ndoor Communication over TV Gray Spaces based on Spectrum Measurements

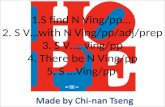

S a ving Ener gy · I mpr o v e I ndoor Air Qualit y · Ex t ... · S a ving Ener gy · I mpr o v e...

Transcript of S a ving Ener gy · I mpr o v e I ndoor Air Qualit y · Ex t ... · S a ving Ener gy · I mpr o v e...

S a v i n g E n e r g y · I m p r o v e I n d o o r A i r Q u a l i t y · E x t e n d E q u i p m e n t L i f e

BUILDING REMEDIATION SCIENCES

The natural, economical & totally GREEN coil cleaning system

The natural, economical & totally GREEN coil cleaning system

Pure-Steam is the natural & economical choice for coil cleaning that is chemical free and totally GREENThere's an old adage about water, shared among health-conscious

ered water, then you are the

The interior of air handling units (AHU’s) are dark, damp, often-times wet conditions that can harbor formations of endotoxins, mycotoxins, bacteria, fungus, pollen, particulate and other bio pollut-ants. These bio pollutants cover metal surfaces with a thin, almost invisible

with millions and millions of tiny microscopic spores. Often times, this bio-mass leads to a musty earth-like smell sometimes known as “Dirty Sock

sive odors.

acts an insulation on the evaporator coils, which decreases system

to produce allergy-like symptoms, coughing, wheezing, watery eyes, asthma type conditions and other symptoms in building occupants. Fouled coils lead to increased pressure drop across them. Increased pressure drop increases fan horse-power requirements, which, in turn, draw more power, increasing current consumption.

Energy SavingsA recent article in the ASHRAE Journal authored by Ross Montgomery, PE entitled Study

revealed a $40,000 a year savings from just one air handling system as a result of the restoration of the air handler/coil system at the 1500 Broadway a 34 story skyscraper building in Times Square, New York City home to ABC Studios and Good Morning America. In addition, the study indicated that they were able

Speak with an Expert NOW!

© 2015 Pure Air Control Services, Inc. Printed in USA.www.pureaircontrols.com 1 800 422-7873 4911 Creekside Dr, Clearwater, FL 33760

The Pure-Steam Process is “saving 7-10% on the chilled water equipment. Some of this is from reduced fan energy and the rest is from an increased delta T across the coil which reduces pumping energy and

35-40% of our utility bills are for HVAC sojust keeping our coils clean should shave

annually, at the low end”.

“as for ROI (return on investment) if you use the most conservative numbers we have paid approximately $0.14 per square foot for coil cleaning to date. We have saved about $0.22 per square foot annually. So the payback is less than 8 months and the ROI 157% annually.”

Energy Savings: 157% Return on Investment

-University Facility Manager

Blistering Hot PureSteam’s

melts away coil-clogging debris, boosting

capacity, while sanitizing the coil.

Air Handling Unit T&B Report

Steam Coil ROI 116%

-1.75A

(in.w

c.) B C D

-0.11 -0.21

0.35

H JI

Actual0.24

E F

External Static

Design Actual Total Static

Design

Motor FrameVFD Setting (HZ.)

G

6286

6286

483

Fan RPM

CFM Return 12700

Design

480

Actual

Average Volts7.6

Unit Total 12700

Actual

Outlet Total

OSAMotor RPM

DesignAirflow Data Motor / Fan Data

Average Amps

Motor Manuf.Motor HP

Static Pressure Profile Data

Miscellaneous Data Phase

Service FactorSP Setpoint

OSA

SUPP

LY A

IR

MIXING BOX

A B C D E F G H I J

RETURN AIR

Airflow Data Motor / Fan DataDesign Actual Design Actual

CFM

Outlet Total Average Amps 8.3Unit Total 12700 8964 Average Volts 480 483

Return 12700 Motor RPMOSA Fan RPM

Motor Manuf.Motor HP

Miscellaneous Data Phase

VFD Setting (HZ.) Service FactorSP Setpoint Motor Frame

Static Pressure Profile Data

(in.w

c.) A B C D E

-0.12 -0.23 -1.81 0.32F G H I J

0.44External

Static Design Actual Total

Static Design Actual

OSA

SUPP

LY A

IR

MIXING BOX

A B C D E F G H I J

RETURN AIR

6286

8964

Before

After

With energy costs rising, Georgia Tech University

had taken a close look at HVAC maintenance, including

the total operating cost of its HVAC system. They found

that the conventional coil cleaning foam/rinse method pushed small debris further into the coil causing and humidity control and decreased the quality of the

indoor air. In addition, GT was concerned about the

thousands of gallons of chemicals that would otherwise

be sent in the water system polluting the eco system.coils were nothing but a pot of gold buried in dust and

debris in these air handling systems. They were right.

T h e C o n c e r n :

T h e S o l u t i o n :

C o i l C l e a n i n g p r o c e s s :

Due to Georgia Techs desire for going green, saving

energy and providing a healthy learning environment scientitists at Pure Air Control Services and the

uniquely developed process of cleaning coils:

PURE-Steam Coil Cleaning. The process is totally (one of the few in the country) and has a proven track

record for saving energy, improving indoor air quality

and improving comfort. GT has recognized a 41%improvement in air�ow and 116% ROI

PURE-Steam Coil Cleaning process is totally

GREEN – uses no chemicals, utilizing a proprietary (up to) 350 degree steam for a deep cleansing of the coils helping to· Sanitize the coils/blowers assembly

(Green process)· Removes latent debris from deep withinthe coils

· C· Create better cooling capacity

· Saving energy (typical .22 cents per sq ft) · Improving indoor air quality· Extends HVAC equipment life

For more information on Pure Air Service Services, Inc,. its Steam Sterilization Coil Cleaning, and/or duct-cleaning

services, contact(800) 422-7873, or visit www.pureaircontrols.com, [email protected].

Project Georgia Tech University Coil Cleaning

BeforePURE-Steam

CFM 62868964

2476 41%

21%

21.30%

0160wc 0.1260.3439.9Pa

31.4Pa8.5Pa

WC

Pa

After PURE-Steam Net Improvement

©2

01

4

PU

RE

AI

R

Co

nt

ro

ls

Air Handling Unit T&B Report

14 months payback

Annual Energy Savings $2,198.00 116% ROI

Steam Coil ROI 116%

CFM - Cubic feet per minuteWC - Inches in water columnPa - Pascalss

-1.75

A

(in.w

c.) B C D-0.11 -0.21

0.35

HJI

Actual0.24

E FExternal Static Design Actual Total Static

Design

Motor Frame

VFD Setting (HZ.)

G

62866286

483Fan RPM

CFM Return 12700

Design

480

Actual

Average Volts 7.6

Unit Total 12700 Actual

Outlet Total

OSAMotor RPM

Design

Airflow Data

Motor / Fan DataAverage Amps

Motor Manuf.Motor HP

Static Pressure Profile Data

Miscellaneous DataPhase

Service Factor

SP Setpoint

OSA

SUPP

LY A

IR

MIXING BOX

A B C D E F G H I J

RETURN AIR

Airflow Data

Motor / Fan Data

Design Actual

Design ActualCFM

Outlet Total

Average Amps8.3

Unit Total 12700 8964Average Volts 480 483

Return 12700Motor RPM

OSA

Fan RPMMotor Manuf.

Motor HPMiscellaneous Data

PhaseVFD Setting (HZ.)

Service Factor

SP Setpoint

Motor Frame

Static Pressure Profile Data

(in.w

c.) A B C D E-0.12 -0.23

-1.81

0.32

F G H I J

0.44

External Static Design Actual Total Static

Design Actual

OSA

SUPP

LY A

IR

MIXING BOX

A B C D E F G H I J

RETURN AIR

6286

8964

Before

After

The natural, economical & totally GREEN coil cleaning system

© 2015 Pure Air Control Services, Inc. Printed in USA.www.pureaircontrols.com 1 800 422-7873 4911 Creekside Dr, Clearwater, FL 33760

of coil cleaning

With energy costs rising, Georgia Tech University had taken a close look at HVAC maintenance, including the total operating cost of its HVAC system. They found that the conventional coil cleaning foam/rinse method only super�ciallly cleaned the surface of the coil and pushed small debris further into the coil causing decreased air �ow, musty odor, decreased temperature and humidity control and decreased the quality of the indoor air. In addition, GT was concerned about the thousands of gallons of chemicals that would otherwise be sent in the water system polluting the eco system.

BUILDING REMEDIATION SCIENCES

Case StudyGeorgia Institute of Technology

w w w . p u r e a i r c o n t r o l s . c o m 1 . 8 0 0 . 4 2 2 . 7 8 7 3 4 9 1 1 C r e e k s i d e D r , S t e C , C l e a r w a t e r F L 3 3 7 6 0

PURE-Steam Coil Cleaning Help

Georgia Tech Facilities Saves

Energy and Improve IAQMontgomery Knight (February 22, 1901 – July 25, 1943) was

an aeronautical engineer who specialized in rotary-wing aircraft.

He was the �rst director of the Guggenheim School of Aeronatics

at the Georgia Institute of Technology and a founder of and

long-time researcher at the Georgia Tech Research Institute

GT is a leading technology and science university renowned for

their deeply-held commitment to improving the human condition.

The faculty and students are solving some of the world’s most

pressing challenges: clean and sustainable energy; disease diagnosis

and treatment; and national defense and security, among others.

The campus of GT participates in the GREEN BUZZ and Leadership in

program and the nationally accepted benchmark for the design,

construction and operation of high-performance green buildings.

T h e P r o j e c t :

© 2014 Building Remediation Sciences

aCoil Sterilization Process

TM

The totally GREEN HVAC sanitizing process

BE

FO

RE

AF

TE

R

BUILDING REMEDIATION SCIENCES

T h e C o n c e r n :

· Sanitize the coils/blowers assembly(Green process)

· Removes latent debris from deep within the coils

· C

· Create better cooling capacity

· Saving energy (typical .22 cents per sq ft)

· Improving indoor air quality

· Extends HVAC equipment life

C o i l C l e a n i n g p r o c e s s :

The natural, economical & totally GREEN coil cleaning system

© 2015 Pure Air Control Services, Inc. Printed in USA.www.pureaircontrols.com 1 800 422-7873 4911 Creekside Dr, Clearwater, FL 33760

BUILDING REMEDIATION SCIENCES

Saving Energy · Improve Indoor Air Quality · Extend Equipment Life

Coil cleaning process

Improved Indoor Air QualityEvaporator coil bio-mass leads to a musty earth-like smell sometimes known as “Dirty Sock Syndrome” a primary cause

These pollutants are known to cause allergy-like symptoms, coughing, wheezing, upper respiratory irritation, watery eyes, asthma-type conditions and other symptoms in building occupants and in healthcare facilities nosocomial infections.

Energy SavingsFouled coils lead to increased pressure drop across them. Increased pressure drop increases fan horsepower require-ments, which, in turn, draw more power, increasing current consumption.

FSUimplementation alone saved the university over $800,000 of their power bills and were able to provide the students and teachers a healthier learning environment. The estimated payback in less than eight months was 157% return on investment (ROI). -- FSU Facilities Management Department

• Lower Capital Cost• No Downtime• Retain Cash in Bank• Extends Equipment Life•• Reduced Energy Bills• Increase AHU Air Flow

• Increase Latent Moisture Removal Capabilities• Totally Green Sustainability (No Chemicals)• GREEN Guard Certifed – PURE-Liner• Improves Indoor Air Quality• Sterilizes Coils at 280 -300 degrees• Reduced Liability

Equip.

Tonnage

KW Hours per

Season (Clean)

Total Cost per

Season (Clean)

KW Hours per

Season (Dirty)

Total Cost Per

Season (Dirty)

Total Savings Per Season Per AHU

5 5,500 $470 8,100 $687 $217 10 12,300 $1,000 16,800 $1,394 $394 15 16,000 $1,370 24,400 $2,092 $722 20 20,800 $1,790 32,400 $2,794 $1,004 25 27,000 $2,290 40,800 $3,493 $1,203 30 30,800 $2,680 48,900 $4,205 $1,525 40 41,500 $3,570 66,400 $5,716 $2,146 50 52,100 $4,470 82,300 $7,056 $2,586 60 63,000 $5,390 98,600 $8,404 $3,014

Extremely Dirty Coil 40—50% Air Flow

Dirty Coil 65—75% Air Flow

Clean Coil 95—100%

Air Flow

The natural, economical & totally GREEN coil cleaning system

© 2015 Pure Air Control Services, Inc. Printed in USA.www.pureaircontrols.com 1 800 422-7873 4911 Creekside Dr, Clearwater, FL 33760

BUILDING REMEDIATION SCIENCES

Saving Energy · Improve Indoor Air Quality · Extend Equipment Life

Conventional Coil Cleaning: Basic Instructions/Procedure:

• Mix 1 part Coil Cleaner to 20 parts tap water•• Wait 3 to 5 minutes and rinse with tap water.

Price$200-$400 (1-3 man hours)Cost Per Hour $125. - $400. per hour

Drawbacks• Potential harsh chemicals can over the years corrode coils •• No deep cleansing process • No Energy Savings• No Improved IAQ• No GREEN Application – Chemicals go to water system • No Improved Air Flow

PURE-Steam Plus + Coil Cleaning Process:

• Steam & Particulate containment extraction set up• PURE-Steam Coil Cleaning at 300 degrees• 300 PSI to get a deep cleansing into the coils• Totally GREEN – NO Chemicals Sustainability• Flushing Procedure (55gal/min) removes any latent

debris loosened by PURE-Steam• Water extraction maintained during process• HEPA Vac Light Clean interior of AHU

Price$1,125. – $1,700. (15-22 man hours)$75./Man Hour

Potential Savings$1,500/Yr. (See Chart)

Net Annual Cost: $0

• Lower Capital Cost• No Downtime• Extends Equipment Life•• Energy Savings - 30Ton approx. $1,500/Yr• Increase AHU Air Flow• Increase Latent Moisture Removal Capabilities• Totally Green Sustainability (No Chemicals)•• Improves Indoor Air Quality• Sterilizes Coils at 280 -300 degrees• Reduced Liability

Options:• Blower Assembly PURE-Steam Cleaning• Drain Pan Cleaning• PURE-Liner – drain pan protection system

What’s the difference?e.g. typical 30 ton A/C System

© 2015 Pure Air Control Services, Inc. Printed in USA.www.pureaircontrols.com 1 800 422-7873 4911 Creekside Dr, Clearwater, FL 33760

Saving Energy · Improve Indoor Air Quality · Extend Equipment Life

Introducing

The drain pain protection solution

What’s the difference?e.g. typical 30 ton A/C System

BUILDING REMEDIATION SCIENCES

• Repairs rusted pans• No volatile organic compound (VOC) emission• Chemical resistant• Exceeds ASTM EB-03 25/50 index• NFPA 90A compliant• LEED compliant• Improves indoor air quality

• Biological organism control• Reduce air handler maintenance• Ultraviolet safe

Dr. Phillips Center for the Performing Arts, Orlando FL

© 2015 Pure Air Control Services, Inc. Printed in USA.www.pureaircontrols.com 1 800 422-7873 4911 Creekside Dr, Clearwater, FL 33760

BUILDING REMEDIATION SCIENCES

No other drain pan solution o�ers the comprehensive coverage of PureLiner.

PureLiner is a specially producedsheet membrane system incorporatingunique resins and antimicrobialtechnologies to provide a pipeand ductwork protection systemfor use indoors and outdoors inschools, hospitals and otherstructures where the growth ofmold, mildew, bacteria, and algaemust be prohibited.

PureLiner is a 40-mil Mold Controlsystem that is surface adhereddirectly to HVAC ductwork anddrain pans, it is VOC free andGreenguard certi�ed

In addition to state-of-the-art technology toprevent microbial growth, PureLiner withMold Control out performs the 25/50requirments for �ame spread and smokeindex as tested in accordance with ASTME84-03 “Standard Method of Test for SurfaceBurning Characteristics of Building Materials”,sometimes known as the Steiner TunnerTest.

The actual (unrounded) �ame spread andsmoke developed indices were 20.8 and 37.6respectively. A copy of the independent testresults are available upon request.

Speak with an Expert NOW!

Surface Flame Spread andSmoke Development:

The drain panp r o t e c t i o n s o l u t i o n

Pour-In-Place Product PureLiner

Restores Structural Integrity

Stops Leaking Water

Stops Rust and Corrosion

Economically Priced

Follows exact contour of original pan design to eliminate standing water

Standard installation time under 4 hours

Pan Cleaner, Acid and Chemical resistant

Chloride and Hydrocarbon resistant

VOC-free installation and a VOC-free product

Antimicrobial protection throughout

Flexible: Withstands Expansion/Contraction and Vibration without cracking or disbonding

Roll-in installation, no cracking, etc.

Complies w/ ASHRAE 62.1 Slope Requirement

Exceeds ASTM E-84 Requirement of 25/50 Flame Spread and Smoke Developed at 21/38

Time (Hours)

(Th

ou

san

ds)

Mold/Bacteria Growth

100,000,000

10,000,000

1,000,000

100,000

10,000

1,000

100

10

1

.1

0 1 2 4 8 24

Untreated

PureLiner withMold Control

The drain pan protection solution

The natural, economical & totally GREEN coil cleaning system

© 2015 Pure Air Control Services, Inc. Printed in USA.www.pureaircontrols.com 1 800 422-7873 4911 Creekside Dr, Clearwater, FL 33760

BUILDING REMEDIATION SCIENCES

Saving Energy · Improve Indoor Air Quality · Extend Equipment Life

Existing ContractsPure Air Control Services o�ers a range of IndoorAir Quality services under our Federal SupplyServices contract with GSA (# GS-10F-0488R).

We can simplify your purchasing activities, servingas a single-source solutions provider for indoor airquality evaluations, consultations, design, remediationand HVAC system cleaning.

General Services Administration (GSA)Federal Supply Services (FSS)Authorized Federal Supply Schedule Price List

Environmental ServicesFSC Group 899 Class: F999

Contract NumberGS-10F-0488R

Special Item Numbers 899-1,899-1RC & 899-8, 899-8RC

Business SizeSmall Business

Pure Air Control Services, Inc.4911 Creekside Drive, Suite CClearwater, FL [email protected]://www.pureaircontrols.com

The Experience AdvantageOn-line access to contract ordering information, terms andconditions, up-to-date pricing, and the option to create anelectronic delivery order is available through GSA Advantage!,a menu-driven database system.

The Internet address for GSA Advantage! is:https://www.gsaadvantage.gov

Please contact your local Pure Air Controls federal representativeor email us at [email protected]

www.brsciences.com1-800-422-7873

4911 Creekside Dr, Ste CClearwater FL 33760