Simulation and research for the future ET mirrors

description

Transcript of Simulation and research for the future ET mirrors

Janyce Franc-Kyoto-GWADW 1

Simulation and research for the future ET mirrors

Janyce Franc, Nazario Morgado, Raffaele Flaminio

Laboratoire des Matériaux Avancés

CNRS

Villeurbanne, FRANCE

Tuesday 18th May 2010

Janyce Franc-Kyoto-GWADW 2

Contents

• Mirror Thermal Noises

• Solutions to reduce Mirror Thermal Noise

– Find New materials– Cool down mirrors– Use Laguerre-Gauss modes

• Mirrors for ET

• Coating research activities at LMA

Janyce Franc-Kyoto-GWADW 3

Mirror thermal noises and ET

w=6 cmInfinite mirror

Unless otherwise specified

ET

Adv. Virgo

Janyce Franc-Kyoto-GWADW 4

Coating Brownian noise

Reduce losses by new coating materialsReduce the temperature

Increase the Ysub by changing the material substrate

Change the beam shape and size

wfY

TkS

s

scbc

23

2 )1(2

Janyce Franc-Kyoto-GWADW 5

Coating materials

TiTa2O5 TiO2 Nb2O5 ZrO2 SiO2 Al2O3

2 10-4 6.3 10-3 4.6 10-4 5.9 10-4 0.5 10-4 2.4 10-4

(kg.m-3) 6425 4230 4590 6000 2200 3700

(W.m-1.K-1) 0.6 0.45 1 1.09 0.5 3.3

C (J. K-1.Kg-1) 269 130 590 26 746 310

(K-1) 3.6 10-6 0.5 10-6 5.8 10-6 10.3 10-6 0.51 10-6 8.4 10-6

(dn/dT) 14 10-6 -1.8 10-4 1.43 10-5 10 10-5 8 10-6 1.3 10-6

Y (GPa) 140 290 80 200 60 210

0.23 0.28 0.2 0.27 0.17 0.22

n 2.06 2.3 2.32 2.15 1.45 1.63

N.B. Parameters available in J.Franc et al. ET-02109

Janyce Franc-Kyoto-GWADW 6

SiO2-Ti:Ta2O5 coating offers the best resultSiO2-Nb2O5 is also a good candidate (but absorption slightly higher)

Coating materials

N.B. Parameters available in J.Franc et al. ET-02109

Comparison of different coatingswith same transmission (6 ppm)

Janyce Franc-Kyoto-GWADW 7

Substrate materials (300K)

Silica remains the best substrate materials at 300K

Also better from an optical point of view

And available in large pieces (just need to increase budget)

TE Noise limits the Si and Sapphire TN

Janyce Franc-Kyoto-GWADW 8

Low temperature: substrate materials

Similar level for Silicon and Sapphire. Silicon is promising because of its interest in microelectronics industry.

SiO2 is unsuitable

10K

Janyce Franc-Kyoto-GWADW 9

Low temperature: Silicon

* Band-to-band absorption reported in literature (Green et al., 1995)

* The total absorption might be higher due to :

- Impurities- Residual conductivity

At 1550 nm impurities expected to be dominant

* The absorption have to be precisely determined!

* Work in progress at LMA

* NB Only 8’’ diameter silicon wafers with the best optical quality are available so far.

Silicon absorption

M. Green and M. Keevers, Optical properties of intrinsic Silicon @ 300K, Progress in Photovoltaic research and Applications, Vol. 3, 189-

192 (1995)

Janyce Franc-Kyoto-GWADW 10

Low temperature: Silicon

Large sensitivity variation vs Temperature!Good results obtained at 4-20K30K must be avoidedNo real interest in working at 18 K because of

Substrate Brownian noiseCoating losses (see next slide)

Janyce Franc-Kyoto-GWADW 11

Low temperature: Coating losses

I. Martin et al. Class. Quantum Grav. 25 (2008) 055005

18K

10K

Janyce Franc-Kyoto-GWADW 12

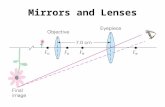

Beam shape (and size)

Advantages : -Best power distribution on the mirror surface-Lower Thermal Noise-Lower Thermal Lensing

To reduce Thermal noise the beam shape and size can be changed.

Janyce Franc-Kyoto-GWADW 13

Beam shape: thermal noise reduction

Coating Brownian Noise

Substrate Brownian Noise

Substrate TE noise(frequency dependent)

TEM00/LG33

Infinite mirror1.7 1.9 1.06-1.8

TEM00/LG33

Finite mirror

(Ø:45cm, h:30 cm)

1.6 1.4 1.08-1.86

LG55 does not demonstrate better resultsET NOTE with all the results: soon available

Janyce Franc-Kyoto-GWADW 14

Solutions for ET

Low frequency ITF High frequency ITF

Temperature 10K 300K

Mirror size Ø : 45 cm

H : 30 cm

Ø : 62 cm

H : 30 cm

Substrate Silicon Silica

Wavelength 1550 nm 1064 nm

Coating Ti:Ta2O5 & SiO2 Ti:Ta2O5 & SiO2

Phi coat 2.10-4 & 0.5.10-4 2.10-4 & 0.5.10-4

Reference : S. Hild et al., CQG, 2010, 27, 015003

Janyce Franc-Kyoto-GWADW 15

At low frequency : 45 cm diameter + silicon + 10K+ TEM00 is enoughAt higher frequency : 62 cm diameter + silica + 300K+ LG33 is possible

Solutions for ET

Janyce Franc-Kyoto-GWADW 16

Study of coating losses at LMA

Mechanical losses measurement at LMA

Coating deposit chambers at LMA

* Ta2O5

* Ti:Ta2O5* SiO2

1. The coating are deposited on silica cantilevers in the same coater used for the Virgo mirrors.

2. The Q of the cantilever is measured before coating deposition (200 000-300 000)=> limitation

3. The Q of the cantilever after deposition is measured and we can deduce the coating loss angle.

4. Good system for Tantala. Not enough sensitivity for silica film.

Janyce Franc-Kyoto-GWADW 17

Q of silica layers

Welded cantilever (frequency of

vibration in Hz)

1st mode 730 000 (50 Hz)

2nd mode 720 000 (300 Hz)

3rd mode 1 250 000 (800 Hz)

Silica cantilever

Silica blockCantilever welded to Silica block

Silica losses (1st mode)

1st cantilever 4.5 (+/- 1) 10-5

2nd cantilever 4.2 (+/- 1) 10-5

In accordance with the reported values of 5.10-5. Need more tests.The tests with classical cantilever did not permit to measure this value.

Collaboration INFN Perugia (H. Vocca)

Janyce Franc-Kyoto-GWADW 18

Q of high index materials

Preliminary studies – Need more measurement before to conclude!

Materials Losses angles

Ta2O5 3 10-4

Ti:Ta2O5 2 10-4

Nb2O5 4.6 10-4

Measurements generally done for a 500 nm thick film.

BUT some variation observed when different thickness are measured…

Janyce Franc-Kyoto-GWADW 19

Q of multilayer coatings

1. Q of multilayer coating can be deduced from losses of materials and coating formula.

2. First measurements showed larger losses in multilayer coatings than foreseen. Thought to be due to defects in the coating coming from poor cantilever surface quality.

3. Recently, mechanical losses of different multilayer coatings with no defects have been measured and confirm larger losses than expected.

4. More studies are needed

Coating Thickness

(nm)

Coating

measured

coating theoretical

doped-tantala deduced

0.817H(1.0736L0.8828H)12 0.0851L

3859 2.5 10-4 1.32 10-4 4.2 10-4

0.87B(HB)20HBB 5222 3.4 10-4 1.34 10-4 5.8 10-4

Some preliminary results :

Janyce Franc-Kyoto-GWADW 20

Conclusions

- By combining different solutions (larger beams, LG modes, Silicon and low T) the ET sensitivity seems achievable.

- But a strong R&D program is necessary to:reduce coating lossesevaluate silicon optical propertiesdevelop LG interferometry…….

- Study of coating losses at LMA with cantilevers:Confirm low losses for silica mono layersShows some excess of losses in thick coatings to be better investigated

Janyce Franc-Kyoto-GWADW 21

At low frequency : 45 cm diameter + silicon + 10K+ TEM00 is enoughAt higher frequency : 62 cm diameter + silica + 300K+ LG33 is possible

Solutions for ET

Janyce Franc-Kyoto-GWADW 22

Low temperature: other coating noises?

=6 10-5 (K-1)

Thermal Exp. coefficient limits sensitivity if value 20 times larger than value @ 300 K

At low temperature a lot of the coating parameters are unknown.

The thermoelastic ( coef.) and thermorefractive ( coef.) noises can not be evaluated.

Question: how large should and to become limited by TE and TR noises?

Answer:- = 6 10-5 K-1

20 times larger than at 300 K! - = 25 10-4 K-1

200 times larger than at 300 K!

Unlikely