SCHMIDT Tension Meter DX2-400-M · DX2-10K 2.5- 10 daN 116 PA: 1.00 m m ¯ ! DX2-20K-L 5- 20 daN...

Transcript of SCHMIDT Tension Meter DX2-400-M · DX2-10K 2.5- 10 daN 116 PA: 1.00 m m ¯ ! DX2-20K-L 5- 20 daN...

A

DX2-50 DX2-120

DX2-200 DX2-400

DX2-1000 DX2-2000

DX2-5000 DX2-8000

DX2-10 K DX2-20 K

DX2-2000 EDM DX2-3000 EDM

!!

A 3

c o n t r o l i n s t r u m e n t s

S C H M I D T

SCHMIDT · 1st IN TENSION METERS WORLDWIDE

Actual size

Model DX2-200

Hand-Held, mechanicalDX Series

Universal tension metersfor most industrial applications

DX SERIES12 Tension rangesfrom 10 - 50 cN to 5 - 20 daN

Special features:

✚ Built-in material thickness compensator improves accuracy for changing diameters on DX2-1000 and higher ranges✚ Special fi nger support reduces the effort to move the outer roller assembly✚ Filament guide and roller shifting mechanism ensure easy acquisi- tion of the running material✚ Custom-built confi gurations and special calibration are available✚ Built-in mounting holes permit fi xed installation for continuous tension measurement

Standard features:

❚ Everything in operator’s view: – the guide rollers – the measured material – the readings❚ Ball-bearing mounted, V-grooved guide rollers❚ Each instrument is individually calibrated for highest accuracy❚ 41 mm Ø scale❚ Rugged aluminium housing❚ Inspection Certifi cate with calibration report optionally available

Best selling tension meter

★★★ worldwide ! ★★★

fi g. 1: Adjustable damping(Code A) toprovide steadytension readings(see page E)

fig. 2: Special fi nger support located on the rear side of the housing

fi g. 3: Material thicknesscompensator with materialsample inserted

SCHMIDT scales are manu-factured according to the moststringent quality requirements.Printed scales are not used. Instead, each scale is indivi- dually marked for the instru- ment involved. This en- sures highest quality. Our special procedure makes it possible to provide tension meters fi ne tuned to a specifi c tension range, or cali- brated to custom supplied material, or units of measure such as g or kg.

Subje

ct t

o ch

an

ge

wit

hou

t n

otic

e.

without dampingwith damping

A

A 4

c o n t r o l i n s t r u m e n t s

S C H M I D T

stIN TEN SIONMETERSWORLDW IDE11

Available Models

MODEL

DX2-50 10 - 50 66 PA: 0.12 mm Ø DX2-120 20 - 120 66 PA: 0.12 mm Ø DX2-200 20 - 200 66 PA: 0.12 mm Ø DX2-400 20 - 400 66 PA: 0.20 mm Ø DX2-1000 50 - 1000 66 PA: 0.30 mm Ø ✔

DX2-2000 200 - 2000 116 PA: 0.50 mm Ø ✔

DX2-5000 400 - 5000 116 PA: 0.80 mm Ø ✔

DX2-8000 1000 - 8000 116 PA: 1.00 mm Ø ✔

DX2-10 K 2.5 - 10 daN 116 PA: 1.00 mm Ø ✔

DX2-20 K-L 5 - 20 daN 216 PA: 1.50 mm Ø ✔Other tension ranges and measuring head widths ava ilable on request.Other units of measure ava ilable – g or kg.* Depending on model, either width of fi lament guide or outer distance between outside guide rollers** Suitable for 95 % of applications (see a lso chart on page 9) PA = Polyamide Monofi lament

Specifi cations DX Series

Ca libration: According to SCHMIDT factory procedure Accuracy: ±1 % full sca le or ±1graduation on sca le Sca le diameter: 41 mm Temperature range: 10 - 45 ºC Air humidity: 85 % RH, max. Housing materia l: D ie-cast a luminium Housing dimensions: 188 x 85 x 45 mm (L x W x H) Weight, net (gross): up to DX2-10 K approx. 470 g (1000 g) DX2-20 K-L approx. 580 g (2000 g)

Hand-Held, mechanicalDX Series

Model DX2

Tension Ranges

cN

Measuring

Head Width*

mm SCHMIDT

Calibration Material**

Materia l

thickness co

m-

pensator

included

Guide Rollers ➔ see page E ➔

V-grooved

Standard 2000 Hardcoated a luminium (No. R 10003) Code K 3500 Hardcoated a luminium Code H 5000 Plasma-coated a luminium (for Model DX2-120 and higher ranges) Code T 1000 Plastic (POM) black Code W 1000 N ickel-plated steel Code ST 1000 Hardened steel Code B 1000 Tempered steel for tire cord Code CE 1 1000 Ceramic Code ASY 1000 Hardcoated a luminium asymmetrica l – Gauge without fi lament guide – groove (for Model DX2-120 and higher ranges)

U-grooved

Code U 2000 Hardcoated a luminium

Wire EDM version(Code EDM)

Model DX2-2000-EDM

with special lever (Code L) foreasy use on higher tension ranges

Model DX2-10 K-L

Line Speed

V̄ max. ... m

/ min

Roller Material

DX2-400 + H + A – M = DX2 – 400 – H – A – M

Code for accessory

Complete Order No.

To place an orderplease indicate the complete model number, e.g.:

Model with tension range

Code for guide rollers

(if not st

andard)

Optional Accessories ➔ see page E ➔

Code A Air damping (Model DX2-120 to DX2-5000 only) Code L Special lever (standard for Model DX2-20 K – recommended for Model DX2-10 K – Code M Memory pointer (DX2-120 and higher ranges) Code EDM Version for electro discharging machines Model DX2-2000-EDM: 50 - 2000 cN Model DX2-3000-EDM: 100 - 3000 cN

Special calibration using customer supplied samples is available: Please supply a sample of at least 5 m in length.

Please ask for additional

informations !

X X

X

1

2

3 34

5

6

7

8

1

4

3

2

8

X

c o n t r o l i n s t r u m e n t s

S C H M I D T

SCHMIDT · ALL OVER THE TECHNICAL WORLD

st

IN TENSION

METERS

WORLDWIDE11

Special scale for customer materials:

✚ Special calibration to customer-supplied material is optionally available.This takes into account the customermaterial’s rigidity and diameter, if itdiffers signifi cant from the SCHMIDTcalibration material. Special calibration

General Information on SCHMIDT Tension Meters

✚ The width of the measuring head varies with the modeldesign and the tension range. Dimension »X« defi nes the mini-mum access space required along the material path. It isdetermined by the width of the fi lament guide, the distancebetween the two outer guide rollers, or the outside dimensionsof the front plate, whichever is the largest.

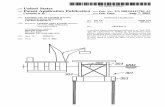

Operating elements DX2:

✚ All SCHMIDT tension metersfeature the 3-roller measuringsystem. The center measuring rolleris defl ected by the tension of themeasured material. This measuringprinciple assures highest accuracyand repeatability.✚ All rollers are equipped withprecision ball bearings.

SCHMIDT tension

meters – everything in

operator’s view:

✚ the guide rollers

✚ the measured material

✚ the readings

Material thickness compensator:

✚ SCHMIDT hand-held tension metersare equipped, if necessary, witha material thickness compensator.This exclusive feature is only found onSCHMIDT tension meters and mini-mizes any error caused by changingmaterial diameters.

1 Material sample 2 + 3 two Discs 4 Sample holder clip

SCHMIDT calibration:

✚ To ensure highest precision, eachtension meter is individually calibratedaccording to the SCHMIDT factoryprocedure. For calibration a knownweight is suspended from the standardcalibration material, vertically, asshown in the fi gure.This method is accepted – worldwide –as the industry standard.

Measuring head width on hand-held instruments:

Measuring head width on online sensors:

Filament guide and roller-shifting mechanism ensure easy acquisition of the running material

1 Measured material2 Measuring roller (center guide roller)3 Outer guide rollers4 Filament guide5 Scale6 Thumbpiece7 Sample holder clip8 Material thickness compensator

to two different materials is optionally available.

Subje

ct t

o ch

an

ge

wit

hou

t n

otic

e.

�$���"��#

! {YÉDX2-400-M

n�+²�6�JU)M�F�e]µ¿eK'XÄS���� ��K'XÄ

R��%º%¼Å2»����|�Ly�p¥�¾½C´Z�DX2����¸�²�]�^�hÀ�¨-�Ä

�²�6�JU�hÀŵ¿eK'��=�Ån4�eK'�T�^J�6aD�<¡Å�:�$6a�HµÄeK'�t]�$�~������!ÄOCÅ�+,}�µ¿e�ÃÅ��8���®1�eK'�¢>=�Å��JUh6aDc+Hµ�4���?�Ä

�������� µ¿edfb�F�~IÁÅ�:����Ku�q�/�ewÄteK'74+��9��Hµ��i±�HÄ��8��]��K'Q��GA�175zÇ]175 cNÈK'Ä#&µ¿eK'ŧ#�350zÇ350 cNÈÅ�(` �eK'�$Å3"HµaD��!�©���Ä

���� DX2K'Xs@���9k�ExWÅW¬��«;��¹U�°} [���*_Ä

��� • mÂv1É��¤�VEª�w� • K'��É20 - 400 cNÇ�20 - 400zÈ • RBɱ1Æ\Dw • ¶�N³É41£g • lB��É10-45ºC • P0 BÉ85ÆRHÅ�� • C´�}É�¾½ • C´¯¦É188×85×45£gÇ.×�×$È • WU=DÉ25� • WU¯¦É29x24x15·g • ��jBÉ2000g/�oÇvrÈ