Scope To develop a interactive electronics control system and fabrication support to design a next...

-

Upload

marilynn-lloyd -

Category

Documents

-

view

217 -

download

1

Transcript of Scope To develop a interactive electronics control system and fabrication support to design a next...

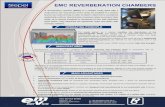

Scope•To develop a interactive electronics control system and fabrication support

to design a next Constant Climate Chambers.

• Existing product with heater, solenoid, and compressor installed.• Door open switch, mechanical assembly,

• Existing product with heater, solenoid, and compressor installed.• Door open switch, mechanical assembly,

Input

• Technical Documentation including user manual, assembly manual, service manual, wiring diagram, system installation training etc. and production training.

• Tested and ready to use control system based on per unit rate.

• Technical Documentation including user manual, assembly manual, service manual, wiring diagram, system installation training etc. and production training.

• Tested and ready to use control system based on per unit rate.

• Implementation of fuzzy-supported PID control to control temperature ±0.5°C.• To upgrade a existing panel based product to dedicated control unit with minimal

modification.

• Implementation of fuzzy-supported PID control to control temperature ±0.5°C.• To upgrade a existing panel based product to dedicated control unit with minimal

modification.

Confidential © Real Time Consultant

Case Study- Constant Climate Chambers

• On board SSR for Compressor, Light and Printer.• DISPLAY - LCD 20X4 Blue Backlight.• Thermal / Dot Matrix Printer interface.• Data Logging facility up to 1000 Record.• Audio - Visual Alarm in Single Fault Condition, Temperature Sensor Failure,

Door open indication, Ambient temperature display and alert, integrated self-diagnosis system.

• Light and FAN controlled by system logic, UV Tube facility for decontamination.

• Temperature range 5 °C to 70 °C with a display and setting accuracy of 0.1 °C or any other customised range available.

• On board SSR for Compressor, Light and Printer.• DISPLAY - LCD 20X4 Blue Backlight.• Thermal / Dot Matrix Printer interface.• Data Logging facility up to 1000 Record.• Audio - Visual Alarm in Single Fault Condition, Temperature Sensor Failure,

Door open indication, Ambient temperature display and alert, integrated self-diagnosis system.

• Light and FAN controlled by system logic, UV Tube facility for decontamination.

• Temperature range 5 °C to 70 °C with a display and setting accuracy of 0.1 °C or any other customised range available.

Challenges

Specification

available

Deliverables

Confidential © Real Time Consultant

Constant Climate Chambers -Horizontal Model

FAN

Core power Supply

Real Time Clock

Microcontroller

Heater

RS-232/485

Interface

OnBoard Solid State Relay (SSR) EEPROM

Humidity Inject

Solenoid

EMI/EMC Filter and protection

Ambient Temp. Sensor

Door Status

Door Sensor

Pt-100 Sensor

interface

Pt-100 Sensor Sample

Monitoring

Pt-100 Sensor Control

Pt-100 Sensor

interface

Sensor interface

Light

UV Light

Profile Timer for UV Light

20x4 LCD

Keypad

Humidity Sensor

Interface

HM1500 Humidity Sensor

12V Coil drive

Water heater

15-06-09 PRG1 21:34TempR:22.2°C S:22.2°CHumdR:60.2°C S:60.2°CUVT: 15min Dly: 3Min

Constant Climate Chambers – Vertical Model

Confidential © Real Time Consultant

Core power supply

Real Time ClockMicrocontroller

Heater

RS-232/485

Interface

On Board Solid State Relay (SSR)

EEPROM

EMI/EMC Filter and protection

Ambient Temp. Sensor

Door Status

Door Sensor

Pt-100 Sensor

interface

Pt-100 Sensor Sample

Monitoring

Pt-100 Sensor Control

Pt-100 Sensor

interface

Sensor interface

Light

FAN

Profile Timer for UV Light

20x4 LCD

Keypad

Humidity Sensor

Interface

HM1500 Humidity Sensor

12V Coil drive

UV Light

Humidity Inject

Solenoid

Water heater

15-06-09 PRG3 21:34TempR:25.1°C S:25.2°CHumdR:70.2°C S:70.0°CUVT: 15min Dly: 3Min

Confidential © Real Time Consultant

Constant Climate Chambers - Value Addition

The active humidification and dehumidification system: When humidifying, the humidity content is controlled via a hot steam generator. This evaporates specific doses of distilled water from an external supply tank and mixes the sterile hot steam with the air stream. Dehumidification takes place through cold traps created with cooled injection technology. This provides the constant climate chamber with a working range of 10 - 90% relative humidity. A multifunctional, fuzzy-supported PID process controller, with permanent performance adjustments and integrated self-diagnosis system, guarantees absolutely reliable temperature control and realistic conditions for perfect environment simulations.Temperature range 5 °C to 70 °C with a display and setting accuracy of 0.1 °C. Ensures perfect and absolutely reliable temperature control and the highest process safety.Multiple overtemperature protection, An adjustable over/under temperature controller takes over control in case of failure at a preset temperature. Automatic Safety Function(ASF) - a unique safety function - for over- and undertemperature automatically following the setpoint in a freely selectable tolerance range. 2 high-grade platinum temperature sensors Pt 100 in a 3-wire circuit (for stable long-term transmission of measurement signals) communicate with each other and ensure uninterrupted error-free temperature control at constant working temperature.Function signals for stand-by, operating mode, heating and over/undertemperature Internal memory with 1024kB to save temperature and error states, with timestamp to the minute Serial printer interface for printout of log data in thermal or dot matrix printer.

Confidential © Real Time Consultant

Area of co-operation

Product Design as per given specification. Ready to use solution based on Embedded H/W and Software.We deliver ready to use solution for your product with latest feature and requirement.Latest technology to meets international standard and feature.Complete customization of product as per customer requirement.Product design as per IEC/UL standard guideline (Safety :IEC60601-1 and EMI-EMC: IEC60601-1-2) Sourcing. Vendor development. Mechanical Design Support.Free onsite support and evolution sample available.No development charges, only per unit rate is charged after product approved by the customer.

Confidential © Real Time Consultant

Constant Climate Chambers -Contact Details

Contact for support and evaluation sample.

Real Time ConsultantDelhi: B-232/1, Chatterpur Extn.

Mehrauli-110074.09350831213, 09958700553.

Mumbai: 101, A-Wing, Lake Bloom Appartment, Andheri (E), Powai, Mumbai09322245924