Section a.11 Raw Water and Circulating Water System

-

Upload

chava-teja -

Category

Documents

-

view

11 -

download

0

description

Transcript of Section a.11 Raw Water and Circulating Water System

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11

RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 1 of 26

11.0 RAW WATER SYSTEM AND CIRCULATING WATER SYSTEM

11.1 Raw Water System

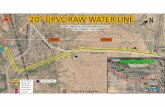

11.1.1 The raw water supply to the entire power plant shall be taken from MIDC.

11.1.3 One Raw water storage reservoir of adequate capacity shall be constructed (by

Owner) in the project site.

Water supply to the proposed fire protection system shall be provided from the

Raw water reservoir. Adequate dead storage as per requirements of Tarrif

Advisory Committee shall be provided in the reservoir.

11.1.4 2 x 100 % capacity Raw water pumps shall be installed near he Raw water

reservoir to supply Raw water o the plant requirements. Provision of necessary

sleeves, valves and piping shall be one by Bidder. Provision shall be made for

isolation of individual river water pumps for maintenance. . The raw water pumps

shall be provided with discharge pipelines along with expansion joints, motorized

butterfly valves and other fittings

Raw water pumps will supply Raw water to clarifier which will be of RCC

construction.

11.1.5 Chlorination dosing equipment with associated pumps, cylinders, safety

equipment, handling and weighing facilities shall be provided as part of river

water chlorination system. The chlorine dosing rate shall be set manually at the

desired value. Cylinder storage area with adequate storage space (15 days

requirement) shall be provided under a roof covered shed with suitable handling

facilities.

11.1.6 Raw Water Clarification System

11.1.6.1 Since water required for various systems in the plant being clarified water (of

turbidity less than 20 NTU), it is proposed to include a pretreatment system to

treat the raw water.

11.1.6.2 It is proposed to install a clarifier of clariflocculator / solid contact type, The raw

water clarifier will produce raw water required for makeup to the condenser

cooling water system and DM water palnt and service water requirements (air-

conditioning & ventilation system and miscellaneous services).

Water from the clarifiers will be stored in above ground storage tanks, Clarified

water storage tank (CWST). The tank will be divided into two (2) compartments

to facilitate cleaning and maintenance and will feed to a common sump. The

capacity of the storage tanks shall be based on 8 hours requirement

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11

RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 2 of 26

The sludge from the clarifier shall be collected in a sludge pit and pumped by two

(2) nos. (one working + one standby) sludge transfer pumps to the sludge

treatment plant which shall include one (1) No. thickener and two (2) Nos. (one

working + one standby) centrifuges.

11.1.6.3 The clarified water from the clarified water storage tank shall be supplied to the

following systems:

Input to DM water plant

- for make-up to the circulating water system by gravity, - to the service water system by service water pumps Clarified water from the CWST shall be led to the the water treatment plant by

two (2) Nos. (One working + one standby) water treatment plant supply pumps.

The service water pumps, water treatment plant supply pumps shall be located

put doors. Chemical dosing equipment including tanks, pumps, Coagulant along

with poly electrolyte dosing system shall be in chemical dosing house with

monorail facility and weighing machine. Adequate chemical storage space (15

days) shall be made available in the pump house. Dosing rate of coagulant and

poly electrolyte shall be set manually at the desired value.

The clarified water storage tank shall be provided with level indicators and level switches with protection interlocks for associated pumps. All pumps drawing suction from the tanks shall be protected against operation under low suction conditions. Annunciation for abnormal conditions like levels (low and high) in the storage tanks shall be annunciated in the control panels located in the clarified water pump house. Make-up water from the circulating water system shall be supplied to the cooling tower basin in the plant through pipes. Near the basin, motor operated make-up control valves shall be provided which in-turn shall be controlled by the level controllers in the basin The MCC for providing power supply to the the pumps located in the DM water pumphouse in a separate room.

11.1.6.4 Clarified water drawn by the water treatment plant supply pumps for the purpose

of demineralisation shall be subjected to chlorination.The DM plant chlorination

dosing equipment with associated pumps, cylinders, safety equipment and

handling & weighing facilities shall be provided as part of clarified water

chlorination system. The chlorine dosing rate shall be set manually at the desired

value. Cylinder storage of 15 days requirement shall be provided. A separate

room within the chemical dosing pumphouse shall be provided for housing the

chlorination equipment along with suitable weighing and handling facilities

11.2 Condenser Cooling Water System 11.2.1 A recirculation type condenser cooling water system shall be provided to meet

the cooling duty necessary to cater to rated plant performance requirements. The system should be capable of ensuring supply of cooling water to the condenser at all conditions of operation.

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11

RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 3 of 26

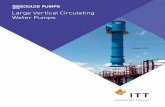

11.2.2 Circulating Water (CW) Pumps

(a) Three (3) Nos. (two operating + one standby) main circulating pumps of indoor vertical, mixed flow, wet pit type - drawing suction from the common sump beyond the CW forebay (which is connected at the other end of the cooling tower cold water outlet channel), shall be provided to cater to the condenser cooling water requirements of the power plant.

(b) The CW pumps discharge piping shall be complete with expansion joints,

motor operated butterfly valves and other fittings on individual pump discharge lines. Necessary piping, valves and fittings shall also be provided.

(c) Provision shall be made for isolation of individual pump chambers for

maintenance.

(d) The CW pumps shall be housed in the CW pumphouse with individual pump chambers. Coarse screens/ stop logs shall be located outside the pump house for each pump chamber. An ellectrically operated crane of capacity suitable for handling the CW pumps/ motors shall be provided in the CW pumphouse. Separate facilities for handling the coarse screens/ stop logs shall be provided

(e) Validation of the design of forebay/ sump / channel shall be substantiated

during post award of Contract from either identical arrangements elsewhere or by physical modeling. The forebay design shall allow operation of any permitted pump combination while ensuring reasonably uniform flow conditions to each pump.

(f) CW pump operation shall be interlocked with the basin level, CW pump

bearing lubrication water flow and the discharge valve position and operation. Pumps shall be protected against operation at low level in the CW pump chambers.

(g) Chemical dosing system for prevention of scaling in the circulating water system and biocide dosing system for control/ prevention of growth of algae/ other organisms and shall be provided (described in clause below).

11.2.3 CW Piping

The CW piping shall have motor operated butterfly valves and expansion joints at CW pumps discharge, condenser inlet/ outlet lines and cooling tower inlet line. The main discharge conduit from the CW pumps to the condenser and from the condenser to the cooling tower shall be buried.

11.3 Chemical Dosing System

11.3.1 Bidder shall design the cooling water circuit to operate at maximum cycle of concentration in order to limit water consumption and minimise blowdown. The Bidder shall substantiate the value of concentration ratio selected with calculations and from past experience. Necessary chemical dosing system to

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11

RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 4 of 26

prevent scale formation / corrosion shall also be included. All required chemical dosing equipment dosing pumps, solution tanks/ carbuoys and solution piping along with handling facilities shall be included. Adjustment of chemical dosing rate shall be manual. Adequate facilities for storage of chemicals shall also be considered (15 days storage).

11.3.2 Bidder shall provide biocide dosing as part of chemical dosing system for prevention/ control of growth of algae and other organisms. If in the opinion of the Bidder, chlorination of cooling water is required in addition to biocide treatment, he may provide a gas chlorination plant to control/ prevent fouling in the complete cooling water system. Residual Cl2 levels permitted in the cooling water shall be limited to not more than the limits permitted by the local regulatory authority. Bidder shall make provisions to ensure compliance with these limits and shall provide the necessary monitoring instrumentation. The dosage rate of chlorine shall be as specified in the data sheets. Required number of chlorine cylinders (15 days storage) with necessary handling and weighing facility and safety equipment along with leak detection and absorption system, pumps, etc. shall also be provided. The chlorination equipment shall be located adjacent to the CW pumphouse.

11.3.3 Chlorine storage / chemical storage area shall be provided under a roof covered shed along with suitable weighing and handling facilities. A separate room within the CW pump enclosure shall be provided for housing the CW chemical dosing/ chlorination equipment along with suitable weighing and handling facilities.

11.3.3 The circulating water make-up shall be ensured by gravity flow of water from the

clarified water storage tank. The quality of circulating water shall be determined by laboratory analysis of grab samples and by conductivity measurements. Accordingly, the cycle of concentration shall be maintained. Make-up to CW system shall be automatically controlled through control valves along the makeup water pipeline, which in turn shall be controlled by the level controllers in cooling tower basin.

11.4 Cooling Tower

11.4.1 One (1) No. induced draught cooling tower shall be provided to cool the hot water from the condenser. The cooling tower shall be complete with basin, associated supporting structures, foundations, casing with internals such as fills, drift eliminators and hot water distribution system including hot water temperature indicator, isolating valves, etc. The basin shall be partitioned into two compartments complete with draining facilities, cold water outlet channel with screens and stoplogs.

11.4.2 Suitable handling facilities to handle fans, associated motors, and screens /

stoplog shall be provided.

11.4.3 Vibration limit switches for cooling tower fans shall be provided..Bidder shall

ensure lightning protection of the cooling tower.

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11

RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 5 of 26

11.4.4 The heat load on the cooling tower shall be based on the condenser parameters.

11.5 CW Blow down

11.5.1 CW system blowdown shall be drawn from the hot water conduits and shall flow by gravity to the the guard pond.

11.6 Auxiliary Cooling Water System

11.6.1 The principal criteria for the design of the system shall be to ensure a continuous and reliable supply of adequate auxiliary cooling water to the GTG coolers and STG coolers at all conditions and at all times.

11.6.2 The auxiliary cooling water system shall be a closed loop system comprising of two (2) nos. (both working) plate type heat exchangers and three (3) nos. (2 operating + 1 standby) auxiliary cooling water pumps. The auxiliary cooling water shall be passivated DM water.

11.6.3 Three (3) nos. (2 working + 1 standby) ACW booster pumps shall be provided to circulate cooling water on the secondary side of the plate type heat exchangers. The booster pumps shall draw suction from tap-off from main condenser cooling water pump discharge header and shall circulate the cooling water through the plate type heat exchangers back into the condenser cooling water line downstream of the condenser.

11.6.4 The ACW pumps and the ACW booster pumps shall be of horizontal centrifugal type along with necessary discharge isolation valve at the outlet of each pump.

11.6.5 The ACW pumps, the ACW booster pumps and the plate type heat exchangers shall be located in the STG building. Make-up to the closed loop ACW system shall be through the ACW expansion tank located on the roof of the STG building.

11.6.6 The technical particulars related to circulating water system have been covered

under the data sheets.

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11

RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 6 of 26

CIRCULATING WATER PUMPS

1.0 Total number of pumps Three (3)

2.0 No. of pumps operating continuously Two (2)

3.0 Design capacity See Note - 4

5.0 Total head ( Excluding losses in the pump) By Bidder

6.0 Location Indoor

7.0 Maximum rated speed rpm By Bidder

8.0 Type of pump Vertical, mixed flow, wet-pit, non-pullout

type.

9.0 Type of line bearing lubrication Self

10.0 Liquid for lubrication Pumped liquid

10.0 Coupling Flexible

12.0 Prime mover Direct with AC Electric motor

13.0 Material of Construction

13.1 Pump column pipe Fab steel to IS 2062 with epoxy painting

13.2 Pump bowel and discharge elbow CI to IS 210 FG 260

13.3 (a) Impeller SS304

13.4 (b) Shaft SS 410

13.5 (c) Line shaft coupling SS 410

13.6 (d) Line shaft bearing Cutlas rubber in SS shell

13.7 (e) All hardware under water SS 304

13.8 (f) Base plate MS IS2062

13.9 (g) Shaft sleeve SS

13.10 (h) Thrust bearing cooling system

pipes and valves

SS

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11

RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 7 of 26

14.0 Shop performance test

To be conducted on all pumps

15.0 Inspection requirements

As per relevant section

NOTE:

1.0 The pump set shall be capable of reverse rotation due to back flow of water from the other

running pump in the event of tripping of the pump for a short duration of time (about 5

minutes)

2.0 Following instruments / monitoring devices shall be provided for each pump: Motor winding temperature detectors and dial type bearing temperature indicators with

alarm contacts.

3.0 The pump shall be capable of operation under shut-off conditions for a duration of 5 minutes

4.0 CW Pumps Total capacity of two pumps shall be equal to 105 % of condenser cooling

water and auxiliary cooling water requirements.

5.0 Motor rating shall be min 116% of duty point requirement at 50 Hz frequency

6.0 The pumps shall be capable of operating from shut-off point to a maximum flow of 10% over

the point of intersection between system resistance curve and pump H-Q curve for single

pump operation.

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11

RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 8 of 26

1.0 Service CW Pumps Discharge / Condenser

Inlet / Outlet - electrically operated

ACW pump discharge / ACW booster

pump discharge - electrically operated

ACW pump suction / ACW booster

pump suction / Plate type heat

exchanger inlet & outlet lines -

manually operated

electrically operated

Raw water pumps discharge

electrically operated

2.0 Valve size mm By Bidder

3.0 Number of valves Nos. By Bidder

4.0 Hand wheel required Yes

5.0 Valve opening / closing time Sec. By Bidder

6.0 Flow - Maximum / Normal m3/hr By Bidder

7.0 Maximum / normal operating pressure kg/cm2 By Bidder

8.0 Design pressure kg/cm2 By Bidder

9.0 Location Indoor

10.0 Face to face dimension mm As per AWWA C504 / BS 5155

11.0 Material Of Construction

11.1 Body CI IS 210 FG 260

11.2 Disc CI IS 210 FG 260

11.3 Shaft SS AISI 410

11.4 Body seat rings SS AISI 410

11.5 Disc seal rings Natural Rubber

11.6 Seal retaining rings SS AISI 410

11.7 Companion Flange Carbon Steel to IS 2062 Gr. B

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11

RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 9 of 26

11.8 Internal hardware SS 304

11.9 External hardware IS 1367, Gr. 4.6

12.0 Bidder shall include end limit switches, torque limits and adjustable limit switches suitably as per

the logics and interlock controls for motorised valves.

13.0

NOTES :

Fabricated valve is acceptable only for sizes 1000 mm and above provided, butt welded joints are

of fill penetration welds, welded ends are subjected to 100% radiography and disc & internal

surfaces of valves are provided with 3 coats of epoxy paint.

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11

RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 10 of 26

COOLING TOWER

1.0 Designation Induced Draught Cooling Tower

2.0 Number of towers One (1)

3.0 Tower Capacity m3/hr Bidder to indicate based on total

cooling water flow and sahll be equal

to the flow of two nos. CW pumps.

4.0 No. of cells Multi cell, Refer Note 1

5.0 Cells operating All, Refer Note - 1

6.0 Type of tower Cross flow / Counter flow

7.0 Design atmospheric wet bulb temperature 0C As per Project Information given

8.0 Cold Water Outlet temperature 0C These shall be equal to the CW inlet

and outlet temperature of the condenser, corresponding to design heat load of condenser.

9.0 Hot Water Inlet Temperature 0C

During 100% HP-IP-LP bypass operation, the CW inlet and outlet temperature would be higher. This would occur for short durations. Refer also Note 2.

10.0 Wind Velocity :

(a) For performance

(b) For design of structures

kmph

m/sec.

10.0

50

11.0 Tower operation Continuous

12.0 Safe bearing capacity of soil Tonne/

Sq.m

By Bidder

13.0 Seismic zone As per Project Information,

14.0 Pumping head at hot water inlet w.r.t.

normal water level in the basin including

static head and friction losses

mWC By Bidder

15.0 Liquid handled Clarified water

16.0 Drift eliminators Yes

Drift not to exceed 0.02% of

circulating water flow

17.0 Screens / stoplogs at CW outlet channel Required

18.0 Monorail with hoist for handling screens,

Required

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11

RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 11 of 26

fans, motors, stoplogs

19.0 Construction

19.1 Type of fill Film

19.2 Tower Arrangement By Bidder

20.0 Elevations

20.1 Grade Level m By Bidder

20.2 Sill Level m 300 mm above ground level

20.3 Normal Water level m By Bidder

21.0 Material of Construction

21.1 Fill PVC

21.2 Fill Support RCC / Stainless steel

21.3 Drift Eliminator PVC

21.4 Water distribution nozzles Polypropylene

21.5 Water distribution system Carbon steel / PVC

21.6 Tower casing / Tower basin RCC

21.7 Fan deck RCC

21.8 Fan blades FRP / GRP

21.9 Fan cylinders / Recovery stack RCC

21.10 Hardware Hot dipped galvanised (HDG) above

fan deck and stainless steel /

phosphor bronze below fan deck

21.11 Screen

a) Frame Mild steel, epoxy coated

b) Mesh Stainless steel, 10 mm sq. mesh

22. Performance Tests Method As per BS 4485 / CTI Code, USA

CTI Code

23. Codes and Standards

23.1 CI Code Standard III

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11

RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 12 of 26

23.2 AGMA

23.3 BS

Note :

1.0 While deciding the number of cells, Bidder shall note that in the event of one cell not being in operation due to maintenance, the remaining cells shall be capable of taking up the entire cooling load and provide cooling water temperature which should permit generation of guaranteed net output of the unit.

2.0 The tower should be capable of cooling the circulating water to the conditions as required as per condenser design, during all conditions, particularly during that of summer months.

3.0 The civil structural requirements as shall be as per Civil section of specification.

4.0 The cooling tower basin shall have a storage capacity of about six (6) hours of make-up water

flow.

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11 RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 13 of 26

1.0 Designation CW System

2.0 Numbers required Nos. CW pumps discharge

Condenser Inlet / Outlet

3.0 Fluid handled *Clarified water ,.

4.0 Flow Normal / Maximum m3/hr By Bidder (Refer Note 2).

6.0 Pressure operating / design / test mwc By Bidder

7.0 Pressure drop across the expansion joint mwc By Bidder

9.0 Vacuum (test) in mm of Hg 700

10.0 Operating temperature 0C By Bidder

11.0 Movements (min)

Axial compression

Axial elongation

Lateral movement

mm

mm

mm

mm

12

12 (Refer Note 1)

12

12

12.0 No of arches By Bidder

13.0 Control unit to be provided Yes

14.0 Companion flanges Can be made in one piece or in

segments. If segmentally welded 100%

radiography shall be carried out

15.0 Material of construction

15.1 Main body High grade abrasion resistant natural or

synthetic rubber compound

15.2 Reinforcement Steel rings

15.3 Retaining ring Galvanised steel retaining rings

15.4 Outer cover Exposed surface shall be given 3 mm

thick coating of neoprene

15.5 Bolts and nuts IS 1367 Gr. 4.6

15.6 Stretcher bolt plates IS 2062

NOTE :-

1. Bidder to check the value with the movement of condenser and design the expansion joint.

2. Flow values to be based on single pump operation.

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11 RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 14 of 26

CHLORINATION EQUIPMENT (for CW system, only if chlorination is required)

1.0 Evaporator

a) Type Electrically heated

b) Control Automatic with thermostat

c) No. of Evaporators 2 x 50% for CW system only

d) Capacity / Evaporator kg/h By Bidder

2.0 Chlorinator

2.1 Quantity 2 x 50% for CW chlorination system

2 x 50 % for DM plant chlorination

system

2.2 Type Free standing floor (or) wall mounted

for CW system and DM plant

chlorination systems.

2.3 Cooling water flow quantity m3/h By Bidder

2.4 Design capacity of each chlorinator kg/h By Bidder

2.5 Booster pumps

2.5.1 No. 2 x 100% (Ref. Note - 1)

2.5.2 Material of Construction Impeller : SS 304 / Bronze ASTM B 584, alloy no. 905

Casing : CI, IS 210, Gr.FG 260

Shaft : Steel 080 M 36, BS 970, Part 1

Impeller ring & casing ring : SS / Leaded Bronze

Stuffing box packing : Asbestos

Base plate : MS IS:2062, epoxy painted

2.5.3 Speed ppm 1500

2.5.4 Capacity / head By Bidder

2.6 Motive pressure available at tap off point kg/sq.cm By Contractor

2.7 Back pressure at dosing point kg/sq.cm 1

2.8 Control Manual regulation and timer operated

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11 RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 15 of 26

3.0 Material of Construction

3.1 Chlorine gas vacuum line UPVC/Fibre glass reinforced polyester

3.2 Chlorine liquid gas pressure line Seamless steel to IS 1239 (Heavy) /

ASTM-A-106-Gr-B

3.3 Motive water lines Carbon steel to IS 1239/ HDPE (up to

NB 150)

Carbon steel to IS 3589 (above NB

150) with rubber lining

3.4 Chlorine solution line UPVC/FRP/steel with 3 mm Rubber

lining

3.5 Injector CIRL/PTFE throat

3.6 Cabinet FRP

3.7 Vaporising Chamber Boiler quality steel

3.8 Water Chamber Galvanised steel

4. Chlorine Cylinders

4.1 No. of Cylinders 15 days storage requirement.

4.2 Gas capacity/cylinder Ton 0.9

4.3 Design code BS 1500 Part-1 Class-I vessels

4.4 Design temperature and pressure 650C / 21kg/sq.cm

4.5 Material of construction IS 2002 Grade 2A/ASTM-A515 Gr 60

4.6 Platform scale of range 0 2 tonne Nos. 1

5.0 Dosage Rate

5.1 Continuous Dosing ppm 2

5.2 Shock Dosing ppm 5

6.0 Safety Equipment (Only For CW System

Chlorination)

6.1 Chlorine gas leak detectors Nos. 2

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11 RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 16 of 26

6.2 FRP hood Nos. 1

6.3

6.4

6.5

6.6

6.7

6.8

7.0

8.0

9.0

10.0

10.1

10.2

10.3

10.4

11.0

Blower

Caustic storage tank

Absorbent tower

Recirculation pump

Flexible hose

Chlorine gas masks

Diffuser Assemblies

Chlorine residual kit of range 0-0.5 ppm in

step of 0.05 pp and 0.5 to 6 ppm in step of

0.5pp

Lifting beam with chain pulley block

List of Instruments

Pressure indicators and pressure switches

on the discharge and suction side of

Booster pump and blowers with alarm and

interlocks.

Differential pressure switch with alarm for strainers, level gauges for absorption tank

Pressure indicators and pressure switches

on chlorine gas lines and solution lines.

All other instruments associated with

chlorinators and evaporators.

Annunciations :

Annunciations for abnormal conditions

such as low chlorine header pressure, low

m

No.

m

Nos.

Nos.

Nos.

Nos.

No.

1 x 100% capacity

10

1

1 x 100% capacity

30

3

As per system requirement with a

minimum of two diffuser sets per pump

chamber.

2

1

Required

Required

Required

Required

Required

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11 RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 17 of 26

vacuum, temperature abnormalities, low

suction pressure in booster pumps, low

ejector vacuum, high pressure in chlorine

gas tanks and other alarms required for

leak detection system shall be annunciated

in the control panel.

NOTE

1) 1.Should biocide treatment be considered

adequate by the Bidder for control/

prevention of growth of algae/ organisms

in the CW system, CW chlorination

described in this section shall be ignored.

2) 2.Bidder to decide the necessity of

chlorination booster pumps for river water

and DM plant chlorination systems. Bidder

to provide booster pumps for CW system

chlorination.

3)

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11 RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 18 of 26

CLARIFIER SYSTEM

1.0 Stilling Chamber and Parshall Flume

1.1 Number One (1)

1.2 Material RCC

2.0 Coagulant Solution Tank

2.1 Number Two (2) nos preparation tanks-cum-

measuring tanks

2.2 Material RCC

2.3 Agitator of SS 316 One(1) for each tank of SS 316 material

3.0 Coagulant Dosing Pumps

3.1 Number 2 x 100 %

3.2 Capacity and Head By Bidder

3.3 Material SS 316

4.0 Flash Mixer

4.1 Quantity One (1)

4.2 Material RCC

4.3 Agitator of SS 316 One (1)

4.4 Accessories

4.4.1 Approach ladder platform, isolating gates,

handrail and SS 316 agitator

Required

5.0 Poly Electrolyte Solution Tanks

5.1 Number One (1)

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11 RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 19 of 26

5.2 Tank material IS 2062 with 4.5 mm thick rubber lining

5.3 Agitator of SS 316 Yes

5.4 Dissolving basket Yes

6.0 Poly Electrolyte Dosing Pumps

6.1 Number Two ( 1 working + 1 stand by)

6.2 Capacity and Head By Bidder

6.3 Material of wetted parts SS 316

7.0 Clarifiers

7.1 Quantity One (1) No.

7.2 Type clariflocculator /solid contact type

7.3 Rise rate By Bidder

7.4 Detention time (minimum) By Bidder

7.5 Accessories

7.5.1 Drive assembly for rack, gear box for rack,

drive assembly for turbine, gear box for

turbine, bridge, platform with chequered

plate, hand-railing, staircase sampling

lines for clarifiers telescopic pipe (one for

each clarifier).

Required

7.6 Painting All steel surfaces shall be coated with

epoxy

8.0 Sludge Pit (Common to both raw water clarifier and DM plant clarifier)

8.1 Quantity One (1)

8.2 Material RCC

8.3 Capacity By Bidder

9.0 Sludge Transfer Pumps (Common to both raw water clarifier and DM water clarifier)

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11 RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 20 of 26

9.1 Number of Pumps Two (2) ( 1 working + 1 standby)

9.2 Capacity / Head By Bidder

9.3 Material

9.3.1 Impeller SS 316

9.3.2 Casing CI 210 Gr FG 260

9.3.4 Shaft and Sleeves SS 316

9.3.5 Impeller ring and casing ring SS 316

9.3.6 Base plate MS or CI with epoxy paint

10.0 Thickener and centrifuge (Common to

both raw water clarifier and DM plant

clarifier)

10.1 Quantity Thickener - One (1) No.

Centrifuge - One

10.2 Material RCC

10.3 Capacity By Bidder

11.0 Inlet control valves to the clarifiers Butterfly valves

12.0 Instrumentation Control

12.1 List of Instruments

12.1.1 One(1) floor mounted control panel to

house the following:

Required

(a) Instruments: Flow indicator,

integrator and recorder for parallel

flume, level indicators for tanks.

Required

(b) Annunciation Window

(i) Clarified water storage tank

common sump level low, DM

plant clarified water storage

tank, sump level low sludge

pit level high, chemical tank

level low

Required

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11 RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 21 of 26

(ii) Control supply failure Required

(iii) Clarified water storage tank

common sump level high, DM

plant clarified water storage

tank high and other

annunciations to make the

system complete

Required

(c) Illuminated push buttons set with

indicating lamps for all the drive

motors

Required

(d) Illuminated push buttons (open /

close) with indicating lamps (green /

red) for the clarifier inlet valves

Required

(e) Selector switch for all motor driven

equipment for selecting the standby

equipment into service

Required

(f) Mimic diagram of plant shall be

displayed on the control panel of

plant

Required

13.0 Minimum clarifier effluent quality to be

guaranteed

Turbidity = 20 NTU

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11 RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 22 of 26

CW-CHEMICAL DOSING SYSTEM

1.0 Type of chemical Dispersant / anti- scalant for prevention

of scaling and maintaining the cycles of

concentration;

Biocide treatment for prevention of

growth of algae and other organisms

2.0 Chemical Dosing Tank

2.1 Numbers 2 Nos. tanks/ carbuoys for storing each

chemical

2.2 Capacity Each tank to store 12 hours requirement

2.3 Material of construction FRP

3.0 Chemical Dosing Pumps

3.1 Number 2 x 100% for each chemical tank

3.2 Capacity and Head By Bidder

3.3 Material of construction (all wetted parts) SS 316

3.4 Stroke length adjustment 0-100%

4.0 Accessories to be provided Suction strainer of SS 316, Ball check

valve, Built in type common base plate

5.0 Type of control Relay based control for chemical dosing

system

6.0 Instrumentation

6.1 Pressure indicators and pressure switches

on discharge and suction line of the

dosing pumps with alarm and interlock with

pumps

Required

6.2 Differential pressure switches across the

suction strainers with alarms.

Required

6.3 Level switches (low levels) and level

gauges for each of the dosing tanks with

alarm and interlocks with pump.

Required

7.0 Safety shower end Eye Wash fountain One (1) No.

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11 RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 23 of 26

Note : 1 For any other chemical required for maintaining the concentration ratio in the CW

circuit/ prevention of scaling/ growth of algae, Bidder shall include 1 No. day tank and

2 x 100% dosing pumps.

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11 RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 24 of 26

1.0 GENERAL

1.1 Service of heat exchanger

Auxiliary Cooling Water/ Condenser

cooling water

1.2 Quantity required 2 Working + 1 Standby

1.3 Location

Indoor

1.4 Operation

Continuous

1.5 Design code ASME VII/ASME.III (ND)

2.0 DESIGN DATA AND CONSTRUC- TION REQUIREMENT FOR ONE HEAT

EXCHANGER

HOT FLUID COLD FLUID

2.1 Fluid circulated Passivated Condenser

DM water cooling

water

2.2 Fluid characteristics

(a) Viscosity kg/m.sec. By Bidder

(b) Specific gravity

(c) Specific heat at mean temp.

kcal/kg. By Bidder

C

(d) Thermal conductivity at mean temp.

kcal/ By Bidder

hr.m

C

(e) pH value By Bidder

(f) Turbidity ppm By Bidder

(G) Chlorides ppm By Bidder

2.3 Flow rate kg/hr. By Bidder

2.4 Heat exchanged kcal/hr. By Bidder

2.5 Operating temperature

(a) Inlet

C By Bidder

(b) Outlet C By Bidder

2.6

Normal operating pressure

kg/cm

(g) By Bidder

2.7 Design pressure kg/cm By Bidder

(g)

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11 RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 25 of 26

HOT FLUID COLD FLUID

2.8 Maximum allowable pressure

drop including in nozzle

kg/cm 0.5 0.7

(g)

2.9 Minimum hydrostatic test

Pressure

kg/cm This shall be 1.5 times the operating

(g) pressure

2.10 Maximum differential pressure

between hot fluid & cold fluid sides

kg/cm Equal to design pressure

(g)

2.11 Design temperature C By Bidder

2.12 Overall fouling resistance

(minimum) to be considered

hr.m 0.4 x 10-4

C/kcal

2.13 Design margin on frame to

accommodate additional plates

15%

2.14 Seismic design criteria, if any

Refer Project information

2.15 Flange drilling standard ANSI B 16.5 #

3.0 MATERIAL OF CONSTRUCTION

3.1 Heat transfer plates SS AISI 316

3.2 Compression/fixed plates IS 2062

3.3 Guide rail SS CLAD IS 2062

3.4 Support beam/column IS 2062

3.5 Tie bolts and nuts

SA 193 GR.B7/ SA 194 GR 2H or 7

3.6 Plate gaskets Nitrile rubber

3.7 Nozzles:

(a) Hot fluid side

(b) Cold fluid side

SA 106 GR.B

SA 106 GR.B

3.8 Nozzle gaskets GRAFOIL

3.9 Nozzle flanges/counter flanges

(a) Hot fluid side

SA 105

-

PIONEER GAS POWER LIMITED

380-425 MW COMBINED CYCLE POWER PLANT APSIPL-05-EPC- 3-A11 RAW WATER SYSTEM AND CIRCULATING WATER

SYSTEM

Page 26 of 26

(b) Cold fluid side SA 105

3.10 Nozzle flange bolts/nuts SA 193 GR. B7/ SA 194 GR. 2H or 7

3.11 Name plate 18-8 SS (3 mm thick)

4.0 ACCESSORIES & SERVICES

4.1 Companion flanges with bolts,

Nuts and gaskets

Yes

4.2 Lifting lugs Yes

4.3 Earthing cleats Yes

4.4 Foundation bolts and nuts Yes

4.5 Name plate with design data Yes

4.6 Erection Yes

5.0 MAINTENANCE TOOLS

5.1 Wrenches for every kind of nuts used Yes

5.2 Pneumatic/Hydraulicoperated Wrench

Yes

6.0 NOTES

6.1 Double gasket system with vents moulded into the gasket shall be provided to avoid mixing and easy detection of leakage.

6.2 All pipes for nozzle shall be seamless

6.3 Holding down bolts shall be provided

6.4 One coat of Zinc Chromate primer followed

by final shop coat of paint, type of which

will be advised later by the

owner/consultant

6.5 All nozzle flanges shall have a raised face

6.6 All testing is to be done using calibrated instruments traceable to national standard.