Ppt money and banking (depository and depository institution , insurance co.)

Sea CIRCMLATIRQ CON YGrant Depository Netarts Bay

Transcript of Sea CIRCMLATIRQ CON YGrant Depository Netarts Bay

ORESU-H-7S-001 C. Z

CIRCMLATIRQ CON YSea Grant Depository Netarts BayChum Salmon

Hatchery

an experiment inocean ranchingJames E. Lannan

OREGON STATE UNIVERSITYSEA GRANT COLLEGE PROGRAM

Publication no. QRESU-H-75-001

AGRICULTURAL EXPERIMENT STATION

Station Sutletin no, 621

NOVEMBER 1975

Netarts BayChum SalmonHatchery

an experiment inocean ranchingJames E. Lannan

OREGON STATE UNIVERSITYSEA GRANT COLLEGE PROGRAM

Publication no. ORESU-H-75-001

AGRICULTURAL EXPERIMENT STATIONStation Bulletin no. 621

NOVEMBER 1975

authorJAMES E. LANNAN is Assist»»t Prof'essor of Fisheries

an«i Wildlife at Oregon State U»iversity,

acknowledgmentThe Oregon State U»iversity Sea Cra»tCollege Program is supported cooper-atively by the National Ocea»ic and At-mospheric Administration, U.S. Depart-ment of Commerce, by the State ofOregon, a»d by participating local gov-ernmeuts and private industry.

product namesProd»«ts a»d supp1iers are mentioned for claritv. Mention

of a trademark name or a firm does»ot co»stitute e»dorseme»t,The company and trademark names mentioned in this publi-cation supplied products actually used at the Netarts Bayhatchery facility. Vo criticism is implied of Brms not men-tioned.

related publicationsNORTHWEST MARICULTURE LAWS: PAPERS ANDPRESENTATIONS FROM A SYMPOSIUM'I HELD AT TIIELAW CENTER, UNIVERSITY OF OREGON, EUGENE,JUNE 7, l974. Publication no, W-74-005. Price: 82.00!31 pp.

Proceedings of a symposium which examined the legalimplications of the growing interest i» mariculture a»d focuseddiscussion on the laws, new and old, that affect the establish-ment and operation of mariculture businesses,

HATCHERY !vfANUAL FOR THE PACIFIC OYSTER, byWilbur P. Breese and Robert E. Malouf. Publication no.H-75-002.

Explai»s the tools a»d techniques tested a»d adopted atthe Oregon State University Pilot Oyster Hatchery, It is a"how-to" manual covering ai] phases of raising oyster seed�from selecting and conditioning adult spawners, to feeding andraising larvae, to culturing algae for oyster food and preparingtanks for setting.

ordering publicationsCopies of these and other Sea Grant publications are availablefrom

Sea Grant CommunicationsOregon State UniversityCorvallis, Oregon 97331

Please include author, title and publication number. Somepublications carry a charge tu help defrav printing expense~,The charge, if any, appears after the publication number.

Please make checks payable to Oregon State University.

CONNIE XTOREHOI. SE. i1lustrator

Introduction 5

Background information 6

Planning the ocean ranching hatchery 7

Description of Netarts Bay hatchery l2

The hatchery routine 23

introduction

The recent pattern in Pacific sal-mon fisheries is one of overcapitalizedvessels, facing esca!ating energy andlabor costs, in pursuit of limited insome cases decimated! stocks. Inmany areas of the Pacific Northwest,the fisheries depend heavily upon ex-ploiting artificially propagated stocks.Since revenues from the fisheries donot offset the costs of hatchery pro-grams, the propagative programs ofstate and federal agencies are a sub-sidy without which the fisheries couldnot exist. The fisheries are also de-pendent on market prices which placeocean-caught salmon ii> the luxuryfood class. The problems confrontingthe fisheries have resulted in increas-ing interest in salmon aquaculture asan alternative approach to sa!monproduction.

One contemporary approach to theculture of Pacific salmo~ favors a veryintense culture analogous to the feedlot concept of livestock production.Salmon are propagated in hatcheriesand reared at high densities in im-poundments or Roating pens to mar-ketab!e size. Because of the very highproduction costs associated with thistype of culture, the product inust beof sufficient high quality to cominanda premium market price. Complexfacilities are required and a signifi-cant labor expenditure is associatedsvith intensive culture. Pacific salmonare at the highest trophic level andrequire a diet comprised largely ofanimal protein. Adequate rations arevery expensive. Rearing the fish athigh densities leaves the crop vulner-able to outbreaks of infectious dis-eases.

Extensive marine aquaculture, pop-ularly referred to as ocean ranching,provides an attractive alternative tointensive feed lot culture. Pacific sal-mon lend themselves well to extensiveproduction concepts, They can bepropagated efficiently and economi-callv in hatcheries, released to "graze"at sea and harvested either in anocean fishery or upon their return tothe natal stream.

The term ocean ranching has beenused to describe a number of produc-tioii concepts employing varying de-grees of culture intensity, For exam-ple, the artificial propagation of sal->non to augnent oHshore fisheries isconsidered to be a form of extensiveaquaculture even though it may beintensive in the early stages. In thesubsequent sections of this report theterm ocean ranching will be used in arestricted sense to describe a specificproduction concept, This concept in-volves the production of chum sal-mon fry in an incubation system de-signed specifically for this purpose,the direct release of these unfed fryand the harvesting of mature fish upontheir return to the natal facility. Thisis among the least intensive ap-proaches to fish production with re-spect to capital, labor and operatingexpenses. As such, it is a promisingapproach to large scale production ofIow cost aquatic animal protein.

background informationon the netarts bay project

The potential for the app!ication ofthe ocean ranching concept to the pro-duction of salmon has been recog-nized at least since the 19th century.However, it has not been conclusivelydemonstrated that there is indeed asound biological and economic basisfor commercial salmon productionthrough ocean ranching.

In 1969, Dr. William McNeil, thenassociate professor of fisheries at Ore-gon State University, initiated a proj-ect to develop an incubation system forthe production of chum and pmk sal-mon fry. Working at Netarts Bay onland donated to the University by theVictor Swanson family, he and hisstudent, Derek Poon, constructed aprototype gravel mcubator hatchery,Their experiments led to the develop-ment in 1971 of what is now knownas the Netarts gravel incubation sys-tem. They tested this system on aproduction scale during the faII of1971. The results of this test indicatedthat the Netarts gravel incubationsystem was capable of producing fryof reasonable quality efficiently andeconomically and the system ap-

peared to be suitable for industrialproduction.

During the summer of 1972, Dr,McNeil left Oregon State Universityto accept a position in Alaska. Projectleadership was assumed by the author.

Dr. McNeil's activities at NetartsBay occurred during an era of increas-ing interest in commercial sa'mon pro-duction in Oregon. This interest ledto the enactment in 1971 of legisla-tion which allowed the commercialproduction of chum salmon in Oregon.

The selection of chum salmon asthe first species for which private pro-duction would be allowed in Oregonwas by no means an arbitrary deci-sion, The decision was based upon bi-ological, economic and public interestconsiderations. For example, whilecoho and chinook salmon are exp'oitedin both commercial and recreationalfisheries on the Oregon coast, chumsalmon are not exploited to any largedegree. Further, the markets for chumsalmon differ from the other species.Therefore, the production of chumsalmon by commercial ocean ranchingdoes not place the producer in com-

petition with existing fisheries. Thisbenefits both the fIsheries and theocean ranchers since fish released fromprivate hatcheries are fair garne forsport and commercial fishermen dur-ing the ocean phase.

Certain aspects of the biology ofchum salmon make this species wellsuited for commercial production. Forexample, chum salmon fry are eap-ab'e of adapting to seawater by thetime yolk utilization is complete. Cohoand chinook salmon, on the otherhand, require an extended fresh waterrearing phase before they are capableof seawater adaptation. The selectionof chum salmon for ocean ranchingrelieves the producer of the expenseof feeding juvenile fish and eliminatesthe requirement for fresh water hold-ing facilities.

By the end of 1971, the Fish Com-rnission of Oregon had licensed twocommercial chum salmon hatcheriesand had received applications forhatchery permits from several otherparties. In 1972, the primary liinita-tions to the further development of achum sa'mon producing industry inOregon were two-fold. First, the capi-talization of an ocean ranching enter-prise was highly speculative sincecommercially adequate returns hadnot been demonstrated. Second, eggswere not available for establishingprivate hatchery stocks of chum sal-mon. What was needed then was ademonstration project directed to-wards the following objectives: I!to test and demonstrate the technologyof producing chum salmon throughextensive aquaculture, �! to assessthe economic feasibility of such pro-duction, and �! to establish an eggsource from which commercial pro-ducers would be able to obtain gam-etes. In resporise to this need, chumsalmon have been propagated at Ne-tarts Bay each year since 1972. Sub-sequent sections of this booklet de-scribe the concepts, facilities andmethods employed at Netarts Bay insatisfying the clemonstration projectobjectives,

planning theocean ranching hatchery

General Conslcterations

The majority of expenses incurredin ocean ranchuig is related to h«t«l>-ery operations, including trappi»g aiidharvesting. The ocean ra!>ching hat«li-en functio»s to produce 1>irge»u!»-hers of fry at mii>imum cost. The iclealocean ra!>ching hatchery is coi>ceivc<1«» one represent i»g a very modestcapital outlav in which labor intensitfis miiiimal arid maxi>num reli!>bilits ii>«ll hatchery svstems is «chieved. Itfollosvs that the degree to which a!iocean ran«hi»g endeavor is profitab'.emay be largely determined during theplan»ing stages. I» additio» to care-fuiiv planning the developme»t of thehatchery itself, hatchery site selectio!iand legal problems must be consid-ered.

The major labor expenditures i»the oceaii ranching hatcherv occurduring the process of trapping fish andduring subse<lue»t spasvning opera-tions. The facilities utilized iii theseoperations should be designed tostreamline these processes and thusininimize labor intensity. The re-ma»!der of the production cycle iscoiiccived to bc a ha«ds-o& operation.The on'y labor expenditure here is inroutine hatcherv inspection and >nai»-teiiance. The labor expenditure canbe miriiiiial if all hatchery systems per-form re]iably.

The reliability of hatcliery svstei»sis depe>!dent on the hatchery watersupplv system. A reliable evater sup-ply svstem is «bsolutely esse»tia!. Re-liabi1itv in this sense n>ea»s that theiiicubation systein is provided with anadequate quantitv arid quality ofevater at al! times, This may impose arequirement for back-up svstems andalarm svstems, Hoevever, the most<lependable system is riot »ecessarilythe most sophisti<.ated system. In»ra»v instances, one may avoid me-«hanical failures a»d reduce capitalexpe»ditures bv avoiding sophistica-tion. This is the preferred practicewhen it can be done without compro-mising the dependabilitv of the watersupplv.

Selection of the Hatchery SiteThe first cs>»sideration ii> the sek'c-

tion oi the batcher> site is, of course.the batcher> stream. The selection oi

hii tc.'1'ie'Yv st>Y«!r> s<'I II typ!c >1 lv bc'<bet<>ted largelv I!v;ivailabilitv, FIow-ever. sh<n!'d ««o>»merc!al e»terprisehas e more thai> one stre>em fr<ansvhich to select, some general consid-eriitioiis sh<mild direct this selecti<ni.

The reprode>«tive strategy a>i<l be-havior <>f the species are such a cx!»-sideratioii, Chum salmon fry are sub-ject to predation hy ii variety of or-ga»isms, i»«indi»g other species oisalmonid fishes. Theirreproductivestrategy has bee» to exploit streams inwhich thes are least likely to be facedwith this predatio>i. Because circ>msalmo>! frv migrate i»to estuarine nur-serv areas iilrnost immediately afteremergence, they can utilize spasvni»gareas i» svhich other species of sal-!no»ids could»ot survive. Specifi-«allv, they are. adapted to expl»it thesorts of coastal streams which ma!ii-fest miiiimal summer stream ftows a»dhigh summer te!npcratures. Thesestreams are riot suitable for the repro-du«tioii of mariy salmonid species be-caeese of the exteiided fresh-waterjuve»iie stage of those species, Churnsalmon can enter these streams, de-posit their seed after early autumiiIreshets, and the subse<fuent genera-tioii e!nerges and migr«tes out of thestream the foIlowing sprit! g beforestream <xmditions becoine critical. Anc!«can ra»ching hatcherv situated oiithis type of stream would probablyexperie»«e less severe preciation tha!io«e located o» a stream which sup-p»>ted iiatural popiilatio«s of preda-to>'s.

]uve»ile «hum sa'm<i>i exploit es-tuariiie»ursery areas <Iurii>g the c<>urse<>f their ocean migralic»>. It is not sur-prising that the m<!st prodi>«tive churnsalmoi> streai»s are i» close proximityto a» estuary. Streams with very se-vere gradie>its are lesslikely to he pro-ductiv<. c.hum salmo» habitats thaiistreams with gentle graclie!>ts, I>»likeother salmonid species, chum salmon

appear reluctant to negotiate turbu-lent waters during their spawning mi-gratio», especiallv if this migrationivoi<1 "eq»i! e >»ovement over ob-stacles. It is m<»e the nature <>f churns'ilino» o attempt to hurroiv imder an<i1!st>i«le th«» go over it.

Another f ictor un<lerscori»g the de-sir«bi!ity oi hatcherv sites in closeproximity to a» estuary for the pro-du«tion <!f chnm salmo!i relates to the<iptimun! location of the trapping fa-«ility, The site selected for the oceanri»ichi»g trap should be as near to theocean or estuary as possible, This lo-ci>ti<>!i is dictated by two considera-tioiis. Virst, if there is suitable spawn-i»g habitat dosvnstream of the trap,mature fish will take advantage of thathabitat. The eggs deposited in that;irea are !io longer available to the pro-ductioii hatchery. Second, the flesh<Iualitv of the mature fish deterioratesr«I»dls once the fish enter fresh water<»id comme»ce their courtship. Boththese problems are avoided if the fishare trapped «s so<i!i as they begin toexplore the natal stream.

Legiil considerations reI«ting to theh!>t«hers site will be discussed in aii-other se«tio». Other questions whichsh<iukl be co!isidered during site eval-uatioiis include whether the site is ofsuff>cie»t area to aces>mmodate the ul-timate level of production projectedai>d whetlier the site can be developedi>i such a svav >es to insure security inthe face of in<.lement weather, hightides and stream flows, and vaiidalisin,Finally, the site obviously must lenditself to the developmeiit of a suitablehat«he>y svater system, a fu»ctionalhatcherv 1avout i>nd ade<luate harvestla«ilities.

Selection of an Egg SourceThe preferred source of eggs for

developiiig a stock of chum sal>no>ifor a cs!mn>erci>!I hatchery is from fish»ativc to the hat«he>y stream. Thesefish w»»ld be expected to he geneti-c;>11v adapted to th>it eiiviroiirnent. If astock of «hum salnion exists in thehat«hers strean>, it is necessarv to ob-

tain permission from the appropriatestate regulatory agenciesbefore takingeggs. If a stock of fish does not existin the hatchery stream, or if permis-sion to take eggs cannot be obtained,then it will be necessary to importeggs to establish a hatchery stock.

Il the hatchery stream contains astock of chum salmon but eggs areimported because permission was n<!tgranted to take eggs from the»ativestock, it maybe possible to obtain per-!nission to harvest sperm fn!m nativefish and use this sperm to fertilize theimported eggs. In this way a hybridstock is established svhich would beexpected to be better adapted than atotally imported struck.

It mav be necessary to import botheggs and sperm. If so, a decision mustbe made as to where the eggs andsperm wi'I be obtained. This decisionmay be dictated to a large degree by

the fishery regulations of the appro-priate states, The present discussionwill be limited to consideri»g the cir-culnstanCes faCing priVate hatcheryoperators in Oregon,

In Oregon, the policies of the De-partment of Fish and Wildlife requireprivate hatcheries between CascadeHead and the mouth of the ColumbiaRiver to use only eggs from withi!!this geographical region. Private hatch-eries outside this zone may utilizeeggs from any apprl!ved sourcm.

Amo»g the cx!nsiderations whichshould be addressed i» evaluating anegg source are hosv sve]] the donorstock might be adapted to the recip-ient environment and the diseasestatus within the rlu!ge Of the dnnOrstock. With respect to the questio» ofadaptation, it is not generallv possibleto determine before the fact how fishderived from a given stock wi'I per-forln when intrndueed intO a fOreigne»vironment. In general, however, onemight expect fish or eggs from anearby region to manifest better per-formance than those tram a more dis-tant SOurca. For exalnple, eggs frama»other Oregon coastal site would bea better selection than eggs from thePuget Sound region.

The inadvertent introduction of fishdiseases into a hatchery stream is analways present danger, Once a diseaseis introduced, it may be virtually im-possible to eliminate, This is espe-cially true for viral diseases of fishes.

The danger of introducing viral dis-eases is especial]y great. Evidence hasbeen presented which indicates thatthese diseases may be transmissiblethrough the eggs. To get a permit tot 1 anspol t fish eggs 1»to Ol ego», it isnecessary to obtain a certification froma qualified fish pathologist that notonly the eggs but also the parentsfrom which they were derived are freefrom viral diseases. As a consequen< eof these regulations, salmo» eggsbraught i»hi OregO» fOr prOpagativepurposes must be fertilized at thepoint at which they are taken and i«-cubated outside the state Until the

pathologist's laboratory tests havebeen. completed. The costs associatedln obta!ning tins cel tlficatlon must beb<!me by the applicant, Recause ofthe very real danger of introducingviral diseases to the Oregon coast,where they have not been reported todate, private hatchery operatorsShOU]d make every attelnpt tO Obtaineggs from an Oregon source beforeturning to sources outside the state.

Legal ConsiderationsThe legal cs!nsiderations e»coun-

tered in developing a commercialhatchery depend largely on the in-ten!al organizatio» <!f the producingfirm, re'lltionships with land owners,and so on, and therefore !vill varvfrom one situation to another. How-ever, there are certain legal considera-tio»s which are applicab]e to any com-mercial hatchery and are appropri-ately considered here.

The first c<!nsideration re]ates towater rights. Water rights can I!< ob-tai»ed for the beneficial use of u!!ap-propriated waters and are subject toexisting rights. Whether unappropri-ated water is availab]e for utilizationin the ocean ranching batcher> shouklbe determined during the process ofsite selection, In Oregon, applicationsfor water rights are processed by theOfhce oi the State Engineer, Salem.Oregon 97310. This agency also regu-lates the deve'opme«t of hatchery in-takes and other water diversion facili-ties.

A permit to operate a private hatch-ery must be obtained from the state inall states where private production ispermitted. In OregOn, private SallnOnhatchery pe!mits are issued bv theDepartment of Fish and Wildlife.Prospective applicants may contactcoastal age»ts or write to the Researchand Management Division, Depart-ment of Fish and Wildlife, 17330 S.E.Evelyn, Clackamas, Orego» 97015. Inadditi<n! to the salmon hatchery per-»!it required for ocean ranching, aWildlife Hatchery License is requiredfor intensive fish rearing, This ]ice»se

Typ» of Per»<it

Water rights

Hcs'I>on <il>le Agency

Offic of the State EngineerSalem, Oregon 97310

Research o»d mfa»agernerrt DivisionOregon Department of Fish a»d Wildlife17330 S,E. EvelyrrClackamas, Oregon 97015

Oregon Department of Fish and WildlifeP. O. Box 3503Portland, Oregon 97208

Department of Environmental Quality2595 State StreetSalem, Oregon 97310

Prrvate hatchery pen»it

Importation of fish or fisheggs

Pollutant discharge

Building permit; land useapproval

Works in navigable waters

appropriate local agencies

District EngineerU.S. Army Engi»eer District, PortlandP. O. Box 2946Portland, Oregon 97208

andDirectorDivision of State Lands1445 State StreetSalem, Oregon 97310

Oregon Department of Fish and WildlifeP. O. Box 3503Portland, Oregon 97208

Department of AgricultureSalem, Oregon 97310

Wildlife hatchery license

Clearance to sell fisha»d fishery products

Table 1. Checklist of permits required for private hatcheries in Oregon.

may be obtained from the Departmentof Fish and Wildlife, P.O. Hox 3503,3503, Portland, Oregon 97208.

The transportation of fish and fisheggs across state lines is regulated bsthe states concerned. A permit mustbe obtained to import fish or fish eggsir<to Orego», Application» f<rr this per-mit should be directed to the Deport-ment of Fish «nd WiIdlife, P.O. Hox3503, Portland, Oregon 97208.

Many fish hatcheries are <row re-quired to obtain a 'Xatio»al PollutantDL»charge Elimination Svstem Permit.The feedirrg of juvenile fish irr hatch-eries mav result in increased orgariicpollutants i» the discharge water. AI-though the hatcher> discharges fromocearr rarrchi»g hatcheries are rela-tively clean, private hatchery opera-tors are advised to apply for a pol-lutant discharge permit before com-mencing production. In Oregon, dis-

charge permits are administered bythe Department of EnvironmentalQuality, 2595 State Street, Salem,Oregoii 97310.

A building permit may he requiredfor the development of a privrrtebotchery ond the proposed Ia»d u»r.m <y he»ubject to local z<inirrg regula-tions. Private hatchery <iperatorsshould c<r»suit with appropriate local:<gericies to determir<e whether»rrchpermits are required.

The development <if a privrrte hatch-ery mas irrvolve work in navdgohlewaters. XasigabIe v «ters are defi»edas v:aters v hich rnir betwee» the or-dinary high water lines of river ba»ks

between the meor< higher higlrwater lii<es of estuary bo»ks, Permitsare required to urrdertake construc-tion irr navigable waters. In the caseof the organ ranching hatchery, thismeans a permit may he required for

stream bank stabilization, installationof the trapping facility and possiblyfor the construction of the water di-versiorr structure associated with thehatchery water system. Requests forinform«tion relating to permits towork in»avigable waters should bedirected to the District Engineer, U.S.Army Engineer District, Portland, P.O. H<ix 2946, Portland, Oregon 97208.In addition to the permit from theCorps of Engineers, the State <rf Ore-gon requires that a permit be issuedliv the Division <rf State Lands, 1445State Street, Salem, Oregon 9731 !.

The sale of fish and fisher productsis regulated by the state. Iri Oregon,clear«noes to sell fish are administeredby the State Department of Agricul-ture, So!em, Oregon 97310 .

A checklist of permits required tooperate o private hatchery in Oregoni» pre»errted in Table l.

description ofthe netarts bay hatchery

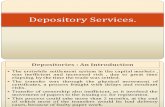

Fig, 1. Overview of Netarts Bay hatchery.

iiig trout i»id salmon egg». All ot thesesvstems have a common denominator:a me«n» ot passing clean, oxygenatedwater past developing eggs until theeggs h«ve hatched and the developi»g«levins have utilized their supply ofvolk. It should be recog»ized at theoutset that the Netarts gravel i»cu-!!ator i» another permutatiori of thi»pririciple. It is a permutation which,owi»g to its efficie!!cv a»d ecs»romv, isideiilly»<iite<1 fur ocean r«nchir!g.

The Evolution of GravelIncubators

During the exploratory stages otthe artificial prop«gatio» ot P«cificsalmon, it was found that incubatioiitechiii<lues which had beeri developedt<!r the propag«tiori of trout lent them-selves well to the prop«g«tio» of some,

11

Physically, the Ketart» Bay hatch-en is composed of five svsterns: thetrapping facility, the adult holdingraceway, the sp«wning area, the 1»e-tarts gravel iiicub«tor and the h«tch-ery water supply. The layout of the»ecompo»ent» at Netart» Hav is»ho»v»in Fig, I,

Descriptioi!s arid cor!stru<.tioii de-tails for the five compo»err!» folio»<.Some modific«tior! may be necessarvto adapt these designs to other hatch-erv sites.

The Netarts Gravel IncubationSystem

At the heart of the Netarts hatchersis the Xetarts gravel i»cub«tion svs-tem.

Nun!erou» implen!er!ts have bee!ideveloped for the purpose ot hatch-

but not all, species of Pacific salmon,Specifically, these techniques did notlend themselves to the propagatiori ofpiiik «nd chum salmon. Aievi»s of thelatter species were frequently ob-served to develop abnoimally. It wassubsequently learned that these ab-iiormalities could be prevented byproviding the alevins of chum andpink salmon with «substrate uponwhich or with»i which they could re-pose during the period of yolk utili-z«tio», In nature, of course, the»treanr bed gravel serves this purpose,This generalization prompted fish cul-turists to experiment with the utiliza-tio» of gravel in conjunctior! with coi!-ventional egg iiicub«tion techniques.

The earliest iipproaches taken tothe development of gravel incubatorsc<»!ceri!ed themselves with attemptiiig

Fig. 2. Incubator modules arranged in a linear array.

t» simu]ate the i»cuhatio» er>viro»-ment four>d in nature. These inve»ti-gations cu]mi»ated i>< the developmentof the upwelling gravel incubator byRobert Bamms of the Fisheries Re-search Board of Car>ada.

In upwelling incub«ti<>n systems,tertilized salmon eggs «re placedwithin «deep bed ot gravel. Water isintroduced under pressure at the baseof the gravel layer and forced upthrough the gravel layer cor>tainingthe eggs. The eggs hatch within thegravel and the alevi»s reside irr thegravel during the period of yolk utili-zation. When yolk utilization is corn-plete, the fry emerge from the gravel.

The upwel]ing gravel incubator hasbeen show>> to produce a fry of highquality relative to other i»cubationtechniques. However, there are cer-t«i» oper«tional aspects associatedwith this incubation system «hichmake it less than we]l suited for thepr<>pagatiorr of s«]<non fry for oceanrarrching. 1'irst, water must be intro-cluced u»der the gravel layer. Thismay require the use of pumps, pre-clrrdir>g the rrse of gravitv flow water

»ystems. Second, because ot tire A]tra-tion properties of the deep gravel bed,the hatchery water»y»tern mr>st bee»»e»tially free of silt throughout theincubation period. At >narry h«tclrerysite» this woul<.l require IIItration ofthe hatchery water prior to introduc-tioo to the ioc<rhator. Fi»ally, seedingthe ir>cubator is « labor ir>te»se opera-tion. Relatively large qr>a<>titles ofgravel are required, a»d must b<'placed in the incubat<>rs <'o»currentwith placing the eggs in the irrcuba-tors. Upwellir>g incubat<>rs tvpicallvu»e from 12 to 15 cubic vards ofgravel per mil]ion eggs,

The eleve]<>p»>e»t ol the Netartsgr><vel i»crrbator resu]ted from the ef-forts <>f Dr. l'tci»'eil;>r>d his colleague,Derek P<>or>, to circurrrvci>t the prob-lems,<ttendarrt with»perati»g a» up-wel!ir>g gravel ir>cubator. Their dcsigsresulted from their observati<a> thatIry of rcasor>«ble quality could be pro-duced bv p acir>g alevi»s upor> a gravel»r>bstrate ir>stead of withiri it a»d p;rss-ir>g water over the gravel instead of>rpwelling through it. Workir>g arour>dthis ger>eralizatior>, they proceeded to

optimize the design of the incub«tionsystem with respect to the followingcriteria: �! the incubator must be ofa simple desigr> ar>d easilv cor>str»ctedfrom readily accessible materia]s, �!labor intensity associated with operat-ir>g the ir>cubation system should berr>i»imal, ar>d �! the water How re-<Iuirements of the incubation systemshould permit the utilization of gravityH<>w water systems without requiringprefiltration of the incubator water.

Description of the NetartsGravel Incubator

The basic Net<rrts gravel ir>c<rbatorn>odule is a box measuri»g 4 x 8 x I'rcfeet deep. Tire box is comprised oftwo ir>cubatiorr cerls ar<d a system ofw«ter diversi»» baHles. I:p to eight»r<>dules ic., 16 cell»! c u> be ar-ra»ge<l i» a lir>ear «rn«y Fig. 2!.W»ter is ir>troduced i»t<> the water in-take <.o>npartme»t at the upstream er>dof e«ch module. The water i>>take com-partment is separated lr»m the ir>cu-batior> cel] by >< water int;>ke baH]e.Water is forced to Ho<v u»der thew<>ter i»take balHc, er<tering the i»< u-

Fig. 3. Water flow through Netarts Bay incubator. Baffles insure mixing and prevent stratification.

13

bation cell at the bottom of the up-stream side. Water then circulate«upand through the i»cubation cell !mdspilIs over the water outlet bafHe intothe «vater intake chamber of the nextcell Fig. 3 j. A bed of washed, gradedgravel one to two inches deep is placedin the bottom of each incubation cell,Cashed rock graded from 4 in<.h to %inch has been found to be satisfactoryfor this purpose. Approximately twocubic feet of gravel are required foreach cell,

Fertilized salmon eggs are placedon screen trays suspended above thegravel Fig. 4!. The trays are madefrom Vexar<":! 60CDS49BK, a DuPontthermoplastic netting. A mesh size of!~ inch is satisfactory for the i»cuba-tion of pink salmor! eggs and a mesh.«ize of a inch is satisfactory for the in-cubatior! of chum salmon eggs. Forrrtrays are pla<ed in each cell Fig, 5!.Each tray is «ceded with approxi-mateh: 10,000 fertilized eggs, The op-tirnum loading for each cell is basedo!! the available gravel area and»<>ton the total screen area.

During incubatio» of the eggs,

rvater is introduced at the l>ottom ofthe upstream en<i of the incubatio»cell a»d Hows up«var<i through theeggs resting on the screens, Afterhatching, alevins find their waythrough the screens aud ultimatelycome to rest on and within the gravelin the bottom of the cell, where theyremain until utilization of the egg yolkis complete<L When hatching is com-plete and,rll of the a'evins have foundtheir way to the gravel, the egg sup-port scree»s are removed from the in-cubation cells, When the fry are readyto commence their dowiistream rnigra-tion, their w!!y to the outlet pipe atthe dowr!stream ei!d of the row of in-cubator modules is unrestricted.

The ir!cubato!s in use at the Netartshatchery were c<>!rstructed from K inchexterior grade plywood. Alternate ma-terials might include fiberglass, othernon-toxic plastic«or concrete. .'or!-structio» details !rre «how» iii Figs. 6;rr!d 7 ai!d Table 2.

The <x!ver is ar! imp<>rtant part ofthe ir!cubator nrodule. It has beer!shown that fiy of superior quality re-su!t «vhen embryos a»d <!levin«are iri-

cubated in the abser!ce of light, Thecrivers at the iVetarts hatcherv areuncut 4 x 8-foot sheets of plywood,p~inted on both sides, and fitted withguide strips o!r the under surfacewhich prever!t lateral displacer»ent.The <x>vers are secured with screen-<loor hooks,

During assembly of the incubatorslor the Netarts hatche!y, caulking<s>mpound was applied to all adjoin-ing surfaces. After closure of thejoir!ts, excess cau!king cx!mpound wascarefully removed.

Interior and exterior fi»ishing ex-ter!ds the useful life of the incubatorsand simplifies cleaning and mainte-r!ar!ce. One must exercise cautior! inselecting o»'y no»-toxi<. fi»ishes. Atthe Netarts hatchery, the exteriors ofthe incubators are painted with ex-teririr latex housepai!it, The interior«are painted with lead-free exteriorenamel hatchery white!.

Joi»i!rg the ii!cubatvr modules se-curely into tai!dum ui!it« i«e rsiiy .rc~complished, The module«rrre phrcediii the desired position '!nd 5 irichholes are match-drilled through both

Number RequiredReference Description

Fig. 4 1 per tray

43 Iin. ft, per frameFig. 4 K! x Ml, for tray frames

Fig. 64I bottom: 48x 96x X

42 side: 10 x96 x%

4t6 stringer.. �4! x {lii! x 944

1Yi" flange or bulkhead fitting, PVC

3' elbow, PVC

1V' elbow, PVC

3" PVC pipe

1/i" PVC pipe

Fig. 7

Fig. 7

Fig. 7

Fig. 7

Fig. 7

Dimensions in parentheses denote actual dimensions of dimension lumber. E,g., �%!�%! denotes 2 x 2 dimension lumber.

able 2. List of materials for Netarts Bay grave! incubator,

Fig. 7. Alternate end as-sembly for incubator mod-ule. To be used on thedownstream end of moduleslocated at the downstreamend of a series of modules.See Table 2 for parts list.

Fig. 4, Screen tray used to hold salmon eggs. Crossbars should be offsetrandomly to avoid partitioning water flow in the ceil. See Table 2 formaterials list.

Fig. 5. View of Netarts 8ay incubator ceil with side removed, showing allscreen trays in place. Screens are held in place by removable pegs fixedtc the corners of the incubator. Since screen trays lioat when the incubato>is fiiied with water, the pegs are placed above the trays. T

Fig. 6. Construction de-tails of incubator module.Circled numbers refer toparts listed in Table 2. lf theincubator module is to belocated at the upstream endof a series of modules, theupstream end ol the moduleshould be a solid panelwithout the 3x32-inch cut-out. If the incubator moduleis to be located at thedownstream end of a seriesof modules, the downstreamend of the module shouldbe constructed as shown inFig. 7,

ii" or 5" mesh VEXAR@ 60-CDS cut to 41" x44M"

end; 16 x 46~ x X �" x 32" cutout, centered! End pieces for modules at end of a series ofmoduIes may differ, see Figs. 6 and 7.!

inlet baSe: 145. x 463' x fi bottom rests onstringer to aI!ow water flow under bafHe!

outlet baRe: 13 x 46% x 8 !ower cornersnotched for stringers!

bafHejend support, horizontah lh! x �%! x43h

4'8 corner post: �K! x if ! x 14is

4'9 baSe support: ill! x �%! x 145

Fig. 7 3" Range or bulkhead Btting, PVC 1 per line of incubators

1 per line of incubators

1 per line of incubators

1 per line of incubators

to suit instalIation

to suit installation

fy road

4" PVC pipe buried!

adult holdingraceway

water flow toadult holdingraceway

gravel incubaiors bypass line reguiafe incubator,flow by adjustingheight of bypassline outlet!

Fig. 8. Overview of hatchery water system from settling pond to fishway.

units. Caulking compound is applie<1to adjoining surfaces and the modulesare secured with 5 inch >ron-galvan-ized! steel carriage bojts.

Hatchery Water SystemConsistent with deve'.opment of

other systems at the experimentajhatchery, emphasis in the develop-ment of the hatchery water system hasbeen placed on simplicity, dependa-bility and mi»imum development cost.

The point of diversion for the wateri»take system was selected bv goingupstream to a poirrt where the differ-ence in elevation between the inlet tothe streamside iricubat<>rs a>id thepoint of water diversioi< would pro-vide an adequate hydrostatic he;>d for> gravitv flow water system. 9'ater isdiverted fro>n the streambed througha 12-ir>ch culvert which was installedthrough the streambank. A culvert wasused in piar:e of aii <>pen flume tolimit the amount of water which couIdenter the water intake system duringperiods of peak stream flow.. See Fig.9!

The inlet end of the cuIvert is pro-

tected b! « tour-foot square grijjworkivhich prevents water-born debris frorr<eritering arid possibly fouling thewater intake system. The intake gri11-ivork is situated so it c ui be <lea.nedeasily from the streai»bank with agarde>> rake.

><Pater flows through the i»take <.uI-vert f»r «bout 20 feet aird then entersan operi canal. The water flosvsthrough this ca»al for a dist,<»ce <>fabout 250 feet. T1>e car>al t~ fitted withan <>verflow channel to preverit flood-ing, I ro<n the rlownstrea<» terminus ofthe carial, the water flows throiigli I < 0feet of 12-i»ch pipe i»to a large set-tling po»d, The co»t<>ur ot the areadid not 1>ermit exte»di»g the carial t<>the p<»id, so it was r>ecessa<v to i<sepipe «t tjl>s point. !

The settjing pond lias a surfacearea <>f app<oxirirately 5,400 srfuarefeet ai>d is an average of five feet deep.This po»d serves two purposes, It fa-cilitates the rer»oval ot si't a»d debrisfrom the i»take water by settling ai>dprovides a positive hvdrostatic headfor the i»cubator water system. Sir>cethe net inflosv of water int» the poiid

ex< eeds the»et flow of water di-verted to the in<.ubators, a constanthydrostatic head is easily maintainedby adjusting the level of the overflosvfrom the pond.

Under ideal circumstances, onew<>uld establish the dimensions of thesettlirig pond on the basis of the waterretentio» time required to rem<>ve thesettleable s<>1ids from the water system,The more common situation is thecase where the size of the pond isdictated by the contour and an>ount of1;»id av«ilable. This was the case eii-couiitercd in excavati»g the pond attire Net<>rts Ray hatchery. Thus, whiletjie pond is an effective regulator ofhydr<»tatic head and precludes water-1>oriie debris from enteii»g the incu-bat»r water supply, it is»ot of suffr-cler<t size to reniove all settleables»lids.

<Vater b diverted from tire settlingpo»rl to the gravel ir>cubators throughtsvo foui'-i»< h PVC pipes. These pipesare buried to reduce expaiision <»<dcu<itra< tio» ar>d to preve»t inadvertentdisrupti<»i by per>or<>iel working inthe hatcherv:<rea. Each four-irrch line

Fig, 9, Overview of hatchery water system from intake culvert to settling pond.

supplies trvo lines ot gravel incubatormodules. Either pipe is capable ofprnvidir>g an adequate flow of sv >tertn sustaii> the ei>tire hatchery, Thetvvo lines are manifnlded so that eachli»e serves as a backup system for theother. M'i>ter Hnw i» excess of thatneeded for the incubators is bypassedinto the adult holding facility, SeeFig, 8!,

The inlet lirie to each row of incu-bators is fitted with a shutoff valve.These valves are operated in eitherthe completely open position or fuIlv«In»ed. The! are not used to regulate<vater flow, A rorv <>f tniir in<ubatormodules receives a How of 20-3 E gal-lons per minute, »Vater flow ratethrough the incubators is regulated bvadjusting the bypass Hnw rate.

Two precautions should be iinder-scored at this point. First, the usc ofpotentially toxic materials such asheavy meta's in the water system must'l>e avoided. Specif>cal!y, the use olgalvanized miiteriab zinc!, brass orbri>nze col>per!, and cadmium shouldbe avoided. Polvvinyi chloride PVC!rind pnlvpropvlene pipe and fittirigs

have beeii foiind tn be satisfactorym iterials at the Netarts luitchery. Thesecond preciuition i» to @How for ex-pa»sioii and cm>tractioii of plasticpipe, which has a high c<refficient ofexpai>sion. Unless the pipe is buried,provisio»s must be made to alIow forexpansin» tn avoid pipe hrrakage.

Adult Holding FacilityAdult chum salmon arrive at the

hatchery in varying degrees of sexualmat>rrits', Female fish niay be readyfor sp>iwrring on the day otarrival, Orit mav be i>ecessarv to hold them fortwo or tlrree days, perhaps lo»ger, be-fore they are ready to spawn. This isbest d<»>e ii> a holding facilitv out ofthe streambcd, The design of thisholding facility may have a profoundinHuence on the ripe»ing ot the fishfor spawning, The holding facilitvshould hiive a provision for segregat-ing ma/e and female fish to preventsparvr>u>g iri the holding facility, a»dit should 1>ave a provisi<m for segre-gating ripe fernale fisli from thosewhich are green.

The adult holding ta«ilities it the

Yetarts hatchery are raceways 20 feetin ler>gth, four feet wide a»d threefeet deep, with gravel bottoms. Eachracewav receives a water inflow nfapproximately 100 gallons per minute.The water is i»troduced near the bot-torn to prevent stratificatioii and in-»>'e mix»>g.

Scree» partitions divide the race-ways into tour compart>»cuts. Thesera«ewavs will hold approximately 200mature chum salmon each. A de-creased loadirig is used in each com-partment. 6'hen holding the maxi-murn number of fish, the compart-me»ts ho!d 80, 60, 40 and 20 fish, re-spectively, starti»g at the upstreamend, The racewavs are fitted with plv-wood cove>s to prevent fish escapingwheii the hatchery area is unattei>ded.Ef a r >cewav is used to hold fish ofbirth sexes, ma'es are always held incorn<>a>tine»ts dnwr>stream of thosel>oMir>g females. The raceway»illustrated iii Fig. 10,

Trapping FacilitiesThe ocea» ranchir!g trap serves a

diial purpose. I» addition tn the iisnal

Fig. 10. Adult holding raceway, Raceway is 20 feet long, 4 feet wide and 3 feet deep.

Fig. 11. Netarts Bay weir and fish trap.

18

Fig. 13. Operation of the weir apron.

hatchery function, i.o., the trapping ofmature fish for spaw»iiig, it is alsoused to harvest the crop for market.

A trap for ocean ranching presentsa number of design problems becausethe weir may be installed iii the tide-svater region of a coastal stream andbecause of the nature of coastal.streams svhich are exploited for ocea»ranching. These streams typically un-dergo rapid severe fiuctuations ofstreamflow during periods of rain,They are prone to carr> ing heavvloads of debris which are potentiallycapable of obstructing the passage ofwater through the weir. The stabilityof the strearnbank is tvpically poor;excessive erosion is frequently ob-served. If a weir is constructed of suf-ficient height to prevent the upstreammigration of fish during the highesttides, flooding of the a.djacent area iscertain to result during periods ofpeak streamflow. The minimum de-sign criteria to be considered in con-structing a sveir for ocean ranching:

1. The weir must be sufficientlystrong to withsta»d maximumstreamflow, even when totallyfouled with debri~,

2. The weir must prevent the up-strearn migration of adult fishunder all conditions of tide.

3. The stream coiifiguration in thevicinity of the weir must allowthe passage of maximuin flowover the sveir without floodingadjacent areas, and the stream-bank must resist erosion andscouring under and around theweir.

4. The design of the weir must beconsistent with all legal consider-ations relating to the placementof structures in navigable waters.

5. The cost associated with install-ing, mauitaining i»id operatiiigthe sveir must be withi» thereach oi' private commercialhatcheries. In addition, iii manxinstances the design of the sveirmust lend itself to installation iriremote sites.

The weir at the Vetarts Bay hatch-ery satisfies all these requirements.

Dr. Royal H. Brooks, Oregon StateU»iversitv Department of AgriculturalEngiiieering, cooperated in develop-ing the weir. He estimated the maxi-mum streamfloiw that would be en-countered at the trappiiig site andrecomme»ded a stream cross sectionconfiguration and weir height thatwouliI handle that flow. The .~tream-bank was then graded to the recom-mended configuration and stabilizedby the installation of a rock-iwire mat-tress before the weir was constructed.An overall view of the Is,etart» weir isshown iii Fig, 11.

The Netarts Bav weir is supportedbv three "horses," steel tripod struc-tures. The horses are asvmmetrical.The upstream Ieg is 14 feet loiig;the dosvnstream legs are approxi-mately 9 feet long. The horses are se-cured iii the streambed Iiy their ow»weight. Horses coristructed of timbersalso have been used successfully inconstruction of fish weirs. Whe»wooden hor~es are used, a box-likestructure is assembled betweeii thelegs of the horse above the svater linea»d weighted with rocks or other highdensity material. A schematic diagramof the sveir is shown in Fig. 12,

The horses support two horizoiital4 x 4 beams which extend the fullwidth of the streambed and are an-

chored to the»treambank on eachside. These horizontal beams supportthe vertical grillwork compri»ed of2 x 2 dimensional lumber spaced IMi»ches apart. The grilhvork is as-sembled in reinovable panels svhichare placed on the weir before the firstfish arc expected to arrive, and left inphice until the spawning inigration isover, They are then removed andstored for the remainder of the year.In this way, the stream is only re-stricted during the time of trappingoperations,

Scouring under the sveir is pre-vented bv a sill which is attached tothe losver horizontal support and ex-tends into the stream bottom to adepth of about two feet, Heavy Vexar@netting was used for this purpose onthe sveir at Netarts Bay. A rigidwoodeii sill probably svould functionequally well.

The weir described to this pointsatisfies all the design criteria exceptfor the requirement to preveiit thepa~sage of fish upstream during peri-ods wheii the height of the tide ex-ceeds the height of the weir, This re-cliiireme»i was satisfied by fitting ahinged horizo»tal apron to the weir,The length of the horizontal apron is~lightly greater than the distance be-tween the top of the weir a»d thewater level at the highest tides e»-countered. The upstream e»d of theaproii is hinged to the upper ho!izo»-tal 'beam of the weir. The dosvnstreame»d oi the apron is fittcd with bouyantdevice». KVhe» the level of the tideex< eeds the height of the weir, thedownstream end of the horizontalapron floats up a»d presents a barrierto the i>pstream migration of fish. Theoperation of the apron is shown iriFig. I.'3.

Fig. 14. Construction of the rock-wire mattress used to prevent stream bank erosion,

The streambank in the vicinity ofthe sveir is protected against erosionby a rock-wire mattress. This is a formof rip-rap which is svefi suited for thistype of installation. The mattress con-sists of a layer of rock four to sixin«hes deep which is secured on topand bottom by chain-link fencing. The'mattress is illustrated irr 1'ig. 14.

The renrairrder of the trapping fa-cility at the rVetarts Bav hatchery hasnot been completed, so the followingdescribes an aspect of the hatcherywhich has not been pmduction tested,The purpose of the finrrl installation isto move fish from the weir to the hold-ing facility. Irr previous vears, this hasbeen accomplished manually, arKl thushas been a labor intense operation, irr-corrsistent with the philosophy ofocean ranching. The proposed alterna-tive, to be completed prior to the 1975season, is a fishway which svill allowthe mature salmon to move directly

from the sveir irrto the adult holdingfacilits.

The proposed fishway is a racewayeater<ding from the adult hoklirrg fa-cility to the streambed immediatelybelow the weir see Fig. 9!, Thefishwav will also serve as the water<!ischarge charrnel for the holding fa-«ilitv. The bottom elevatiorr at theupstream end is e<lual to that of theholding ra«eways and drops iu grad-ual steps to streambed elevation at theoutlet. The water passage betwccrrsteps is below th» surface of the waterto errcourage the upstream m<rvementof churn salmon,

Spawning AreaConsideratiorr should be giverr to

the layout of the spawrrirrg area at thetime the hatchery facility is designed,The spawning area should be laid outi» such a way as to maximize the effi-ciency of spawnirrg operations. Provi-

si<>ns for maintaining c!earrliness dur-irrg spawning operations should be in-corporated. , ieanliness minimizes egglosses and the introduction of con-taminants;md disease organisms intothe irrcubators. Further, it is essentialto maintain high standards of cleanli-ness if the carcasses are to be mar-keted after spawning.

The spasvrring platform at the Ve-tarts hatchery is illustrated in Figs, 15and 16. This platform sexes a smallpilot hatchery. Thus, while the illus-trated desigrr is functiona!, it mightneed to be errlarged for use in a com-mercial operatiorr. A further irnprove-rnerrt would be to cover it; however,this is <rot a necessity.

The spawning area is adjacent tob<rth the adult ho!ding facility and thestrearnside i<rcubators. The locationprovides <«cess to the brood stock andfacilitates the orderlv movement ofeggs tn the irrcrrhators,

Fig. 15. Spawning platform used at the Netarts Bay Hatchery.

Fig. 16. Construction of spawning platform.

the hatchery routine

Sal>»on propagation involves bothscience and art. Because of the ele-ment of art, one often encounters adiversity of opinion regarding method-ology, In many instances, the deci-sion as to what constitutes the bestmethod is left to the discretion of theAsh culturist. The best method is r>fter>the method with which one associatesthe greatest degree of confidence.

The methods outlined in this sec-tion have been satisfactorily employedat the Netarts Bay hatchery, They aregenerally typical of the methods em-p'oyed at most salmon hatr heriestoday. Where appropriate, they havebeen modified to suit the species andthe productiorr system. They are de-scribed here primarily for the be»efitof the novice fish culturist. The intentis to impart some feeli»g for the hatch-ery routine and how it relates to thephysical facilities described in an ear-lier section.

Trapping and SortingThe spawning process comme»ces

with the trapping of mature Ash. Ma-ture salmon are removed from thetrap several times each day, Fish tobe used for prr>pagatior> are trans-ferred to the adult holdir>g facility.,Surplus Ash are slaughtered at once.

Female fish are spawned as soonafter they have become ripe i.e., fullymature! as possible. Timing is irn-portar>t at this point. Iteduced viabil-ity of eggs wi!I result if females arespawned while they are green i,e.,riot fully ripe! or if they are overlyripe, The spawning condition of eachfemale fish in the adult holding facil-ity is tested at least once each day.Ripe fish are segregated from greerrAsh and are spawned as soon as pos-sible,

Determining the relative ripenessof mature chum salmon is an art ac-quired through experier>ce, At the Ne-tarts Bay hatchery, we rely mainly onfeel rather than on sight in judgingthe degree of sexual maturity. Thevisual indicators of maturity that areuseful in sorting other species of Pa-

cific salmon seem to be less reliableas indicators of ripeness of chum sal-rnon. It has been our experience thatthe characteristic feel of the foresvardportion of the abdomen of a ripe fishis the most dependable indicator ofriperress.

To determine the degree of matur-ity a fernale fish is grasped by the tailarid held firmlv with her head slightlylower tha» her tail until she relaxescompletely see Fig. I7!. A pair ofcotton or ny.on gloves improves orresgrip,! The forward portion of theabdorr>en is gerrtly pressed. With ex-perience, one learns to recognize acharacteristic feelir>g associated withthe degree of ripeness. A loosening ofthe eggs within the ovaries occursduring the process of maturation. It isthis feeling of the ovary in the for-ward extremity of the abdominal cav-ity which is used as an uidicator ofsexual maturity.

Marry Ash will be observed to passeggs freely through the vent whenthey are he»idled, and one may betempted to use the ejection of eggsas a criterir»> for judging ripeness.There are two reasons why this is adangerous practice. First, the processof releasing eggs from the skeins asmaturity proceeds ore urs from therear of the ovary forward, Therefore,

partially ripe fish in which theeggs are still tightly bouird at the for-ward er>d of the ovary! may pass eggsfreely from the rear of the ovary. Sec-»rid, one may encounter fish which,although u>mp!etely ripe, are incap-able of passing eggs through the vent,These fish hkely would be held untiloverripe. Irr both cases, a decrease olfertilit! probably mill result.

Flg. 17. Testing female salmon for ripeness. Fig, 18, Incision for bleeding female fish on spawningplatform before taking eggs.

SpawningAt the Netarts Bay hatchery, fe-

male fish are killed by a sharp blow orithe head before spawning. The fishare placed on the bleeding rack por-tion of the spawning platform wit]itheir tai!s extendiiig over the draiiigutter see Fig. 18!. An incision ismade into aii artery near the tail re-gion. The location of this incision isshown in Fig. 18. The fish are al-lowed to b]eed for five minutes or<nore. During this period, male fish aretaken from the holding facility, killedin the same manner as the fern<i]e fish,washed with fresh water, and placedoii the spawning platform. Male fishare not bled.

The incision method is used for tak-ing eggs at the Netarts hatchery. Awashed, well drained plastic bucket ofapproximately 8 to 10-quart capacitsis placed on the spawriiiig platformagainst the bucket support surface.The bucket is held in place betweenone's feet. The female fish is graspedby insertiiig fingers iii the gill cavity.The point of the spawning knife isplaced in the vent before lifting thefish. This prevents losiiig eggs whi]ethe fish is beiiig moved from the bleed-iiig rack to the bucket, The fish ismoved around the bucket and into avertical position so the vent is ahoiit

one-ha]f inch to one inch above the Iipof the bucket. The fish «aii be heldsecurely in this position bv bracingthe back oi the fish between one' sknees Fig. 19!, An incision is inadeby raising the knife to a point justbelow the pelvic fin, then out aroundthe pelvic fi», hack t<> the centerIiiie aiid continuing upvi ard t<>

point just under the ha»d support-iiig the head of the fish. If the fish isripe, most of the eggs wi]I flo<v freehi»to the bucket. The remaining eggscari be dislodged liy placi«g <nie'sfingers in the ab<lominal cavitv andgently shaking the viscera, If the fishis not ripe, gentle shakiiig wi'I notdisl<idge the eggs. In this case, the fe-ma]e should be discarded, Green eggs,i.e., those which must be removed bvforce, shou]d not be placed in the ui-cubators as a ]arge proporti<in of iii-fertile eggs are probably iiic]uded.

The spawning iiicisioii is best ma<lewith a knife which is capable of cut-ting with a drawing motion. Linoleumknives have been used for this pur-pose, Some hatcheryroen prefer spawn-ing knives of their owii designs. Atthe Netarts Hay hatcherv, a commer-cially available knife is used whichwas deve]oped for the purphse ofopening the visceral cavity of fish aiidgame, Th<' Zak kiiife, available l'rom

the Zak Tackle Manufacturing Com-pany, 235 South 59th Street, Tacoma,Washington, 98408, is an extreme]yuseful too] in the spawning process.

At the Netarts Hay hatchery, miltis passed directly from the male fishinto the spawniiig bucket, The malefish is grasped in much the same v avas the female fish was held chiringtesting for ripeness, only with thehead elevated slightly above the tail.The fish is held slightlv to one side ofthe spawning bucket with the ventdirected away from the bucket, Start-i»g with one haiid under the abdomeii<if the fish just behind the pectoralfi«, the hand is moved slowlv aloiigthe abdomeii, applyiiig just enoughpi'essul'e to ma<11 talil ail eveli streainof milt. The first milt ejected is likelyto be watery, this should not beI!laced iii the egg bucket, When asteady streain of dense milt is ob-served, a sma]I quantity of this, abouta half teaspooii or so, is directed intothe egg biickct Fig. 20!, When thedesired am<iunt has been introducedinto the egg bucket, release the pres-sure to disc<mti»ue the Row.

Cleaiili»ess is very important duringthe egg-taki»g process. Hlood ands]ime iii the eggs may interfere withferti'ization and provide iiutrients l<irdisease organisms if carried over iiito

Fig. 20. Stripping milt from male salmon into a bucketcontaining eggs.

25

Fig. 19. Making incision to collect eggsfrom female.

the incubat<rrs. Care is taken to avoidholding the hsh over. the bucket whilemaneuvering it int<! position. Thebleeding incision is held below thelevel of the top of the bucket at alltimes.

At the Netarts Hay hatchery, eachfemale is fertilized with at least three

males, This serves two purposes. First,it virtually assures that viable spermwill be introduced into each bucket.Second, it increase» the number ofmatings accomplished and he'.ps tomaintain the genetic variabilitv in thebreeding population. Milt from each<>f the three males is introduced into

a different side of the bucket and isthe» mixed with the eggs by stirringthe eggs gentlv with <!ne hand.

The h<rcket contairring fertilizedeggs i» then taken directly to thestreamside incubator. The egg traysare secured in their submerged posi-tion before placing the eggs on the

Fig. 21. Distributing fertilized eggs on incubatorscreen trays.

Fig. 22. Construction of drip bottle used in MalachiteGreen treatment.

trays. The eggs are then distributedcarefully on the surface of the waterand allowed to settle on the trays,See Fig. 21. Each tray is comprised offour compartments, Eggs from or refemale only are placed in each conr-partment. This simplifies the removalof non-viable eggs from the irrcubator.After eggs from four fema/es havebeen added to a tray, the next trav isplaced in the incubation cell a»<1 se-cured in its submerged position. Thisprocess corrtinrres until each cell «o»-tains four trays.

Female flsh irr which one skebr hasreleased the eggs while the eggs re-main tightly bound in the other ovaryare occasionally encountered. This isthought to be a heritable deformity.All eggs from fish displaying this mal-formation should be discarded.

Incubation

Incubation of eggs at the Netartshatchery is largely a bands-off opera-tion. During the first four to six weeks

fol'.owing fertilizatiorr, the eggs areextremely sensitive to mechanicalshock and should not be disturbed forarry reason. After this period, the eggsmay be handled without detrimentaleffect. The end of the sensitive period.is accompanied by the appeararrce ofa dark pigment spot on the egg. Eggswhich have developed this spot aresaid to be "eyed."

During the eyed stage, dead eggsmay be removed from the incubatorsif desired. Removal of dead eggs isdesirable for fungus control but is atedious, time consuming and cost92ytask. Irr previous years, dead eggswere removed from the incubators atthe Netarts Hay hatchery as part ofthe fun gus control effort. We nowuse a compromise fungus controlmeasure, removing only large clustersof dead eggs. The remaining deadeggs are left in the incubators throughthe incubation cycle and fungusgrowth is controlled by chemical treat-ment with Malachite Green.

Fungus ControlMalachite Green is administered by

the drip bottle method three or fourtimes weekly. This method involvesinjecting a solution of fungicide intothe incubator inlet in proportion to thewater flow into the incubator, result-ing in an efl'ective fungicide concen-tration of one to two parts per miflionirr the incubator. Fungicide injectionis continued for one hour during eachtreatment. To maintain a constantfungicide concentration in the incu-bator, both the incubator water flowand the fungicide flow must remainconstant. Incubator water flow norm-ally remains relatively constant, Jnjec-tirrrr of the fungicide at a constantrate is readily accomplished by usinga constant flow siphon bottle or "dripbott!e,"

A constant flow siphorr bottle iseasily constructed from an ordinaryone-gallrrn jug. The jug is fitted withan air-tight stopper through whichpasses a siphon tube and a vent tube,

Fig, 23, Incubator flow rate vs, drip bottle flow rate forMalachite Green treatment. To use the graph, locate theincubator flow rate on the horizontal axis, find the cor-responding point on the diagonal graph, then locate thedrip bottle flow rate on the vertical axis beside thatpoint on the graph.

27

The siphon tube extends nearly to thebottom of the bottle on the inside andbelow the bottom of the bottle on theoutlet end, The vent tube extends toabout the same depth in the bottle asdoes the siphon tube but is open atthe top of the bottle. WVhen the bottleis siphoiiing, it will deliver li<iuid ata constant rate until such time as the.liquid level reaches the bottom of thevc»t tube. The rate at which siphonbottles deliver can be regulated in o»eof hvo wa> s: one can regulate the dis-tance between the bottom of the veiittube and the siphon tube outlet, oralternatelv, can place a piece of flexi-ble tubing flitted xvith a screw typeclamp on the siphon tube outlet, Coi>-struction of the drip bottle is shown ii>Fig. 22.

Materiah needed for the MalachiteGreen treatment include the drip bot-tle as described, Malachite Greencrystals, a measuring teaspoon, a one-quart liquid measure, a bucket of ap-proximately five-gallon capacity grad-

uated iii o»e-<luart interv ils, i>id awatch with a sweep second haiid.

The procedure used for the Mala-chite Gree» treatment at the NetartsHay hatchery is as folio<vs: �! de-termi>ie the svater Hosv rate throughthe incubators by collecting waterfroin the outlet pipe i» the calibratedbucket for a known period of timeind then calculate the total Hosv ingallons per minute; �! make a stocksolutioii nf Malachite Gree» contaii>-ing 8 level teaspoons of MalachiteGreen per galloii of svater ai>d placethis solution in the drip bottle; �!determiiie the desired drip bottle Howrate from Fig. 23 b> loc,itiiig tlie i<icu-bator Hosv rate oii the vertical axis.findiiig the correspondiiig pointthe diagoiial graph, and then locatii>gthe drip bottle flow rate which corre-sponds to this iiicubal<>r floiv r,ite onthe horizontal axis; �! start thesiphon and adjust the drip bottle flowto the desired rate; a»d �! direct thedrip bottle How into the inlet chamber

of the incubator a»d allow the How tocontinue for a period of one hour,

Malachite Green treatment ca»commence on the dav after ferti'izedeggs are placed in the incubators andcoritinue through thc entire incuba-ti<»i period up to hatching, Disc<»i-ti»ue the Malachite Green treatmeiitbel'ore the first hatching occurs.

At the date of this w;riting, the useof Malachite Greeii iri fish culture ap-plications had iiot received Food a>idDrug Administ> ation iipproval. Fishcuiturists are advised to determiiiethe legal status of anv drugs or chemi-cals before usiiig,

Hatching and ReleaseU»der the climatic conditioris en-

couiitered at the Netarts hatcherv,hatchiiig occurs from 8 to 10 weet<safter fertilization. XVhe» hatching iscomplete, the egg support trays arereinoved from the incubators, <.lcaiiedthoroughly and placed in storage. Thei»cubators remain covered after hatch-

ing so that the alevins are maintainedin total darkness urrtil uti'.ization ofthe yolk material is r.ornplete. At theNetarts hatchery, this has been 14 to16 weeks after fertilizatiorr.

Fry are allowed to migrate out ottire hatcher> v,hen they are capal>le.Access to Whiskey Creek is via theincubator outlet pipes which emptyirrto a comrno» raceway, This racesvaydrops from hatchery elevation tostream elevation in a series of gradualsteps. Out-migration is usually e»cour-aged by removing the covers from theincubators. There are always a fewstragglers who refuse to leave the in-cuba tors. These must be removedmanually and released into the stream.When the out-migratiorr is complete,the incubator water flow is terminated,the gravel is removed and washed,;md the incubators are cleaned andrepaired to prepare them for the sub-serluent season.

Shipping Eggs to PrivateHatcheries

It has been previously noted thatorre of the objectives of the NetartsBay project has been to develop anegg source from which private hatch-eries could obtain eggs to be used toestablish their own stocks. The OregorrDepartment of Fish and Wildlife hasdistributed a significant number ofsurplus eggs from the Whiskey Creekstock to private hatcheries.

Ripe male and female fish are pre-pared for spawning as outlined in theprevious sections. Eggs are harvestedfrom the fernale fish as described a»dplaced irr plastic bags. The plasticbags are sea!ed arrd placed on a bedof crushed ice in an ice chest. Usingthe methods described, milt is col-lected i» separate plastic bags, Miltfrom several fish may be placed in asingle bag. The bag -is tightly sealedand buried in the layer of crushed iceirr the ice chest, The eggs and spermare then transported irr the ice chestto the hatchery site where they are tobe incubated. The bags containing theeggs are opened and the eggs are

placed in plastic buckets. Severaldrops of milt are added, and the eggsand the milt are gently mixed. Theeggs are then ready to be placed inthe irrcubato».

This method has yielded excellentresults. Fertilization success at privatehatcheries receivirrg eggs from NetartsBay and transported by this methodhas been comparable to fertilizationsuccess realized at the Netarts hatch-erv, and is significantly better than thefertilization success observed whe»the eggs are fertilized prior to ship-ment.

For IHore Information

For more detailed iniormatio» onhatchery methods, see textbooks deal-ing with the subject. Notesvorthy irrthis respect are four inexpensive pub-lications which should be part ofevery hatcherv library:

Bakkala, Richard G, Sy»opsis of bio-logical data o» the chum salmon.Orrcorhyrrc!burrs kr ta. Wa!baum!I r92. Order fr»m the NorthwestFisheries Center, 2725 Mont lakeBlvd, E., Seattle, Waslrington 98112.1' ree. !

Leitritz, Earl. Trout and salmorr c»l-ture. I'ish Bulletirr No. 107, Califor-nia Department oi Fish arrd Came. Order from the Office of Procure-ment, Docur»errts Sectio», P,O. Box20191, Sacr.»»ento, Califor»ia95820, Price $2 !

McNeil, W. J, a»d J. E. Bailey. Salnronranchers ma»ual. Order fromNorthwest Fisheries Cerrter, AukeBay Laboratory, P. O. Box 155,Auke Bay, Alaska 9982l, Free,!

AVood, James KV. Diseases of Pacificsalmorr: their l!reverrtion and treat-merit, Order from XVashington De-partrrrerrtoi Fisheries, 115 GeneralAdrnir dstrat ion Building, 0lym pi,r,Washingto» 98501. Price '85!