Shear Force Full Report

-

Upload

mohd-shafiq -

Category

Documents

-

view

43 -

download

1

description

Transcript of Shear Force Full Report

1

1.0 OBJECTIVE

1.1 Part 1: To plot Shear force influence line.

1.2 Part 2: To verify the use of a shear force influence on a simply supported

beam

INTRODUCTION

Moving loads on beams are common features of design. Many road bridges are constructed from beam, and as such have to be designed to carry a knife edge load, or a string of wheel loads, or a uniformly distributed load, or perhaps the worst combination of all three. The method of solving the problem is to use influence lines.

THEORY

Defination: Shear influence line is defined as a line representing the changes in shear force at a section of a beam when a unit load moves on the beam

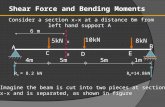

Part 1: This Experiment examines how shear force varies at a cut section as a unit load moves from one end to another (see Figure 1). From the diagram, shear force influence line equation can be written. For 0 x a a shear line is given by:

Sy = x/ L (1)

For a x b shear line is given by:

Sy = 1 x L. (2)

Part 2: If the beam are loaded as shown in Figure 2, the shear force at the cut can be calculated using the influence line. (See diagram 2).

Shear force at cut section = F1 y1 + F2 y2 + F3 y3 (3)

(y1, y2 and y3 are ordinates derived from the influence line in terms of x1, x2, x3, a, b and L)

APPARATUS

Shear Force machine

Weight (Loadings)

Beam

Digital Force Display

Load

PROCEDURES

Part 1

1. Digital Force Display meter reads zero with no load is checking.

2. Hanger with any mass range between 100g to 300g was placed at the first grooved hanger support at the left support and the Digital Force reading recorded in Table 1.

3. The procedure to the next grooved hanger until to the last grooved hanger at the right hand support was repeated.

4. The calculation in Table 1 was completed.

Part 2

1. Three load hangers with 100g. 200g and 300g mass respectively placed at any position between the supports. The positions and the Digital Force Display reading recorded in Table 2.

2. The produce with three other locations was repeated.3. The calculation in Table 2 was completed.

RESULT

Part 1:

Location of load from left hand support (m)Digital Force Display Reading ( N )Shear Force at cut section ( N )Experimental Influence line valueTheoretical Influence lines value

0.040.20.20.102-0.091

0.060.30.30.153-0.136

0.080.40.40.204-0.182

0.100.50.50.255-0.227

0.120.60.60.306-0.273

0.140.70.70.357-0.318

0.160.80.80.408-0.364

0.180.90.90.459-0.409

0.201.01.00.510-0.455

0.221.01.00.510-0.500

0.241.11.10.561-0.545

0.261.21.20.612-0.591

0.34-0.5-0.5-0.2550.227

0.36-0.4-0.4-0.2040.182

0.38-0.3-0.3-0.1530.136

0.40-0.2-0.2-0.0510.091

Part 2:

Position of hanger from left handShear force Digital Reading (N)Theoretical Shear ( Nm )

Locationsupport ( m )

100g200g300g

10.220.240.062.01.962

20.160.080.242.41.581

30.260.040.141.81.156

40.100.240.380.91.000

6.1CALCULATION

Part 1:

1) Experimental Influence line values = Shear Force (N)

Load (N)

Eg. Experimental Influence line values = 0.2 N

= 0.102

200 x 9.81/1000

2) Theoretical Influence lines value; 0.04 x 0.26m

Theoretical value, Sy = -x/L

Eg.Theoretical value, Sy = -0.04/ 0.44

= - 0.091

3) Theoretical Influence lines value; 0.32 x 0.38m

Theoretical value, Sy =1 -x/L

Eg.Theoretical value, Sy = 1 -0.34/ 0.44

= 0.227

Part 2:

Location 1

Y3 Y1 Y2

300g 100g200g

60mm

220mm

140mm

240mm

300mm

a/L

b/L

a/L

=300/440

=0.682

b/L

=140/440

=0.318

y1 / 220=0.682 / 300

y1=0.500

y2 / 240=0.682 / 300

y2=0.546

y3 / 60 =0.682 / 300

y3=0.136

Theoretical Shear = F1y1 + F2y2 + F3y3.

= [(0.1 x 0.5) + (0.2 x 0.546) + (0.3 x 0.136)] x 9.81

=1.962 NmLocation 2

Y2 Y1 Y3

200g 100g300g

80mm

160mm

140mm

240mm

300mm

a/L

b/L

y1 / 160=0.682 / 300

y1=0.248

y2 / 80=0.682 / 300

y2=0.124

y3 / 240=0.682 / 300

y3=0.372

Theoretical Shear = F1y1 + F2y2 + F3y3.

= [(0.1 x 0.248) + (0.2 x 0.124) + (0.3 x 0.372)] x 9.81

=1.581 NmLocation 3

Y2 Y3 Y1

200g 300g100g

40mm

140mm

140mm

260mm

300mm

a/L

b/L

y1 / 200=0.682 / 300

y1=0.403

y2 / 40=0.682 / 300

y2=0.062

y3 / 140=0.682 / 300

y3=0.217

Theoretical Shear = F1y1 + F2y2 + F3y3.

= [(0.1 x 0.403) + (0.2 x 0.062) + (0.3 x 0.217)] x 9.81

=1.156 NmLocation 4

Y1 Y2

Y3

100g 200g

300g100mm

140mm

240mm

60mm

300mm

a/L

b/L

y1 / 100=0.682 / 300

y1=0.155

y2 / 240=0.682 / 300

y2=0.372

y3 / 60=0.682 / 300

y3=0.043

Theoretical Shear = F1y1 + F2y2 + F3y3.

= [(0.1 x 0.155) + (0.2 x 0.372) + (0.3 x 0.043)] x 9.81

=1.008 Nm7.0DISCUSSIONS

Part 1:

1. Derive equation 1 and 2.

Equation 1

Mcut = 0

Fy = 0

(L-x)/L -1 Sy = 0

Sy = -x/L

Equation 2

Mcut = 0

Fy = 0

(L-x)/L Sy = 0

Sy = (L-x)/L

Sy = 1 x/L

2. On the same graph paper, plot the theoretical and experimental values against distance from left hand support.

3. Comment on the shape of graph. What does it tell you about how shear force varies at the cut section as a load moved on the beam?

The experimental result increases with the increasing of the distance of load from the left hand support at the left side of the cut. Based on the result, the values of shear force at cut section (N) increases when a load moves nearer towards the cut.

4. Comment on the experimental result compared to the theoretical result.

Based on the results that we got, shows a totally different result between the theoretical and experimental values. For the experimental influence line value, there are a big different between those experimental and theoretical. Overall, based on the procedure, we followed the right instruction. It might be the error of the machine itself and not in the good condition.

Part 2 :

1. Comment the experimental result and the theoretical result in Table 2.

In this part, we used the load 100g, 200g and 300g. From this experiment, the value for the location 1 to 4, the value for the experimental is bigger than the theoretical value. The value is depend on the location but the value for both results is not so much differences.

8.0CONCLUSION

Part 1 :

From the experiment, we know that the value for the experimental and theoretical values is totally difference. From the graph it shows totally difference result between theoretical and experimental result. Based on the result, the values of shear force at cut section (N) increases when a load moves nearer towards the cut.

Part 2 :

From the experiment, its shows that the location is one of the causes for the differences between the value. We should know that, influence lines can be used to calculate the shear force at the cut section.

![[9] shear force n bending moment](https://static.fdocuments.us/doc/165x107/553af101550346f92f8b4613/9-shear-force-n-bending-moment.jpg)