Safe Work Permits – A Safety Advantage

Transcript of Safe Work Permits – A Safety Advantage

Safe Work Permits – A Safety Advantage

J. Dan McCausland Senior Director,

Worker Safety & HR

AMI Safety Conference March 20, 2013

AMERICAN MEAT INSTITUTE

Safe Work Permits • Everyone knows what a “Hot Work Permit” is -- right?

– Where do we use HWP’s? Where don’t we use HWP’s? – Why do we use? Provides “extra” focus on fire prevention.

• Do you use “Work Permits” at your facility? What permits do you require? – Each type focuses on specific hazards outside “normal” work.

• Permits should be a key part of any plant safety program/process. – Makes us stop and assess the hazards within an entire unit

of work before exposures occur. – Minimizes risk in non-standard situations.

AMERICAN MEAT INSTITUTE

Safe Work Permits • Typically, we focus on production work.

– Also, on routine Sanitation and Maintenance work – We know this work, and its hazards, well.

• Routinely prepare as needed for safety.

• Non-standard work are things outside our normal frame of reference. – Often things done quarterly, or as part of other projects. – Or, certain kinds of maintenance work.

• Ammonia system work • Specialty sanitation (e.g. fumigation)

– Each type has intrinsic hazards that must be dealt with. – Each type presents hazards that “intrude” on production work

• Permits for such work are task/hazard specific.

AMERICAN MEAT INSTITUTE

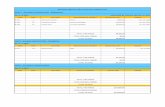

Safe Work Permits Today’s Agenda: • What is this about? What is the “big picture” with

regard to Safety Permits?

• Why are permits necessary and/or appropriate? • When are permits most useful?

• Where should permits be applied?

• How do you implement a Safety Permit process?

• Examples of permit applications

AMERICAN MEAT INSTITUTE

• What is this all about? – Most of our work is standard and repetitive in nature. – Has a variety of risks, but usually those are well known and

with safe job practices in place. – We are de-sensitized – work is “normal” in a normal area.

• Non-standard work also occurs from time to time.

– Need to prepare for those occasions, because they are out of the ordinary frame of reference for standard work.

– Such work may pose particularly serious hazards and require more than “normal” attention.

– These situations are perfect applications for the use of task-specific safety permits.

Safe Work Permits

AMERICAN MEAT INSTITUTE

• Why bother? – One word, Safety. – Makes us evaluate the work that will be performed in our

otherwise “normal” work area for possible hazards. – Makes us define what “Safe Work” practices are, and how to

follow same for this case. • When

– Every time non-standard work will be done – Permit(s) should at least be considered – up front.

• Where – Throughout the facility, and grounds.

Safe Work Permits

AMERICAN MEAT INSTITUTE

• How do we set up a Safe Work Permit Process? – Identify each type of non-standard work.

• Key is to do this “up front”, with time to plan. – Evaluate risk/hazard potential.

• Involve local SME’s (subject matter experts). • Use the “What If” analysis approach.

– Define the safe work process (to be followed). • Develop in sufficient detail. • Practice the doctrine of “no surprises”.

– Define who will be involved, who needs to approve, etc. – Plan work well in advance.

• Cross check for complications of other work being done at same place and time.

• Resolve any “territorial issues”.

Safe Work Permits

AMERICAN MEAT INSTITUTE

• How do we set up a Safe Work Permit Process (continued)? – Notify all who may be in the work area doing other tasks; may

have to clear the work area. • Work site security is essential. • No non-essential personnel in area during permit work.

– Follow through with work according to permit plan. – Close the permit: follow-up session to learn for next

occurrence. – Maintain a file on each class of permits – will ultimately be

very helpful for repeated occurrences of such work.

Safe Work Permits

AMERICAN MEAT INSTITUTE

Safe Work Permits • What kind of work may warrant a Safe Work Permit?

– Ammonia system – line breaking/opening, device work, etc. – Confined Space Entry – as required for “permit spaces”. – Energized (live) Electrical Work – all occasions – Natural Gas work – venting, blowing, purging, etc. – Hot work – outside the welding shop, etc. – Sprinkler system impairments, maintenance – Extraordinary Hazardous Chemical work – Trenching – Crane/derrick rigging and lifting – Critical Safety Bypass/Device Override situations

• Let’s consider potential permits for each of these work types.

AMERICAN MEAT INSTITUTE

• Valves, Relief valves, Flanges, Piping, Insulation, etc. • Pre-work Safety review/plan

– Subject matter experts involved in review/plan of work. – Procedures for opening a pressurized system – Lines pumped down and confirmed empty – Pipes plugged or capped as appropriate – PPE – including SCBA, eye wash/shower – in place – LO/TO for all related valves, vessels – Nearest shut-off valves pre-identified

• Other permits needed – Hot work, etc. • Return to service protocol to assure safe restart

– Leak tests completed – Formal sign-off on completion of work, permit.

Ammonia Line Breaking Permit

AMERICAN MEAT INSTITUTE

• Follow OSHA rules @ 29CFR1910.146 – these things can be deadly; no “2nd Chance to get it right”.

• Plan the work – Characterize the space as Permit or non-Permit – Plan the entry – based on the hazard(s) present – Atmospheric checks – initial, ongoing – Isolation, ventilation – Lockout as appropriate to condition – PPE – body harness, tripod, SCBA, etc. – Communication and Rescue procedures planned

• Permit closing review

Confined Space Entry Permit

AMERICAN MEAT INSTITUTE

• Require justification – why do we have to “work hot”? • Assess Hazard(s) – devices, max. voltage/current, etc. • Plan the work

– Job brief by (at least 2) qualified employees – Establish Arc Flash boundaries – PPE – Helmet, V-rated gloves, FRC, etc. – Clear the area – Complete work under direct supervision

• Return to service protocol to assure safe restart – System returned to “Safe” status – Exposed electrical devices/wiring closed. – Formal sign-off on completion of work, permit.

Energized Electrical Work Permit

AMERICAN MEAT INSTITUTE

• Incidents where NG permits were not used. – “Slim Jim” plant (NC) explosion and fire – Kleen Energy utility plant (CT) explosion – Gas-fired hot water heater installation

• Plan the work and permit conditions – Purging, Blowing, or Venting applications – Line breaking or new equipment installation – Secure ignition sources; clear area – Lockout valves – Ventilate

• Return to service protocol to assure safe restart – Formal check for leaks – Sign-off on completion of work, permit.

Natural Gas Line/Use Permit

AMERICAN MEAT INSTITUTE

• Welding, cutting, plasma arc – all types of hot work • Use FM Global HWP process – very comprehensive • Plan the work

– Precautions specific to area – flammables, gases, liquids, etc. – Explosive atmospheres must be neutralized – Pressurized vessels must be purged, vented and neutralized – Pre-work cleanup (e.g. dust) and LO/TO as appropriate. – Sprinklers, extinguishers in place and working – Protect materials on other side of walls, ceilings, etc. – Fire watch – during and 1-2 hours after work

• Return to service protocol to assure safe restart – Formal check-off 4 hours post work – Sign-off on completion of work, permit.

Hot Work Permit

AMERICAN MEAT INSTITUTE

• Whenever a FP water supply valve is closed or water shut-off to the system; sprinklers are out of service.

• Notify property insurer, fire department, etc. • Post fire watch during maintenance work.

– Provide extra fire safety support. – No Hot Work allowed during impairment.

• Restore system to service and check pressure at inspectors test valve to assure safe restart. – Formal check for leaks, other issues. – All valves verified as “open” (in fire water supply loop). – Sign-off on completion of work, permit.

Sprinkler System impairment Permit

AMERICAN MEAT INSTITUTE

• Use for non-routine chemical applications where chemicals present toxic/deadly properties. – Specialty cleanup work, Pesticide/fumigate applications, etc.

• Plan the work – Pre-work meeting; who’s required, timeframe, preparations, etc. – Review nature of chemicals to be used, OSHA safety data

sheets; application criteria and hazard analysis. – PPE – as appropriate to hazards – Secure the area to be treated; no non-essential employees. – Perform work.

• Return to service protocol to assure safe restart – Formal check for residual chemical properties – Sign-off on completion of work, permit.

Hazardous Chemical Permits

AMERICAN MEAT INSTITUTE

• Trenching – Treat as a Permit-required Confined Space – Follow OSHA rules on shoring, use trench boxes, etc. – Monitor from outside trench.

• Critical Safety Device Override – Similar to “hot” electrical work – Lockout to extent possible – Active monitoring in place while bypass is in effect.

• Cranes and Derricks – Lifting Permits – Clear the area below the lift; maintain security. – Review crane and rigging documentation, certificates, etc. – Follow OSHA rules – rigging, supervision, load control, etc.

Other Potential Permits

AMERICAN MEAT INSTITUTE

Conclusion • What is “unique” to each of these work

situations? – They are outside the normal conduct of production

work. Not on our typical “radar screen”. – Hazards associated with each are deadly; injury

potential is severe. – Bad planning (or no planning) can result in

fatalities.

• Permit processes create safe work conditions, and that is essential.

AMERICAN MEAT INSTITUTE

Conclusion

•Questions and discussion… • Sample permits are available for those

who would like a copy. •We will be happy to discuss later as

well, and appreciate your time today.

Thank you!