Simonazzi Motorized Valve

description

Transcript of Simonazzi Motorized Valve

-

Simonazzi

Simonazzi Motorized Valve Rev 0-3.doc Rev 0.4 Eng. 1/5

Simonazzi Motorized Valve Instruction Manual

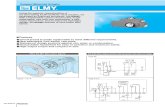

Drive Structure

Control Card Controls the motor and end of stroke sensors.

Step Motor Moves the transmission system. The step motor used, with integrated drive, allows to reduce the dimension and complexity of the electronic card and improves the dynamic response of the valve.

Timing Belt The timing belt transfers the rotating movement to the screw. The timing belt is maintenance free.

Screw The screw converts the rotating movement of the step motor to a linear movement.

Springs The springs placed in the junction between the valve and the stem allow to apply a force to ensure the perfect closing of the valve. Is important to verify the compression of the springs to adjust the closing of the valve without overcome the maximum torque calculated for the motor and transmission (see the note in page n.3).

Electrical connections Remove the cover of the valve to access to the control board. In the bottom of the board there are two connectors with two different cables.

Externals cables connectors

J1 Supply motor and control board Cable 4 Wires + Ground (0.5 mm2)

J3 Analog input signals and digital input/output signals Cable 4 Wires + Shield (0.5 mm2)

Other connectors

J4 Zero sensor in reverse mode J5 Zero sensor in direct mode J2 Cable supply and signals to the motor. The electrical connection of this cable is Pin To Pin (1-1, 2-2 etc.)

-

Simonazzi

Simonazzi Motorized Valve Rev 0-3.doc Rev 0.4 Eng. 2/5

Calibration procedure The calibration procedure is necessary to give the Maximum Stroke and Zero to the positioner. The Zero point corresponds to a reference signal of 4 mA, the Maximum Stroke signal corresponds to a reference signal of 20 mA.

Work direction Dip Switch 4

OFF Direct (the zero position is in the lower position of the valve) CO2 valve ON Reverse (the zero position is in the upper position of the valve) Water and Syrup valves

High and Low speed Dip Switch 5

ON Low speed (not used) OFF High speed (all the valves)

-

Simonazzi

Simonazzi Motorized Valve Rev 0-3.doc Rev 0.4 Eng. 3/5

Calibration of close position 1. Set the switch 4 (Direct/Reverse) in the right position (see above). 2. Set the switches 1,6,7,8 in OFF position. 3. Switch on the power supply to the valve. 4. Delete any previous calibration of the valve restoring the factory

conditions: to do that set the switch 2 in ON position for 1 Sec. 5. Set ON the switch 1 in the control board. 6. Put the valve in the right zero position, (corresponding to an input

signal of 4 mA) with the pushbuttons UP and DOWN, paying attention to the spring compression1 (see picture).

7. If the spring is too compressed is possible that the motor looses the step; in this case bring again the Switch 1 in OFF position and repeat the procedure from point n. 4.

8. Store in the eeprom memory the zero position setting ON and then OFF the switch 2 in the control board (the red dot of the display will switch on to confirm the storage of the calibration).

Calibration of maximum opening position. 9. Put the valve in the maximum opening position, 40 mm from the full close position, (corresponding to an input

signal of 20 mA) with the pushbuttons UP and DOWN. 10. If the physical maximum opening position is overcomed is possible that the motor looses the step; in this case bring

again the Switch 1 in OFF position and repeat the procedure from point n. 4. 11. Store in the EEprom memory the zero position setting ON and then OFF the switch 3 in the control board. 12. Set OFF the switch 1 to leave the learning mode and set ON the switch 6 to enter in automatic mode.

Check of calibration. At the end of calibration procedure we recommend to check the calibration of the valve and the compression1 of the spring opening and closing the valve from the PC maintenance screen; if its no good repeat the calibration.

Working Modes

Automatic Mode Switch 6 ON Switch 7 OFF Switch 8 OFF

Automatic Mode active: the valve follows the analog input reference 4..20 mA

Manual Mode Switch 6 OFF Switch 7 ON Switch 8 OFF

Manual Mode active: is possible to move manually the valve using the pushbuttons UP and DOWN

Test Mode Switch 6 OFF

1 The valve is close correctly when, in the zero position, the spring is compressed about 0.5mm. Is very important to pay attention to

the spring compression during the zero position calibration, because overcoming the maximum torque is possible to damage the transmission system and the belt of the valve; in the other hand a spring compression too low may not ensure the correct closure of the valve.

-

Simonazzi

Simonazzi Motorized Valve Rev 0-3.doc Rev 0.4 Eng. 4/5

Switch 7 OFF Switch 8 ON

Test Mode active: the valve does full strokes between 0% and 100% position

RESET Mode Switch 1 OFF Switch 2 ON ( 1 Sec ) Switch 6 OFF Switch 7 OFF Switch 8 OFF

RESET Mode: deletes any calibration of the valve restoring the factory conditions.

Control Board

Connectors

Connector J1 Power supply connector (motor + control board)

Pin1 + 24V Step Motor Pin2 +0V Step Motor Pin3 +24V Control Board Pin4 +0V Control Board

Connector J2 Step Motor connection

Pin1 COMMON (Signal) Pin2 PULSE Pin3 CW_CCW Pin4 BOOST Pin5 +24V (Motor) Pin6 +24V (Motor) Pin7 0V (Motor) Pin8 0V (Motor)

Connector J3 PLC Signals connector

Pin1 + in 4..20 mA Pin2 - in 4..20 mA Pin3 Shield

-

Simonazzi

Simonazzi Motorized Valve Rev 0-3.doc Rev 0.4 Eng. 5/5

Pin4 0V digital Pin5 Out Valve close Pin6 In Aux

LED DL1 VCC ( +5V ) DL2 PULSE DL3 BOOST DL4 CW_CCW DL5 Sensor valve close in Reverse mode (Off = sensor engaged) DL6 Out Valve closed DL7 Sensor valve close in Direct mode (Off = sensor engaged) DL8 Auxiliary Input DL9 Power (+ 24V )

DIP SWITCH DW1 Learning Mode DW2 Save Zero Position DW3 Save Full Open Position DW4 Reverse Mode DW5 Low Speed Mode DW6 Automatic Mode DW7 Manual Mode DW8 Test Mode

NB. With switches 1 , 6 , 7 , 8 OFF and setting the switch 2 ON for 1 Sec the EEProm of the control board is erased and all the calibrations of the valve are deleted.

DISPLAY

The display shows the state of the valve as follows:

Automatic Mode Test Mode

Manual Mode EEPROM Erased

Learning Mode Position stored

Motor Connector

-

Simonazzi

Simonazzi Motorized Valve Rev 0-3.doc Rev 0.4 Eng. 6/5

1 8

COMMON

PULSE

CW-CCW

BOOST

+24V

+24V

GND

GND

CONNECTORFront View

1

2

3

4

5

6

7

8