Series Q35 MIZER Automatic Vent Damper System Technical Bulletin

Transcript of Series Q35 MIZER Automatic Vent Damper System Technical Bulletin

Installation Sheets Manual 121Energy Conservation and Miscellaneous Kits Section Q

Technical Bulletin Q35Issue Date 0300

© 2000 Johnson Controls, Inc. 1Part No. 24-8711-595, Rev. www.johnsoncontrols.comCode No. LIT-121515

Y15Damper

Q35

M35Actuator

M35CoverY84 Wiring

Harness

Q15 IgnitionSystem

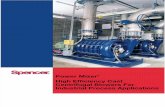

Figure 1: Q35 MIZER Automatic Vent Damper Systemand Q15 Ignition System

The Q35 energy-saving, high-efficiency, automatic vent damper systemretains heat that is normally wasted through the open flue when theappliance is not firing. The Q35 consists of a Y15 damper, M35 actuator,and Y84 wiring harness. The damper section is available in sizes from102 mm (4 in.) through 305 mm (12 in.) nominal duct diameter.

The Q35 damper system can be used with boilers, furnaces, and othergas-fired appliances.

The Y84 wiring harness is used to connect the M35 actuator to theappliance. The Y84 electrically interlocks the damper system to theappliance. Unplugging either end results in a system shutdown. Inaddition, the Y84 incorporates a circuit that blows a special fuse found inmost electronic ignition controls. This is designed to prevent systemoperation if a bypass plug, supplied with the ignition control, is later usedin place of a damper.

Series Q35 MIZER™Automatic Vent Damper System

Application

2 QSeries Q35 MIZER Automatic Vent Damper System Technical Bulletin

! CAUTION: Equipment Damage. The following restrictions

apply to the Q35 MIZER damper system.

• Must not be used on Liquefied Petroleum (LP) gas applications.

• Must not be used with gas valves that can be manually opened.

• Must be used in conjunction with an intermittent pilot or directignition system incorporating two automatic gas valves, piped inseries, both of which control gas flow to the main burner and arede-energized on each thermostat off cycle.

• Must be installed only on an appliance connected to a factory-builtchimney or vent complying with a recognized standard, or a masonryconcrete chimney lined with a lining material acceptable to theauthority having jurisdiction.

Table 1: SpecificationsProduct Q35 Automatic Vent Damper

Voltage 24 VAC, 50/60 Hz

Nominal DuctDiameter

Do (Effectiveness)

mm in. Intermittent Ignition Standing Pilot

Available 102 4.00 0.006 0.065

Sizes 127 5.00 0.004 0.041

152 6.00 0.002 0.028

178 7.00 0.002 0.021

203 8.00 0.002 0.017

230 9.00 0.069 0.081

255 10.00 0.070 0.079

305 12.00 0.085 0.092

Material Stack/Blade: 430 Stainless SteelCover/Case: Galvanized Steel

MaximumOperatingTemperature

Actuator: 66°C (150°F)Stack: 274°C (525°F)

Y84 WiringHarnessTermination

Actuator End: Board Edge Connection (Standard)Molex Receptacle (Optional)

Appliance End: Molex Plug (Standard)Bare or Terminals (Optional)

AgencyListing

Q35 components Y15 and M35CSA (AGA/CGA) Report Number 112518-0-23

SpecificationStandards

ANSI Standard Z21.66CGA 6.14

The performance specifications are nominal and conform to acceptable industry standards.For application at conditions beyond these specifications, consult the local Johnson Controlsoffice. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication ormisuse of its products.

Refer to the Q35 Series Product Bulletin (LIT-4350750) for necessary information on operating andperformance specification of this product.

Specifications

QSeries Q35 MIZER Automatic Vent Damper System Technical Bulletin 3

The damper actuator opens and closes the damper blade upon heat demandfrom the system thermostat.

The damper must be in the open position before the main burner circuit isenergized. It will remain open while the main burner is operating.

Visible on the front label of the actuator are a damper blade positionindicator and a green light (see Figure 2). The light signifies that powerfrom the thermostat has opened the damper and that power is available tothe appliance for main burner ignition.

AUTOMATIC DAMPER

M35BA-1

INPUT 24V 50/60 HzOPERATING CURRENT: 0.2ACONTACT RATING: 2A STEADY 5A INRUSH

POSITION INDICATOR

OPEN ROTATION

CLOSED

INDICATOR LIGHT"ON" - DAMPER OPEN

Figure 2: Label Diagnostic Indicators

The Q35 operates as follows:

1. The damper is in the closed position.

2. The thermostat contacts close on a call for heat.

3. The M35 actuator rotates the damper blade to the open position. Poweris available for main burner ignition (green light is on).

4. The main burner ignites.

5. The system thermostat reaches setpoint and contacts open.

6. The burner circuit is de-energized and the M35 closes the damper.

7. The system is now ready for the next heating cycle.

Operation

Sequence ofOperation

4 QSeries Q35 MIZER Automatic Vent Damper System Technical Bulletin

IMPORTANT: This technical bulletin is intended as a guide forauthorized service personnel installing or servicingJohnson Controls products. Carefully follow allinstructions in this bulletin and all instructions onthe appliance. Limit repairs, adjustments, andservicing to the operations listed in this bulletin oron the appliance.

! WARNING: Fire or Explosion. The system must meet all

applicable codes. Improper installation may causegas leaks, explosions, property damage, andinjuries.

! WARNING: Shock Hazard. Avoid electrical shock and

equipment damage. Disconnect electrical powerand turn off the gas before installing the ventdamper.

All installations must comply with local codes or, in the absence oflocal codes, with the National Fuel Gas Code, ANSI Z223.1, and theNational Electrical Code, ANSI/NFPA 70.

Before any attempt is made to install the automatic vent damper system,perform an inspection of the existing appliance installation. Follow theExhibit A Procedure for Safety Inspection of an Existing ApplianceInstallation section. Also follow the first two steps in the Exhibit BProcedure for Installing Electrically Operated Automatic Vent DamperDevices on Existing Appliances section.

Installation

QSeries Q35 MIZER Automatic Vent Damper System Technical Bulletin 5

Mount the damper as close to the draft hood outlet as possible. Verticalmounting of the damper stack section is preferred. If a diagonal orhorizontal installation is the only option, mount the damper so that theactuator is not more than 30° above or below the horizontal (see Figure 3).This will protect the actuator from overheating if mounted above thehorizontal, and from dripping condensate if mounted below the horizontal.

NormalPosition

Optional PositionPermitted

30 Maximum

30 MaximumO

O

Figure 3: Typical Mounting Positions

! WARNING: Asphyxiation Hazard. If more than one appliance

is served by a common vent, the damper must beinstalled only in the branch of the appliance towhich it is wired.

Mount the damper as follows:

1. Shut off power to the appliance.

2. Turn off gas at the manual shutoff valve adjacent to the appliance.

3. Install the damper assembly in the vent pipe with the flow arrowpointed away from the appliance.

The damper assembly must be installed downstream of the appliancedraft hood, as close to the hood as practicable, and withoutmodification of the draft hood. If the hood is oval, an adapter sectionof pipe must be used. Secure with sheet metal screws.

Ensure that the damper assembly is mounted at least 152 mm (6 in.)from combustible materials.

Mounting

6 QSeries Q35 MIZER Automatic Vent Damper System Technical Bulletin

The M35 actuator is powered with 24V, 50/60 Hz supplied through thewiring harness. Install the wiring harness between the actuator and theappliance’s ignition circuit in accordance with the appliancemanufacturer’s instruction. In the absence of specific instructions, use thefollowing procedure. Figure 4 illustrates a typical connection diagram.

Note: If the wiring connection is inconvenient with the damper mounted,the actuator can be rotated 180°. Remove the actuator cover andremove the two mounting screws holding it to the damper. Rotatethe actuator 180° and refasten it to the damper.

Flame Sensor

Thermostat

P.V. M.V.

Transformer

G770, G775, G776Ignition Control

PL

UG

5 24 V LED

THS 2

PV 1

MV 3SENSE 4

GROUND

Pilot Valve

Main Valve

1 2

1

2

AU

TO

MA

TIC

DA

MP

ER

M3

5B

A-1

INP

UT

24

V 5

0/6

0 H

z

OP

ER

AT

ING

CU

RR

EN

T:

0.2

AC

ON

TA

CT

RA

TIN

G:

2A

ST

EA

DY

5

A I

NR

US

H

PO

SIT

ION

IN

DIC

AT

OR

OP

EN

RO

TA

TIO

N

CL

OS

ED

IND

ICA

TO

R L

IGH

T

"ON

" -

DA

MP

ER

OP

EN

Spill Switch

Pilot BurnerAssembly

Main BurnerGround

PilotGas Supply

Q35 VentDamper System

Blocked VentShutoff System

Connector

M35Actuator

EdgeConnector

Y84Wiring harness

PowerSupply

Limits in ThermostatLine Only

Figure 4: Typical System Connection

1. Route the wiring harness inside the appliance jacket when possible.Use conduit openings or provide holes. Use clamps or bushings toprotect wiring from sharp edges. Type NM or Romex strain reliefconnectors are provided to secure wiring in the damper actuator strainrelief bracket and the 22 mm (7/8 in.) conduit hole where the wiringenters the jacket. Where wiring runs outside the jacket, secure it to thesurface with cable clamps. Run the wiring through a 22 mm (7/8 in.)conduit opening or provide an opening in the jacket near the ignitioncontrol.

2. Plug the end of the wiring harness securely into the M35 actuatorconnector.

Wiring

QSeries Q35 MIZER Automatic Vent Damper System Technical Bulletin 7

3. Slide the U-shaped strain relief bracket to the actuator and clip it intothe slots in the end of the case. Note that the round edges of thebracket face the back of the actuator (see Figure 5).

Figure 5: U-shaped Strain Relief Bracket Connection

4. Run the male plug end of the wiring harness through the hole in theappliance jacket and plug it into the ignition control receptacle afterdiscarding the shorting plug.

5. Install the Type NM or Romex strain relief connector in the conduithole.

6. Neatly store wiring inside the appliance jacket, away from open flame,hot surfaces, and high voltage spark cables.

7. If the actuator is intended for direct interface with a Blocked VentShutoff System (BVSS), make sure the connection is secure and thewires are not in contact with hot surfaces.

8. Carefully check the entire installation to ensure it is in compliancewith instructions and codes.

8 QSeries Q35 MIZER Automatic Vent Damper System Technical Bulletin

A qualified service agency should conduct an annual inspection of the flueproduct carrying areas, the vent system, and the damper device fordeterioration from corrosion, and for safe operation by performing thisprocedure. More frequent inspections by the home owner for corrosionand safe operation of the damper device in accordance with this checkoutprocedure are recommended.

1. Turn on the electrical power and gas supply to the appliance.

2. Turn the system thermostat to a high setting (call for heat).

3. Observe that the damper rotates open and that the ignition circuit isenergized only after the damper is fully open, as shown by theposition indicator and green light on the actuator.

4. If the actuator is directly interfaced with a BVSS, unplug the BVSScable momentarily to ensure that the ignition circuit de-energizes.

5. Turn the thermostat to a low setting. The ignition circuit shouldimmediately de-energize (the green light goes off), and the dampershould rotate and stop in the closed position.

6. Return the thermostat to its normal setting. Adjust the thermostat’sheat anticipator if necessary (see Figure 6).

7. Before leaving the installation, observe at least three completeoperating cycles.

CheckoutProcedure

QSeries Q35 MIZER Automatic Vent Damper System Technical Bulletin 9

The anticipator setting is normally equal to the ignition system currentdraw, plus that of the pilot and main valve.

Due to variations in wiring and valve options, it is advisable to measurethe actual current draw of the heating system at the thermostat location.Measuring this current can be accomplished by opening the thermostatcontacts (lowering the setpoint) and installing an AC ammeter across theterminal, or by using a clamp-on ammeter with a 10-turn multiplierattached to the terminals (see Figure 6).

IMPORTANT: Measuring the current with an ammeter willenergize the system. Wait until the appliance is inthe run cycle before taking a current drawmeasurement.

Ten Turns

W R

W R

AC Ammeter Low Scale Setting

Clamp-on Ammeter(Divide reading by ten.)

ToHeatingSystem

ToHeatingSystem

Figure 6: Measuring the Thermostat Current

ThermostatHeatAnticipator

10 QSeries Q35 MIZER Automatic Vent Damper System Technical Bulletin

If the ignition circuit is not operating when the system thermostat iscalling for heat and the damper is open with the green light on, check thefollowing.

• BVSS

• appliance ignition circuit (valves, pilot, ignition control, etc.)

If the damper is not in the open position (with the green light on) when thesystem thermostat is calling for heat, verify that the transformer,thermostat, limits, and Y84 wiring harness are not the problem. If itappears that the actuator has failed and a replacement is not readilyavailable, the appliance may temporarily be returned to service bymanually turning the damper to the open position.

To manually open the damper:

1. Turn off the electrical power to the appliance at the disconnect switch.

2. Remove the M35 actuator cover.

3. Remove the motor wire from Terminal A and reconnect it toTerminal B (see Figure 7). This disables the motor.

Place it here.Remove wirefrom here.

Figure 7: Moving Motor Lead Wire

4. Turn on the power at the disconnect switch and turn the systemthermostat to a high setting.

EmergencyOperation

QSeries Q35 MIZER Automatic Vent Damper System Technical Bulletin 11

! CAUTION: Equipment Damage. Forcing the shaft in the

wrong direction could damage the switches andcause unsafe operation.

5. Locate the section of flat shaft between the actuator and the damper.Using a small wrench or pliers, gently turn the shaft only in thedirection indicated by the rotational arrows (as shown on the actuatorcover) until the green light comes on (see Figure 8).

Figure 8: Manual Rotation

6. Replace the actuator cover and return the system thermostat to itsnormal setting.

The damper will now remain in the open position and supply power to theignition circuit on demand of the system thermostat; however, the damperwill not provide energy savings until a replacement actuator is obtained.

The Q35 MIZER vent dampers are not field repairable, other than theemergency operation procedure. Do not attempt field repairs. For areplacement M35 actuator or vent damper, contact the nearestJohnson Controls distributor.

Repairs andReplacement

12 QSeries Q35 MIZER Automatic Vent Damper System Technical Bulletin

“The following procedure is intended as a guide to aid in determining thatan appliance is properly installed and is in a safe condition for continuinguse.

This procedure is predicated on central furnace, boiler and water heaterinstallations, and it should be recognized that generalized procedurescannot anticipate all situations. Accordingly, in some cases deviation fromthis procedure may be necessary to determine safe operation of theequipment:

a. This procedure shall be performed prior to installation of the automaticvent damper device.

b. If it is determined there is a condition which could result in unsafeoperation, the appliance should be shut off and the owner advised ofthe unsafe condition. Do not install the automatic vent damper deviceuntil the unsafe condition has been corrected.

The following steps are to be followed in making the safety inspection:

1. Conduct a gas leakage test of the appliance piping and control systemdownstream of the shutoff valve in the supply line to the appliance.

2. Visually inspect the venting system for proper size, horizontal pitchand vent termination, and determine there is no blockage or restriction,leakage, corrosion and other deficiencies which could cause an unsafecondition.

3. Determine that the chimney or vent is acceptable to the authorityhaving jurisdiction.

4. Shut off all gas to the appliance and shut off any other fuel-gasburning appliance within the same room. Use the shutoff valve in thesupply line to each appliance.

5. Inspect burners and crossovers for blockage and corrosion.

6. Applicable only to furnaces - inspect heat exchanger for cracks,openings, or excessive corrosion.

7. Applicable only to boilers - inspect for evidence of water orcombustion product leaks.

Exhibit AProcedure forSafetyInspection ofan ExistingApplianceInstallation

QSeries Q35 MIZER Automatic Vent Damper System Technical Bulletin 13

8. Insofar as is practical, close all building doors and windows and alldoors between the space in which the appliance is located and otherspaces of the building. Turn on clothes dryers. Turn on any exhaustfans, such as range hoods and bathroom exhausts, so they will operateat maximum speed. Do not operate a summer exhaust fan. Closefireplace dampers. If, after completing Steps 9 through 14, it isbelieved sufficient combustion air is not available, refer to local codes,or in the absence of local codes, to the National Fuel Gas Code,ANSI Z223.1 or CAN/CGA-B149 Installation Codes, for guidance.

9. Place in operation the appliance being inspected. Follow the lightinginstructions. Adjust thermostat so appliance will operate continuously.

10. Determine that the pilot(s) is burning properly and that main burnerignition is satisfactory by interrupting and reestablishing the electricalsupply to the appliance in any convenient manner. Test the pilot safetydevice to determine it is operating properly by extinguishing the pilotburner(s) when the main burner(s) is off and determining, after3 minutes, that the main burner gas does not flow upon a call for heat.

11. a. Visually determine that main burner gas is burning properly:i.e., no floating, lifting or flashback. Adjust the primary airshutter(s) as required.

b. If the appliance is equipped with high and low flame controlling orflame modulation, check for proper main burner operation at lowflame.

12. Test for spillage at the draft hood relief opening after 5 minutes ofmain burner operation.

Vent connected gas utilization equipment shall be operated for severalminutes and checked to see that the combustion products are going upthe chimney, or gas vent, properly by passing a lighted match, taper orcandle around the edge of the relief opening of the draft hood. If thechimney or gas vent is drawing properly, the match flame will bedrawn into the draft hood. If not, the combustion products will tend toextinguish the flame. If the combustion products are escaping from therelief opening of the draft hood, the equipment should not be operateduntil proper adjustments or repairs are made to provide adequate draftthrough the chimney or gas vent.

13. Turn on all other fuel-burning appliances within the same room sothey will operate at their full inputs. Follow lighting instructions foreach appliance.

14. Repeat Steps 11 and 12 on the appliance being inspected.

15. Return doors, windows, exhaust fans, fireplace dampers, and any otherfuel-gas burning appliances to their previous conditions of use.

14 QSeries Q35 MIZER Automatic Vent Damper System Technical Bulletin

16. Applicable only to furnaces- Check both the limit control and the fancontrol for proper operation. Limit control operation can be checkedby blocking the circulating air inlet or temporarily disconnecting theelectrical supply to the blower motor and determining that the limitcontrol acts to shut off the main burner gas.

17. Applicable only to boilers -a. Determine that the water pumps are in operating condition.

b. Test low water cutoffs, automatic feed controls, and relief valves inaccordance with the manufacturer’s recommendations to determinethey are in operating condition.”

“This procedure is intended as a guide to aid in safely installing anelectrically operated automatic vent damper device on an existingappliance, so that the modified appliance will continue to operate safelyand satisfactory.

This procedure is based on the assumption that the history of the specificappliance has been one of safe and satisfactory operation.

This procedure is predicated on central furnace, boiler and water heaterinstallations, and it should be recognized that generalized procedurescannot anticipate all situations. Accordingly, in some cases deviation fromthis procedure may be necessary to determine safe operation of theequipment.

The following steps are to be followed in making the modifications:

1. Perform a safety inspection of the existing appliance installation. SeeExhibit A Procedure for Safety Inspection of an Existing ApplianceInstallation for the recommended procedure for such a safetyinspection.

2. Shut off all gas and electricity to the appliance. To shut off gas, use theshutoff valve in the supply line to the appliance.

3. Install the automatic vent damper device in strict accordance with themanufacturer’s installation instructions. Make certain the device is notlocated in that portion of the venting system that serves any applianceother than the one for which the damper is installed.

4. Made certain wiring connections are tight and wires are positioned andsecured so they will not be able to contact high temperature locations.

5. When an additional automatic valve has been incorporated or anexisting gas control replaced, conduct a gas leakage test of theappliance piping and control system downstream of the shutoff valvein the supply line to the appliance.

6. Visually inspect the modified venting system for proper horizontalpitch.

Exhibit BProcedure forInstallingElectricallyOperatedAutomatic VentDamperDevices onExistingAppliances

QSeries Q35 MIZER Automatic Vent Damper System Technical Bulletin 15

7. Check that the damper and gas valve(s) are in the correct operatingsequence.

a. The damper must be in the full open position before the gasvalve(s) opens.

b. The damper must remain in the full open position while the gasvalve(s) is open.

c. The gas valve(s) must be closed before the damper begins itsreturn to the closed position.

d. The damper shall remain in the closed position during the off cycleof the appliance.

8. Determine the amperage draw of the gas control circuit and damperdevice.

a. Check appliance transformer for adequate capacity.

b. Check heat anticipator in comfort thermostat to determine it isproperly adjusted.

9. Do not install a damper device unless sufficient combustion andventilation air is available. This can be determined by demonstratingsatisfactory operation of the appliance as described in Steps 10through 14. Sequence the appliance through at least three normaloperating cycles.

10. Insofar as is practical, close all building doors and windows and alldoors between the space in which the appliance is located and otherspaces of the building except in a room where an exhaust fan islocated. Turn on clothes dryers, stove top barbecues, and centralvacuum cleaners. Turn on any exhaust fans, such as range hoods andbathroom exhausts, so they will operate at maximum speed. Do notoperate a summer exhaust fan. Close fireplace dampers.

11. Place appliance in operation. Follow the lighting instructions. Adjustthermostat so appliance will operate continuously.

12. Test for spillage at the draft hood relief opening after 5 minutes ofmain burner operation.

Vent connected gas utilization equipment shall be operated for severalminutes and checked to see that the combustion products are going upthe chimney, or gas vent, properly by passing a lighted match, taper orcandle around the edge of the relief opening of the draft hood. If thechimney or gas vent is drawing properly, the match flame will bedrawn into the draft hood. If not, the combustion products will tend toextinguish the flame. If the combustion products are escaping from therelief opening of the draft hood, the equipment should not be operateduntil proper adjustments or repairs are made to provide adequate draftthrough the chimney or gas vent.

16 QSeries Q35 MIZER Automatic Vent Damper System Technical Bulletin

13. a. Visually determine that main burner gas is burning properly,i.e., no floating, lifting or flashback. Adjust the primary airshutter(s) as required.

b. If the appliance is equipped with high and low flame controlling orflame modulation, check for proper main burner operation at lowflame.

14. Determine that the pilot(s) is burning properly and that main burnerignition is satisfactory by interrupting and reestablishing the electricalsupply to the appliance in any convenient manner. Test the pilot safetydevice to determine it is operating properly by extinguishing the pilotburner(s) when the main burner(s) is off and determining, after3 minutes, that the main burner gas does not flow upon a call for heat.

15. Applicable only to furnaces - Check both the limit control and the fancontrol for proper operation. Limit control operation can be checkedby blocking the circulating air inlet or temporarily disconnecting theelectrical supply to the blower motor and determining that the limitcontrol acts to shut off the main burner gas.

16. Applicable only to boilers -a. Determine that the water pumps are in operating condition.

b. Test low water cutoffs, automatic feed controls, pressure andtemperature limit controls and relief valves in accordance with themanufacturer’s recommendations to determine they are inoperating condition.

Complete the device label with:a. Name of qualified agency responsible for damper installation.

b. Date of installation.”

Controls Group www.johnsoncontrols.com507 E. Michigan Street FAN 121P.O. Box 423 Installation Sheets ManualMilwaukee, WI 53201 Printed in U.S.A.

![ACATacat.or.th/download/acat_or_th/journal-4/04 - 04.pdf · APmin APmax Appendix G [1] AP APmax Overpressure Relief Damper Damper 12 Relief Damper Relief Damper (Vent) Fire Damper](https://static.fdocuments.us/doc/165x107/5f7cb481641db55595223717/-04pdf-apmin-apmax-appendix-g-1-ap-apmax-overpressure-relief-damper-damper.jpg)