Silt Fence Installation - Home - Biosystems and ... Fence Installation Kody R. Featherston Candice...

Transcript of Silt Fence Installation - Home - Biosystems and ... Fence Installation Kody R. Featherston Candice...

Silt Fence Installation

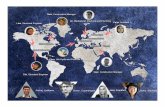

Kody R. Featherston

Candice L. Johnson

J. Kent Evatt

Monica L. Johnston

BAE 4022 – Spring 2004

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

WHAT IS SILT FENCE?

• A silt fence is a temporary sediment barrier consisting of filter fabric entrenched into the

soil and attached to supporting posts.

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

PROBLEM DEFINITION

• Common failures are caused by:

– Improper Installation

– Incorrect Location

– Inadequate Strength

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

FAESF

• Failure Avoidance and Effective Silt Fence Technology

– control undercutting and overtopping

– control lateral flow along the silt fence

– improve the trapping of fine silts and clays

– provide adequate strength posts and fence

– provide for adequate bearing capacity of post footings

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

STATEMENT OF WORK

• Enviro-Mech will focus on reducing failure due to improper installation.

• Dr. Barfield’s team will continue developing a new filter fence material configuration and support mechanism.

• Enviro-Mech will design and build a machine which will create a trench, lay the fence, and backfill the trench.

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

INVESTIGATION

• Recommended Silt Fence Practices

• Current Equipment Patented and in Production

• Similar Vibratory Plow Applications

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

RECOMMENDED PRACTICES

• Information Concerns

– Trench Dimensions

– Fence Location

– Post Height

– Fence Size

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

CURRENT EQUIPMENT

• Tommy Silt Fence Machine

• Erosion Runner

• ImpleMax SF12c

• McCormick Equipment

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

VIBRATORY PLOW

• Cable Installation Blades

– Integrated Slot

– Four Bar Linkage

Groove

on Back

Edge of

Blade

Cable

Guide

Hook to

Secure

Guide

Upper

Latch

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

CONCEPT DEVELOPMENT

• Design Criteria

– FAESF Research Group

– Charles Machine Works

• Potential Solutions

– Proposal A - Two-Disk Method

– Proposal B - Feed Channel Method

– Proposal C - Tension Rod Method

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

DESIGN CRITERIA

• FAESF Proposed Design

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

DESIGN CRITERIA

• Design compatible with current power source provided by Charles Machine Works

• Economical

• Marketable

• Safe

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

INSTALLATION METHODS

• Proposal A - Two-Disk Method

• Proposal B - Feed Channel Method

• Proposal C - Tension Rod Method

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

PROPOSAL ATWO-DISK METHOD

• Two narrow disks pinch the fabric.

• The disks feed the fabric into the slot.

• Fabric is released at the bottom of the slot.

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

PROPOSAL BFEED CHANNEL METHOD

• Channel will be attached similar to four-bar linkage currently used.

• The fence will require added bulk to bottom edge.

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

PROPOSAL CTENSION ROD METHOD

• Spring loaded rod will guide material through slot.

• The end of the rod acts as a pressure point.

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

TEST AND ANALYSIS

• Testing was required to determine the most effective and financially feasible solution.

– Methods Testing

– Concept Testing

– Final Design Testing

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

CONCEPT TESTING

• Max lift capacity of machine

• Extensions and Tubular Frame to attach test components

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

LOAD DATA

0

25

50

75

100

125

0 5 10 15 20 25

Time (sec)

Fo

rce

(lb

s)

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

FRAME DESIGN

• Parallel Frame Rails

• Over the Top

• Wrap Around

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

FINAL DESIGN TESTING

• Issues Discovered

– Soil Packing Against Tension Rod Inside Shield

– Wind Unrolling Fabric Faster than Installed

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

FINAL DESIGN TESTING

• Forces for removal measured

SoilCondition

Force (lb)

Bare, Unpacked 15

Bare, Packed 50

Grass, Unpacked 40

Grass, Packed > 50

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

FINAL DESIGN TESTING

• Surfaces

– Grass

– Bare Soil

• Paths

– Straight

– Curved

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

FINAL DESIGN

• Frame

– Main Frame

– Sub Frame

• Components

– Shield

– Tension Rod

– Fabric Tension Arm

– Packing Wheels

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

SAFETY

• Rounded Corners

• Clearly Labeled Pinch Points

• Spring Pins

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

MANUALS

• Operators Manual

• Parts Manual

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

PROJECT SCHEDULE

Fall Semester Accomplishments

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

PROJECT SCHEDULE

Spring Semester Accomplishments

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

PROTOTYPE EXPENSES

$304

$204

Fabrication Cost

$689

$744

Total Cost

$540Projected Budget

$385 Actual

Cost

Material Cost

$55 Under Budget

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

ESTIMATED MANUFACTUING COST

Direct Material

Labor and Overhead

Total

OSU Silt Fence

Installer

$110 $350 $460

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

COMPETITIVECOMPARISON

$7177Tommy Silt Fence Machine

$6400OSU Silt Fence Installer

and Vibratory Plow

$11795ImpleMax SF12c

$4925McCormick Silt Fence Installer

Retail Price

Estimated Retail of $1150

BAE 4022 – Spring 2004 K. Featherston, C. Johnson, M. Johnston, J.K. Evatt

THANK YOU

• Richard Sharp -Project Engineer

• Kelvin Self -Manager R & D

• Dr. Billy Barfield -FAESF Research Group

• Dr. Ellen Stevens -FAESF Research Group

• Wayne Kiner -BAE Laboratory Manager

• Dr. Paul Weckler -Senior Design Instructor

• Dr. Ron Elliot -BAE Department Head

Enviro-Mech would like

to thank those who have

contributed to our Senior

Design Project.