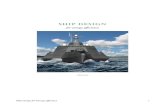

Ship energy efficiency in simulations and energy system ...

Transcript of Ship energy efficiency in simulations and energy system ...

Ship energy efficiency in simulations and energy system analysisModelling and Optimization of Ship Energy SystemsOctober 23 - 25, 2017. EPFL Sion, SwitzerlandInvited speakerAssoc. Prof. Kari Tammi, Aalto UniversityJari Vepsäläinen, Klaus Kivekäs, Juuso Autiosalo, Guangrong Zou

ContentBackground

Previous examples

• HT water control

• Power turbine usage

• Shaft generator usage

• Power demand estimation

Current work on uncertainty in power system design

• Cycle uncertainty

• Robust design

• Digital twin

Future outlook

Background & team

Kari Tammi, Aalto University 2015-

Earlier Research Professor at VTT:

electric machines, energy efficiency,

electric vehicles, dynamics & control

At CERN 1997-2000 (LHC/CMS)

Teaching: Mechatronic machine

design (5 cr), Vehicle mechatronics

(5 cr), Design of electric vehicle

systems at IIT Guwahati, India 2016

Panu Sainio. Chief Engineer, expertise:

vehicle technology, hybridization, electric

powertrain

Shashank Arora. Post-doc, expertise:

batteries, mechanical modelling

Klaus Kivekäs. Electric powertrain

optimization with statistical methods

Jari Vepsäläinen. Multi-objective robust

design of electric powertrain

Juuso Autiosalo. Digital twin for industrial

products

Ship Energy Flow Modelling

Mechanical Power, 48%

Exhaust Gas, 25.5%

HT Water, 15%

LT Water, 11%

Heat Radiation, 0.5%

FuelMarine Diesel

Engine

625/10/2017 6

95% of worldwide transport of goods by ships

Increasingly high fuel cost

Accumulatively strict IMO rules GREEN SHIPPING!

Motivation – Why Ship Energy Efficiency?!

shipping 95% aviation 1%

others 4%

EE

DI [g

.CO

2/te

.nm

]

Cut-off limit Capacity [DWT or GT]

Fig. 1: An EEDI reference figure of new-building ships enforced by IMO. (Source: Lloyd’s Register, (2012), Implementing the Energy

Efficiency Design Index)

725/10/2017 7

0 10 20 30 40 50 60 70

Container ships

Dry bulk vessels

Dry cargo vessels

Tankers

Passenger ships

Fuel cost for container ships is the highest among all the other ship types

Many are struggling to balance their financial sheets

Fuel costs as a percentage of total operational

costs for different ship types

825/10/2017 8

Motivation – How to Improve Ship Energy Efficiency?!

Better planning

Slow steaming Energy management

Novel technology

How to evaluate the overall effectiveness of each solution?

How to estimate the Return On Investment of each

solution?

Challenge

925/10/2017 9

Multi-Domain Energy Flow Simulation in Brief

Started in 2009

Aim at a general tool for ship power plant simulation

To find globally optimal ways to improve ship overall energy efficiency

To be modelled at a system level, ONLY main sub-systems included

Simulator modelling environment Matlab/Simulink/Simscape

Different physical interactions are modelled in DOMAINS in Simscape

Available: Mechanical, Electrical, Thermal, pneumatic

Self-developed: Electrical AC, Thermalfluid, Steam

Component libraries for each domain using Simscape language

1025/10/2017 10

To AirTo SEA

PowerGeneration

ElectricalSystems

HT Water Systems

Steam Powered Systems

FUEL

Acronym:DG - Diesel GeneratorEGE - Exhaust Gas EconomizerHT - High TemperatureLT - Low TemperatureMD - Main DistributionOFB - Oil Fired Boiler

EGE1

EGE2

DG1

DG2

DG3

DG4

OFB2

EGE3

EGE4

POD2

POD1

BOW THRUSTER

PROPULSION

ENGINE ROOM

CHILLERHOTEL

MD

AC CHILLER 1

AC CHILLER 2

AC CHILLER 3

MD20 MD30 MD40 MD50 MD60 MD70

AC CHILLER 4

OFB1

HOTEL

ENGINE

ENGINE PRE-HEATING

TANK HEATING

FUEL OIL HEATING

AIR-CONDITIONING

SWIMMING POOL

PORTABLE WATER HEATING

GALLEYS

LAUNDRY

FRESH WATER EVAPORATOR

HT WATER AIR-CONDITIONING

FRESH WATER EVAPORATOR

FRESH WATER EVAPORATOR 1

FRESH WATER EVAPORATOR 2

LT-WATER EXHAUST GAS

STEAM

Flow Colors:Black - Diesel (l/h)Green - Electrical power (kW)Purple - Exhaust Gas (kW)Red - Steam (kW)Blue - HT Water (kW)Light Blue - LT Water (kW)

Helpful to thoroughly understand the energy distribution and consumption

Potential to utilize the simulation method in different types of ships

Multi-Domain Energy Flow Simulation – Example

1125/10/2017 11

Ship Energy Flow Simulator

Sub systems

Electrical AC

4 DG sets

HT/LT FWC

STEAM

Data I/O &

processing,

result display

--Simplified Marine Engine Energy Flow Simulator--

EGE_T

EGE_mdot

EGE_T1

EGE_mdot1

Sub_STM2

EGE_T

EGE_mdot

EGE_T1

EGE_mdot1

Sub_STM1

HT_kw3

LT_kw3

HT_kw4

LT_kw4

To_HRC

From_HRC

Sub_FCW2

HT_kw1

LT_kw1

HT_kw2

LT_kw2

From_HRC

To_HRC

Sub_FCW1

TO_DG1&2

TO_DG3&4

Sub_ElectricAC

f(x)=0

To_HT12

From_HT12

From_HT34

To_HT34

EVAP&HVAC

DG_S

im

DG_R

eal

DG D

iff

DG_S

w

Fuel

_Sim

Fuel

_Com

p

Fuel

_Rea

l

Mdo

t_HT

P_HT

Q_H

T

T_HT

Fuel

_STM

HT_kw3

LT_kw3

HT_kw4

LT_kw4

Exh_T3

Exh_mf3

Exh_T4

Exh_mf4

To_ElecAC

DGset_3&4

Exh_T1

Exh_mf1

Exh_T2

Exh_mf2

HT_kw1

LT_kw1

HT_kw2

LT_kw2

To_ElecAC

DGset_1&2

1225/10/2017 12

Model validation results

0 1 2 3 4 5 6

x 105

0.8

0.9

1

1.1

1.2

1.3

Time (s)

Ra

tio

DG power difference (simulation results / measured data)

0 1 2 3 4 5 6

x 105

0.6

0.7

0.8

0.9

1

1.1

1.2

1.3

Time (s)

Ra

tio

DG power output

mostly within [0.95 1]

Ship fuel consumption

mostly within [0.95 1.15]

The energy flow simulator can accurately represent the energy flow

distribution in the case ship.

1325/10/2017 13

HT water control example

4N02

4V02

DE

4V01

LT Flow

HT Flow4P14

To test and verify different energy saving technologies and ideas

QUESTION: Can we harvest a part of the wasted heat energy by tuning

the set-point of valve 4V02?

1425/10/2017 14

HT water control example

0 10 20 30 40 50 60 70 80 90 10068

70

72

74

76

78

80

82

84

Engine Load (%)

Te

mp

era

ture

(C

)

Flow temperature control of 3-way mixing thermostat

To specify the set-point of valve 4V02 as a function of engine load

To Check:

Working efficiency

WHR

Working safety

– Constant set point

– Variable set point

1525/10/2017 15

Power and steam turbine usage

Shaft generator system (SG)

ME

Water Cooling systems

Aux. DG 1 Aux. DG 2 Aux. DG 3 Aux. DG 4 Aux. DG 5

Ringnet1 Ringnet2Cargo

3~BT

3~Engine Rooms

Dual-PEGE

TurboCharger

MSB, Electrical6600 V

Freq. Converter

PMS

Motoring

Gen

erating

Shaft Gen./Motor

Gen

erat

ors

SteamTurbinePower

Turbine

Waste heat recovery system (WHR)

1625/10/2017 16

Shaft generator usage

• Generator mode • Parallel generation • Motor/booster mode

Harvest energy from ME shaft to generate electricity, less fuel consumption

More flexible energy utilization to achieve higher overall energy efficiency

>=50%

(Source: Rolls-Royce, Hybrid shaft generator propulsion system upgrade)

1725/10/2017 17

Results

Different energy saving solutions evaluated

under operation cycles recoded on-board

Improved HT water temperature control

ROI 1 year, annual fuel savings 50 kUSD

(HT/LT 3-way valve), [1]

In collaboration with ABB & Deltamarin

Power turbine in waste heat recovery

ROI 2 years, annual fuel savings 2 M€, [2-3]

In collaboration with ABB

1. Zou G., Elg M., Kinnunen A., Kovanen P., Tammi K. & Tervo K. Modeling ship energy flow with multi-

domain simulation. CIMAC.2013

2. Zou G., Kinnunen A., Tervo K., Orivuori J., Vänskä K. & Tammi K. Evaluate Ship Energy Saving

Scenarios Using Multi-Domain Energy Flow Simulation. COMPIT.2014

3. Solution developed was installed in 14 new container ships. ABB to provide waste heat recovery

systems for 14 container ships. World Maritime News. Nov 15, 2013

http://worldmaritimenews.com/archives/97685/abb-to-provide-waste-heat-recovery-systems-for-14-

container-ships/

0 1 2 3 4 5

x 105

0

15

30

45

60

75

Time (s)

Recovere

d h

eat

gain

(%

)

0 1 2 3 4 5

x 105

40

50

60

70

80

90

Time (s)

Engin

e load (

%)

0 1 2 3 4 5

x 105

1

1.5

2

2.5

3

3.5x 10

6

Time (s)

Recovere

d h

eat

(W)

Variable set point

Constant set point

(b)

(a)

(c)

1925/10/2017 19

Energy flow prediction

How to estimate energy flows within ship based on

incomplete measurement information?

How to predict / forecast the energy flows 6-32 hours

ahead as accurately as possible?

How to operate and control ship and ship systems as

energy efficiently as possible?

Driving cycle and passenger load uncertainty - approach• How much do the variations in the driving cycle and

passenger load on a single bus route affect the energy

consumption?

• Create a method to generate varying synthetic cycles and

passenger flows and then run them with a simulation model.

• Case example: Line 11 in Espoo, battery electric bus

• Note: “driving cycle” substantially more complicated in ships

due to high auxiliary loads

Driving cycle and passenger load uncertainty - methods• Divide route into segments between bus stops

• Create new cycles by randomly choosing respective

segments from measured cycles

• Segments need to be connected

• The bus stops at which the vehicle stops are also randomized

• Cycle synthesis validated:

• Passenger flow is sampled from a multivariate distribution

• Energy consumption

distribution acquired

• Resembles normal distribution

• Mean: 0.913 kWh/km, Range: 0.301 kWh/km

• Consumption correlates

strongly with number of stops

• Pearson coefficient: 0.778

• Lesser correlation with

passenger load

Driving cycle and passenger load uncertainty - results

Robust Design – Approach (1/2)

• Noise factors cause unwanted

variation in vehicle performance

• Robust design = make the system

insensitive to these variations

• Identify noise factors and their

range of values

• Study control factors that reduce

the effect of noise factor variation

Payload

User Behaviour

Age & Wear

Waves & Storms

Operating Temperature

Robust Design – Approach (2/2)

• Robustly optimize control

factors to guarantee long lasting

quality design, without

unnecessary oversizing of

components

Payload

User Behavior

Age & Wear

Waves & Storms

Temperature

Energy Storages+

Propulsion

Energy Generation & Control+ +

Robust Design – Methods

Challenge: Complex

dynamic model

Solution: Surrogate

analytical model (PCE)

Sensitivity analysis:

Impact of Noise Factors

Noise

FactorsControl

Factors

Robust Design – Results Case: Electric City BusThe consumption varied from 0.4 to 2.3 kWh/km in the

selected route

• Key noise factors1. Ambient temperature

2. Rolling resistance

3. Mission

4. Driver aggressiveness

5. Traffic

6. Payload

7. Headwind

25.10.2017

29

Digital Twin

25.10.2017

30

Physical Twin Digital TwinKnowledge

Data

1. Can be inspected with

all senses on location

2. Obeys laws of physics

3. Doesn’t have

intelligence

4. Is constantly changing

1. Can be inspected through a user

interface from anywhere around the

world

2. Laws of physics must be simulated

3. Can have artificial intelligence that can

be used to control physical twin

4. Must be updated to match the physical

twin

IoT & Digital Twin, Approach

Ship energy systems are constantly producing vast amount of

data. This data could be utilized better with enhanced

connectivity and data management

Currently, there is no standardized way of transferring and

displaying data. Standardizing work is necessary, and good

standards can only be achieved through experience

Functional demonstrators will crucial for creating the future

standards.

IoT & Digital Twin, Benefits

Benefits of Digital Twin come from multiple factors:

1. Deeper knowledge of the energy process state

2. Centralized data interface

3. Deductions from comparing large populations with e.g with

artificial intelligence

4. Truly integrating connected products to each other with

standardized data formats

Energy system optimisation

Operation optimisation

Fleet management

Technologies (to be) studied

IoT: automation systems provide with various measurements

Computer power enables on-line control and e.g.

• Uncertainty and sensitivity in design

• Tracking simulator approaches

Emerging technologies:

• Electrification (hybridization), DC grid, variable AC

• Energy storages, electric and thermal

• Waste Heat Recovery (ORC, connection to energy storages)

• Absorption chillers

• Power turbines and multi-stage turbo charging

SET final publication in VTT Technology serieshttp://www.vtt.fi/inf/pdf/technology/2017/T306.pdf.