Serie j y jp

-

Upload

jose-luis-jarpa -

Category

Education

-

view

590 -

download

0

description

Transcript of Serie j y jp

Protect Your Investment

Sp e c i a l t y S e a l s

The D.S. Brown Company • 300 East Cherry Street • North Baltimore, Ohio 45872 • 419.257.3561 • www.dsbrown.com

Expansion Joint Systems for Bridge, Parking Garage

and Architectural Applications

Epoxy Adhesive

Joint Opening Joint Opening

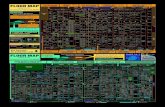

J and JP-Series Profiles

JP– 400 Series Profile

Concrete or Steel Substrate

Concrete or Steel Substrate

Epoxy Adhesive

J-Series Profile JP-Series Profile

Product Size and Movement

2

Product Name

Seal Width in (mm)

Seal Height in (mm)

Min. Width in (mm)

-50%

Mid-Range @ 70oF in (mm)

Max.Width in (mm) +50%

Total Movement

in (mm) J-100 J-150 J-200 J-250 J-300 J-400 J-500

1.00 (25.4) 1.50 (38.1) 2.00 (50.8) 2.44 (62.0) 3.25 (82.6)

4.00 (101.6) 5.00 (127.0)

1.19 (30.2) 1.88 (47.8) 2.44 (62.0) 2.94 (74.7)

3.94 (100.1) 4.50 (114.3) 6.50 (165.1)

0.50 (12.7) 0.75 (19.1) 1.00 (25.4) 1.25 (31.8) 1.50 (38.1) 2.00 (50.8) 2.50 (63.5)

1.00 (25.4) 1.57 (39.9) 2.00 (50.8) 2.57 (65.3) 3.00 (76.2)

3.94 (100.1) 4.88 (123.9)

1.50 (38.1) 2.38 (60.3) 3.00 (76.2) 3.88 (98.4)

4.50 (114.3) 5.88 (149.3) 7.26 (184.4)

1.00 (25.4) 1.63 (41.3) 2.00 (50.8) 2.50 (63.5) 3.00 (76.2) 3.88 (98.4) 4.74 (120.9)

Product Name

Seal Width in (mm)

Seal Height in (mm)

Min. Width in (mm)

-35%

Mid-Range @ 70oF in (mm)

Max.Width in (mm) +35%

Total Movement

in (mm) JP-100 JP-150 JP-200 JP-250 JP-300 JP-400 JP-500

1.00 (25.4) 1.50 (38.1) 2.00 (50.8) 2.44 (62.0) 3.25 (82.6)

4.00 (101.6) 5.00 (127.0)

1.19 (30.2) 1.88 (47.8) 2.44 (62.0) 2.94 (74.7)

3.94 (100.1) 4.50 (114.3) 6.00 (152.4)

0.65 (16.5) 0.98 (24.9) 1.30 (33.0) 1.63 (41.4) 1.95 (49.5) 2.60 (66.0) 3.25 (82.6)

1.00 (25.4) 1.50 (38.1) 2.00 (50.8) 2.50 (63.5) 3.00 (76.2)

4.00 (101.6) 5.00 (127.0)

1.35 (34.3) 2.02 (51.3) 2.70 (68.6) 3.38 (85.9)

4.02 (102.1) 5.40 (137.2) 6.75 (171.5)

0.70 (17.8) 1.05 (26.7) 1.40 (35.6) 1.75 (44.5) 2.10 (53.3) 2.80 (71.1) 3.50 (88.9)

The J and JP-Series Profiles include an extruded elastomeric profile and a high-strength, two-part epoxy based structural adhesive. The product, when inserted into an expansion joint in a substrate, will seal the opening from the intrusion of water and debris. This unique de-sign allows the seal to function under compression as well as in ten-sion. The standard J-Series is used for parking garage applications, where normal as well as vertical movements are a design parameter. The JP-Series are designed for architectural applications, meeting ADA guidelines and providing a smooth walking surface for pedestrians. In addition to architectural and parking garage projects, the J and JP Series can also be used for bridge applications.

• Ease of Installation – Using a vacuum, the seal is collapsed and easily inserted. Once the vacuum is released, the air pressure returns to normal and compresses the sidewalls against the concrete

surfaces. Installation does not rely on a positive air pressure, which can over inflate the seal and squeeze out adhesive. • Concrete and Steel Adhesive is VOC Compliant – The adhesive has a zero VOC rating. The material resists humidity, salt spray, and extreme temperature ranges. • Fatigue Tested for One-Million Cycles – The profiles were cyclically opened and closed in tension

and compression for one-million cycles. The seals were stretched to 200% of their original width with no bond failure.

• No Block-out Recess Required – The J and JP-Series are a solid choice with the pre-cast concrete

industry in that no block-out recess is required. The seal profile can be installed directly between the joint interfaces.

The seal profile is available in two specific designs. The profiles are extruded from high-quality poly-chloroprene (neoprene) material meeting ASTM D3542 with physical requirements as shown in Ta-ble 1. The adhesive is a high-strength, two-part modified epoxy-based material. It is 100% reactive and will develop a strong bond in approximately 24 hours at room temperature. For typical physical properties, see Table 2 at right.

Physical Properties

TABLE 1 – Physical Properties of the Neoprene Seal

ASTM Test Method Requirement

Tensile strength, min. Elongation at break, min. Hardness, Type A durometer Oven aging, 70h @ 212º F Tensile strength, max. Elongation, max. Hardness, Type A duro. Oil swell, ASTM Oil No. 3 70h @ 212 º F Weight change, max. Ozone resistance, 20% strain 70 hours aging, D573, 3 ppm in air

D412 D412 D2240 D573

D471 D1149

2000 psi

250% 60 +/-5

20% loss 20% loss

0 to +10 pts

45%

No cracks

Features and Benefits

Delivery and Storage

The J and JP seals are delivered to the jobsite in con-tinuous lengths. Epoxy adhesive is packaged in one-liter containers for parts A and B with a total weight of 4.4 pounds and a shelf life of six (6) months.

Limitations

The J and JP-Series waterproofing capabilities are dependent on the internal forces generated while the seal is under compression. For this reason, it is very important that the proper seal size be selected from the Product Size and Movement Table found in this brochure.

TABLE 2 - Physical Properties of the High Strength Adhesive Requirement

Adhesive type

Tensile Strength Axial Compression

Pot life Flash point

Non-volatile content Initial cure @ 70 F

2-Component thixotropic paste

4500 psi 8775 psi

45 minutes at 68 F >200 F (both components)

100% reactive 24 hours

3

CS Series AF Series

Delastic® CS & AF preformed seals provide a level top surface that is particularly suited for pedes-trian traffic. Once in the joint opening, the top sections are much closer together forming a level walk-ing surface and a pleasing visual effect for exposed vertical applications. The AF and AW Series seals also feature a level top surface suited for pedestrians and lower traffic volumes. The “honeycomb” design creates the necessary outward pressure for a watertight seal.

CS/AF/AW Concourse Seals

Delastic® Seal Nominal Width (W)

Nominal Height (H)

Max. Movement

Narrowest Opening (A)

Widest Opening (A)

Minimum Depth (B)

CS-200 2.00(51) 1.50(38) 0.70(18) 1.00(25) 1.70(43) 1.80(46)

CS-250 2.50(64) 2.00(51) 0.83(21) 1.30(33) 2.13(54) 2.30(58)

CS-300 3.00(76) 2.16(55) 1.07(27) 1.48(38) 2.55(65) 2.46(62)

CS-362 3.62(92) 2.25(57) 1.45(37) 1.65(42) 3.10(79) 2.55(65)

CS-400 4.00(102) 2.75(70) 1.40(36) 2.00(51) 3.40(86) 3.05(77)

CS-500 5.00(127) 2.75(70) 1.75(44) 2.50(64) 4.25(108) 3.05(77)

CS-600 6.00(152) 3.00(76) 2.10(53) 3.00(76) 5.10(130) 3.40(86)

AW-262 2.62(66.55) 2.00(50.80) 1.38(35.05) 1.10(27.94) 2.23(56.64) 2.50(63.50)

AW-362 3.62(91.95) 2.25(57.15) 1.75(44.45) 1.35(34.29) 3.10(78.74) 3.00(76.20)

AF-200 2.00(51) 1.50(38) 0.80(20) 0.90(23) 1.70(43) 1.75(44)

AF-225 2.25(57) 1.50(38) 0.90(23) 1.00(25) 1.90(48) 1.75(44)

AF-250 2.50(64) 2.00(51) 1.10(28) 1.20(30) 2.13(54) 2.20(56)

AF-300 3.00(76) 2.12(54) 1.45(37) 1.40(36) 2.55(65) 2.50(64)

AF-400 4.00(102) 2.81(71) 1.80(46) 1.60(41) 3.40(86) 3.20(81)

AF-500 5.00(127) 3.25(83) 2.30(58) 1.95(50) 4.25(108) 3.70(94)

Seal Characteristics Joint Design Criteria

AW Series

4

D.S. Brown's Delastic® Neoprene Sponge Joint (NSJ) seals are preformed and made from closed cell neoprene expanded rubber. The NSJ expansion joint seal is designed for small movement expansion joint applications such as: small movement bridge expan-sion joints, perimeter joints around buildings, vertical wall applications and slab-to-wall conditions, exterior columns, elevator shafts, and stair towers. NSJ ex-pansion joint seals remain in contact with the joint walls through normal compression and tension of their shape and are bonded to the joint with a high quality epoxy adhesive.

Delastic® Neoprene Sponge Joint

5

Features/Advantages:

• Can be used in new construction and/or reseal projects • Extended performance life • Ease of installation • Watertight epoxy adhesive • Can be combined with D.S. Brown PaveSaver™ elastomeric concrete header

Design Data

Physical Properties

Packaging

Shipped in a carton and delivered on a pallet.

Delpatch™ WAF System is an excellent rehabilitation material for parking garages. In larger movement glands the “honeycomb” design assures a watertight walking surface. Various seal sizes are available. Design Data

Features/Benefits

The WAF Seals are cast in Delpatch™ Elastomeric Concrete:

• Delpatch™ Elastomeric Concrete is a quick-setting, free-flowing material that is easily installed and can accept traffic within one hour of placement.

• The minimum installation temperature for Delpatch™ is 45° F.

• Delpatch™ is resistant to spalling and has excellent bonding characteristics.

• No external heat is necessary to cure Delpatch™ Elastomeric Concrete.

* Includes joint opening width and varies slightly depending on structure temperature.

Delpatch™ WAF System Block Out Width* Block Out Height Total Movement

WAF-100 9 ¾” ¾” 1.75”

WAF-250 9” ¾” 1.50”

WAF-300 9 ¾” ¾” 1.90”

WAF-400 10 ¾” ¾” 2.4”

Delpatch™ WAF System

Delpatch™ WAF System

Delpatch™ Elastomeric Concrete

WAF Neoprene Seal

6

In 1960 The D. S. Brown Company began designing and extruding the first generation of Delastic® Preformed Neoprene Compression Seals. Since that time continuous improvements have been made to this versatile, cost-effective joint sealing solution. To withstand the demanding requirements of bridge/highway installations, all Delastic® Preformed Compression Seals are extruded from neoprene (polychloroprene) compounds which satisfy the ASTM standard specification D3542 for Preformed Polychloroprene Elastomeric Joint Seals for Bridges. In addition to highway and bridge applications, Delastic® Neoprene Compression Seals have also been used in spillways, dams, parking structures, stadium ramps, and pedestrian over-passes. Information on additional seal designs is available.

Installation In all installation applications, the joint width must be properly set for the specified Delastic® seal. Also, the verti-cal faces of the joint must be clean and free of spalled concrete. Desirable installation temperatures range from 35ºF (2ºC) to 80ºF (27ºC). At temperatures below this range the lubricant/adhesive has limited effectiveness, while at temperatures above this range the seals become difficult to compress for installation. Manual and automatic tools are available to facilitate installation. D. S. Brown Delastilube™ or Delastilube™ HS lubricant/adhesive is used primarily to lubricate the seal for installation purposes. The Delastilube™ products meet ASTM D2835 and D4070 standards.

Design Data The table below can be used to select the appropriate Delastic® Neoprene Compression Seal for your project. In addition to accommodating perpendicular movements (summarized in the table), Delastic® seals are also capable of accepting approximately 15-20% lateral shear, vertical shear, and rotational movements.

Delastic® Preformed Neoprene Compression Seals

DELASTIC® SEAL

JOINT DESIGN CRITERIA

Nominal Width (W)

Nominal Height (H)

Max. Movement

Narrowest Opening (A)

Widest Opening (A)

Minimum Depth (B)

CV-1250 1.25 (32)

1.25 (32)

0.50 (13)

0.56 (14)

1.06 (27)

1.63 (41)

CV-1625 1.63 (41)

1.88 (48)

0.60 (15)

0.73 (19)

1.38 (35)

2.25 (57)

CV-1752 1.75 (44)

1.75 (44)

0.70 (18)

0.79 (20)

1.49 (38)

2.40 (61)

CV-2000 2.00 (51)

2.00 (51)

0.75 (19)

0.95 (24)

1.70 (43)

2.75 (70)

CV-2250 2.25 (57)

2.33 (59)

0.90 (23)

1.01 (26)

1.91 (49)

3.00 (76)

CV-2502 2.50 (64)

2.50 (64)

1.00 (25)

1.13 (29)

2.13 (54)

3.20 (81)

CV-3000 3.00 (76)

3.25 (83)

1.20 (31)

1.34 (34)

2.55 (65)

4.25 (108)

CV-3500 3.50 (89)

3.50 (89)

1.40 (35)

1.58 (40)

2.98 (76)

4.45 (113)

CV-4000 4.00 (102)

4.00 (102)

1.65 (42)

1.75 (44)

3.40 (86)

5.63 (143)

CV-4500 4.50 (114)

4.50 (114)

1.80 (46)

2.03 (52)

3.83 (97)

6.13 (156)

CA-5001 5.00 (127)

5.00 (127)

2.35 (60)

1.90 (48)

4.25 (108)

6.25 (159)

CA-6000 6.00 (152)

6.00 (152)

2.90 (74)

2.20 (56)

5.10 (129)

7.75 (197)

DELASTIC® SEAL CHARACTERISTICS

Bold numbers represent inches; metric (mm) shown in parentheses. Joint opening dimensions (A) are based on minimum and maximum pressures allowed in ASTM D3542. Minimum depth dimensions (B) include a 0.25 inch (6 mm) recess below the roadway surface.

7

Solutions for the Long Term

Innovation, quality, responsiveness and productivity are integral components of the D.S. Brown mission statement. With its complete vertical integration and custom manufacturing capabilities, The D.S. Brown Company has become a leader in the transportation infrastructure construction market while expanding its customer base to include other industries. Since 1890, customers have continued to rely on the lon-gevity and proven performance of D.S. Brown products.

Signature Projects

The Broadway Bridge, Daytona Beach, Florida. Design by FIGG.

Central Artery/Tunnel Project, Boston Massachusetts. Design by FIGG.

Alfred Zampa Memorial Bridge, San Francisco, California.

The D.S. Brown Company

300 East Cherry Street North Baltimore, Ohio 45872

419.257.3561 Fax: 419.257.2200

email: [email protected] www.dsbrown.com