SCOR 9.0 Quick Reference

-

Upload

rakesh-chandran -

Category

Documents

-

view

136 -

download

3

Transcript of SCOR 9.0 Quick Reference

Version

9.0

SCOR Quick Reference

PLAN SOURCE MAKE DELIVER RETURN

SCOR is a registered trademark in the United States and Europe

Supply-Chain Operations

Reference-modelTop Level

(Process Types)

ConfigurationLevel

(ProcessCategories)

Process ElementLevel

(DecomposeProcesses)

ImplementationLevel

(DecomposeProcess Elements)

Su

pp

ly-C

ha

in O

pe

ratio

ns R

efe

ren

ce

-mo

de

l

Not in

Scope

P1.1Identify, Prioritize, and

Aggregate Supply-Chain Requirements

P1.2Identify, Assess, and

Aggregate Supply-ChainResources

P1.3Balance Supply-ChainResources with Supply-

Chain Requirements

P1.4Establish and Communicate

Supply-Chain Plans

Level

# Description Schematic

1

2

3

4

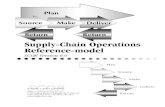

SCOR Contains Three Levels of Process Detail

ReturnReturn

Source Make

Plan

Deliver

PLANP1Plan Supply Chain

P2Plan Source

P3Plan Make

P4Plan Deliver

P5Plan Return

P1.1: Identify,Prioritize, &AggregateSupply-ChainRequirements

P1.2:Identify,Assess, &AggregateSupply-ChainResources

P1.3:BalanceSupply-ChainResources with Supply-ChainRequirements

P1.4:Establish &CommunicateSupply-ChainPlans

P2.1: Identify,Prioritize, &AggregateProductRequirements

P2.2: Identify, Assess,& AggregateProductResources

P2.3: BalanceProductResources withProductRequirements

P2.4 EstablishSourcing Plans

P3.1: Identify,Prioritize, &AggregateProductionRequirements

P3.2: Identify, Assess,& AggregateProductionResources

P3.3: BalanceProductionResources withProductionRequirements

P3.4: EstablishProductionPlans

P4.1: Identify,Prioritize, &AggregateDeliveryRequirements

P4.2: Identify, Assess,& AggregateDeliveryResources

P4.3: BalanceDeliveryResources withDeliveryRequirements

P4.4:EstablishDelivery Plans

P5.1: Identify,Prioritize, &AggregateReturnRequirements

P5.2: Identify, Assess,& AggregateReturnResources

P5.3: Balance ReturnResources withReturnRequirements

P5.4: Establish &CommunicateReturn Plans

EP.1: ManageBusiness Rulesfor PlanProcesses

EP.2: ManagePerformance ofSupply Chain

EP.3: Manage PlanData Collection

EP.4: ManageIntegratedSupply ChainInventory

EP.5: ManageIntegratedSupply ChainCapital Assets

Enable Plan

EP.6: ManageIntegratedSupply ChainTransportation

EP.7: ManagePlanningConfiguration

EP.8:Manage PlanRegulatoryRequirements& Compliance

EP.9:Manage SupplyChain Risk

EP.10:Align SupplyChain UnitPlan withFinancial Plan

DELIVERD1DeliverStockedProduct

D2DeliverMake-to-Order

D3DeliverEngineer-to-OrderProduct

D4DeliverRetailProduct

D1.1: Process Inquiry &Quote

D1.2: Receive, Enter &Validate Order

D1.3: Reserve Inventory &Determine DeliveryDate

D1.4: Consolidate Orders

D1.5: Build Loads

D1.6: Route Shipments

D1.7: Select Carriers &Rate Shipments

D1.8: Receive Product fromSource or Make

D1.9: Pick Product

D1.10: Pack Product

D1.11: Load Product & Generate Shipping Docs

D1.12: Ship Product

D1.13: Receive & VerifyProduct by Customer

D1.14: Install Product

D1.15: Invoice

D2.1: Process Inquiry &Quote

D2.2: Receive, Configure,Enter & ValidateOrder

D2.3: Reserve Resources &Determine DeliveryDate

D2.4: Consolidate Orders

D2.5: Build Loads

D2.6: Route Shipments

D2.7: Select Carriers &Rate Shipments

D2.8: Receive Productfrom Source or Make

D2.9: Pick Product

D2.10: Pack Product

D2.11: Load Product &Generate ShippingDocs

D2.12: Ship Product

D2.13: Receive & VerifyProduct by Customer

D2.14: Install Product

D2.15: Invoice

D3.1:Obtain & Respond toRFP/RFQ

D3.2: Negotiate & ReceiveContract

D3.3: Enter Order, CommitResources & LaunchProgram

D3.4: Schedule Installation

D3.5: Build Loads

D3.6: Route Shipments

D3.7: Select Carriers &Rate Shipments

D3.8: Receive Productfrom Source or Make

D3.9: Pick Product

D3.10: Pack Product

D3.11: Load Product &Generate ShippingDocs

D3.12: Ship Product

D3.13: Receive & VerifyProduct by Customer

D3.14: Install Product

D3.15: Invoice

D4.1:Generate StockingSchedule

D4.2: Receive Product atthe Store

D4.3:Pick Product fromBackroom

D4.4: Stock Shelf

D4.5: Fill Shopping Cart

D4.6: Checkout

D4.7: Deliver and/orinstall

ED.1: ManageDeliverBusiness Rules

ED.2: Assess DeliveryPerformance

ED.3: ManageDeliverInformation

ED.4: ManageFinishedProductInventories

ED.5: ManageDeliver CapitalAssets

Enable Deliver

ED.6: ManageTransportation

ED.7: ManageProduct LifeCycle

ED.8: ManageImport/ExportRequirements

ED.9:Manage Supply ChainDeliver Risk

MAKEM1Make-to-Stock

M2Make-to-Order

M3Engineer-to-Order

M1.1:Schedule ProductionActivities

M1.2: Issue Product

M1.3: Produce and Test

M1.4: Package

M1.5: Stage Product

M1.6: Release Product to Deliver

M1.7:Waste Disposal

M2.1:Schedule ProductionActivities

M2.2: Issue Product

M2.3: Produce and Test

M2.4: Package

M2.5: Stage Product

M2.6: Release Finished Product to Deliver

M2.7:Waste Disposal

M3.1: Finalize Engineering

M3.2: Schedule ProductionActivities

M3.3: Issue Product

M3.4: Produce & Test

M3.5: Package

M3.6: Stage Product

M3.7: Release Product to Deliver

M3.8:Waste Disposal

EM.1: ManageProductionRules

EM.2: ManageProductionPerformance

EM.3: Manage MakeInformation

EM.4: Manage In-ProcessProducts (WIP)

EM.5: ManageEquipment andFacilities

Enable Make

EM.6: ManageTransportation

EM.7: ManageProductionNetwork

EM.8: ManageProductionRegulatoryCompliance

EM.9:Manage Supply ChainMake Risk

SOURCES1Source StockedProduct

S2Source Make-to-OrderProduct

S3Source Engineer-to-OrderProduct

S1.1: Schedule Product Deliveries

S1.2: Receive Product

S1.3: Verify Product

S1.4: Transfer Product

S1.5: Authorize Supplier Payment

S2.1: Schedule ProductDeliveries

S2.2: Receive Product

S2.3: Verify Product

S2.4: Transfer Product

S2.5: Authorize Supplier Payment

S3.1: Identify Sources of Supply

S3.2: Select Final Supplier(s) and Negotiate

S3.3: Schedule Product Deliveries

S3.4: Receive Product

S3.5: Verify Product

S3.6:Transfer Product

S3.7: Authorize Supplier Payment

ES.1: ManageSourcingBusiness Rules

ES.2: Assess SupplierPerformance

ES.3: MaintainSource Data

ES.4: ManageProductInventory

ES.5: Manage Capital Assets

Enable Source

ES.6: ManageIncomingProduct

ES.7: ManageSupplierNetwork

ES.8: ManageImport/ExportRequirements

ES.9: Manage Supply ChainSource Risk

ES.10: ManageSupplierAgreements

The Supply-Chain Operations

Reference-model (SCOR) is the

product of the Supply-Chain Council

(SCC), an independent, not-for-profit,

global corporation with membership

open to all companies and organizations

interested in applying and advancing

the state-of-the-art in supply-chain

management systems and practices.

The SCOR-model captures the

Council’s consensus view of supply

chain management. While much of the

underlying content of the Model has

been used by practitioners for many

years, the SCOR-model provides a

unique framework that links business

process, metrics, best practices and

technology features into a unified

structure to support communication

among supply chain partners and

to improve the effectiveness of

supply chain management and

related supply chain

improvement activities.

RETURNSR1 DR1 SR3 DR3

SR1.1:IdentifyDefectiveProductCondition

SR1.2:DispositionDefectiveProduct

SR1.3:RequestDefectiveProductReturnAuthorization

SR1.4:ScheduleDefectiveProductShipment

SR1.5:ReturnDefectiveProduct

DR1.1: AuthorizeDefectiveProductReturn

DR1.2: ScheduleDefectiveReturn Receipt

DR1.3: ReceiveDefectiveProduct(includesverify)

DR1.4:TransferDefectiveProduct

SR2.1:Identify MRO ProductCondition

SR2.2: DispositionMRO Product

SR2.3:Request MRO ReturnAuthorization

SR2.4: Schedule MRO Shipment

SR2.5:Return MRO Product

DR2.1: AuthorizeMRO Product Return

DR2.2: ScheduleMRO ReturnReceipt

DR2.3:Receive MROProduct(includes verify)

DR2.4: Transfer MROProduct

SR3.1: IdentifyExcessProductCondition

SR3.2: Disposition ExcessProduct

SR3.3:RequestExcessProductReturnAuthorization

SR3.4: ScheduleExcessProductShipment

SR3.5:Return ExcessProduct

DR3.1:AuthorizeExcessProductReturn

DR3.2: ScheduleExcess ReturnReceipt

DR3.3: ReceiveExcessProduct(includesverify)

DR3.4:TransferExcessProduct

SourceReturnMROProduct

DeliverReturnMROProduct

SourceReturnExcessProduct

DeliverReturnExcessProduct

SourceReturnDefectiveProduct

DeliverReturnDefectiveProduct

SR2 DR2

Enable Return ER.1: ManageBusiness Rulesfor ReturnProcesses

ER.2: ManagePerformance ofReturnProcesses

ER.3: Manage Return DataCollection

ER.4: Manage ReturnInventory

ER.5: Manage Return CapitalAssets

ER.6: Manage ReturnTransportation

ER.7: Manage ReturnNetworkConfiguration

ER.8: Manage ReturnRegulatoryRequirements& Compliance

ER.9:Manage Supply ChainReturn Risk

For more information:In USA:Supply Chain Council1400 Eye Street, Suite 1050Washington DC, 20005Tel: +1 202-822-4660Fax: +1 202-822-5286Email: [email protected]

In Europe:Supply Chain Council287 Avenue Louise2nd FloorBE - 1050 BrusselsTel: +32 2 627 0160Fax: +32 2 645 2671Email: [email protected]

www.supply-chain.org

S1 Source Stocked ProductS1.2 Detail

S1.5 Authorize Supplier PaymentS1.4 Transfer Product

Scheduled ReceiptsS1.1 Schedule

Product Deliveries

Receipt verificationProduct

Defective Products

MRO

Products

Excess Products

Receipt verification

Receipt verification

Receipt verification

Receipt verification

To ED.8: Manage Import/ExportRequirements in ED Enable Deliver

To ES.8: Manage Import/ExportRequirements in ES Enable Source

To ES.6: Manage Incoming Productin ES Enable Source

To ES.1: Manage SourcingBusiness Rules in ES Enable

To ES.2: Assess SupplierPerformance in ES Enable Source

S1.2 Receive Product

From DR1.4: Transfer Defective Productin DR1 Deliver Return Defective

From DR2.4: Transfer MRO Product inDR2 Deliver Return MRO Product

From DR3.4: Transfer Excess Productin DR3 Deliver Return Excess Product

Receipt Verification

Receipt Verification

TransferredProduct

S1.3 Verify Product

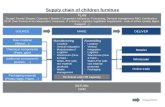

Supplier SCOR Model StructureA set of standard notation is used throughout the Model. P depicts Plan elements, S depicts Source elements, M depicts Make elements, D depicts Deliver elements, and R depicts Return elements. SR = Source Return and DR = Deliver Return. An E preceding any of the others (e.g., EP) indicates that theprocess element is an Enable element associated with the Planning or Execution element (in this case, EPwould be an Enable Plan element). Every Level 1 Process has Enable Processes associated with it.

As indicated in the chart showing the Three Levels of Process Detail, the Model is hierarchical with threelevels. Here is a sample of the detailed workflow for S1.2. S1.2 is a notation that indicates a third levelprocess element. In this case, it is a Source (S = Level 1 Source) element that is concerned with sourcingstocked product (S1 = Level 2 Source Stocked Product) and is specific to receiving product (S1.2 = Level 3Source Stocked Product Receive Product). Though the other S1 processes are shown here to Level 2, theLevel 3 detail is only included for S1.2.

The Level 1 Metrics are the calculations bywhich an implementing organization canmeasure how successful they are in achievingtheir desired positioning within the competitivemarket space. Most metrics in the Model arehierarchical – just as the process elements arehierarchical. Level 1 Strategic Metrics are cre-ated from lower level calculations and are pri-mary, high level measures that may cross mul-tiple SCOR processes. Lower level calculations

(Level 2 and 3 metrics) are generally associatedwith a narrower subset of processes. Level 2and 3 metrics associated with Level 1 metricsare included in the SCOR 9.0 MetricsHierarchy in the Metrics Chapter. Additionalmetrics that do not “roll up” to Level 1 areneeded as diagnostics (used to diagnose varia-tions in performance against plan) and areincluded in the Metrics chapter with definitionsand process locations listed.

Level 1 Strategic Metrics

Performance Attributes and Level 1 MetricsLevel 1 Strategic Metrics are primary, high level measures that may cross multiple SCOR processes. Level 1 Metricsdo not necessarily relate to a SCOR Level 1 process (PLAN, SOURCE, MAKE, DELIVER, RETURN). The MetricsChapter also now includes a unique code for every metric based on its attribute, level and alphabetical sequenceunder each level. This is especially useful for benchmarking. For coding, see the SCOR Model.

Level 1 MetricsPerfect Order FulfillmentOrder Fulfillment Cycle TimeUpside Supply Chain FlexibilityUpside Supply Chain AdaptabilityDownside Supply Chain AdaptabilitySupply Chain Management CostCost of Goods SoldCash-to-Cash Cycle TimeReturn on Supply Chain Fixed AssetsReturn on Working Capital

Reliabilty Responsiveness Agility Cost Assets!

!

!

!

!

!

!

!

!

!

Customer-Facing Internal-FacingPerformance Attributes