Sam Beet Mishra

-

Upload

aniket-pallav -

Category

Documents

-

view

222 -

download

1

description

Transcript of Sam Beet Mishra

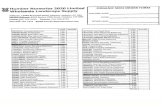

Sambeet MishraPGDM - NMIMS Hyderabad

ExperienceIntern at National Aluminium LimitedJanuary 2010 - Present (3 years 8 months)

Analysed breakdowns and maintenance activities in the cast house department to implement an improved

preventive

maintenance schedule through a daily updated database

Intern at Hindustan Aeronautics LimitedJanuary 2008 - Present (5 years 8 months)

Worked with the MIG and Sukhoi Fighter Aircraft Divisions, HAL , Koraput

- Undertook internship on Strategic Overhauling and maintenance processes of Sukhoi Su-30 Fighter Aircraft

Mechanical Engineer at Krishna Movers & Mineral Private LimitedMarch 2011 - September 2011 (7 months)

-Responsible for Daily Monitoring, procurement planning and transportation of raw materials from mines to

the destination

port/rail depots/industries

- Trained a team of 6 from administrative and support staff on smart card usage, information security, all

statutory norms,safety tools and health and application of 5S in Vehicle Maintenance Workshop

Graduate Engineer at Vedanta Aluminium LimitedJuly 2010 - January 2011 (7 months)

1.Responsible for maintenance and equipment commissioning activities in the anode rodding plant

2.Shift-in-charge - Lead a team of 8 employees in maintenance division

3.Working knowledge of Hydraulics, Pneumatics, power Transmission Devices, Bearing, Overhead Cranes,

Material Handling Systems, Conveyors, Industrial de-dusting units, lubrication systems, induction furnace

and P & F conveyor loops

4.Elementary Knowledge of 5S, Six Sigma and Spare part management

5.Implemented and improvised preventive maintenance system to reduce maintenance expenditure

6.Conceptualized a training workshop covering 2 teams (25+ participants) for better and more efficient

equipment handling

7.Reduced Avg Breakdown downtime by ~3 hrs. to improve production efficiency by approx. 14%

SAE BAJA - INTERNATIONAL at SAE Baja CompetitionSeptember 2008 - October 2009 (1 year 2 months)

Project Represented University Team at international level among 30+ international teams

Involved in end to END DETAILED DESIGN AND ASSEMBLY OF THE MINI BAJA VEHICLE

Designed and procured customized spares and parts from ALF Engineering Pvt Limited, Nashik.

Page1

Use of CATIA 3D, AUTOCAD for design and analysis

LanguagesEnglishHindiOriya

Skills & ExpertiseCADCatiaC++Pro EngineerANSYSAutoCADEngineeringProject EngineeringMechanical EngineeringCManufacturingSolid EdgeProcess EngineeringMS ProjectSix Sigma

EducationNarsee Monjee Institute of Management StudiesPost Graduate Diploma in Management, Strategy and Operations, 2012 - 2014Grade: 3.63/4.0Activities and Societies: 1. Editor - iNM Magazine, All India B-School, Magazine2. Participant : L.I.M.E, 20123. Member : Operations and Finance Club4. Research Paper - "Talent Acquisition and Competency Mapping"

Manipal Institute of TechnologyBE, Mechanical, 2006 - 2010Grade: 87.4%Activities and Societies: 1. Leo Club2. Institute of Engineers (Mechanical)3. SAE Baja4. Octave (Cultural Fest)5. Editor - "Impulse" - Departmental Magazine

DAV Public SchoolSSE, Science, 2005 - 2006Grade: 88.2%

Page2

Activities and Societies: 1. Participant : 7th National Level Physics Quiz competition

Dav Public SchoolHSE, Science, 2003 - 2004Grade: 92.2%Activities and Societies: 1.National Cadet Corps - A Certificate holder

Page3

Sambeet MishraPGDM - NMIMS Hyderabad

Contact Sambeet on LinkedIn

Page4