Site Location Map - US EPA

Transcript of Site Location Map - US EPA

Figure 2-2 Aerial Photograph of the Chevron Cincinnati Facility in March 1975.

@ Most above grade slructures were removed after 1986.

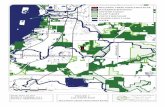

Monifonng Weii ,. . ....._... Vapor Monitoring Weii

" " Chevron ProductioniRecovsry Weii

I i

iioiizontai Soii Vapor Extiaaion Weii

'g3 Boiehoie Location (See Figure 2-51rCr

..--. s.' 0 - L? Twfisea (See Figure 2-4)

----- Chevron Cincinnati Facili* Boundary

1

300 0 160 300

SCALi IN FEET

600

I-1 Civil 8 EnvironmentalCincinnau, OHConsultants, Inc.

. . . . Pittsburgh, PA . Columbus, OH . Indianapolis, IH Nashville, TRI

DWN. BY: JK1 / SCALE: / DATE:1 AS SHOWN / A U ~2000

/ Far:ility Diagram 1 GFEVRON PRODUCTS COMPANY/ Cincinnati Faciiiw

Hoovsn Coun Ohio

/ PROJECT-NO 1 FIGLJRE-NO! 9905415 1 Fiaure 2-3

- -- -

D WEST

D' EAST

MW96S MW96D

520 -

500 -nal 9!

480 -::3

460 -% 8

440 -I-

2 nr 420 -

400 -

MW44

480

460

440

420

.- - - - - - - - - .- - - - - - - . 400

Lepend

Cincinnati Fadlity ' Hwven. Mtio

4898005 i-Figure 2-4I Interval Generalized Geologic Cross

Section, D-D' ?:and

Shale & Occasional (See Figure 2-3for Section Location)r--Z1 ~imestone Chewon Products~ompany 3

Sand Clayey Sand & Gravel

Sand and Gravel o I EnvironmentalScience &

aSilty Clay APPROXIMATESCALEINFEET Engineering, Inc. **rmc-.rs

F i

m W/lS/W ciwwm gR.,+..de pr.r2.

Permeabi l i ty vs. D e p t h - C H 2 Permeabi l i ty vs. Depth - C H 3 Permeabi l i ty vs. Depth - C H 61 I Permesbility (10E-3cmls) Permeability (10E3cmls) Permeability (10E-3c d s )

0 5 10 15 20 25 0 5 10 15 20 25 0 5 10 15 20 25 L- .--d7 0 ti---i-"&-.I

O/----L

....... ........

Permeability vs. Depth - C H 8 Permeability vs. Depth - CHI6 1 Permeability (1OE-3cmls) Permeability(10E-3c d s )

0 5 10 15 20 25 0 5 10 15 20 25 2-..-.,..--, 2 I 0 .i---..i i.-.__i

!

Figure 2-5 Permeability versus Depth from Borings CH2 - CH16.

(see Figure 2-3 for boring locations)

.....

Groundwater Corrective Meanaes Study October 26,2001

5-OF Elevation

k.;crihtion To~fioil

491.9 Br- silty clay with medim gravel (Fill)

Brow silty coarse sand, gravel and z-& fragmrnts

Dark gray silty coarse serd ad gravel (hydrocarbonodor throughom,]

Grades less silty at 23 Ft.

Large cobbles at 28 ft.

Gray cparse sand and Fine m M i -gmvel

Brarn fint sand Brm Fine m coarse sand

GrayiPih brom coarse send ad fine to d i m gravel, dense, wet with hydro- carban/watcr at 38 ft.

B r a n =dim m coarse gravel, s- send, "'et (hydracarban odor diminished st 43 Ft.1

Brom tnedim w coarse sand and Fine m m d i m gravel, same cobble lenses

B r a n Fine sand. media dewe

B r m silty coarse sane and $ravel

B r a n highly weathered shale (soFt, claye:

Gray weathered shale (very soft eMI claye:

d Sanple selected For

grain size analysis

-Y WEST O R I L L I S , I=.

Figure 2-6 Lithology Log of MW-20D

a CHEVRON ClNClNNATl FACILIN PROPERTY LINE

__---_--___--APPROXIMATE EXTENT OF I FREE-PHASE LNAPL

a

__1 ----A-.

b

MONiiORiNG WELL

CHEVRON PROOUCiiCIU RECOVERY WELL CI-EVRON PRODUCTS COMP FEEPHASE WWL " I I C ~ E S Si~ WEUS. F.

- LIQUID HWROCARBON PRESENT zone Concentrations in Groundwater - --- - = ESIIMTED M M OF DISSOLMD PHASE PLUME

NOIE: DATA P R E E N E D IN TABLE 1

HIGH WATER TABLE

PROPERTY LINE -

EXTENT OF LIQUID HYDROCARBON PLUME.

LOW WATER TABLE -

AREA OF CONCEPTUAL SITE MODEL -SEE FIGURE 2-19

ir

Figure 2-18. Site Map

CrouncIwater Corrective Meusures St~~cly Octobrr 26, 2001

LNAPL enters and Water table rises, At water table At water table floats on top of entrapping LNAPL maximum, LNAPL minimum, LNAPL the water table, at 2-phase residual may be entirely will be most

Saturation. Immobile. Mobile.

t 0.8 0.6 0.4 0.2 0

residual water

-C .-0

-2 w

0 0.2 0.4 0.6 0.8 t

S, sw Note: S, = Saturation of water, S, = Saturation of L U M L

Figure 2-20

Schematic of LNAPL Redistribution by a Fluctuating Water Table

Groundwater CorrectiveMeasures Study October 26, 2001

controlled by measuring the effluent dissolved oxygen (DO) concentrationand the

oxygen feed is set so that the effluent DO remains at 1.5 mg 02/L(see Figure 4-2).

Figure 4-2

Chevron Cincinnati GAC-FBR System Schematic

for High Water Table Operation

During fall and winter, the focus of the pump-and-treat operation shifts to free-phase

LNAPL recovery. As a result, the groundwater pumping rate may double, to 3400 gpm,

of which 860 gpm is clean oxygen canier water from PW 4 or 5. This requires that both

treatment trains be used; in essence two of the systems depicted in Figure 4-2 are

operated in parallel. At times, the system is oxygen-limited, i.e., even with the N1340

cfh oxygen generating capacity in use, the water flow rate must be reduced to meet the

1.5 mg 02/L parameter in the system effluent.

The effluent from the FBR system is conveyed to an impoundment where it is polished

before dischargeto the Great Miami River.

EXTRACTION GREAT MIAMI

WAPL-FREE

Figure 6-1. Conceptual Design of Partially-Penetrating Barriers at the Chevron Cincinnati Faclilty

. . RECOVERYlDlSPOSAL

, : . . . ,.. . ,.'

*

BASE OF MLUVlALW F E R

Figure6-2. Conceptual Deslgn of Capillary Barrier System at the Chevron Clnclnnatl Facllity

------ - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

-POTENT!AL HEAT

CONTAMINATED RECOVERY AND SOIL GAS REINJECTION

M!ZRkfAL ----iOXIDIZER AIR IN f?!. \ )

3 NOTE: A VERTICAL SVE SYSTEM IS SHOWN FOR CLARrrf. 1HORIZONTAL SVE WEUS MAY BE MORE

APPLICABLE FOR MIS sm. 8 iia

Figure 6-3. Conceptual Design of SVE at the Chevron Cincinnati Facility

SAND AND GRAVEL STRIPPED AWIFER MATERIAL I I /HYDROCARBONS I

SAND AND GRAVE!. W I F E R MATERIAL L,,,

INFLUENCE

REWIRED SVE SYSTEM NOTSHOWN;UPPER SILT ZONE NOT PRESENT E V E M E R E )

Figure 6-4. Conceptual Design of in-Situ Air Sparglng System at the Chevron Cincinnati Facility

AIR INJECTW4

TO VOC VAPOR

AIR INJECTION UNE

VOC CONTAMINATED AIR

PACKER OR DIVIDER

UPPER RECHARGE SCREEN

AIR STRIPPED

GROUNDWATER CIRCULATION ZONE

VOC CONTAMINATED GRWNDWATER

Figure 6-5. Conceptual Desi at the 8n for Groundwater Circulation Well Technology

hevron Cincinnati Facility

Extracted L

iquids

C -.O e

4 i.1

GS

.au

b--4 .2

35

$3

5 LZ h

i3 a '2

aA

A

0

C -

0

MI: .O*

* ~i .-

u

5 2

8 g

i

5 .Z

O.~

3-u

e 0 2

s a

8 Ej 0

g 3m Surfactant Injection W

ells 6 5 3 &'

9

4' +

Extracted L

iquids

i

. .

APPROXIMATE EXTENT OF

a

@ CURRENTIPOTENTiAL EXTRACTION WELL LOCATIONS GRAPHIC SCALE EXiSTlNG SVE WELLS

- -- CONCEPTUAL WATER TABLE CONTOURS

CONCEPTUAL GROUNDWATER FLOWPAT'H

Figure 7-1: Afternative I: Containment

APPROXIMATE EXTENT OF FREE-PHASE LNAPL,

NOVEMBER 1999

. CLEVES

- ,

EXISTING SVE WELLS

FOTENTIAL SVE LOCATION 300-FT. CENTERS

--- @ CURRENTIPOTENT!AL EXTRACTION WELL LOCAT!ONS

- -- CONCEPTUAL WATER TASLE CONTOURS

GRAPHIC SCAJ.3

1 inch = 600 rt.

Figure 7-2: Alternative 2: Containment & SVE

APPROXIMATE EXTENT OF

NOVEMBER 1999

%

EXISTING SVE WELLS @ CURRENVPOTENTIAL EXTRACTION GRAPHIC SCALE WELL LOCATIONS

POTENTiAL SVE LOCATION1 300-F;. CENTERS - A - CONCEPTUAL WATER TABLE CONTOURS

. . . ~ ~ ~POTENTIAL iAS WELL GRID1 ~ ~ , ~ .. . .. . . 50-i-. CENTERS ~ CONCEPTUAL GROUNDWATER FLOWPATH

Figure 7-3: Alternative 3:Conlainanent & SVE & IAS I

* APPROXIMATE EXTENT OF

FREE-PHASE LNAPL, NOVEMBER 1999

e

EXISTING SVE WELLS

---rPOTENTIAL SVE LOCATION/ 300-Fr.CENTERS GRAPHIC SCALE

. . .. . . POTENTIAL SEAR WELL GRID1 CONCEPTUAL GROUNDWATER FLOWPATH i : i i i so-n.CENTERS HORIZONTAL. . . . , , 15-F. CENTERS VERTICAL

1 inch = 600 ft.

Figure 7-4: Alternative 4: Containment 6t SVE & SEAR

Groundwater CorrectiveMeaswe StuQ October 26.2001

Table 7-2

Estimated Time from Present Needed for the

Groundwater Benzene Concentration to Drop Below the MCL ( 5 w )

0

Containment Only SVE SVE + IAS W E + SEAR

Technology

Figure 7-5

Projected Durations from Present to 5 pg/L Benzene, versus Technology

GroundwaterCorrectiveMeasures SIudjt O c t h26,2001

Table 7 4

PresentWorth of All Costs Associated with Alternatives 1through 4

Containment mE SVE + IAS SVE + SEAR

Figure 7-6 PresentWorth of Alternatives

The following observationscanbe made:

Total present worth costs increase significantly as intxshgly aggressive

source removal technologies are applied:Alternative 1 (Containment)<

Alternative 2 (Containment + SVE) <Alternative 3 (Containment+SVE

+IAS)<Alternative4 (Containment+SVE +SEAR).

Alternative 4 (Containment +SVE +SEAR) is the fastestalternative,as

discussed in Section 7.4.1. It is also the most expensive altemative.

Figure 1 0 ~ 1 Chevron Cincirindti

Groundwater Remedy lrnplernentatiort Scheduie

ITask Name CMS Process

Chevron Submits Draft GWCMS to EPA

EPA Submits comments to Chevrori

Clievron Submits a response to comments

EPA approves the GWCMS

EPA subrnits Statement of Basis to Public

Public Hearing (probabiy corresponding with a (

End of Comment Period

Flnai Ueclsiori Response to Coirirnenis

3 Evaluation of Coritainment Options

Seiection of Containmelit Optioris

3 Uesign of Selected Option

Constructioii of Selected Option

Start of lono-term O&M

..

1 Rolled Up Task Project Surnniary

Roiled up Split , , , > , , , , , , , , , , ~ z , > External Miiestone

~ o i i o du p Milestone 0 i)8adiine

1 / Miiastone Hoiied Up Progress 1

Note: The actual design and construction times wiil be dependent uporl tile coinpiexity of the selected coiitailiinent optiori. -.