Schematics and Valves

-

Upload

aquilesreina -

Category

Documents

-

view

224 -

download

0

description

Transcript of Schematics and Valves

-

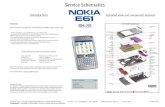

Schematics and ValvesReference info

-

Fundamentals -- Monoprop Blowdown System

-

Fundamentals -- Regulated Monoprop System

-

Typical Prop System Safety Features (CONTOUR)

-

Add a ValveUsually solenoid valves (sometimes torque motor valves may be used)Most often series dual seatSeats may be metal or elastomerMay be sliding fit or S-spring typeTi is available, but CRES (corrosion resistant steel) is most commonMost valves have small integral inlet filtersConsume 10 to 45 watts continuously when openValve to thruster seal is usually a qualified O-ring face or gland sealTrapped volume from valve seat to thruster inlet is the dribble volume that exhausts after valve is closed

-

Typical Solenoid Valve Cross-Section

-

Valve Sourceshttp://www.moog.com/Space/SpacecraftFluid/

http://www.valvetech.net/products.html

http://www.vacco.com/space2.html

-

Add Propellant LinesPropellant lines may be CRES or Ti. Bipropellant systems are usually Ti because oxidizer leaches iron out of CRES.Standard seamless tubing in several wall thicknesses is availableFittings are rarely used, most systems are welded with orbital arc weldingI design layouts clearance must be left for weld headTubing diameter is sized to minimize system pressure drop quarter-inch and 3/8 inch are common outer diametersIn a system layout, provisions must be made to support tubing

-

Group an Isolated ManifoldThrusters may be chosen for a manifold group by function, for redundancy or by locationIsolation valves are often latch valves, but can also be pyro valvesValve material usually is selected to be the same as tubing materialPyro valves generate particulates and must have downstream filtersLatch valves usually have integral inlet filtersLatch valves are $$$$Manifolds generate coupled pressure effects

-

Latch Valve Cross Section

-

Typical Pyrovalve

-

Isolation Valve Sourceshttp://www.moog.com/Space/SpacecraftFluid/

http://www.vacco.com/space2.html

http:www.conaxfl.com

-

Add Service ConnectionsService valves allow filling the propellant tank, evacuating and bleeding-in the system and adding pressurantUsually simple, light-weight, quarter-turn shut off valves to connect to fueling systemUsually are flown with caps in place Service inlets in system may be gravity determined low points or highpointsService valves are usually on the outside of the vehicle

-

STEREO SchematicMR-111C 1.0 lbf Rocket Engine Assemblies

-

Add a Pressurization SystemPressurant tank (He or N2) is usually very high pressure (3000 to 5000 psia)Often a composite over-wrapped tank is usedRegulators are $$$$$Regulators are sensitive to contaminationRegulators are often less reliable than other componentsCheck valves are usually employed on the pressurization inlet as well as the propellant outlet of the tank for the same reason