Shock Absorber - HASMAKhasmak.com.tr/smc/shock/rj.pdf · Shock Absorber Soft type Stops transported...

Transcript of Shock Absorber - HASMAKhasmak.com.tr/smc/shock/rj.pdf · Shock Absorber Soft type Stops transported...

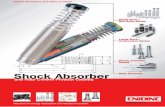

Series RJ

Suitable for softy stopping light objects or objects transferred at low speeds

Unique mechanism to achieve a variable sectional area of the fluid channel proportional to the stroke

30% reducedabsorption time(compared with SMC RB series)

� Mounting interchangeable with the RB series.

� Selectable according to impact mass and collision speed.

PAT.PEND

Smooth absorption with a spiral groove structure

Conventional product

RJ

Flui

d ch

anne

l sec

tiona

l are

a [m

m2 ]

Stroke [mm]

Shock AbsorberSoft type

Stops transportedobjects softly

Shortened takt time of short stroke actuators, such as air slide tables.

Cap type short stroketype

RJ-L type

1000

10

1

0.10.01 0.1 1 10

100

Impa

ct m

ass

m (

kg)

Collision speed υ (m/s)

Series RB

RB0806

10 2 3

0.35

0.3

0.25

0.2

0.15

0.1

0.05

0

RJ-H type

RJ-short stroke type

RJ-short stroke type

0.05 to 1 m/s

0.05 to 2 m/s

0.05 to 1 m/s

• Standard stroke L type

• Standard stroke H type

• Short stroke type

With cap

Short stroke type

Cap type short stroketype

Abs

orpt

ion

time

(sec

)

Energy (J)

M8 size absorption time

<Example shows an absorber with air slide table MXQR attached>

Cap type and short stroketype added!Offering greater optimization.

CAT.ES20-200C

Impa

ct m

ass

m (

kg)

Collision speed υ (m/s)

Impa

ct m

ass

m (

kg)

Collision speed υ (m/s)

Impa

ct m

ass

m (

kg)

Collision speed υ (m/s)

Impa

ct m

ass

m (

kg)

Collision speed υ (m/s)

Impa

ct m

ass

m (

kg)

Collision speed υ (m/s) Collision speed υ (m/s)

Impa

ct m

ass

m (

kg)

0

2

4

6

8

0 0.5 1 1.5 20

10

5

20

15

30

25

0 0.5 1 1.5 20

10

20

30

40

0 0.5 1 1.5 2

RJ1412H

RJ1410

RJ1412L

0

10

5

15

20

0 0.5 1 1.5 2

RJ1412L

RJ1412H

RJ1410

0

10

8

6

4

2

12

0 0.5 1 1.5 2

RJ1007L

RJ1007H

0

1

2

3

5

4

0 0.5 1 1.5 2

RJ0806L

RJ0806L

RJ1006

RJ0806H

RJ0805

RJ1007H

RJ1007L

RJ0806H

RJ0805RJ1006

Load

Load

Graph q/RJ08�� Absorbed energy Graph w/RJ10�� Absorbed energy Graph e/RJ14�� Absorbed energy

� Type of ImpactImpact of air cylinder actuation(Downward)Check the procedure “Model Selection Step” from z to c prior to use.

Load

Graph r/RJ08�� Absorbed energy Graph y/RJ14�� Absorbed energyGraph t/RJ10�� Absorbed energy

Shock Absorber

Model Selection 1Series RJ

Model Selection Graph

� Type of ImpactFree horizontal impact Impact of air cylinder actuation(Horizontal/Upward)Check the procedure “Model Selection Step” from z to c prior to use.

∗ The model selection graphs q to !2 are at room temperature (20 to 25°C).

Shock absorber

1

Equ

ival

ent m

ass

Me

(kg)

Collision speed υ (m/s)

Equ

ival

ent m

ass

Me

(kg)

Collision speed υ (m/s)

Equ

ival

ent m

ass

Me

(kg)

Collision speed υ (m/s)

0

2

4

6

8

0 0.5 1 1.5 20

10

5

20

15

30

25

0 0.5 1 1.5 2 20

10

20

30

40

0 0.5 1 1.5

RJ1412H

RJ1410

RJ1412LRJ0806L

RJ1006RJ0805

RJ1007L

RJ0806H

RJ1007H

0

1

2

3

4

0 0.5 1 1.5 2

Impa

ct m

ass

m (

kg)

Collision speed υ (m/s)

RJ0806L

RJ0806H

RJ0805

0

2

4

6

8

10

12

0 0.5 1 1.5 2

Impa

ct m

ass

m (

kg)

Collision speed υ (m/s)

RJ1007L

RJ1007H

RJ1006

0

5

10

15

20

25

30

0 0.5 1 1.5 2

Collision speed υ (m/s)

Impa

ct m

ass

m (

kg)

RJ1412H

RJ1410

RJ1412L

Graph u/RJ08�� Absorbed energy Graph o/RJ14�� Absorbed energyGraph i/RJ10�� Absorbed energy

� Type of ImpactOthers (such as thrust impact or swing impact other than air cylinder actuation)Check the procedure “Model Selection Step” from z to m to calculate equivalent mass Me prior to use.

Graph !1/RJ10�� Absorbed energy Graph !2/RJ14�� Absorbed energyGraph !0/RJ08�� Absorbed energy

Shock Absorber Series RJ

Model Selection Graph

� Type of Impact

Check the procedure “Model Selection Step” from z to c prior to use.

∗ The model selection graphs q to !2 are at room temperature (20 to 25°C).

Load

Free fall impact

2

Select the RJ1007L.

Type of impact1

SymbolmυhωrFTntµ

Operating conditionsImpact mass

Collision speedDropping height

Angle speedDistance between rotational center and impact point

ThrustTorque

Operating frequencyAmbient temperature

Friction coefficient

Type of impact

Collision speed υNote 1)

1

YES

E1 ≈ 0.63J

� Thrust energy E2

Select the RJ1007L temporarily and obtain E2 by using the formula.

E2 ≈ 1.05J

Use Formula “Absorbed energy E = E1 + E2 = 0.63 + 1.05 = 1.68 J” to calculate Me by using E and 0.5 for υ.

� Equivalent mass Me

YES

Me ≈ 13.4 kg

In order for the shock absorbers to operate accurately for long hours, it is necessary to select a model that is well-suited to your operating conditions. If the impact energy is smaller than 5% of the maximum absorbed energy, select a model that is one class smaller.

Caution on Selection

Model Selection Step Example of Selection

Model Selection

Shock Absorber

Model Selection 2Series RJ

Impact of thrust of load (Horizontal)Impact of thrust of load (Downward)Impact of thrust of load (Upward)Free horizontal impact (Impact of inertial force)Free fall impactSwing impact (With torque)

Operating conditions2

Unitkg

m/secm

rad/secmN

N ·mcycle/min

°C—

Confirmation of specifications and precautions3Ensure the collision speed, thrust, operating frequency, ambi-ent temperature and atmosphere fall within the specifications.∗ Be aware of the minimum installation radius in the case of

swing impacts.

4 Calculation of kinetic energy E1Calculate kinetic energy E1 by using the formula according to the impact type.

5 Calculation of thrust energy E2Calculate thrust energy E2 by selecting a model temporarily.

6 Calculation of equivalent mass MeCalculate absorbed energy E to confirm it is not more than the max-imum absorbed energy of the temporarily selected shock absorber.

Equivalent mass Me = — · E 2υ2

7 Selection of applicable modelSubstitute the obtained equivalent mass Me, and the collision speed υ by using “Model Selection Graph” !0 to !2 to check if the temporarily selected model is compatible with the condi-tion of application. If satisfactory, then the temporarily select-ed model will be the applicable one.

Kinetic energy

Thrust energy

Absorbed energy

E1

E2

E

MeEquivalent massNote 2)

Operating conditions

2

Confirmation of specifications and precautions

3

Calculation of kinetic energy E1

4

Calculation of thrust energy E2

5

Calculation of equivalent mass Me

6

Check adequacy of the selected model RJ1007

7

Impact of thrust of load (Horizontal)(Impact of thrust from sources

other than air cylinder actuation)

Load

Shock absorber

υ

— · m · υ2 1 2

— · E2 υ2

F · S

E1 + E2

= 5 kg= 0.5 m/s= 150 N= 30 cycle/min= 25°C

mυFnt

� Confirmation of specificationsυ · · · 0.5 < 1.0 (max.), 2.0 (max.) t · · · –10 (min.) < 25 < 60 (max.)F · · · 150 < 422 (max.)

� Kinetic energy E1

Use Formula to calculate E1 by using 5.0 for m and 0.5 for υ.

� Selection of applicable modelAccording to Graph !1, the temporarily selec-ted RJ1007L satisfies Me = 13.4 kg < 14.5 kg, resulting in an operating frequency of n = 30 < 70, without causing a problem.

3

Load

Load

Load

Load

Load

1 2 — · m · υ2 1

2

υ

m · g · µ · S

E1 + E2

m · g · h

m · g · S

E1 + E2

ω · R

E1 + E2

— · Ι · ω2 1 2

T · —SR

2 gh

Type of Impact1

Type of impact

Collision speedυ

Kinetic energyE1

Thrust energyE2

Absorbed energyE

Equivalent massMe

Impact of thrust ofload (Downward)(Impact of thrust

from sourcesother than air

cylinder actuation)

Impact of thrust ofload (Upward)

(Impact of thrustfrom sourcesother than air

cylinder actuation)

Load onconveyor

(Horizontal)Free fall impact

Swing impact(With torque)

Symbol Specifications

Absorbed energy

Kinetic energy

Thrust energy

Thrust

Gravitational acceleration (9.8)

Dropping height

Moment of inertia around the center of gravity

Operating frequency

Distance between rotational center and impact point

Shock absorber’s stroke

Torque

Ambient temperature

Collision speed

Impact mass

Equivalent mass

Angle speed

Friction coefficient

Unit

J

J

J

N

m/s2

m

kg ·m2

cycle/min

m

m

N ·m

°Cm/s

kg

kg

rad/s

—

<Symbol>

Note 3) For the formula for moment of inertia Ι (kg ·m2), refer to the rotary actuator’s catalog.

E

E1

E2

F

g

h

Ιn

R

S

T

t

υm

Meω

µ

Note 3)

Note 1)

Note 2)

υ

— · m · υ2 1 2

F · S + m · g · S

E1 + E2

— · E2 υ2

υ

— · m · υ2

F · S – m · g · S

E1 + E2

— · E2 υ2

— · E2 υ2

— · E2 υ2

— · E2 υ2

Note 1) This is the momentary speed at which an object is impacting against a shock absorber. The collision speed is υ = 2υ when the speed (average speed υ) is calculated from the air cylinder's stroke time.

Note 2) This is the theoretical mass, which is converted into the mass of the impacting material under no thrust collision conditions. Hence, E = —·Me ·υ212

4

Shock Absorber Series RJ

RJ

Shock absorber/soft type

0806 H U

Collision speed rangeHL

0.05 to 2 m/s

0.05 to 1 m/s

Model

RJ0806

RJ0806�U

RJ1412

RJ1412�U

RJ1007

RJ1007�U

1

8

6

80

2.8

5.4

245

15

16

10

14

12

45

6.4

17.4

814

65

70

3

10

7

70

5.4

8.4

422

–10 to 60 (No freezing)

23

25

H

0.05 to 2

H

0.05 to 2

H

0.05 to 2

L

0.05 to 1

L

0.05 to 1

L

0.05 to 1

Max. absorbed energy (J) Note)

O.D. thread size (mm)

Stroke (mm)

Collision speed (m/s)

Max. operating frequency (cycle/min) Note)

Spring force (N)

Max. allowable thrust (N)

Ambient temperature (°C)

Weight (g)

Extended

Retracted

Symbol

080610071412

O.D. thread

8 mm

10 mm

14 mm

Stroke

6 mm

7 mm

12 mm

Note) Max. absorbed energy and max. operating frequency values are at room temperature (20 to 25°C).

Option

Nil

JNS

SJSN

Hexagon nut

2 pcs.

3 pcs.

—

2 pcs.

3 pcs.

—

Stopper nut

—

—

—

1 pc.

1 pc.

1 pc.

Symbol

How to Order

Specifications

Basic type

With cap

Basic type

With cap

Collision speed range

O.D. thread size/stroke

With CapBasic Type

With urethane cap

Nil

U

5

Shock Absorber

Series RJ

Sheet 3.qxd 09.10.20 2:09 PM Page 1

RJShock absorber/soft type

0805 U

Specifications

ModelRJ0805

RJ0805U

RJ1410

RJ1410U

RJ1006

RJ1006U

0.5

8

5

80

2.8

4.9

245

15

16

3.7

14

10

45

6.4

14.6

814

65

70

1.5

10

6

70

5.4

8.0

422

–10 to 60 (No freezing)

23

25

0.05 to 1

Max. absorbed energy (J) Note)

O.D. thread size (mm)

Stroke (mm)

Collision speed (m/s)

Max. operating frequency (cycle/min) Note)

Spring force (N)

Max. allowable thrust (N)

Ambient temperature (°C)

Weight (g)

Extended

Retracted

Symbol

080510061410

O.D. thread

8 mm

10 mm

14 mm

Stroke

5 mm

6 mm

10 mm

Note) Max. absorbed energy and max. operating frequency values are at room temperature (20 to 25°C).

RBC C08

RJ0805, 0806

RJ1006, 1007

RJ1410, 1412

081014

Option

Nil

JNS

SJSN

Hexagon nut

2 pcs.

3 pcs.

—

2 pcs.

3 pcs.

—

Stopper nut

—

—

—

1 pc.

1 pc.

1 pc.

Symbol

How to Order

Short stroke type

O.D. thread size/Stroke

With capBasic Type

With urethane cap

Nil

U

Basic type

With cap

Basic type

With cap

Replacement Part no./Cap (Resin part only)

Caps cannot be mounted on basic types. Please specify a type with cap when ordering.

Applicable model

Cap

6

Shock Absorber

Series RJ

Sheet 3.qxd 09.10.20 2:09 PM Page 2

!0

!4!5

ouyteq!1!3r!2iw

yi !2 r !1 e t u o !0 qw

RJ10, 14

No. Material Treatment

Special steel

Special steel

Stainless steel

Tool steel

Copper

Steel wire

Structural steel

Synthetic rubber

Synthetic rubber

Synthetic rubber

Synthetic rubber

Structural steel

Urethane

Electroless nickel plated

Electroless nickel plated

Zinc chromated

Zinc chromated

Electroless nickel plated

Zinc chromated

Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Tube

Piston rod

Piston

Bearing

Spring guide

Lock ring

Return spring

Stopper

O-ring

Plug

Accumulator

Rod seal

O-ring

Cap bracket

Cap

Component Parts

H: Electroless nickel plated

L: Black electroless nickel plated

Construction

RJ08

Special bearingmaterial

—

7

Series RJ

C

B

K

h

G

øD

LL

H S

MM

Cap MM

LL

Z

øE

H SG

h

Cap bracket

Dimensions

Dimensions

∗ The dimensions of H- and L-type are the same.

Model

2.8

3

5

2.8

3

5

M8 x 1.0

M10 x 1.0

M14 x 1.5

M8 x 1.0

M10 x 1.0

M14 x 1.5

D 6

7

12

5

6

10

H46.8

52.3

79.1

45.8

51.3

77.1

LL40.8

45.3

67.1

40.8

45.3

67.1

SMM5

7

8

5

7

8

G 7

9

12

7

9

12

KRJ0806�URJ1007�URJ1412�URJ0805URJ1006URJ1410U

RJ0806�RJ1007�RJ1412�RJ0805RJ1006RJ1410

Hexagon nut With cap

13.9

16.2

21.9

13.9

16.2

21.9

C12

14

19

12

14

19

B h4

4

6

4

4

6

E 6.8

8.7

12

6.8

8.7

12

LL55.3

62.3

92.6

54.3

61.3

89.6

Z 8.5

10

13.5

8.5

10

13.5

RB08SRB10SRB14S

DimensionsModel

Basic type

RBC08SRBC10SRBC14S

With cap

15

15

20

f 9

11

15

d23

23

31

h2 6.5

8

11

h1

13.9

16.2

21.9

C12

14

19

BM8 x 1.0

M10 x 1.0

M14 x 1.5

MMRBC08CRBC10CRBC14C

DimensionsModel

6

7.5

10

SR 6.8

8.7

12

B 6.5

9

12.5

A

Material: Polyurethane

OptionStopper nut Cap

For cap typeFor basic type

Basic type

With cap

Replacement Parts

∗ Replacement parts for cap type. Cannot be mounted on basic type.

8

Shock Absorber Series RJ

2 x øD

X

MM

L

HB

T

Foot Bracket for Shock Absorber

Foot mounting bracket is available for the RJ series.

Part no.

RB08-X331

RB10-X331

RB14-X331

Applicable absorber

Part No.

∗ Order the foot bracket separately.

RJ0806

RJ1007

RJ1412

Dimensions

Model Mounting boltXTMMLHDB

RB08-X331RB10-X331RB14-X331

15

19

25

7.5

9.5

12.5

32

40

54

M8 x 1.0

M10 x 1.0

M14 x 1.5

10

12

16

20

25

34

M4

M5

M8

4.5 drill, 8 counterbore depth 4.4

5.5 drill, 9.5 counterbore depth 5.4

9 drill, 14 counterbore depth 8.6

9

Series RJ

Back page 1

Safety InstructionsThese safety instructions are intended to prevent hazardous situations and/or equipment damage. These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or “Danger.” They are all important notes for safety and must be followed in addition to International Standards (ISO/IEC)∗1), and other safety regulations.∗1) ISO 4414: Pneumatic fluid power – General rules relating to systems.

ISO 4413: Hydraulic fluid power – General rules relating to systems.IEC 60204-1: Safety of machinery – Electrical equipment of machines. (Part 1: General requirements)ISO 10218-1: Manipulating industrial robots - Safety.etc.

1. The compatibility of the product is the responsibility of the person who designs the equipment or decides its specifications.Since the product specified here is used under various operating conditions, its compatibility with specific equipment must be decided by the person who designs the equipment or decides its specifications based on necessary analysis and test results. The expected performance and safety assurance of the equipment will be the responsibility of the person who has determined its compatibility with the product. This person should also continuously review all specifications of the product referring to its latest catalog information, with a view to giving due consideration to any possibility of equipment failure when configuring the equipment.

2. Only personnel with appropriate training should operate machinery and equipment.The product specified here may become unsafe if handled incorrectly. The assembly, operation and maintenance of machines or equipment including our products must be performed by an operator who is appropriately trained and experienced.

3. Do not service or attempt to remove product and machinery/equipment until safety is confirmed.1. The inspection and maintenance of machinery/equipment should only be performed after measures to prevent falling

or runaway of the driven objects have been confirmed. 2. When the product is to be removed, confirm that the safety measures as mentioned above are implemented and the

power from any appropriate source is cut, and read and understand the specific product precautions of all relevant products carefully.

3. Before machinery/equipment is restarted, take measures to prevent unexpected operation and malfunction.

4. Contact SMC beforehand and take special consideration of safety measures if the product is to be used in any of the following conditions. 1. Conditions and environments outside of the given specifications, or use outdoors or in a place exposed to direct

sunlight.2. Installation on equipment in conjunction with atomic energy, railways, air navigation, space, shipping, vehicles, military,

medical treatment, combustion and recreation, or equipment in contact with food and beverages, emergency stop circuits, clutch and brake circuits in press applications, safety equipment or other applications unsuitable for the standard specifications described in the product catalog.

3. An application which could have negative effects on people, property, or animals requiring special safety analysis. 4. Use in an interlock circuit, which requires the provision of double interlock for possible failure by using a mechanical

protective function, and periodical checks to confirm proper operation.

Warning

Caution:

Danger :

Warning:

Caution indicates a hazard with a low level of risk which, if not avoided, could result in minor or moderate injury.

Danger indicates a hazard with a high level of risk which, if not avoided, will result in death or serious injury.

Warning indicates a hazard with a medium level of risk which, if not avoided, could result in death or serious injury.

Safety Instructions

Limited warranty and Disclaimer/Compliance Requirements The product used is subject to the following “Limited warranty and Disclaimer” and “Compliance Requirements”.Read and accept them before using the product.

1. The product is provided for use in manufacturing industries.The product herein described is basically provided for peaceful use in manufacturing industries. If considering using the product in other industries, consult SMC beforehand and exchange specifications or a contract if necessary. If anything is unclear, contact your nearest sales branch.

Caution

Limited warranty and Disclaimer

1. The warranty period of the product is 1 year in service or 1.5 years after the product is delivered.∗2)

Also, the product may have specified durability, running distance or replacement parts. Please consult your nearest sales branch.

2. For any failure or damage reported within the warranty period which is clearly our responsibility, a replacement product or necessary parts will be provided. This limited warranty applies only to our product independently, and not to any other damage incurred due to the failure of the product.

3. Prior to using SMC products, please read and understand the warranty terms and disclaimers noted in the specified catalog for the particular products.

∗2) Vacuum pads are excluded from this 1 year warranty.A vacuum pad is a consumable part, so it is warranted for a year after it is delivered. Also, even within the warranty period, the wear of a product due to the use of the vacuum pad or failure due to the deterioration of rubber material are not covered by the limited warranty.

Compliance Requirements1. The use of SMC products with production equipment for the manufacture of weapons of mass destruction (WMD) or

any other weapon is strictly prohibited.

2. The exports of SMC products or technology from one country to another are governed by the relevant security laws and regulations of the countries involved in the transaction. Prior to the shipment of a SMC product to another country, assure that all local rules governing that export are known and followed.

Back page 2

Selection

Caution7. Parallel usage

When using multiple shock absorbers in parallel, energy will not be divided evenly because of differences in product di-mensions and devices. For this reason, select the following options.E= Ea/N/0.6E: Energy used per shock absorberEa: All energiesN: The number of shock absorbers used in parallel.

Series RJSpecific Product Precautions 1Be sure to read this before handling. Refer to back pages 1 and 2 for Safety Instructions, “Handling Precautions for SMC Products” (M-E03-3) for Common Precautions.

Danger1. Absorbed energy

Select a model so that the aggregated energy of an impacting material should not exceed the maximum absorbed energy. Otherwise, it could cause changes in properties or result in damaging the shock absorber.

2. Equivalent massSelect a model so that the equivalent mass should not exceed the allowable range. Otherwise, pulsation could occur in buffer capacity and deceleration force, thus making it difficult to ab-sorb shock smoothly.

3. Collision speedUse the product within the specified collision speed range. Otherwise, it could cause the changes in buffer characteristics or result in damaging the shock absorber.

Warning1. Static load

Design the system so that any other forces than the buffer ca-pacity or impacts should not be applied to the piston rod which is stopped at the retracted state.

Caution1. Maximum operating frequency

Design the system in the conditions under which it is not used at the frequency exceeding the specified maximum operating frequency.

2. StrokeThe specified maximum absorbed energy cannot be exerted unless the full stroke is used.

3. Work surface of an impacting materialThe contact surface of an impacting material with which the piston rod comes into contact must be highly rigid.A high surface compression load is applied to the contact sur-face of the impacting material with which the piston rod comes into contact. Therefore, the contact surface must be highly rig-id (hardness of HRC35 or more).

4. Be aware of the backlash of the impacting material.When used in a conveyor line, the object may be pushed back by the built-in spring force after energy is absorbed. For back-lash, refer to the spring force in the specifications. (page 5)

5. Selection of sizeAs the number of operation proceeds, the maximum absorbed energy of shock absorbers will be decreased by the reasons such as abrasion, or deterioration, etc. of the internal working fluid. Taking this into consideration, selecting a size which is 20 to 40% affordable against the amount of absorbed energy is recommended.

6. Reaction forceIn general, the values of reaction force (reactive force gener-ated during operation) generated by the operating speed will vary in oil hydraulic shock absorber. The RJ series can adapt to such this fast/slow speed and can absorb shock smoothly in a wide range of speed.But, take note the stroke time could be long, and the motion would not be smooth, etc., depending on the operating condi-tions. If this would be a problem, we recommend the stroke amount should be restricted by using our optional component “stopper nut”, etc.

Back page 3

Operating Environment

Danger1. Operation in an environment which requires explo-

sion-proof• When mounting in places where static electricity is accumu-

lated, implement a distribution of electrical energy by grounding.

• Do not use the materials for buffer face which might cause to spark by collision.

Warning1. Pressure

Do not use the product in the vacuum state which is substan-tially different from the atmospheric pressure (above sea lev-el) and in the atmosphere under being pressurized.

2. Using inside a clean roomDo not use the product in a clean room, as it could contamin-ate the clean room.

Caution1. Temperature range

Do not use the product, exceeding the specified allowable temperature range. Seal could be softened or hardened or worn out, or leading to working fluid leak, deterioration, or buffer characteristic changes.

2. Deterioration by atmosphereDo not use the product in the presence of salt damage, sulfur-ous acid gas which makes the metal corroded, or solvent which makes the seal deteriorated.

3. Deterioration by ozoneDo not use the product under the direct sunlight on the beach, or by the mercury lamp, or the ozone generator, because the rubber material will be deteriorated by ozone.

4. Cutting oil, water, blown dustDo not use the product under the condition where the liquid such as cutting oil, water, solvent, etc. is exposed either di-rectly or in atomized form to the piston rod, or where blown dust could be adhered around the piston rod. This could cause malfunction.

5. VibrationWhen vibrations are applied on an impacting material, imple-ment a secure guide on the impacting material.

S: Shock absorber’s stroke(Catalog values)

Stopper nutS

a

Bottom set screw (Do not rotate.)

Piston rod

Do not damage.

Load

Mounting

Caution1. Tightening torque and mounting thread

When threading on the mounting frame in order to mount a shock absorber directly, refer to the below prepared hole dimensions. Observe the below tightening torque of a nut for shock absorber.If the tightening torque exceeds the below value, the shock absorber could be damaged.When a shock absorber is mounted on a cylinder, follow the torque values listed on each cylinder.

6. Adjust the stopping time by using a stopper nut.Control the stopping time of the impacting material by turning the stopper nut in or out (thus changing length “a”). After es-tablishing the stopper nut position, use a hexagon nut to se-cure the stopper nut in place.

Allowable eccentric angle θ1 < 3°

2. Deviation of impactMount the shock absorber so that the point of contact of an impacting material must be within the allowable eccentric an-gle range. If the eccentric angle exceed 3°, an excessive load could be placed on the bearings, resulting in oil leak in a short time.

4. Do not scratch the sliding portion of the piston rod or the outside threads of the outer tube.Failure to observe this precaution could scratch or gouge the sliding potion of the piston rod, or damage the seals, resulting in oil leak or malfunction. Furthermore, damage to outside threaded portion of the outer tube could prevent the shock ab-sorber from being mounted onto the frame, or result in mal-function by internal component parts deformation.

5. Never turn the screw on the bottom of the body. This is not an adjusting screw. Otherwise, oil leak could occur.

M10 x 1.0

3.14

ø9.1 + 0.10

Thread dimensions (mm)

Nut tightening torque (N ·m)

Thread prepared hole dia. (mm)

M8 x 1.0

1.67

ø7.1 + 0.10

M14 x 1.5

10.8

ø12.7 + 0.10

Model RJ10��RJ08�� RJ14��

RJ0805RJ0806RJ1006RJ1007RJ1410RJ1412

Model Load on mounting frame

3. Rotating angleIf swing impacts are involved, the installation must be de-signed so that the direction in which a load is applied should be perpendicular to the shock absorber’s axial center.The allowable rotating eccentric angle to the stroke end must be θ2 < 3°.

Allowable rotating eccentric angle θ2 < 3°

Caution

Installation Requirement for Swing Impacts (mm)

Model S(Stroke)

5

6

6

7

10

12

96

115

115

134

191

229

258

277

306

325

449

487

3°

θ2

(Allowable rotating angle)

R (Min. installation radius)

RJ0805RJ0806RJ1006RJ1007RJ1410RJ1412Note) Load on mounting frame is at room temperature (20 to 25°C).

For cap type θ1 < 1°

Series RJSpecific Product Precautions 2Be sure to read this before handling. Refer to back pages 1 and 2 for Safety Instructions, “Handling Precautions for SMC Products” (M-E03-3) for Common Precautions.

Warning1. Before performing installation, removal, or stroke

adjustment, make sure to cut the power supply to the equipment and verify that the equipment has stopped.

2. Installation of protective coverWe recommend the protective cover should be installed for fear that workers might be getting close during the operation.

3. Strength of mounting frameThe mounting frame needs to have sufficient strength. When deciding the strength of the mounting frame, consider the force applied to the mounting frame at the upper limit of oper-ating conditions shown in the below table, and allow a suffi-cient safety factor.

380 N

630 N

900 N

1600 N

1700 N

2000 N

With capBasic type

Back page 4

Akihabara UDX 15F, 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021, JAPANPhone: 03-5207-8249 Fax: 03-5298-5362URL http://www.smcworld.com© 2009 SMC Corporation All Rights Reserved

Specifications are subject to change without prior notice and any obligation on the part of the manufacturer.

1st printing MU printing NS 12200SZ Printed in Japan.D-SZ

This catalog is printed on recycled paper with concern for the global environment.

Safety Instructions Be sure to read “Handling Precautions for SMC Products” (M-E03-3) before using.

Record of changes

Edition C

Maintenance

Caution1. Confirm that the mounting nut is not loosen.

The shock absorber could be damaged if used in a loosen state.

2. Pay attention to any abnormal impact sounds or vi-brations.If impact sounds or vibrations become abnormally high, the shock absorber may reach the end of its service life. Replace the shock absorber. If using continuously in such a state, equipment could be damaged.

3. Confirm that there is no oil leak on the outer sur-face.When a large amount of oil is leaking, replace the product, be-cause it is believed to be happening something wrong with it. If using continuously in such a state, equipment could be damaged.

4. Check for cracks and wear in caps.For shock absorbers with caps, the caps will wear out first. Replace caps early to prevent damage to colliding objects.

Caution1. Position of the piston rod during storage

If the product is stored for an extended period (30 days or more) with the piston rod pushed, the absorption capacity could decrease. Avoid this kind of storage condition.

Caution1. As a guide, the maximum operating life of the prod-

uct (number of cycles) when operated within the specifications is as follows.3 million cycles RJ08��, 10��, 14��Note) This value (adequate replacement period) is at room temperature (20

to 25°C). The life can depend on conditions such as temperature so the product may need to be replaced before the above number of cycles is reached.

Life and Replacement Period of Product

Storage

Series RJSpecific Product Precautions 3Be sure to read this before handling. Refer to back pages 1 and 2 for Safety Instructions, “Handling Precautions for SMC Products” (M-E03-3) for Common Precautions.

· Addition of cap type and short stroke type. NS