SERVICE MANUAL - s.eet.eu · The shredder uses two rotating cutting shafts, which are driven by an...

Transcript of SERVICE MANUAL - s.eet.eu · The shredder uses two rotating cutting shafts, which are driven by an...

SERVICE MANUAL(2009.12.18)

GDS2213GDX1813GDM1013GDHS713

GDS2219GDX2019

GSS208GSX168GSM128RSS2030RSX1630RSM1130

RDS2250RDX1850RDM1150RDSM750

RDS2270RDX2070

© 2009 All Rights Reserved

No part of this publicationmay be reproduced in any

form without expressedwritten permission from

Electronically Printed and Designed in the USA.

2

8-9

INTRODUCTION

SAFETY YINSTRUCTIONS

TROUBLESHOOTING

DISASSEMBLY/ADJUSTMENTS

MAINTENANCE

10.0 SPECIAL INSTRUCTIONS

INSTALLATION

Table of Contents

1

SPECIFICATIONS

2

3-7

Introduction 11

g

hi d

a

f

1

3

e

b

Models:

c

i

f

e

g

b

h d

a1

2

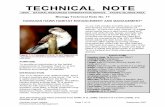

Introduction

Thank you for choosing this shredder from GBC. We are sure it will serve you well, but please take a little time to study these instructions to ensure you get the best out of your machine.

a Important Safety Symbolsb GSS208, GSX168, GSM128:

Pull Out Drawer GDS2213, GDX1813, GDS2219, GDX2019, GDM1013, GDHS713: Door for Bin

c Wheelsd On/O� Button (Rear of machine)e Auto Buttonf Reverse Buttong Continuous Forward Functionh CD Guide (not �tted on GDM1013, GDHS713, GSM128)

1 Bin Full (Red Light) 2 Door Open (Red Light) 3 Cool Down (Red Light)

2Specifications

Speci�cationsGSX168

15-16 sheets

4 mins on / 20 mins o�

120V AC / 60Hz

4.0A

Yes

GSM128

10-11 sheets

4 mins on / 20 mins o�

120V AC / 60Hz

No

GDS2213

19-22 sheets

Continuous

120V AC / 60Hz

3.0A

Yes

Models

Sheet Capacity 80gsm paper -

Duty Cycle

Volts / Hz

Amperage

CD / Credit Card

IMPORTANT: ONLY INSERT ONE CD OR ONE CREDIT CARD AT A TIME. Models GDM1013, GDHS713 and GSM128 cannot shred CDs, credit cards, paper clips or staples. Sheet capacity may vary with AC line voltage.

GDX1813

16-18 sheets

Continuous

120V AC / 60Hz

4.5A

Yes

GSS208

17-20 sheets

4 mins on / 20 mins o�

120V / 60Hz

Yes

•

Models

Sheet Capacity 80gsm paper -

Duty Cycle

Volts / Hz

Amperage

CD / Credit Card

GDM1013

10-11 sheets

Continuous

120V AC / 60Hz

No

GDHS713

6-7 sheets

Continuous

120V AC / 60Hz

No

GDS2219

21-22 sheets

Continuous

120V AC / 60Hz

3.0A

Yes

GDX2019

18-20 sheets

Continuous

120V AC / 60Hz

5.0A

Yes

Speci�cations

RSS2030

20 sheets (19 sheets @ 207V/50Hz)

4 mins on / 20 mins o�

230V AC / 50Hz

1.5A

RSX1630

16 sheets (15 sheets @ 207V/50Hz)

4 mins on / 20 mins o�

230V AC / 50Hz

1.9A

RSM1130

11 sheets 10 sheets @ 207V/50Hz)

4 mins on / 20 mins o�

230V AC / 50Hz

2.2A

RSX1632

16 sheets (15 sheets @ 207V/50Hz)

4 min on / 30 min o�

230V AC / 50Hz

2.9A

RSS2232

22 sheets (21 sheets @ 207V/50Hz)

4 min on / 30 min o�

230V AC / 50Hz

1.9A

RDS2250

22 sheets (21 sheets @ 207V/50Hz)

Continuous

230V AC / 50Hz

1.2A

Models

Sheet Capacity 80gsm paper -

Duty Cycle -

Volts / Hz

Amperage

IMPORTANT: ONLY INSERT ONE CD OR ONE CREDIT CARD AT A TIME. Models RDM1150, RDSM750 and RSM1130 cannot shred CDs, credit cards, paper clips or staplesm

RDX1850

18 sheets (17 sheets @ 207V/50Hz)

Continuous

230V AC / 50Hz

2.0A

Models

Sheet Capacity 80gsm paper -

Duty Cycle -

Volts / Hz

Amperage

RDM1050

11 sheets (10 sheets @ 207V/50Hz)

Continuous

230V AC / 50Hz

3.5A

RDSM750

7 sheets (6 sheets @ 207V/50Hz)

Continuous

230V AC / 50Hz

3.5A

RDS2270

22 sheets (21 sheets @ 207V/50Hz)

Continuous

230V AC / 50Hz

1.2A

RDX2070

20 sheets (19 sheets @ 207V/50Hz)

Continuous

230V AC / 50Hz

2.0A

Mechanical Operation

The shredder uses two rotating cutting shafts,which are driven by an electrical motor to shredpaper.

Electrical Operation

When the on/o� switch on back of unit is on, and center auto button is pressed. This will

The shredder will nowbe in standby mode and the “Power-on” symbol on the indicator panel will be illuminated amber.When the shredder is in standby mode and the thecabinet door is opend,the normally closed dooradjar micro switch is opened and prevents power to the motor until the door is closed.. When the bag fullsensor is triggered, the bag full icon will illuminate.The control board will then disable the motor circuituntil the shredder bag is either cleared or emptied.

When the shredder is severely loaded down, thecontrol board will illuminate red and disable the motor circuit.

Electrical Components

Motor - Thermally protected motor designed for continous operation.

Capacitor - AC motor run capacitor.

Power on/Auto feed on switch - The Power on/Auto feed on switch, when depressed, connectsthe hot and neutral circuits to electrical componentsof the shredder.

Door ajar, Machine head safety switch - The safetyswitch is a normally open micro switch which isactuated by a trigger located inside of the cabinet door.The switch is normally closed when the door isclosed and when the machine head is installed on thecabinet.

Bag Full Flap Sensor - The Bag Full Sensor is a normallyclosed switch actuated by paper blocking sensor path.When the shred bag becomes full of shredded material,the bag full sensor is blocked and power is thenremoved from the motor circuit.

Paper Sensors - Located in the throat area consist-ing of two components, the emitter and receiver.

Emitter - The infrared light beam from the light emit-ting diode is sensed by the receiver to activate/deac-tivate the control board.

Receiver - The receiver is a light activated diode,which works in conjunction with the emitter to acti-vate/deactivate the control board.

Testing Electrical Components

WARNING!Always disconnect the power cord from receptaclebefore making continuity or resistance tests.

SwitchesSet meter to read resistance. Check switches forcontinuity from common to closed contacts andity from common to the open contact.

Emitter - Set meter to the diode setting. Disconnectemitters from the control board. With the positivemeter probe on the emitter wire and the negativemeter probe on the black-stripped emitter wire,check for approximately .639 ohms. Reverse themeter leads and should be read.

Receiver - Set meter to read 20M ohms. Disconnectthe receiver from the control board. With the positivemeter probe on the receiver wire and the negativemeter probe on the receiver wire check for app-roximately 4.62 Mega ohms under normal roomlight. The resistance will increase when blocked.Reverse the meter leads and should be read.

5.0 T 8Troubleshooting 3

inate the anti-jam indicatorillum-

5.0 T

General Troubleshooting

Malfunction corrections are based on visual obser-vations made by the operator. The causes of themalfunctions are isolated by the symptom of themalfunction and noting at which point in the operat-ing cycle the malfunction occurred. Malfunctionsmay be pinpointed to a defective electrical compo-nent or mechanical part by referring to thePrinciples of Operation, the troubleshooting guideand the wiring diagram.

Troubleshooting Chart

The troubleshooting guide chart that follows isarranged in order of the normal operationalsequence. When a malfunction occurs, read downthe SYMPTOM column until you the appropri-ate description for your symptom. Read the corre-sponding PROBABLE CAUSE, then perform therecommended procedure in the CORRECTIVEACTION column. When replacing electrical compo-nents that have push on terminals, label the electri-cal leads that were removed, to facilitate reconnecting them. Refer to the wiring diagram in Figure 5.7to resolve any wiring di culties that may occur.

WARNING!Always unplug the shredder to avoid possible elec-trical shock hazard before attempting to performany repairs.

Troubleshooting 4

5.0

Shredder Does NotOperate, No Indication OfPower

Shredder Does NotOperate, With IndicationOf Power Present

Shredder Does NotOperate, (When Paper IsPresent In The Throat)

Shredder RunsContinuously

Sheet CapacityDiminished

Power Cord Disconnected.

Power switch DefectiveMain Board Defective

Shredder Head NotInstalled Properly

Cabinet Door Open

Shred Bag Full

Motor Thermal CutTriggered

Door Switch Defective

Defective Capacitor

Motor Defective

Emitter/Receiver Defective

Main Board Defective

Dust Or Scratch OnEmitter/Receiver

Defective Control Board

Emitter/Receiver Defective

Dry Blades

Dull Cutters

Worn Bearings

Connect Power Cord

Replace Power SwitchReplace Main Board

Reposition Shredder Head

Close Door

Empty Bag

Allow Motor To Cool

Replace Door Switch

Replace Capacitor

Check Motor Input VoltageReplace Motor If Necessary

Replace If Necessary

Replace If Necessary

Clean Or Replace

Replace If Necessary

Replace If Necessary

Lubricate Cutters

Replace Cutters

Replace Bearings

Troubleshooting 5

6Troubleshooting

Line_SW

TCO

Neutral

Line_SW

TCO

Reverse1

Line_SW

Forward1

NE

UTR

AL

Reverse1

Forward1

Line_SW

Neutral

Neutral

Neutral

Forward1

Neutral

Reverse1

Reverse Forw

ard

Jam_S

IG

Reverse1

Forward1

5V10V

9V~18V

5VS

W

5V5V

SW

5VS

W

5VS

W

5VS

W

5VS

W

5VS

W

5V

Reverse

Forward

Timm

er

TCO

_SIG

Jam_S

IG

DO

OR

_open

USE Traic control motor function

USA: 160K 1/2W

EU: 2uF 400V

EU&JP: 27uF 50V

USA: 160K 1/2W

USA: 11K 1/4W

USA: 11K 1/4W

USA: 11K 1/4W

USA: 51K 1/2W

USA: 51K 1/2W

USA: 11K 1/4W

MOTOR

OPEN V1 FOR USA &JP

C3

0.01uF/250VC

30.01uF/250V

R24

160K 1/2W

R24

160K 1/2W

R33

470K 1/2W R33

470K 1/2W

C14

220uF/35V

C14

220uF/35V

R26

22K

R26

22K

C15

33UF 50V

C15

33UF 50V

R11

1KR

111K

R8

1.5K 1/8W

R8

1.5K 1/8W

R28

22K 1/4W

R28

22K 1/4W

R20

220K 1/2W

R20

220K 1/2W

R15

470RR

15470R

R31

22K

R31

22K

CA

P

CO

N\3.96M

M\3-2P

CA

P

CO

N\3.96M

M\3-2P

13

R1

1K R1

1K

U2F

74HC

14

U2F

74HC

1413

12

R2310K

R2310K

CX

1

o.47uF/250V CX

1

o.47uF/250V

U2C

74HC

14

U2C

74HC

14

56

QA

3TM

G16C

60Q

A3

TMG

16C60

3

21

D4

DIP

/1N4004

D4

DIP

/1N4004

U5

EL-817U

5E

L-817

12

43

R2

10K 1/8W

R2

10K 1/8W

D9

IN4004

D9

IN4004

D6

SM

T/1N4148

D6

SM

T/1N4148

LINC

N2

LINC

N2

1 1

CO

N\3.96M

M\6-5P

CO

N\3.96M

M\6-5P

11

22

33

44

55

CY

2472/400VC

Y2

472/400V

R103

680RR

103680R

QA

1S

S8550

QA

1S

S8550

31

2

R7

10KR

710K

U1C

74HC

14

U1C

74HC

14

56

+C

4

4.7UF/25V

+C

4

4.7UF/25V

C8

0.1uF

C8

0.1uF

UB

2M

OC

3063U

B2

MO

C3063

12

4 5

3

6

QA

2TM

G16C

60Q

A2

TMG

16C60

3

21

R17

10KR

1710K

DA

DD

1IN

4004D

AD

D1

IN4004

R22

22K

R22

22K

D7

DIP

/1N4004

D7

DIP

/1N4004

R13

47R 1/2W

R13

47R 1/2W

U2D

74HC

14

U2D

74HC

14

98

D3

DIP

/1N4004

D3

DIP

/1N4004

+

C1

10UF/25V

+

C1

10UF/25V

R14

47R 1/2W

R14

47R 1/2W

R4

47R 1/2W

R4

47R 1/2W

SW

2D

OO

RS

WS

W2

DO

OR

SW

NC

NO

U7

LM7805/TO

-220U

7LM

7805/TO-220

1

2 3

UB

1M

OC

3063U

B1

MO

C3063

12

4 5

3

6

C7

0.1uF C7

0.1uF

C5

0.01uF/250VC

50.01uF/250V

C6

0.01uF/250VC

60.01uF/250V

R101

1.5KR

1011.5K

U6

EL-817

U6

EL-817

12

43

R104

680RR

104680R

U2B

74HC

14

U2B

74HC

143

4

R5

47R 1/2W

R5

47R 1/2W

R27

220K 1/2W

R27

220K 1/2W

R10

1K 1/8WR

101K

1/8W

R30

160K 1/2W

R30

160K 1/2W

D1

1N4148

D1

1N4148

R25

22K

R25

22K

DA

DD

2IN

4004

DA

DD

2IN

4004

U1B

74HC

14

U1B

74HC

14

34

R19

22K

R19

22K

D2

SM

T/1N4148

D2

SM

T/1N4148

D5

SM

T/1N4148

D5

SM

T/1N4148

Line

PA

D

Line

PA

D1

Q1

SC

1815Q

1S

C1815

1

2 3

AC

PO

WE

R C

OR

DA

C P

OW

ER

CO

RD N

L

GND

R34

220K 1/2WR

34220K

1/2W

R18

1KR

181K

R32

470K 1/2W

R32

470K 1/2W

L_IN

PA

D L_IN

PA

D 1

R99

680RR

99680R

D8

DIP

/1N4004

D8

DIP

/1N4004

U3

EL-817

U3

EL-817

12

43

F1FUS

E\21M

M

F1FUS

E\21M

M

C2

0.01uF/250VC

20.01uF/250V

R12

1K R12

1K

C12

0.1uF

C12

0.1uFP

OW

ER

SW

Pow

er SW

(RO

CK

) 16A/250V

AC

PO

WE

RS

W

Pow

er SW

(RO

CK

) 16A/250V

AC

R16

1KR

161K

C10

0.1uF

C10

0.1uF

V1

VAR\MOV0.4

V1

VAR\MOV0.4 1 2

R3

1k 1/8WR

31k 1/8W

C11

3.5UF 250V

C11

3.5UF 250V

R102

1.5KR

1021.5K

NE

UT

CN

1

NE

UT

CN

1 11

CY

1472/400VC

Y1

472/400V

U2A

74HC

14

U2A

74HC

14

12

U2E

74HC

14

U2E

74HC

14

1110

R6

470RR

6470R

D10

IN4004

D10

IN4004

R29

22K

R29

22K

R9

47K 1/8W

R9

47K 1/8W

U4

EL-817

U4

EL-817

12

43

C9

0.1uF

C9

0.1uF

R21

22K 1/4W R

21

22K 1/4W

C13

470uF/16V

C13

470uF/16V

R100

680RR

100680R

Troubleshooting7

OS

C1

RE

S

D3

D2

D1

D0

D4

D5

D1

D0

Green_LE

DR

ed_LED

D5

Auto_key

D2

Auto_key

For_key

Rev_key

Red_LE

D

Green_LE

D

For_keyR

ev_key

D4

D3

Auto_key

B

1Y

1Y

2Y2Y

Rev_key

For_key

D6

D6

A

A B

D6

2YA

Rev_key

B

1Y

Green_LE

DR

ed_LED

D0D1

D2

For_keyR

ev_key

D1

D0

Green_LE

DR

ed_LED

D5

Auto_key

Rev_key

For_keyA

uto_key

Green_LE

DR

ed_LED

D0

D1

D5

D5

D5

D2

Green_LE

DR

ed_LED

D0

D2

OS

C2

OS

C1

OS

C2

RE

S

5V

5V

5V

5V5V

5V

5V

5V

5V

5V

5V

5V

5V

5V

5V

5V

Jam_S

IG

Reverse

Forward

Timm

er

Door_open

Binfull/

CD

_Trigger/

Paper_Trigger/

AntiJam

_IR2

AntiJam

_IR1

TCO

_SIG

TCO

_SIG

Door_open

CD

_Trigger/

Binfull/

Paper_Trigger/

Add TestPoint AntiJam_IR2&D6 spare

part for Max sheet

Design D+ LED PCBA

Add TestPoint

Plus&Silver Key Board

0R or the IC

Silver E+ LED Board

Silver F+ LED Board

PCBLAYOUT add this part

SWC1

SWC2

R84

10kR

8410k

R74

10k

R74

10k

Forward

Forward

R93

10kR

9310k

C26

0.1uFC

260.1uF

R83

10kR

8310k

R4

470RR

4470R

R3

470RR

3470R

R2

470RR

2470R

LED

6

Auto(B

LUE

)

LED

6

Auto(B

LUE

)

R90

10KR

9010K

R4

470RR

4470R

R3

470RR

3470R

R76

0R R76

0R

CO

N1

CO

N1

123456R

68100R

R68

100RR77

10k

R77

10k

R80

10KR

8010K

R82

0R R82

0R

R4

470RR

4470R

R71

1KR

711K

Q2

2SC

1815_SM

TQ

22S

C1815_S

MT

1

2 3

U10

74HC

153

U10

74HC

153

1G/E

N1

B2

1C3

3

1C2

4

1C1

5

1C0

6

1Y7

GN

D8

2Y9

2C0

10

2C1

11

2C2

12

2C3

13

A14

EN

/2G15

VC

C16

C2730P

C2730P

Auto on/off

Auto on/off

R62

1KR

621K

CO

N1A

1

CO

N\2.0M

M-12P

CO

N1A

1

CO

N\2.0M

M-12P

123456789101112

R81

10KR

8110K

R73

100K

R73

100K

X1

4MH

Z

X1

4MH

Z

R88

10KR

8810K

LED

5

GR

EN

/RE

D

LED

5

GR

EN

/RE

D

R75

10K

R75

10K

R70

470RR

70470R

LED

5

GR

EN

/RE

D

LED

5

GR

EN

/RE

D

R78

0R R78

0RR86

0R R86

0R

Q3

2SC

1815_SM

TQ

32S

C1815_S

MT

1

2 3

R72

30KR

7230K

R94

150RR

94150R

R92

10k

R92

10k

Q3

2SA

1015Q

32S

A1015

3

12

LED

1

BinFull(R

ed)

LED

1

BinFull(R

ed)

C23

0.1uF

C23

0.1uF

LED

1

BinFull(R

ed)

LED

1

BinFull(R

ed)

LED

5

GR

EN

/RE

D

LED

5

GR

EN

/RE

D

HT48R

0AA

-1-24U

9H

T48R0A

A-1-24

U9

PB

28

PA

24

PA

15

PA

06

PB

37

PA

33

PD

0/INT

12

RE

S15

PC

5/TRM

R1

14

OS

C1

17

VD

D16

VS

S11

PB

0/BZ

10

PC

0/TMR

013

PB

42

PB

51

OS

C2

18

PA

719

PA

620

PA

422

PA

521

PB

1/BZ

9

PB

723

PB

624

C24

0.47uF

C24

0.47uF

R65

470RR

65470R

R69

0R R69

0R

C22

0.01uF

C22

0.01uF

LED

2

TCO

(red)

LED

2

TCO

(red)

LED

1

BinFull(R

ed)

LED

1

BinFull(R

ed)

R64

470RR

64470R

R79

10KR

7910K

ZD1

3V/0.5WZD

13V

/0.5W

1 2

CO

N1A

1C

ON

1A1

1234567891011

R87

3KR

873K

C25

0.1uFC

250.1uF

LED

3

Door(R

ed)

LED

3

Door(R

ed)

LED

2

TCO

(red)

LED

2

TCO

(red)

LED

3

Door(R

ed)

LED

3

Door(R

ed)

R67

470RR

67470R

R1

470RR

1470R

R63

100RR

63100R

R85

0R R85

0R

R89

3KR

893K

R1

470RR

1470R

SW

C3

ReverseS

WC

3R

everse

R2

470RR

2470R

R61

470RR

61470R

R91

100RR

91100R

R66

47K

R66

47K

LED

4

GR

EN

/RE

D

LED

4

GR

EN

/RE

D

LED

4

GR

EN

/RE

D

LED

4

GR

EN

/RE

D

C21

4.7uF/10VC

214.7uF/10V

LED

4LE

D4

R3

470RR

3470R

R2

470RR

2470R

R1

470RR

1470R

CO

N1

CO

N1

123456

R60

470RR

60470R

Necessary Tools

1.2. #2 Phillips Screwdriver

Disassembly of the shredder is described in the following steps.

Bottom Housing Removal

WARNING!Disconnect the unit from the receptacle before performing anydisassembly procedures.

1.Unplug the power cord from the outlet power supply.2.Open cabinet door and remove the 5 philip head screws thatsecure shredder head to cabinet base.3.Remove shredder head from cabinet by sliding it towards you.Lay the unit upside down with the back of the head facing up.4.Remove the e l e v e n phillip head screws supporting thebottom housing5.Flip unit over so top housing is facing up. Remove top cover.

1.Complete Section, Bottom Housing Removal.

2.Remove the capacitor and six phillips screws that attach main board to bottom housing.3.Remove the four philip screws that secure the cutting head to the bottom base.

4.Remove the ground wires from the right hand side frame.

4.Carefully rotate the complete cutter assembly toward you andplace the underside of the cutter assembly on your work area.

Troubleshooting

Adjustable wrench

Also disconnect any wires from main board that are mountedto cutting head assy.

8

Gear Box Removal

1. Remove the six phillips screws from the gear box cover.2. Remove the gear box cover

Motor Removal

1. Remove both metal and nylon double drive gears.2. Remove the eight philips screws that secure the motorin place, remove motor.

External Cleaning

Make sure you disconnect the shredder from its power sourcebefore cleaning. The cover and cabinet may be cleaned witha soft cloth moistened with a mild detergent and warm water.Do not use chemical cleaners or solvents as these may havea harmful e ect. Use detergent sparingly to avoid contact withelectronic components.

InspectionWhenever the cover has been removed for corrective mainte-nance, visually inspect for defects such as loose screws ornuts, damaged wire insulation, loose terminals, etc. Correctany defects before returning the shredder into service.

5.0 Troubleshooting 9

12/18/09

Full Circle ServiceTM

10303 80th AvenuePleasant Praire, Wi 53158