line (Post)

% v/v

CAL

2 Zero Down Sampling Line (Pre) % v/v

CAL

3

N/A

- 08:50 - 09:49

Parameter Units Run 1

Sampling Times

Average Temperature

Span Gas Value

-0.06

Zero Down Sampling Line (Pre) % v/v

Conditioning Unit Temperature Units Run 1

Instrument Range % v/v 25

CAL

1 Zero Down Sampling Line (Pre) % v/v

°C N/A

YesZero Drift Acceptable

Temperature Acceptable - N/A

Units Run 1

Allowable Temperature < °C

0.06Zero Down Sampling Line (Post) % v/v 0.00

Zero Down Sampling Line (Post)

% v/v

OXYGEN: SAMPLING DETAILS & QUALITY ASSURANCE

% v/v 5.00

% v/v

% v/v

-Allowable Zero Drift ± % v/v 0.25

Zero Drift

Sampling Dates - 29/09/2016

% v/v

APPENDIX 2

Span Drift 0 0 0

Span Drift 0 0 0

Span Drift 0 0 0

Method Deviations

1

x

- - -

- - -

- - -

Span Drift Acceptable - Yes

Test Conditions Units Run 1

Run Ambient Temperature Range °C 14 - 19

Run 1

Span Down Sampling Line (Post) % v/v

% v/v

Span Drift Units

Run Number

% v/v

CAL

3

(x = deviation applies to the associated run)

There are no deviations associated with the sampling employed.

Nature of Deviation

Span Down Sampling Line (Post) % v/vSpan Down Sampling Line (Pre) % v/v

4.824.84

% v/v

Allowable Span Drift ± % v/v 0.25

CAL

2 Span Down Sampling Line (Pre) % v/vSpan Down Sampling Line (Post) % v/v

CAL

1 Span Down Sampling Line (Pre)

% v/v 0.02

CAT-RT (Version BP)Page 23 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 26 of 42

% rangeDependence on voltage 0.02 % full scale/10VLosses in the line (leak) 1.60 % of value

0.01 %vol

% of full scale

%vol%vol

Atmospheric pressure dependence

Combined interference 0.56

Uncertainty of calibration gas 2.00

Standard deviation of repeatability at zero use rep at span %volStandard deviation of repeatability at span level

N/A %vol6.0 %

0.02

Atmospheric pressure dependence 0.30 % of value/kPaVolume or pressure flow dependence 0.20

Ambient temperature dependence

Combined interference (from MCERTS Certificate) 0.08 %vol

RUN 1 Units

-0.07 % full scale/10K

Lack of fit 0.00 %volDrift -0.14 %volVolume or pressure flow dependence 0.00

Ambient temperature dependence -0.01 %vol

Deviation from linearity% full scale

Span drift 0.41 % full scale

0.03 % of valueZero drift -1.24

Number of readings in measurement 60 -Repeatability at zero 0.04Repeatability at span level 0.04 % full scale

Range Used 25.0 %volCal gas conc. 21.2 %vol

Performance characteristics

4.51 %vol

% full scale

secondsResponse time 60

Performance characteristics RUN 1 Units

Measured concentrationTGN M2 Allowable MULimit value

% of value

Performance characteristic RUN 1 Units

APPENDIX 2

OXYGEN: MEASUREMENT UNCERTAINTY CALCULATIONS

k =

%volCombined uncertainty

Expanded uncertainty (no O₂) - at 95% Confidence 8.50 % of ValueResult of Compliance with Uncertainty Requirement in M2 COMPLIANT -

Expanded uncertainty 1.96 0.38 %vol

RUN 1 Units

Requirement for SRM is that Uncertainty should be 0.5%vol absolute or 6% relative whichever is the lower, on a dry gas basis. Ref EA TGN M2.

Combined interference (from MCERTS Certificate) 0.08Dependence on voltage 0.00 %volLosses in the line (leak) 0.04 %volUncertainty of calibration gas 0.05 %vol

RUN 1 UnitsMeasurement uncertainty Result 4.51

0.20 %vol

CAT-RT (Version BP)Page 24 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 27 of 42

Sample Runs

- -

- -

- -

- -

- -

General Sampling Information

Sample Cell Temperature (°C)

±g/hr

Yes

Value

101.8Sample Cell Pressure (mbar)

Technical Procedure CAT-TP-22(b)

191

200.02

Uncertainty

APPENDIX 2

OXIDES OF NITROGEN (AS NO₂): RESULTS SUMMARY

Edenderry Power Ltd, Edenderry

Sampling System Path Length (m)

A1-1 Main Boiler

9.42

Standard TGN M22

Heated Head Filter Used

9.42

Mass Emission g/hr 83448.7

Parameter

Stainless Steel

83448.7

mg/m³ 200.02

Uncertainty ±mg/m³

5486.4 5486.4

5.11

Analysis Areas (Wave Number Limits) 1875 - 2138 & 2700 - 2950

Units Run 1

Concentration

Mean

Parameter

Probe MaterialFiltration Type / Size 0.1µm Glass Fibre

FORMAT: Number Used / Number Required

FORMAT: Number Used / Number Required

References Used in Analytical Algorithm Application

Reference Conditions

Reference Conditions are: 273K, 101.3kPa, dry gas, 6% oxygen.

Concentration of References

20, 40, 60, 81.3, 100, 200, 300, 398, 500, 1000, 1500, 2058

Number of Sampling Points Used

180°C

Nitrogen (5 Grade)

12.0059

Gas Cylinder Concentration (ppm)Check Gas Start Pressure (bar)

Instrument Specific

Sample Point I.D.'s A3

Yes

150

Number of Sampling Lines Used 1 / 1

411.5Check Gas Uncertainty (%)

1 / 1

Check Gas Type NO

Type of Reference

09/08/2018

Heated Line TemperatureHeated Head Filter Used

2Zero Gas Type

Check Gas Reference NumberCheck Gas Expiry Date

CAT-RT (Version BP)Page 25 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 28 of 42

Graphical Trend of Data

APPENDIX 2

OXIDES OF NITROGEN (AS NO₂): DATA TREND

COVER ME WITH CHART/S

0.0

50.0

100.0

150.0

200.0

250.0

08:5

0

08:5

2

08:5

4

08:5

6

08:5

8

09:0

0

09:0

2

09:0

4

09:0

6

09:0

8

09:1

0

09:1

2

09:1

4

09:1

6

09:1

8

09:2

0

09:2

2

09:2

4

09:2

6

09:2

8

09:3

0

09:3

2

09:3

4

09:3

6

09:3

8

09:4

0

09:4

2

09:4

4

09:4

6

09:4

8

Conc

entr

atio

n (m

g/m

³)

Oxides of Nitrogen (as NO₂) At Reference Conditions

- Run 1

CAT-RT (Version BP)Page 26 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 29 of 42

Lack of FitZero DriftSpan DriftSensitivity to Atmospheric PressureSensitivity to Sample Gas PressureSensitivity to Ambient TemperatureSensitivity to Electrical VoltageInterferentsStandard Deviation of Repeatability at ZeroStandard Deviation of Repeatability at SpanUncertainty of Certified Reference Material

Combined Uncertainty

Expanded Uncertainty (ppm)Expanded Uncertainty (%age of Reading)

RUN 1 Measured (ppm) 84.34Oxides of Nitrogen (as NO₂) NOx (as NO₂) NOx (as NO₂) Range (ppm) 80Source of Uncertainty Value (±%) Probability Distribution

OXIDES OF NITROGEN (AS NO₂): MEASUREMENT UNCERTAINTY CALCULATIONS

APPENDIX 2

Divisor Conversion Factor ui | ppm0.75 rectangular √3 0.843427963 0.3650.50 rectangular √3 0.8 0.2312.00 rectangular √3 0.8 0.924N/A rectangular √3 N/A 0.000N/A rectangular √3 N/A 0.0000.34 rectangular √3 0.32 0.063-0.08 rectangular √3 0.2 -0.008-3.20 rectangular √3 0.8 -1.4780.10 normal 1 0.8 0.080N/A normal 1 N/A 0.0002.00 normal 2 0.843427963 0.843

- normal - - 1.987

- t-distribution (k=2) - - 3.973- t-distribution (k=2) - - 4.71

CAT-RT (Version BP)Page 27 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 30 of 42

Sample Runs

- -

- -

- -

- -

- -

General Sampling Information

Parameter Value

5.11Sample Cell Temperature (°C)

Uncertainty

Uncertainty ±g/hr 398.4

Yes

0.18

0.95

Mass Emission

Sampling System Path Length (m)

101.8

g/hr 73.2

±mg/m³

TGN M22Technical Procedure

191

Filtration Type / Size

398.4

Sample Cell Pressure (mbar)

Analysis Areas (Wave Number Limits) 2000 - 2222 & 2540 - 2590

Standard

0.1µm Glass Fibre

0.95

73.2

Stainless SteelProbe Material

Heated Head Filter Used

mg/m³ 0.18Concentration

Run 1Units

CAT-TP-22(b)

APPENDIX 2

NITROUS OXIDE: RESULTS SUMMARY

Mean

Edenderry Power Ltd, EdenderryA1-1 Main Boiler

Parameter

FORMAT: Number Used / Number Required

FORMAT: Number Used / Number Required

References Used in Analytical Algorithm Application

Reference Conditions

Reference Conditions are: 273K, 101.3kPa, dry gas, 6% oxygen.

Concentration of References

180°CYes

Heated Line Temperature

1 / 1

12.0059Check Gas Expiry Date 09/08/2018

Check Gas Type

411.5

NO

150

Number of Sampling Lines Used

Heated Head Filter Used

Check Gas Reference Number

Check Gas Uncertainty (%)

Sample Point I.D.'s A3

Type of Reference

1 / 1Number of Sampling Points Used

Gas Cylinder Concentration (ppm)2

Check Gas Start Pressure (bar)

Instrument Specific 10, 20, 40, 60, 81.3, 100, 200, 300, 398, 500, 1000, 1500, 2058

CAT-RT (Version BP)Page 28 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 31 of 42

Graphical Trend of Data

COVER ME WITH CHART/S

NITROUS OXIDE: DATA TREND

APPENDIX 2

0.0

0.0

0.0

0.1

0.1

0.1

0.1

0.1

0.2

0.2

0.2

08:5

0

08:5

2

08:5

4

08:5

6

08:5

8

09:0

0

09:0

2

09:0

4

09:0

6

09:0

8

09:1

0

09:1

2

09:1

4

09:1

6

09:1

8

09:2

0

09:2

2

09:2

4

09:2

6

09:2

8

09:3

0

09:3

2

09:3

4

09:3

6

09:3

8

09:4

0

09:4

2

09:4

4

09:4

6

09:4

8

Conc

entr

atio

n (m

g/m

³)

Nitrous Oxide At Reference Conditions

- Run 1

CAT-RT (Version BP)Page 29 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 32 of 42

Lack of FitZero DriftSpan DriftSensitivity to Atmospheric PressureSensitivity to Sample Gas PressureSensitivity to Ambient TemperatureSensitivity to Electrical VoltageInterferentsStandard Deviation of Repeatability at ZeroStandard Deviation of Repeatability at SpanUncertainty of Certified Reference Material

Combined Uncertainty

Expanded Uncertainty (ppm)Expanded Uncertainty (%age of Reading)

APPENDIX 2

0.82 rectangular √3 0.000772911 0.00040.50 rectangular √3 0.1 0.02892.00

NITROUS OXIDE: MEASUREMENT UNCERTAINTY CALCULATIONS

RUN 1 Measured (ppm) 0.08Nitrous Oxide N₂O N₂O Range (ppm) 10Source of Uncertainty Value (±%) Probability Distribution Divisor Conversion Factor ui | ppm

rectangular √3 0.1 0.1155N/A rectangular √3 N/A 0.0000N/A rectangular √3 N/A 0.00000.46 rectangular √3 0.04 0.01060.10 rectangular √3 0.0 0.00123.00 rectangular √3 0.1 0.17320.00 normal 1 0.1 0.0000N/A normal 1 N/A 0.00002.00 normal 2 0.000772911 0.0008

- normal - - 0.2104

- t-distribution (k=2) - - 0.4209- t-distribution (k=2) - - 544.51

CAT-RT (Version BP)Page 30 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 33 of 42

Sample Runs

- -

- -

- -

- -

- -

General Sampling Information

CAT-TP-22(b)

330.51

Run 1

Edenderry Power Ltd, Edenderry

Stainless SteelFiltration Type / Size

330.51

APPENDIX 2

SULPHUR DIOXIDE: RESULTS SUMMARY

Uncertainty ±g/hr 8981.7

A1-1 Main Boiler

Parameter

±mg/m³ 15.29

Sample Cell Pressure (mbar)

Units

8981.7

Parameter

Standard TGN M22

g/hr

Technical Procedure

Heated Head Filter Used

Mean

5.11

Yes

Mass Emission

0.1µm Glass Fibre

Analysis Areas (Wave Number Limits) CHOOSE: 1050 - 1250, 1100 - 1366 or 1200 - 1366

Probe Material

15.29

Concentration mg/m³

Uncertainty

191Sample Cell Temperature (°C)

Value

137892.9137892.9

101.8

Sampling System Path Length (m)

FORMAT: Number Used / Number Required

FORMAT: Number Used / Number Required

References Used in Analytical Algorithm Application

Reference Conditions

Reference Conditions are: 273K, 101.3kPa, dry gas, 6% oxygen.

Check Gas Expiry Date

Check Gas Type SO₂

2

Check Gas Reference Number

Gas Cylinder Concentration (ppm) 100.9

1 / 1

Sample Point I.D.'s

180°CHeated Head Filter Used

Check Gas Start Pressure (bar) 150

Yes

Type of Reference Concentration of References

09/08/2018

Check Gas Uncertainty (%)

A3

12.0059

Heated Line Temperature

Number of Sampling Lines Used

Instrument Specific 4, 8, 12, 16, 100, 200, 300, 403, 600, 1200, 1800, 2460

Number of Sampling Points Used 1 / 1

CAT-RT (Version BP)Page 31 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 34 of 42

Graphical Trend of Data

SULPHUR DIOXIDE: DATA TREND

COVER ME WITH CHART/S

APPENDIX 2

0.0

50.0

100.0

150.0

200.0

250.0

300.0

350.0

400.0

08:5

0

08:5

2

08:5

4

08:5

6

08:5

8

09:0

0

09:0

2

09:0

4

09:0

6

09:0

8

09:1

0

09:1

2

09:1

4

09:1

6

09:1

8

09:2

0

09:2

2

09:2

4

09:2

6

09:2

8

09:3

0

09:3

2

09:3

4

09:3

6

09:3

8

09:4

0

09:4

2

09:4

4

09:4

6

09:4

8

Conc

entr

atio

n (m

g/m

³)

Sulphur Dioxide At Reference Conditions

- Run 1

CAT-RT (Version BP)Page 32 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 35 of 42

Lack of FitZero DriftSpan DriftSensitivity to Atmospheric PressureSensitivity to Sample Gas PressureSensitivity to Ambient TemperatureSensitivity to Electrical VoltageInterferentsStandard Deviation of Repeatability at ZeroStandard Deviation of Repeatability at SpanUncertainty of Certified Reference Material

Combined Uncertainty

Expanded Uncertainty (ppm)Expanded Uncertainty (%age of Reading)

SULPHUR DIOXIDE: MEASUREMENT UNCERTAINTY CALCULATIONS

RUN 1 Measured (ppm) 100.17Sulphur Dioxide SO₂ SO₂ Range (ppm) 100

APPENDIX 2

Source of Uncertainty Value (±%) Probability Distribution Divisor Conversion Factor ui | ppm0.90 rectangular √3 1.001724947 0.5210.50 rectangular √3 1 0.2892.00 rectangular √3 1 1.155N/A rectangular √3 N/A 0.000N/A rectangular √3 N/A 0.000

-0.46 rectangular √3 0.4 -0.1060.10 rectangular √3 0.2 0.012-2.80 rectangular √3 1 -1.6170.23 normal 1 1 0.225N/A normal 1 N/A 0.0002.00 normal 2 1.001724947 1.002

- normal - - 2.317

- t-distribution (k=2) - - 4.633- t-distribution (k=2) - - 4.63

CAT-RT (Version BP)Page 33 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 36 of 42

Sample Runs

- -

- -

- -

General Sampling Information

Units Run 1 Mean

Concentration % v/v 23.04 23.04

5.11

Edenderry Power Ltd, Edenderry

Yes

3200 - 3401

Sampling System Path Length (m)

WATER VAPOUR: RESULTS SUMMARY

TGN M22

APPENDIX 2

Standard

Sample Cell Temperature (°C)

0.79 0.79

Parameter Value

101.8

Uncertainty % v/v

Heated Line Temperature

A1-1 Main Boiler

Parameter

Probe Material

180°C

Check Gas Type

191

Heated Head Filter Used0.1µm Glass Fibre

Stainless SteelFiltration Type / Size

C₃H₈Check Gas Reference Number 12.0059

Sample Cell Pressure (mbar)

Technical Procedure CAT-TP-22(b)Analysis Areas (Wave Number Limits)

FORMAT: Number Used / Number Required

FORMAT: Number Used / Number Required

References Used in Analytical Algorithm Application

A3

10, 20, 30, 40

Check Gas Expiry Date

Sample Point I.D.'s

83.63Check Gas Uncertainty (%)

Number of Sampling Lines Used 1 / 1

Check Gas Start Pressure (bar) 150Gas Cylinder Concentration (ppm)

Concentration of References

Number of Sampling Points Used 1 / 1

2

Instrument Specific

Type of Reference

Check Gas Reference Number 12.005909/08/2018

CAT-RT (Version BP)Page 34 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 37 of 42

Graphical Trend of Data

COVER ME WITH CHART/S

APPENDIX 2

WATER VAPOUR: DATA TREND

0.0

5.0

10.0

15.0

20.0

25.0

30.0

08:5

0

08:5

2

08:5

4

08:5

6

08:5

8

09:0

0

09:0

2

09:0

4

09:0

6

09:0

8

09:1

0

09:1

2

09:1

4

09:1

6

09:1

8

09:2

0

09:2

2

09:2

4

09:2

6

09:2

8

09:3

0

09:3

2

09:3

4

09:3

6

09:3

8

09:4

0

09:4

2

09:4

4

09:4

6

09:4

8

Conc

entr

atio

n (%

v/v

)

Water Vapour Water Vapour

- Run 1

CAT-RT (Version BP)Page 35 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 38 of 42

Lack of FitZero DriftSpan DriftSensitivity to Atmospheric PressureSensitivity to Sample Gas PressureSensitivity to Ambient TemperatureSensitivity to Electrical VoltageInterferentsStandard Deviation of Repeatability at ZeroStandard Deviation of Repeatability at SpanUncertainty of Certified Reference Material

Combined Uncertainty

Expanded Uncertainty (% v/v)Expanded Uncertainty (%age of Reading)

APPENDIX 2

WATER VAPOUR: MEASUREMENT UNCERTAINTY CALCULATIONS

RUN 1 Measured (% v/v) 23.04Water Vapour H₂O H₂O Range (%v/v) 20Source of Uncertainty Value (±%) Probability Distribution Divisor Conversion Factor ui | % v/v

0.40 rectangular √3 0.230438471 0.05320.50 rectangular √3 0.2 0.05772.00 rectangular √3 0.2 0.2309N/A rectangular √3 N/A 0.0000N/A rectangular √3 N/A 0.0000

-0.37 rectangular √3 0.08 -0.0172-0.10 rectangular √3 0.0 -0.00231.80 rectangular √3 0.2 0.20780.05 normal 1 0.2 0.0100N/A normal 1 N/A 0.00002.00 normal 2 0.230438471 0.2304

- normal - - 0.3952

- t-distribution (k=2) - - 0.7904- t-distribution (k=2) - - 3.43

CAT-RT (Version BP)Page 36 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 39 of 42

Sampling Details

Quality Assurance

0 00 0

Method Deviations

1

- - -

- - -

- - -

Value

M22 FTIR SAMPLING DETAILS & QUALITY ASSURANCE

Background / Zero Calibration Check

AU0.0050

CAL

1

29/09/2016Sampling Date

Parameter Units

Nature of Deviation

(x = deviation applies to the associated run)

°C 14 - 18⁰C

Run Number

AU -0.00390.0004

Allowable Energy in Cell ± AUMaximum Energy in Cell

-

APPENDIX 2

Run 1

Sampling Times

Test Conditions Units

Minimum Energy in Cell

(PAGE 1 OF 2)

Run 1

Run Ambient Temperature Range

- 08:50 - 09:49

Units

- - -

Interference Check

PWater Vapour

P

DAY 1

Oxides of Nitrogen (as NO₂)

Nitrous Oxide

Sulphur DioxideP

Target Parameter

P

where "P" = Pass and "F" = Fail

CAT-RT (Version BP)Page 37 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 40 of 42

Difference 0 0 0 0 0

0

Difference 0 0 0 0Drift

NOTE: Drift correction will be automatically applied to the data if the maximum check gas drift is between 2 - 5%.

ppm

Check Gas Check - Post Test

Allowable DriftYes

- Yes

Yes

%

Yes4.2

0.2 2.50.8 0.4

120120200Yes

Response Time from ASC, ASC T₉₀ s0

120

Check Gas Value 83.686.6

C₃H₈

200Yes

100.9

ppm

120

Yes Yes

(PAGE 2 OF 2)

1.3

120

REACTIVE GAS CHECK

120

Check Gas Reading - Post Test ppm

Check Gas Check - Pre Test

102.4

1200

120

ppm 99.5-1.4

3.1 0.4 2.0

103.7 99.5 86.6

Units CO

± ppm 5.120.6

Yes

101.4

Check Gas Acceptable

2.0 0.3

Allowable Difference

ppm

± % 5.0 5.0 5.0 5.0Yes

405.4 98.9408.4 104.2 101.4

29/0

9/20

16

86.8

10.1Yes

SO₂C₃H₈CO SO₂

5.0

Units

CAL

1

NO

-Drift Acceptable

Check Gas Reading - Pre Test

Yes

Check Gas Reading on Analyser

200

120

200

Response Time, T₉₀

411.598.9

SO₂

-2.0

-

1200

(performed against decreasing H₂O)

3.0

0

SO₂

405.4

200Reverse Response Time, RT₉₀

ss

Allowable Response Time

12.0059

M22 FTIR SAMPLING DETAILS & QUALITY ASSURANCE

12.0059 12.0059

60

12.0059 12.0059

CAL

1 100.9

-6.1

APPENDIX 228

/09/

2016

sResponse Time Acceptable

ppm

-

System Lag Time [ASC T₉₀ - T₉₀] s

Yes

NO

Yes

60

Check Gas Reference Number

103.7

CAT-RT (Version BP)Page 38 of 38

Edenderry Power LtdEdenderryA1-1 Main Boiler

Job Number: P0482-04CAR-16-01, Version 2Sample Date/s: 28th - 29th September 2016

Industrial Emissions Licence: P0482-04

Site Visit Report - SV08119 - Edenderry Power Limited Page 41 of 42

Summary

See report.

FOLLOW-UP ACTIONS

You are required to complete the instructions and actions, as outlined in this report, within the specified timeframe. Where required, you shall respond to actions specified in Compliance Investigations within the required timeframe. The licensee shall maintain documentary evidence, for review by the EPA, that the prescribed corrective actions were completed within the required timeframe.

You are not required to respond directly to items contained in this EPA site visit report; where an issue requires a direct response, the EPA will generate a Compliance Investigation through the EDEN system. You will receive notification when a Compliance Investigation instruction or action is generated.

Please note that this Site Visit Report will be made available for public viewing via the EPA’s Licence Enforcement Access Portal within one day of the issue date and will be published on the Licence Details Page of the EPA’s website, www.epa.ie, that relates to your licence 60 calendar days after the issue date.

You may if you choose submit, within 45 calendar days of the issue date of this Site Visit Report, a Licensee Public Response that will be published alongside the Site Visit Report. This Response, should you wish to avail of it, provides you with an opportunity to inform the public about how you are implementing the actions set out in the report, activities underway, timescales and target completion dates. Please be aware that the content of your Licensee Public Response must be factual and should not breach the EPAs stated online publication standards.

If you wish to submit a Licensee Public Response to an EPA Site Visit Report, you should do this by clicking on the ‘Make a Response’ link on the Site Visits page in EDEN. A .pdf document containing your response can be attached and submitted from here.

Please note that you are required to comply with the conditions of your licence at all times, and where noncompliance occurs you must restore compliance within the shortest possible time. These actions will be verified during subsequent EPA visits.

Please quote the above Inspection Reference Number in any future correspondence in relation to this Report.

Site Visit Report - SV08119 - Edenderry Power Limited Page 42 of 42