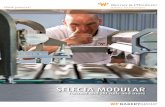

SELECTA MODULAR - WP BAKERYGROUP · SELECTA MODULAR. KEY BENEFITS. lexible modular system conceptF...

Transcript of SELECTA MODULAR - WP BAKERYGROUP · SELECTA MODULAR. KEY BENEFITS. lexible modular system conceptF...

think process! Bakery Technologies

+SELECTA MODULAR

Stamped rolls, cut rolls and much, much more….

think process!

SELECTA MODULAR

KEY BENEFITS Flexible modular system concept

Configuration based on product specific requirements

Stainless steel finish

Hygiene concept

Robot operation compatible, expandable with sheet metal loading device

Variable performance

Automated production process, reproducible quality

HYGIENE CONCEPT Hygiene cup works with removable cups,

dishwasher safe for wet cleaning

- Optimized cleaning options

- Improved visibility

- Easier accessibility

Trays removable for easy cleaning

Exchangeable modules can be cleaned outside of the machine

Removable equipment covers

Removable climate stones

Removable flour duster

Double degermination station

WP BakingQuality

Dough protecting product specific processing

WP SmartControl

Easy to operate thanks to on demand accessible product programs

WP GreenEnergy

Energy efficient system operation

WP CleanTec

Hygiene concept

BENEFITS // FLEXIBILE, MODULAR SYSTEM CONCEPT THAT MEETS HIGHEST DEMANDS // VARIABLE PERFORMANCE // EXTREMELY EASY TO CLEAN

Bakery Technologies

Basic Features – Main Module

3,600 rolls per hour

Optional Features – Main Module

Increase of hourly output

Various exchangeable modules

Solution for long moulding, stamping, final batch long moulding and folding

SELECTA MODULAR roll Production of:

Cut rolls

Long moulded goods

Final batch long rolled products

Smooth rounds

MODULAR DESIGN The configuration of the system is based on

product-specific requirements

System can be expanded or tailored to different product-specific requirements

Hourly output can be retroactively increased

BASIC FEATURES BASE MODULE 3/4/5-row baking system for small baked

goods

12 min. proofing time

Touchscreen control

Special degermination program

Tray drying available

Automatic chain tensioning

Maintenance free tray

Pneumatic bypass line input and output

Placement device for proofing trays

Proofing goods carrier with drawer

Prefitted for connection of a WP sheet metal loading robot

Operation end running direction: left

OPTIONAL FEATURES BASE MODULE

Climate control

Placement device with final layer modification

Increased system height

Output line on the side

Data connection for complete Multimatic S actuation via the system control unit

Pressure roller via spreader belt

SELECTA MODULAR form

Production of

Kaiser rolls

Smooth rounds

Basic Features – Main Module

4,500 rolls per hour

Optional Features – Main Module

Increase of hourly output

CleanTec cutter with exchangeable cutter cups

Large selection of cutting inserts

Additional flour duster

Basic Features - Main Module

4,500 rolls per hour

Optional Features – Main Module

Increased hourly output

Various exchangeable modules

Various solutions for long moulding, stamping, final batch moulding and folding

Large selection of cutting inserts

Supplementary flour tray

SELECTA MODULAR kombi

Production of:

Kaiser rolls

Smooth rounds

Cut rolls

Long moulded goods

Final batch long moulded products

SELECTA MODULAR Base Module

+

+

+

think process!

Werner & Pfleiderer Lebensmitteltechnik GmbHvon-Raumer-Straße 8-18 | 91550 Dinkelsbühl | Germany | Phone +49 9851 905 - 0 | Fax +49 9851 905 - 342 | [email protected] | www.wp-I.de

SELECTA MODULAR

SELECTA MODULAR PERFORMANCE OPTION 1 PERFORMANCE OPTION 2 PERFORMANCE OPTION 3 PERFORMANCE OPTION 4

Hourly output*Stamped rolls – 5 rows units/hourCut rolls – 4 rows units/hourBaguette rolls – 3 rows units/hour.

4,5003,6003,240

6,0004,8004,320

7,5006,0005,400

9,0007,2006,480

Proofing time min. 12/12/10 12/12/10 12/12/10 12/12/10

Weight range5 rows (stamped rolls) g4 rows (cut rolls) g3 rows (baguette rolls) gVia bypass (green mode) g

40 – 65 (75 at T=115)40 – 6535 – 9090 (150 at MUS-G)

40 – 65 (75 at T=115)40 – 6535 – 9090 (150 at MUS-G)

40 – 65 (75 at T=115)40 – 6535 – 9090 (150 at MUS-G)

40 – 65 (75 at T=115)40 – 6535 – 9090 (150 at MUS-G)

Proofing tray dimensions mm

400 x 600580 x 780580 x 980

400 x 600580 x 780580 x 980

400 x 600580 x 780580 x 980

400 x 600580 x 780580 x 980

Electrical (without dough divider) Cut roll system (+ Opt.) kW kWStamped roll system (+ Opt.) kWCombined system (+ Opt.) kW

10.35 (10.70)10.85 (10.95)11.55 (11.95)

10.35 (10.70)10.85 (10.95)11.55 (11.95)

11.35 (11.70)11.85 (11.95)12.55 (12.95)

11.35 (11.70)11.85 (11.95)12.55 (12.95)

Cold water connection “ 1/4 1/4 1/4 1/4

Pressurized air – ½ “ plug-in connector 5 Normal m³/h or 84 Nl/min. bei 6 – 8 bar

5 Normal m³/h or 84 Nl/min. bei 6 – 8 bar

7 Normal m³/h or 117 Nl/min. bei 6 – 8 bar

7 Normal m³/h or 117 Nl/min. bei 6 – 8 bar

Dimensions L x W x H mm(cover components may extend 100 mm over the basic dimensions)

3,000 x 1,000 x 2,500 3,000 x 1,000 x 2,850 3,000 x 1,000 x 3,250 3,000 x 1,000 x 3,250

Input opening mm 1,000 x 2,550 1,000 x 2,900 1,000 x 3,300 1,000 x 3,300

Input on divided design

mm 1,000 x 2,000 1,000 x 2,000 1,000 x 2,000 1,000 x 2,000

*Hourly output varies depending on the productv

Subj

ect t

o te

chni

cal m

odifi

catio

ns