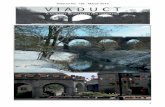

Seismic Damage of and Seismic Rehabilitiion Techniques for Railway Reinforced Concrete Structures

Seismic Design of a Railway Viaduct in a High Seismic Zone · Seismic Design of a Railway Viaduct...

Transcript of Seismic Design of a Railway Viaduct in a High Seismic Zone · Seismic Design of a Railway Viaduct...

Seismic Design of a Railway Viaduct in a High Seismic Zone9th Small Bridges Conference, Australia 2019

1. Project Overview

2. Typical Project Features

3. Design Preparation

4. Earthquake in the Philippines

5. Design Standards

6. Design Earthquake

7. Key Considerations for Railway Viaducts

8. Displacement Limit

9. Geotechnical Consideration

10. Structural Modeling

11. Determination of Natural Period

12. Key Learning

Outline

Seismic Design of a Railway Viaduct in a High Seismic Zone

1. Project Overview

Item Description

Guideway Total Length:37.6 kmStandard Superstructure Width:10.3mTrack: Double Track Standard Gauge(1,435mm)

Number of Stations

10 Stations by 2021,(5 Future Stations by 2030)

Structure Viaduct: 34.8kmEmbankment: 2.2kmBridges: 2@100m center span & 1@58m center span Balanced Cantilever Bridges; 18 cast-in-situ tapering superstructures at station approaches

Depot 1 Depot on, 14Ha Land, 15 Stabling tracks, Workshop, Light repair shop and OCC

Trains 8Trains (10 in Future)

Design Speed Max Design Speed: 120km/hHeadway: 6 Minutes

Expected Socio-Economic Impact

Cutting travel time into less than 1/5th

2. Typical Project Features - 2

Typical Viaduct Substructure

⚫ reinforced concrete pier supported on bored piles.

⚫ Elastomeric bearings with steel seismic restraint pins to transfer seismic forces from superstructure to substructure.

⚫ Drainage pipes hidden inside the box girder and the pier to discharge to ground level longitudinal drainage.

Typical Viaduct Superstructure

⚫ Typical 40m spans of simply supported precast segmental box girder erected span by span with over head gantries

⚫ 10.3m Width of Double Tracks⚫ Slab Track⚫ Bottom Slab of 4.5m wide⚫ Cable Trough below the emergency

walkway⚫ PC Parapet wall⚫ Drain pipe at the center of the Box

4500

10300

Cable TroughWal

kway

Wal

kway

24

00

300mm∅Drainage Hole

Hole for SeismicRestrainer(Each Side)

4 ElastomericBearings

Four (4) 1500mm ∅Bored Piles

Drainage Outlet

3. Design Preparation

Key Parameters

• Pier Height Range:

H = 3.1m ~17.1m

• Design Height Cases: (m)

• Type of Super Structures

Double Track, Single Track

• Span Length

Typically 40m,

Ranges from 25m to 50m

• Geotechnical Conditions:

485 Boreholes

• Design geotechnical model Cases:

6 Models

Classification on boreholes for

Substructure design

4 6 8 10 12 14 16

4. Earthquake Prone Areas in Philippines

The Luzon area has great risk of major seismic activity and large seismic magnitude, with over a 100 recorded major earthquakes.

Project Area

4. Earthquake Prone Areas in Luzon Sub Region

The main source of seismic activity can be attributed to a nearby active fault, only 6 km South East of the project alignment West Valley Fault Imperative to conduct a thorough seismic design to ensure safe operations and resiliency

Susceptibility to

Liquefaction

Susceptibility to

Ground Shaking

Project Site

ProjectSite

ProjectSite

West ValleyFault

5. Design Standards

• Department of Public Works and Highways, Philippines - Bridge Seismic Design Specifications 1st Edition 2013 (DPWH-BSDS) ;

• Department of Public Works and Highways, Philippines - Design Guidelines, Criteria and Standards; Volumes 1 to 6, 2015 (DPWH-DGCS);

• American Association of State Highway and Transportation Officials Guide Specifications for Load Resistance Factor Design Bridge Design 7th Edition (2012) including amendments up to 2016 (AASHTO-LRFD);

• American Association of State Highway and Transportation Officials Guide Specifications for Load Resistance Factor Design Seismic Bridge Design 2nd Edition (2011) including amendments up to 2016 (AASHTO-LRFD-S);

• Japanese Design Standards for Railway Structures and Commentary (Seismic Design) (2012) (JDSRS); and

• Japanese Road Association Standard (JRA) (2012) .

6. Design Earthquake

Design Earthquake Level

Probability of Occurrence Seismic Performance Requirement

Design Seismic Acceleration

• Level 1

1:100 year Return Period

• Has the probability of occurring multiple times during the design life of the structure.

• Design is essentially to limit stresses in reinforcement to yield values and ensure an elastic design

• Structural damage due to earthquake is limit to the minimal.

• Train Derailment is prevented.

• 0.12g

• Level 2 1:1000 year Return Period

• The largest Earthquake that can be conceived for area of construction of the structure, and that may happen once or never during the design life of the structure

• Collapse of structures is prevented

• Damage in structures is limit to a level that repair and recovery can be achieve in a short period of time.

• 0.6g

7. Key Considerations for a Railway Viaduct

While the Philippine Bridge Codes and AASHTO design codes address earthquake effects on a bridge, they do not specifically address the particular issues arising on railway bridges.

The Japanese Design Standard for Railway Structures (Seismic Design) provides specific guidance to address earthquake design for railway structures.

The key considerations include:

1. The increased stiffness of substructure required to limit the transverse displacement of the structure to prevent derailment of the train during the Level 1 Earthquake event.

2. A limit on the natural period of the structure to ensure robustness – this is not directly required in the code which recommends more detailed investigation or analysis if the natural period of the structure exceeds 2 seconds in either the longitudinal or transverse direction of the bridge. Hence, the natural period was limited to 2 seconds.

3. Time History Analysis is recommended but due to the lack of time-history data in the Philippines, detailed Non Linear Static Analysis (pushover analysis) is specified.

8. Displacement Limit

The principle to the displacement limit is concern that the Level 1 earthquake event is a 1:100 year event and expected to occur a few times during the design life of the structure. The likelihood of this event occurring during train operations is considered to be likely.

During normal train operations, the train has a rocking motion on its suspension as it travels along the viaduct. At the same time, there is the corresponding vertical vibration of the train and the bridge girder.

When the earthquake strikes, there is the risk that if the natural period is not controlled by limiting the natural period of the structure, the resulting overall movement could result in the over-turning or derailment of the train.

Lateral Oscillationof Train

Lateral Vibration Displacement of Structure

Wheel Uplift

8. Displacement Limit – Cont’d

In Japan, a specialist dynamic interaction analysis software is used to model:a) The rolling stock;b) Track structure interaction;c) Bridge substructure and soil

interactiond) Earthquake excitation

8. Displacement Limit Cont’d

Displacement Limit Defined in the JDSRS codes

9. Geotechnical Considerations

• Approx 485 boreholes over the project = 1 borehole every 80m approx.

• 6 Different soil models – based on shear wave velocity derived from average, idealised SPT N values – method described in AASHTO LRFD;

• Liquefaction analysis to determine extent of liquefaction possible –generally sandy layers with SPT N<10 considered to be liquefiable;

• In the liquefiable zones, soil springs ignored – negative skin friction AFTER the seismic event is considered as additional load to the hinging loads. Considered very conservative as negative skin friction takes place after the seismic event and there is a case made to ignore this effect;

• Non Linear horizontal, vertical and pile toe springs behaviour allowed in accordance with the Japanese codes

10. Structural Modelling

• Member lengths defined by hinging lengths – pier and piles;

• Important to model all loadings accurately in order to excite the correct mass;

• Generally, eigenvalue analysis carried out to determine natural period/frequency of structure. The cracked section properties are estimated and input. This is not accurate as required in the Japanese codes for major earthquakes. Non Linear material properties along with non linear soil springs are required to be modelled to get an accurate consideration of the natural period of the structure;

• Non linear material properties need to be specified – not difficult, AASHTO prescribes what is required. A program capable of carrying out moment curvature relationships based on section defined and non linear material properties is required

Consideration of Lateral Soil Forces on PilesWhere liquefaction is a concern, lateral forces are induced in the piles due to the soil movement.

This is automatically modelled in Japanese software, however, we had to adopt a different method.

A pseudo static PLAXIS ground lateral displacement profiles; were obtained for the two (L1 and L2) earthquakes.

Both linear elastic and Hardening Soil material models were defined and the deflection profiles are compared to the results from the Japanese software.

The Hardening Soil (HS) model could not handle the earthquake L2, due to its large PGA, leading to large displacements but the linear elastic model produced results very similar to the Japanese.

10. Structural Modelling

Ground Displacement caused by lateral flowOf soil

Vertical Load

Analysis Model

Force due to lateral flow of soil in non-liquefied layer

Force due to lateral flow of soil in liquefied layer

Subgrade reaction taking into Consideration effect of liquefaction

Upper non-liquefied layer

Liquefied layer

Non-liquefied layer

Layer in whichThe effect ofLateral flow ofSoil must be consideredb

Layer in whichThe effect ofLateral flow ofSoil need not be considered

Consideration of Ground Displacement Caused by Lateral Flow of Soil

Ground displacement caused by lateralFlow of soil induced to the pilesThrough subgrade reaction

11. Determination of Natural Period –Japanese Code

The figure on the left shows a typical Force – Displacement curve obtained from the Pushover Analysis.

In AASHTO an idealised bi linear moment curvature relationship is input and therefore, the corresponding Force –Displacement curve is similar but different.

Idealised Moment Curvature Diagram from AASHTO

11. Determination of Natural Period – Japanese Method

11.Determination of Natural Period – Japanese Method – Cont’d.

According to the DSRS, the point D is deemed to the yield point of the whole structure and the effective natural period of the structure is calculated using this value from

Teq = 2 SQRT(deq/kheq)

Where K = the seismic intensity coefficient (related to stiffness) where khm can be set to 1.0 so kheq is a fraction of 1.

AASHTO however, derives the Natural Period of the Sructurefrom a dynamic eigenvalue analysis which does not permit non-linear soil springs and only models the cracked stiffness of the structure as manually input. In a simplified manner, T is calculated as follows

11. Determination of Natural Period –Japanese Method – Cont’d.

Generally, we found that the difference in Natural Period calculated in the two methods is very small – typically 0.4 seconds difference in periods but as can be see the previous slide, a difference of 0.4 seconds is significant in softer soils (G4 to G6 soils)

In these softer soils, or where the structure did not meet the transverse displacement limits, the following iterations were carried out:a) Increase rebar in piles upto max. 4% ;b) Increase pier rebar upto max. 4%; c) Increase column size and re-start.

12 Key Learnings

• Confirm the Design Criteria early and DOCUMENT the reasons why the values were determined;

• Confirm Durability Criteria as early as possible;

• Communication is a MUST!

• International codes are not all encompassing! Lot to learn from other Codes and Engineers!

• Check and verify the software before using the results;

• Pushover is a relatively easy, detailed method of analysis leading to a clearly economical and rational solution

Copyright © Pacific Consultants Co., LTD.

2.1 Soil Class- Ground Acceleration (Japanese Standard)

Railway Standard Soil Classes

Soil Class Ground Natural Frequency (TG(sec)

Soil Profile Name

G0 - Hard Rock

G1 - Rock

G2 ~0.25 Very Dense soil to Soft Rock

G3 0.25~0.5 Dense soil

G4 0.5~0.75 Dense to Soft soil

G5 0.75~1.0 Soft soil

G6 1.0~1.5 Very Soft soil

G7 1.5~ Extremely soft soil

Copyright © Pacific Consultants Co., LTD.

2.5.Operational Safety and Deflection Limit