Roy, Raja; Cohen, Susan Exploiting pre-existing...

Transcript of Roy, Raja; Cohen, Susan Exploiting pre-existing...

1

Exploiting pre-existing capabilities to explore the performance frontier during product-market

fusion in the U.S. machine tool industry in the 1980s

Raja Roy Assistant Professor in Management

LeBow College of Business Drexel University

317 Academic Building 101 N 33rd Street

Philadelphia, PA 19104 Phone: 504-296-5223

E-mail: [email protected]

Susan K. Cohen Associate Professor in Strategy

Katz Graduate School of Business 252 Mervis Hall

University of Pittsburgh Pittsburgh, PA 15260 Phone: 412-648-1707

E-mail: [email protected]

Draft dated: December 26, 2011

2

Exploiting pre-existing capabilities to explore the performance frontier during product-market

fusion in the U.S. machine tool industry in the 1980s

ABSTRACT

We explore the role of firm capabilities during product-market fusion and answer the question,

“During exploration of the performance frontier of the fused product-market, which firms are more likely

to be closer to the frontier- those that exploit their pre-existing capability or those that explore such

capability?” The context of our study is the US Machine Tool industry in which a drastic shift in demand

and supply conditions in the 1970s and 1980s fused several product-market segments and increased

market penetration by Japanese new entrants. We find that firms with pre-existing component capability

were more likely to explore the performance frontier through innovations in product performance

features, whereas those with pre-existing architectural capability were more likely to explore the frontier by

changing the proportions of various performance features in the product.

Keywords: Product innovation; technological change; product-market fusion

3

INTRODUCTION

Strategy and Technology researchers have observed that many existing products originate in the

fusion of several product-markets. A visit to the Carillon Historical Park museum in Dayton, OH reveals

that Marganthaler Linotype, the revolutionary printing press introduced in the early 1900s, fused several

previously distinct product-markets such as typesetting and casting. The popular press has reported

product-market fusion in various industries in the past decade. For example, The Wall Street Journal (March

9, 2004; pp. B3) reported that the fusion of the yogurt and soft drinks markets is bringing Coke, Pepsi,

General Mills, and Groupe Danone SA into direct competition with one another and The Financial Times

(March 25, 2004; pp. 8) reported product-market fusion in the medical imaging industry and cited Nathan

Rosenberg as suggesting that the industry is “on the verge of a merger between diagnostic techniques and

therapeutic procedures.” Recently, the iPhone, the iPad, and the smartphone have brought together

previously distinct product-markets such as cell phones, digital cameras, laptop computers, MP3 music

players, and GPS. Despite this, strategy and technology literature is yet to address how firms navigate this

challenge.

We define product-market fusion (PMF) as a process that enables a general-purpose versatile

product to provide a range of services that was earlier available from multiple stand-alone products.

Anecdotal evidence suggests that fused products present a substitution threat to the manufacturers of the

stand-alone products (e.g., Apple iPhone 4S commercials mentioning that it is “only camera you may need”),

and under such conditions, PMF challenges firms to explore the “performance frontier”- the maximum

performance available from a given technology at a given time as it evolves following the S-shaped

Technology Improvement Curve (Sahal, 1981; Foster, 1986; Schilling 2008). Anecdotal evidence also

suggests that, during PMF, firms are challenged to explore performance frontier by- i) improving multiple

performance features of the fused product simultaneously, and ii) maintaining a dynamic trade-off among

the values of the various performance features so as to improve the versatility of the product. For

4

example, manufacturers of the fused camera and cell phone improved each of the performance features in

the fused product. The first cell phone with a built-in camera, Sanyo’s SCP 5300, introduced in 2002, had

a resolution of 0.3 megapixel (MP). Nokia’s 7610, introduced in 2004, was the first cell phone with a 1 MP

camera, and the iPhone 4S, introduced in October 2011, has a built-in 8 MP camera. Additionally, cell-

phone manufacturers have to ensure the versatility of their fused product by maintaining a trade-off

among the values of various performance features like camera resolution, Bluetooth connectivity,

multimedia options, conference-calling ability, and others.

Porter (1996) observed that trade-off occurs when the efforts to improve one activity have

negative effects on other activities. Similarly, during PMF, efforts to improve one performance feature in a

fused product often have negative effects on the values of other performance features in the product and

firms have to trade-off among the values of several performance features. For example, the Ford Escape

SUV, which fused the “fuel economy” demanded by sedan users and the “convenience” demanded by

SUV users, improved gasoline consumption in the city (from 30 to 34 mpg), total horse power (from 155

to 177 HP), and cargo space (from 65.5 to 66.1 cubic feet) simultaneously compared with its 2006 to 2011

model. Ford could have raised one performance feature like the gasoline consumption to 45 or 50mpg as

Toyota Prius has, but the larger battery needed for such an improvement would have negatively affected

other performance features, such as cargo space. The trade-off is also a dynamic one as the values of the

various performance features evolve over time with customer preferences. Unlike Christensen’s (1997)

notion of “disruptive technological change,” where firms concentrate on innovations along one “major

performance feature,” PMF challenges firms to explore the performance frontier by innovating and

maintaining a trade-off among the values of multiple performance features.

Technology research suggests that to explore the performance frontier firms either exploit their pre-

existing capabilities or explore such capabilities (March, 1991; Levinthal and March, 1993). In line with

these theoretical predictions, we find that in the fusion of cell phones and cameras, Sharp had to exploit its

5

pre-existing capability in manufacturing digital vision sensors and cell phones to develop the new product

whereas Nokia (a stand-alone cell phone manufacturer since the 1990s) had to explore the capability

required to manufacture digital cameras before it could manufacture the fused product (Nelson, 2004).

Given the firm-level challenges of PMF, we build on prior research that has investigated firms’

exploration and exploitation of technological capabilities and answer the research question, “During

exploration of the performance frontier of the fused product-market, which firms are more likely to be

closer to the frontier- those that exploit their pre-existing capability or those that explore such capability?”

Our research question is important for at least two reasons. First, it is at the heart of the Strategic

Management and Entrepreneurship literature. Among strategic management researchers, tension exists

regarding the role of pre-existing capabilities; on the one hand, they limit firms to a proximity trap (March,

1991; Levinthal & March, 1993), but on the other, they serve as the mechanism that helps firms to explore

new opportunities (Klepper and Simons, 2000). However, researchers have yet to investigate if firms that

exploit their pre-existing capability and those that explore that capability during PMF are likely to differ in

their explorations of the performance frontier. Such an understanding is critical, because technological

changes are driving PMF at a rapid pace, thereby challenging entrepreneurs, managers, and policy makers

around the globe (Economic Report of the President, February 2011).

Second, despite recent efforts by researchers to understand the dynamics of PMF (Yoffie, 1997;

Harianto and Pennings, 1994), the field lacks a theory to predict how firm-level differences affect their

exploration of the performance frontier. This is a critical gap that needs to be addressed if scholars are to

understand firm performance in a dynamic world where technological changes are fusing product-markets

at a rapid pace.

Because knowledge of both components (which are needed to manufacture the fused product)

and product architecture (which is needed to combine the components into the fused product) is critical

to manufacturing the fused product, we relied on two sources of firm differences- component and

6

architectural capabilities- to address the gaps in the literature that we identified. In accordance with

Henderson and Cockburn (1994) and Roy and McEvily (2004), we define component capability as the

knowledge of components and subsystems used in designing and manufacturing a product and

architectural capability as the knowledge of linking components and subsystems in products manufactured

by a firm. Hence, the more focused research question for our paper is, “During exploration of the

performance frontier of the fused product-market, which firms are more likely to be closer to the frontier-

those that can exploit their pre-existing component and architectural capabilities or those that explore those

capabilities?”

To fill the voids in the literature, we concentrated on an industrial-product industry with a mature

technology as the dominant design1,2. The machine tool industry and other such industries are crucial to

the world economy (Szirmai, 2011); recently President Obama emphasized the importance of

manufacturing (Economic Report of the President, February, 2011). To set the boundary conditions of

1 Firms in industries with a mature technology as the dominant design typically have economic

disincentives such as the “sunk cost effect,” “replacement effect,” and relationships with existing

customers (Besanko et al., 1996; Christensen, 1997) that ensure that these firms find it more challenging to

respond to technological changes. Hence, our theoretical model is more rigorous if we concentrate on an

industry where firms compete with a mature technology as the dominant design.

2 In industrial products industries such as machine tools and robotics, in which users experience the

product before placing purchase orders, advertisements and “vaporware” (Schilling, 2008) are largely

ineffective in persuading users. In such industries, demand is relatively more vertically differentiated as

compared to consumer-product industries, and manufactures have higher incentive to be as close as

possible to the performance frontier (Juran and Gryna, 1988; Robinson, 1988; Hambrick, 1983) to

maximize the value these products create for buyers.

7

our theory (Dubin, 1978), we assume an industrial-products industry based on technological capability T1

that emerged around time t0 and was a mature technology by time t1, where t1>>t0. At t1, product

architecture P1 is the dominant design (Abernathy and Utterback, 1978). For simplicity, we assume that

the industry has two product-markets (M1 and M2) and that customers in these product-markets prefer

major performance features F1 and F2, respectively. Ceteris paribus, buyers prefer higher values of the

major performance feature in their products. The product-markets are therefore vertically differentiated, and

firms have the incentive to be at the forefront of the performance frontier. Because of technological

limitations, products manufactured with T1 could meet customers’ requirements (Fi*) in only one

performance feature (= i). Hence, most of the users bought two products- one with the major

performance feature F1 and another with F2- to meet their needs. The performance features in products 1

and 2 made with T1 were (F111 > F1*; F21

1 < F2*) and (F121 < F1*; F22

1 > F2*) respectively, where Fijk denotes

the performance feature i for product j made with technology k. We assume that at time t2, where t2 >t1,

i) A new generation of product architecture (P2) emerges that is based on a new technological

capability T2, and new entrants from other countries challenge the firms in the focal industry using the

new product architecture. These new entrants define the performance frontier.

ii) Products manufactured with T2 rival those made with T1 in terms of product performance

features. Thus, F1j2 F1j

1. Additionally, products made with T2 could provide almost equivalent values of

multiple performance features that were traditionally available from multiple different products made with

T1. Thus, product 3 made with T2 would have F132 F11

1 and F232 F22

1.

iii) At a time t3, where t3>t2, one single product made with T2 exceeded the performance features

provided by several different products made with T1. Thus, the value of performance features 1 and 2 in

product 3 made with T2 would be F132 > F11

1 and F232 > F22

1. Hence, from t3 onwards, the product-markets

M1 and M2 fused into product-market M3. In other words, M3 was a perfect substitute for both M1 and M2.

Thus the existing manufacturers had to explore the fused product-market M3.

8

iv) Firms have to trade-off the values of F1 and F2

of their products so as to ensure that both F132 >

F1* and F23

2 > F2*. If a firm chooses a value F13

2 such that F132 >> F1

*, then there is an adverse effect on F232

such that F232 < F2

*. Similarly, if F232 >> F2

* the negative effect on F132 is F13

2 < F1*.

v) Over time, the minimum customer preferences F1* and F2

* in the fused product evolve. Hence

the trade-off between the values of these features is a dynamic one.

vi) Manufacturers that had entered the industry prior to t1 differed in their pre-existing

capabilities; more specifically, they differed in their pre-existing component and architectural capabilities.

vii) At time t3, firms that had entered prior to t1 were challenged to explore the performance

frontier of the fused product-market and be as close as possible to the frontier.

In this study, we concentrated on- i) time t3 onwards, and ii) on those manufacturers producing

the industrial-product with T1 at time t1, adopted T2 between t1 and t3, and then competed with new

entrants, using T2 to explore the fused product-market. We predict how differences in their component

and architectural capabilities explain the differences in their exploration of the performance frontier of the

fused product-market. The performance frontier of a fused product with two performance features, F1

and F2, is shown in Figure 1, is similar to the Technology Improvement S-curve (Schilling, 2008; p. 47),

with three differences. First, the performance feature of the fused product-market has multiple

performance features that evolve over time. Second, unlike the Technology Improvement curve, which

emerges at low levels of performance (at time t0), the curve for a fused market emerges at higher levels of

each performance feature (at time t3). Third, unlike the Technology Improvement curve, firms have to

trade-off the values of various performance features. The dotted lines in Figure 1 are along the F1-t plane

and F2-t plane and represent the “standard” technology improvement curve in products with just F1 or

F2. Thus, in the figure, the highest value of F1 at any time t is reached when the corresponding value of

F2 is low (for ease of explanation, the value of F2 is “zero” for the dotted curve in the F1-t plane). In the

case of a fused product, since customers demand minimum values (Fi*) of each of the performance

9

feature, firms trade-off the values of the two performance features and the dashed line represents the

performance frontier.

Insert Figure 1 about here

We concentrated on the U.S. Machine Tool (MT) industry to test our predictions. Using a panel

dataset of 45 U.S. MT manufacturers that had manufactured MT with mechanical controls prior to the

mid-1970s and had adopted Computer Numerical Control (CNC) systems when challenged by Japanese

new entrants in the mid-1970s, we found that those firms that could exploit their pre-existing component

capability were at the forefront in exploring the performance frontier by improving multiple performance

features in their fused product. In contrast, firms that could exploit their pre-existing architectural

capability were at the forefront in exploring the performance frontier by maintaining a balance among the

various performance features. We contribute to the literature by highlighting the role of exploitation of

pre-existing technological capabilities in exploration of the performance frontier during PMF, a

technological change that increasingly affects firms in several different industries.

Next, we review the literature that deals with firm exploration and exploitation of technological

capabilities, in particular, component and architectural capabilities. Thereafter, we predict the role of

component and architectural capabilities in a firm’s exploration of the performance frontier during PMF.

LITERATURE REVIEW

Strategy and Entrepreneurship research has documented that technologies evolve through several

phases (Tushman and Anderson, 1986). During the emergence of a new technology or during substitution

of a new technology for an existing technology, firms rely on product innovation to gain competitive

advantage (Abernathy and Utterback, 1978).

The organizational exploration and exploitation literature (March, 1991) generally concludes that,

during technological transitions, firms are more likely to exploit, rather than explore, in developing new

products. Researchers (e.g., Levinthal and March, 1993, p.106) postulate that firms’ past successes create

10

“success traps,” i.e., because of their scale and scope advantages, firms are more efficient users of their

existing capabilities. This gives them the incentive to exploit their existing capabilities even more, which in

turn increases the economic cost of exploration. This argument resonates with Christensen and

Overdorf’s (2000) observation that firms such as DEC, Seagate, and Xerox chose to exploit their existing

capabilities in “sustaining” innovations aimed at their existing customers. In this paper, we build on

Levinthal and March’s seminal paper and investigate how a firm’s pre-existing capabilities can help it to

explore the performance frontier of the new fused product-markets. Since the two important technological

capabilities that a firm possesses are component and architectural capabilities (Henderson and Clark,

1990), next, we discuss the literature that has investigated the role of these capabilities during

technological changes.

Component capability. The engineering design literature distinguishes between the components

and the product (e.g., Marples, 1961; Clark, 1985; Vincenti, 1990) and defines a component as a physically

distinct portion of the product that embodies a core design concept and performs a well-defined function.

Component capability includes an understanding of the technologies embodied in components and the

design heuristics for manipulating them. Khanna and Iansiti (1997) illustrate the central role of component

capabilities in helping mainframe manufacturers develop a number of “competence-destroying”

technological innovations over time. Roy and McEvily (2004) demonstrated the positive effects of

component capability on firm survival during technological change. Anecdotal evidences suggest that a

component affects several performance features of a product simultaneously and may have positive

effects on one performance feature while negatively affecting another. For example, in the case of Honda

Civic hybrid, electric motor system plays the role of both motor and generator. The electricity generated

by the regenerative braking subsystem is captured in a battery. However, due to the additional

motor/generator subsystem in the product architecture, while gas mileage improves, at least two other

performance features of the product are sacrificed as compared to a “non-hybrid” Civic: the storage space

11

in the trunk is significantly reduced, and the “sudden start” of the gasoline engine after idling reduces

driving comfort.

Architectural capability. Architectural capability is the knowledge of the linkages among the

various components that a firm uses to manufacture its products. This capability affects product

performance by determining how individual components fit and work together to deliver the product’s

functions (Ulrich, 1995; Baldwin and Clark, 2000). For example, the same components (i.e., battery,

electric motor, and internal-combustion engine) are combined is different ways to create a parallel

drivetrain (in Honda Civic Hybrid) or a series-parallel drivetrain (in Toyota Prius) in hybrid vehicles.

Henderson and Clark (1990) observed that existing architectural capability could blind a firm to

the design changes required to explore new performance frontiers during technological changes. Several

scholars (e.g., Kogut and Zander, 1992; Roy and McEvily, 2004) have used terms such as integrative and

combinative capabilities to suggest that architectural capability may affect a firm’s innovativeness during

technological transitions. This capability helps the firm to realize how the alteration of the linkages among

the components is likely to affect the relative importance of the various performance features and

potentially affects a firm’s exploration of the performance frontier by maintaining a trade-off among the

values of the various performance features in the fused product.

Next we discuss the literature that forms the theoretical base of our arguments that firms explore

the performance frontier during PMF.

Performance frontier exploration by improving multiple performance features in a

product: The strategy literature suggests that one of the most prevalent ways by which firms respond to

technological changes is to improve the product performance features that the mainstream customers

value (Christensen, 1997). While Strategy scholars have concentrated on one major performance feature,

Industrial Organization Economics scholars such as Hotelling (1929) and Learner and Singer (1937) noted

in their seminal papers that firms try to “leapfrog” their competitors by improving multiple product

12

performance features simultaneously. Willard and Cooper (1985) extended these seminal papers to the

context of technological changes and observed that survivors of a shake-out in the U.S. color TV industry

in the early 1970s explored the performance frontier by improving the performance features in their

products to manufacture better quality products. Thus, the theoretical lineage of our arguments for

improving multiple performance features in a product simultaneously can be traced back to Hotelling

(1929).

Performance frontier exploration by trading-off the values of various performance features

in a product: Several researchers in the Industrial Organization Economics tradition have investigated the

trade-offs involved in improving multiple performance features in their products. This stream of research

also has its roots in Hotelling’s (1929) model of spatial competition in a linear market. Lancaster (1966),

Eaton and Lipsey (1975), Hay (1976) and others extended Hotelling’s model to the multi-dimensional

product characteristics space. Shaw (1982; pp.71) extended Lancaster’s theory and observed that, in the

UK fertilizer industry, firms strategically relocated their products in multi-dimensional product

characteristics space by trading-off the values of nitrogen, phosphorus, and potash in their products.

Research by Agarwal et al (2004) on the disk drive industry also provide support for exploration of

performance frontier by trading-off the values of various performance features such as capacity per track

in bytes, track density per inch, rotational speed per minute, average positioning time in milliseconds,

average access time in milliseconds, and data transfer rate in kilobytes per second.

Next, we predict the role of component and architectural capabilities on exploration of the

performance frontier during PMF.

THEORY DEVELOPMENT AND HYPOTHESES

Performance frontier exploration during PMF: Component capability and improving

multiple performance features in the product: Because components embody the core technologies of a

product (Clark, 1985; Vincenti, 1990), component capability is likely to help firms improve product

13

performance features in two ways. First, firms with component capability know the cause-and-effect

relationship between a component and the focal performance feature in a product. For example,

automobile manufacturers can predict how changes in the engine of a car are likely to affect performance

features like horsepower and torque. Thus, firms can exploit their capability in engines to explore the

performance frontier in horsepower and torque. Second, capability in one component can help firms to

identify other components that operate on the same basic scientific or engineering principle and explore the

performance frontier further along multiple performance features. For example, in the case of industrial

robots, capability in resolvers can help a firm to identify and incorporate another component such as a

transducer, that works on the same basic principle—the stator and rotor windings-- to improve multiple

performance features simultaneously. Hence, exploitation of component capability derived from a

component helps a firm to explore the performance frontier in two ways: i) by improving certain

performance features using that component, and ii) by improving additional performance features by

incorporating other components that work on similar technical know-how. Thus, the more component

capability that a firm can exploit, the more it can explore the performance frontier by improving multiple

performance features simultaneously.

Several anecdotal evidences suggest this beneficial role of exploitation of component capability.

For example, in 2002, the demand for early detection of coronary artery diseases led GE Medical Systems

to develop the LightSpeed scanner. This product was result of the fusion of positron emission

tomography (PET) technology and computed tomography (CT) scanning technology. GE had had

experience in manufacturing a vast array of medical imaging products (such as equipment for surgical and

vascular imaging, conventional and digital X-rays, computed tomography, electron beam tomography,

magnetic resonance, ultrasound and bone mineral densitometry, positron emission tomography, and

nuclear medicine). Thus GE was able to exploit its pre-existing component capability to explore the

14

performance frontier by improving multiple performance features such as 3D imaging and image

resolution in the fused product (GE news release, 12/1/2002).

However, as compared to pre-existing component capability, pre-existing architectural capability

will be less helpful in exploring the performance frontier by improving multiple performance features

simultaneously. Architectural capability can help a firm to combine several components in a product, but

knowledge of the combination of components cannot help a firm extract the best performance out of a

given component. For example, a hybrid-car manufacturer with knowledge of linking several components

in a variety of ways can neither improve gas mileage nor improve the storage capacity unless it has

capability in manufacturing the motors and generators used in the “regenerative braking” of a hybrid car.

Thus, we posit that during PMF in a vertically differentiated product-market,

H1a: The more pre-existing component capability that a firm can exploit, the better it will be in exploring the performance

frontier by improving multiple performance features of its products.

H1b: The effect of a firm’s pre-existing component capability on its exploration of the performance frontier by improving

multiple performance features of its products will be greater than the effect of its pre-existing architectural capability.

Performance frontier exploration during PMF: The proportions of various performance

features in a product: A firm can exploit its pre-existing architectural capability to choose the linkages

among the components, thereby extracting the desired value of each performance feature from each

component used in the product, and thereby trading-off the values of the various performance features.

This is consistent with Iansiti’s (1997) observations that firms exploit their architectural capability to

address the trade-offs involved in improving the various performance features. In the case of Honda Civic

hybrid, where the electric motor system plays the role of both motor and generator, and leads to a trade-

off between gas mileage improvement and reduced storage space and reduced driving comfort due to the

“sudden start,” Honda had to exploit its pre-existing architectural capability of manufacturing hatchback

15

vehicles and improve the storage capacity/gas mileage ratio of the Insight model relative to that of the

Civic Hybrid model (Source: Honda.com; for 2011 models of both Civic Hybrid and Insight).

Thus, as opposed to component capability, which helps firms to improve the performance

features, architectural capability can be exploited to trade-off the values of the different performance

features in a product. Hence, during PMF in a vertically differentiated product-market, when the fused

product is a substitute for the previously differentiated products, we predict,

H2a: The more pre-existing architectural capability that a firm can exploit, the better it will be in exploring the performance

frontier by maintaining the proportions of the various performance features of its products, and,

H2b: The effect of a firm’s pre-existing architectural capability on its exploration of the performance frontier by maintaining

the proportions of various performance features of its products will be greater than the effect of its pre-existing component

capability.

Taken together, our hypotheses suggest that during PMF, firms need to exploit both component

and architectural capability to explore the performance frontier of the fused product-market. Moreover, the

effect of exploitation of component capability is different from that of architectural capability. Next, we

discuss the context of our study.

CONTEXT

Machine tools (MTs) are used to perform a wide range of metal cutting and forming operations in

manufacturing automobiles, aircrafts, weapons, toys, computers, and MTs themselves (Ashburn, 1988).

The industry’s origins can be traced back to 1715 when the first gun-boring machine was installed in the

Royal Arsenal of England (Klemm, 1959). Two of the largest U.S. MT manufacturers, Pratt & Whitney

and Brown & Sharpe, began producing MTs in the early 1860s. In the late 1970s, the US MT industry was

smaller than a division of General Motors, one of the larges buyers of MTs.

The Association for Manufacturing Technology (AMT), the central organization for MT

manufacturers worldwide, identifies 12 different categories of MTs. In this study, we concentrated on only

16

two of these, category 8 (consisting of milling and boring machines) and category 12 (consisting of lathe

and turning machines), for several reasons. First, for manufacturing these two categories of MTs, firms

need similar component and architectural capabilities. Second, these two categories of MTs are used for

similar purposes (e.g., to remove metal with the help of a cutting tool, either by rotating the tool as in a

category 8 machine or by rotating the work-piece as in a category 12 machine). Third, the challenge from

Japanese entrants was strongest and resulted in PMF in these two categories of MTs (Ashburn, 1988),

whereas the other categories were relatively unaffected by Computer Numerical Control (CNC)

technology. Fourth, the AMT Economic Handbook indicates that these two categories of MTs have

traditionally accounted for 50-60% of the total U.S. MT market by value. Thus, concentrating on these

two categories to investigate PMF in the MT industry seems appropriate3.

While the traditional MTs had mechanical controls, to meet the needs of the U.S. Air Force during

the 1940s, the MIT Servomechanisms Laboratory started a stream of research that eventually led to the

development of the numerical control systems, which later developed into Computer Numerical Control

(CNC) systems (Rosenberg, 1976; Reintjes, 1991). With the help of CNC, traditional stand-alone MTs like

milling machines and lathes could perform several functions milling, boring, and others. Several types of

MTs were thus fused into the more versatile machining centers and turning centers. A user of MT, such as

Ford Motor Co., which earlier had to route a job through milling machines, boring machines, and drilling

machines, could now perform the three functions with one single CNC MT. Both American and Japanese

manufacturers started producing CNC MTs by the mid-1970s; in contrast to the Japanese CNC MTs,

however, most of those produced in the U.S. were little more than the traditional stand-alone machines

retrofitted with CNC controls. Therefore, most of the U.S. MT manufacturers did not fully exploit the

CNC systems and lagged behind the Japanese MT manufacturers in the performance features of their

products.

3 Henceforth in this paper, we use the term ‘MT industry’ to refer to category 8 and category 12 MTs only.

17

During the late 1970s and early 1980s, the demand pattern of MTs in the U.S. started changing

drastically. The largest buyers of MTs, U.S. automakers, faced with increasing competition from overseas,

were forced to seek ways to cut costs and to reduce the productivity gap between them and their highly

efficient Japanese competitors (Phillips, Way, Lowry, and Laing, 1982). Thus, they sought MTs that would

increase their productivity. Japanese MTs made with CNC could best satisfy their needs (Seeman, 1983).

Utilizing CNC, the Japanese MTs could increase users’ productivity in two ways- i) by providing higher

values of multiple performance features, they helped users to finish their jobs faster, and ii) by addressing

the trade-offs involved in improving several performance features simultaneously, they helped users to

perform several types of jobs with one MT, reducing their “down time,” and thus be more efficient.

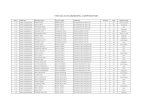

MT consists of several components and subsystems linked in various architectures; table 1 lists the

various components and subsystems used, many of which can be linked in different ways to manufacture

machines with unique architectures. For example, a vertical and a horizontal milling machine have similar

components, but the linkages among the components are quite different in the two. The performance of

an MT is specified in several ways. For example, spindle rotation per minute (RPM) denotes the speed with

which the spindle of a machine can rotate, rapid traverse in inches per minute (IPM) denotes the speed with

which the tool (or the work-table) can travel, number of axes refers to the number of degrees of freedom

that the MT has, and number of spindles refers to the number of rotating shafts in an MT. Table 2 shows the

various performance features of MTs and the components that affect performances.

Insert Tables 1 and 2 about here

PMF: Japanese challenge to U.S. MT manufacturers

PMF had catastrophic consequences for U.S. MT manufacturers as demand for Japanese MTs

grew, as shown in Figure 2. In almost every year since the early 1980s, Japanese MTs were superior to the

U.S. MTs introduced in that same year in almost all performance parameters. Figures 3 and 4 illustrate this

trend for two performance features, rapid traverse in inches per minute (IPM) and spindle rotation per

18

minute (RPM), respectively. Japanese MTs were thus at the forefront with regard to performance features.

The competitive advantage of the Japanese MT manufacturers was driven by two factors: i) the demand

from Toyota, Honda and other automobile manufacturers who wanted to be the global leaders in

operational effectiveness, and ii) the intense rivalry among the MT manufacturers themselves in Japan

(Porter, 1990). Consequently, the Japanese firms defined the performance frontier (Porter, 1996), and the

number of establishments in the U.S. metalworking industry (SIC 3541) declined from 1394 in 1982 to

624 in 1987 (U.S. Bureau of the Census). The number of workers employed and the profitability of firms

also began to decline drastically around 1981.

Insert figures 2, 3, and 4 about here

The context of PMF in the MT industry, the diversity in the capabilities possessed by the US MT

manufacturers, and the diverse quality of CNC MTs manufactured by them fits nicely with the theoretical

boundaries of our study delineated in the Introduction section and makes the context a nice fit to seek the

answer to our research question. The various key characteristics of our study are as follows:

Mature industrial-product industry: The MT industry.

T1: Technological knowledge required to manufacture MTs with pre-CNC mechanical controls: knowledge of

mechanical components such as gears, cams, etc.

M1, M2, and other stand-alone product-markets: Markets for milling machines, lathes, boring machines,

and other products.

T2: Technological knowledge required to manufacture MTs with CNC: knowledge of electrical and electronic

circuitry, electrical motors, potentiometers, modulators, rectifiers, etc.

t0: Time when MT industry emerges, around late 1700s and early 1800s.

t1: Early 1970s, when the technology T1 has matured and T2 .

19

t2: Late-1970s, when products with T2 are introduced by new Japanese entrants and these rival the performance of

those with T1.

t3: Early 1980s, when machining centers and turning centers made with CNC can better meet the needs of users of

milling machines, boring machines, drilling machines etc. than the stand-alone MTs.

M3: The product-markets of machining centers (which fused the milling machine, drilling machine, and boring

machine product-markets) and turning centers (which fused the lathe, turning machine, and drilling machine product-

markets).

DATA: SOURCES AND DESCRIPTION

The AMT Members Directory, 1975 through 1987, served as the primary source of data on

industry participants and the products they offered. This directory lists both American and non-American

manufacturers of MTs. We also used the American Machine Tool Distributors’ Association (AMTDA)

Membership Directory, 1975 to 1987. The AMT and AMTDA directories together cover almost 100

percent of the manufacturers of U.S. MTs. In addition, we also used Huebner’s Directory of MTs (1980

and 1982), Reynolds RMT Redbook, Ward’s Industrial Directory, Million Dollar Directory, Society of

Manufacturing Engineers Handbook of Horizontal and Vertical Machining Center Manufacturers (1982),

and D&B Metalworking Directory to track U.S. manufacturers of MTs and their year of exit. We met with

Andy Ashburn (late former Editor, American Machinist), Tony Bratkovich (Engineering Director, AMT),

Joe Jablonowski (Editor, Metalworking News), Ralph Nappi (President, AMTDA) and Mark Rogo (CEO,

Morton Machinery) to further our understanding of the U.S. MT industry.

For product introductions and performance features of MTs manufactured by U.S. and non-U.S.

manufacturers, we relied on the advertisements in American Machinist from 1975 to 1987. We also

corroborated and extended these data by use of sales and technical publications of the relevant

20

manufacturers.4 The industry experts, advertisements in American Machinist, product introduction

literature, and Engineering textbooks (e.g., Chryssolouris, 1992) suggest that the four performance

features of MTs most important to improving users’ efficiency are the spindle RPM, rapid traverse in

IPM, number of axes, and number of spindles. Hence, in this study we concentrate on these four

performance features. For the age of firms, we drew on Compustat, Ward’s directories, and Million Dollar

directories. Control variables came from the AMT Economic Handbook, the AMT Member’s Directory,

the AMTDA Member’s Directory, and the Census of Manufacturers.

Our database includes 45 U.S. manufacturers of category 8 and category 12 MTs. AMT Members’

Directory and American Machinist’s Buyers Guide mentions about 85 U.S. manufacturers of category 8

and 12 products in the late 1970s and early 1980s. Paucity of information about product introductions

restricted the number of firms in our sample. Industry experts felt that the firms excluded from our

sample were the smallest job-shop MT manufacturers, none of whom had introduced innovative new

products with CNC into the market. Our results would have been stronger if we could have collected data

on the smallest manufacturers. In the year 1980, the median annual sales of the firms in our database were

about $70 MM and the number of people employed was 10541 (mean) and 850 (median). The age of the

firms in our database was 58.4 years (mean) and 55 years (median) in the year 1980. These figures closely

match the respective figures of the AMT Economic Handbook for the industry. All 45 of the US

manufacturers had introduced CNC MTs by 1980. Moreover, for the products manufactured by each of

these firms, the performance features of CNC MTs were superior to those of MTs with mechanical

controls. Our product introduction database consists of 1802 category 8 and category 12 products

introduced in the U.S. market by 103 U.S. and foreign firms, including the 45 U.S. firms. We also tracked

all the products (both MTs and non-MTs) manufactured by the 45 US manufacturers from various

4 Mr. Mark Rogo, CEO of Morton Machinery, provided us with access to his library, which included

product information on all MTs introduced in the US market during the period of our study.

21

secondary sources and validated them with experts. The Machine Tool Blue Book, published annually by

Andy Ashburn, and other secondary sources such as the annual reports and trade magazines, helped us in

collecting this information.

METHODS

For operationalizing the variables, we follow the time-line described below:

1975-1980: Pre-fusion period. Component and architectural capabilities (the independent variables), the initial

performance and initial versatility of the products introduced by a firm (the control variables) are measured in

this period.

1981-1987: PMF period. Performance frontier exploration (time-varying firm-level dependent variable), age and

sales (the time-varying control variables) are measured during this period.

We restrict our PMF period to 1987, since the PMF period was most challenging for the US

Machine Tool industry up to 1987. Sales of the “fused” CNC MTs in the US surpassed $500 million in

1987 and continued to increase after 1987 (Figure 5). Also in that year, the proportion of CNC lathes

exceeded 75% of the total value of lathes shipped in the U.S. (Figure 6). Moreover, Finegold et al. (1994)

points out that 1987 was the worst period in history for U.S. MT manufacturers as new capital

expenditure in the U.S. MT industry reached an all-time low during 1987.

Insert figures 5 and 6 about here

Dependent variables

Exploring performance frontier by improving multiple performance features of the product

(PRODPERF): To create a measure of PRODPERF, we needed to determine the relative importance of

the four most significant performance features in an MT. To generate these weights, we used hedonic

regression to estimate the influence of the four performance features (spindle RPM, rapid traverse in IPM,

number of axes, and number of spindles) on MT price. We followed Stavins (1995) and separately

estimated the relative importance of the four performance features during the pre-fusion and the fusion

22

periods. In both periods, we included maximum horsepower (HP) of an MT as a control, as several

performance parameters depend on the HP of a MT, and used year fixed effects to account for

competitive forces that might cause prices to fluctuate over time. Tables 3(a) and 3(b) describe the

variables and table 3(c) presents the results for the hedonic regressions. Model 1 in table 3(c) gives the

results for the pre-fusion period and Model 2 the results for the fusion period. We used the weights from

models 1 and 2 to calculate the overall location of machines in the four-dimensional plane, with the four

performance features as the four dimensions5.

Insert Tables 3(a), 3(b), and 3(c) about here

We measure PRODPERF as the value of the average distance of the MTs produced by a firm

from the origin in the four-dimensional (4D) Euclidean space. To account for multi-product firms, we

measure the performance of a firm’s products by using the formula: PRODPERFit = SUMj

[SUMk(PRODPERFijkt / Max[PRODPERFjt])] / Nit, where i indexes firms, j indexes type categories, k

indexes products, t indexes time periods in the fusion period and N indexes the number of products.

Porter (1990; 1996) noted that the Japanese MT manufacturers were the leaders in improving the

5 We used log transformation of all the variables in the hedonic regression because price is a multiplicative

function of product characteristics. Moreover, in our data collection, collecting price data was the most

challenging, because a large buyer would typically make a “lumpy” purchase of several MTs just once in a

decade or so. Prices were negotiated between the buyer and the seller, and, because MT manufactures

were typically small firms and buyers were large corporations such as GM and Ford, the manufacturers

had little bargaining power in these negotiations. Consequently, most of the MTs for which we could

obtain price information were from Cincinnati Milacron, and we did not use firm dummy variables in the

hedonic regressions in our analyses. However, our results are similar when we used a dummy variable for

Cincinnati Milacron, the largest and most reputable American Manufacturer of MTs in the 1970s and

earlier.

23

performance features, we treat Max[PRODPERFjt] as the performance frontier and the MTs that

represented the frontier were always introduced by the Japanese manufacturers. Max[PRODPERFjt] in

the formula refers to the performance frontier: best performing product produced by the entrants in type

category j at time t. The further an MT is from the origin in the 4D space, the better its performance and

the higher the value of PRODPERF for a firm, the better is the firm in exploring the performance

frontier in terms of improving the various performance features in the product.

Exploring performance frontier by trading-off the values of various performance features in a

product (TRADEOFF): We measure this variable as the extent to which the trade-offs among the values

of various performance parameters in a U.S. product matched those of the more versatile Japanese

counterpart. Figure 7 (see also figure 2 of Shaw (1982), pp.71) shows two competitors’ products along the

two dimensions of performance of MTs: spindle rpm and rapid traverse. The angle () in figure 7

represents the extent to which a U.S. manufacturer has approached the performance frontier at a given

time in terms of the trade-off among various performance features. The smaller the value of the angle, the

better is the firm in exploring the performance frontier in terms of trading off the values of various

performance features in its products.

Insert Figure 7 about here

We measure the angle (in degrees) as follows: Angleit = SUMj [SUMk(αijkt)] / Nit, where i indexes

firms, j indexes type categories, k indexes products, t indexes periods, and N indexes the number of

products. αijkt refers to the angle between a product k introduced by firm i in type category j at time t and

the best performing product produced by the entrants in that same type category in the same year. The

value of TRADEOFFit = (Angleit).

Independent variables

We measured the pre-existing component capability from the information in Table 1. We developed this

list of components (e.g., bearings, spindles) and subsystems (e.g. ionization, heat treatment) by using a

24

variety of engineering textbooks (e.g., Smith, 1993) and validated this list with the MT experts. Our

measure of the pre-existing component capability counts the maximum number of different components that a

firm used in manufacturing any product (including MTs) from 1975 to 1980. We collected this

information from several sources, including annual reports of publicly traded firms, trade journals and

magazines, newspapers, and several reports published by the AMT. The trade journals we consulted

include all the issues of American Machinist from 1975 through 1995. American Machinist often carried

articles on the manufacturers of MTs and discussed their strengths and pre-existing capabilities. Yet

another publication, The Blue Bulletin, published annually from 1967 through 1995 by Andy Ashburn,

late ex-Editor-in-Chief of the American Machinist, also documented MTs and other products

manufactured by the MT manufacturers and we made a list of components used in manufacturing each of

these products using engineering textbooks such as DeGarmo, Black, and Kosher (1997) and Smith

(1993) and validated those with the industry experts mentioned earlier. To illustrate our measure, imagine

a firm that manufactures two products (either two MTs or one MT and one non-MT product) in a given

year. If gears and bearings are components of the first product and gears and spindles are components of

the second, then the component capability for this firm in that year is 3 (= 1 for gear + 1 for spindles + 1 for

bearings). Table 1 suggests that the maximum value of pre-existing component capability for a firm is 31.

We measure pre-existing architectural capability of a firm by using the information about the

architectures of MTs that it produced in the pre-fusion period. AMT sub-categorizes the two categories of

MTs, category 8 and 12, and table 4 lists the various subcategories within these two categories. Each of

these subcategories is produced in many different sizes, and a change in product size typically necessitates

modifying the linkages among the components in that product (Henderson, 1992). Experience in scaling

products up or down thus contributes to the accumulation of architectural capability (Christensen, 1992).

Hence, we subdivided each of the eight subcategories identified in table 4 into seven size-categories: less

than 5 HP, > 5 to 10 HP, > 10 to 15 HP, > 15 to 25 HP, > 25 to 50 HP, > 50 to 100 HP, and > 100 HP.

25

Thus any firm in any given year could have a maximum architectural capability of 56 (= 8 subcategories *

7 size-categories)6. We measure pre-existing architectural capability by the number of ways in which a firm can

link the components used in a product. Thus, if a firm manufactured one 5 HP horizontal milling machine

and one 5 HP vertical milling machine in the time period 1975-1980, it had the capability of linking the

components in two different ways when the product-markets fused, and hence the pre-existing architectural

capability for this firm was 2. If the firm also manufactured a 40 HP horizontal milling machine during

1975-1980, then its pre-existing architectural capability was 3.

Insert Table 4 about here

Control variables

We controlled for the innovativeness of the firms at the beginning of the PMF period because a

firm that manufactured innovative products during the pre-fusion period would likely continue to do so

during the fusion period. These firms are likely to have the values, processes, and routines to develop and

introduce innovative products into the market (Mitchell and Singh, 1993). The initial value of closeness to the

performance frontier in terms of multiple performance features (Initial PRODPERF) averages the Euclidean

distances, from the origin in the 4-D plane, of all the products introduced by a firm in 1975-1980 as a ratio

of the best in the industry in that time period using the same formula used in calculating PRODPERF. We

6 For both component and architectural capabilities, we concentrate on those that were “relevant” to

manufacturing MTs with CNCs. Based on standard engineering textbooks (see, e.g., DeGarmo, Black, and

Kosher, 1997) and our discussions with industry experts, we assume that although a firm can transfer its

relevant component knowledge from a product manufactured by another division of the firm, the relevant

architectural knowledge only comes from manufacturing different architectures of MTs. For example, in

the case of Honda, we assume that the capability require to manufacture the vision sub-system in ASIMO

robot is relevant for manufacturing intelligent automobiles, but the product architecture of ASIMO robot

is not a relevant capability for manufacturing automobiles.

26

use the estimates of the pre-fusion hedonic regression (Model 1 of Table 3(c)) to estimate the relative

weights of the four performance features. Similarly, we controlled for Initial TRADEOFF, the proportion

of the various performance features in products manufactured by a firm in a given year compared with the

performance frontier in that year, as it is likely that a firm that had explored the performance frontier prior

to PMF would continue to do so during the fusion period.

We included the age (in years) of the firm as a control variable, because previous research suggests

that age affects the innovative capabilities of firms (Hannan and Freeman, 1977). The size of the firm also

affects its strategy; large firms have values systems and organizational processes that might become

sources of inertia during technological change (Christensen and Overdorf, 2000). We use natural

logarithm of the dollar values of sales of a firm as a control variable to account for the size of the firm.

Since the fused products were based on CNC product architecture, the proportion of CNC products

introduced by a firm in a given year is likely to affect its exploration of the performance frontier. Hence

we control for firm-year variable CNC ratio = (number of category 8 and 12 MTs with CNC introduced by

a firm in a year)/(number of category 8 and 12 MTs introduced by the firm in that year). Firms that have

invested more resources in category 8 and 12 of MTs are likely to have different incentives to explore the

performance frontier compared with others. Hence, we control for the proportion of category 8 and 12 products

in a firm’s portfolio; this is the ratio of (number of category 8 and 12 MTs introduced by a firm in a given

year)/(total number of MTs introduced by the firm in that year). To control for year-specific effects, we

create dummy variables for each year and use these dummies as controls. Since almost all the MT

manufacturers neither patented their innovations nor devoted significant resources devoted to R&D, we

were unable to gather information on some of the other common firm-level control variables such as

R&D Intensity and the number of patents. Table 5 has the summary of the variables and their correlation

matrix.

Insert Table 5 about here

27

Estimation of the coefficients of Performance response: We estimate the coefficients of PRODPERF

from the equation PRODPERFi,t = f(Initial PRODPERFi, Component capabilityi, Architectural

capabilityi, Agei,t, Salesi,t, CNC ratioi,t, Proportion of category 8 and 12 productsi,t, Year dummy variables),

where i indexes the firms and t indexes the years 1981-1987. Similarly, we estimate the coefficients of

TRADEOFF from the equation TRADEOFFi,t = f(Initial TRADEOFFi, Component capabilityi,

Architectural capabilityi, Agei,t, Salesi,t, CNC ratioi,t, Proportion of category 8 and 12 productsi,t, Year

dummy variables).

Because firms can pursue both PRODPERF and TRADEOFF simultaneously, we estimate the

coefficients by using the two-stage least square method. This method suggests that if y1 and y2 are the two

dependent variables and x1 and x2 are the two independent variables, then using the reduced form

equation y2=h1x1+h2x2+q2, one can compute the predicted values of the endogenous variable

. In the second stage, one runs an OLS regression for the structural equation, using the

predicted values from the first stage regression: . Because the predicted values are

just a weighted average of the exogenous variables, both of the explanatory variables in this second stage

regression are independent of the errors, and the second stage regression will give an unbiased estimate

(Wooldridge, 2002). Thus, we use the predicted values of PRODPERF and TRADEOFF as control

variables while calculating the estimates of TRADEOFF and PRODPERF respectively.

Moreover, because we used a panel dataset, we test for the presence of autocorrelation using

Wooldridge’s (2002; pp.282-283) test. The user program to conduct this test in STATA, the xtserial

program, was developed by Drukker (2003). This test has the size and power properties appropriate for

reasonably sized samples. To use the xtserial program, one needs to specify dependent and independent

variables, and a significant test statistic indicates the presence of serial correlation. The test indicated that

the null hypothesis (H0 = no first order autocorrelation) could be rejected (p > 0.000). Similarly, we tested

for heteroskedasticity by using the Breusch-Pagan test. In this case, too, the null hypothesis (H0 = constant

ˆ y 2 ˆ 1x1 ˆ 2x2

2y 1121 bxyay

28

variance) could be rejected (p > chi2 = 0.000). We used feasible generalized least squares (FGLS) for panel

data with panel-specific autocorrelation and heteroskedastic error structure, since FGLS allows panel-data

linear models estimation in the presence of AR(1) autocorrelation within panels and heteroskedasticity

across panels. Table 6 presents the results for all the hypotheses.

Insert Table 6 about here

RESULTS AND ANALYSES

Estimates of the coefficients for PRODPERF: Models 1 and 2 in Table 6 refer to the estimates of

PRODPERF response. Model 1, which consists of the control variables, indicates that a firm with higher

initial PRODPERF is more likely to continue to innovate during the fusion period. This is not surprising,

because as firms move closer to the performance frontier, they are more likely to have the routines that

may help them to continue to be closer to the frontier during the fusion period (Mitchell and Singh, 1993).

Neither firm sales nor age affects PRODPERF. The higher the ratio of CNC products in a firm’s product

portfolio, the greater is the exploration of the performance frontier. This is expected, since the exploration

of the performance frontier was possible only with CNC product architecture. The higher the proportion

of category 8 and 12 products in a firm’s portfolio, the less likely it is to explore the frontier. These firms

are likely to be more inertial in exploring the performance frontier because of their sunk costs in the pre-

CNC product architectures. In Model 2, we introduce the explanatory variables component capability and

architectural capability. The coefficients for the former are both positive and significant, but those for the

latter are negative and significant. This suggests that the more architectural capabilities a firm possesses,

the more challenge it faces in allocating resources for improving several performance features

simultaneously. The results support our Hypothesis 1a, in which we had predicted that the more a firm

could exploit its component capability, the more likely it would be to explore the performance frontier in

terms of improving multiple performance features. Our Hypothesis 1b, in which we predicted that for this

29

exploration, firms that could exploit their component capability would be closer to the frontier than those

that could exploit architectural capability, was also supported.

Estimates of the coefficients for TRADEOFF: Model 3 in table 6 gives the estimates for the control

variables. Firms that explored the performance frontier in terms of the proportion of performance

features prior to the fusion period continued to be closer to the frontier during the PMF period. Neither

age nor sales significantly affected TRADEOFF. In Model 4, we included component and architectural

capabilities. The coefficient of architectural capability is negative and significant. This means that with unit

rise in architectural capability, firms can move closer to the performance frontier by 14.03% in terms of

the proportion of various performance features (because a negative value of the estimate means a smaller

angle, which implies a firm is closer to the frontier as compared to another with a greater angle). The

coefficient for component capability is negative but not significant. Hence, consistent with our predictions

in Hypothesis 2a, we found that the more a firm could exploit its pre-existing architectural capability, the

more it could explore the performance frontier in terms of trading-off the values of various performance

features. Moreover, as predicted in Hypothesis 2b, we find that the effect of architectural capability was

greater than that of component capability on exploring the frontier.

Robustness check: Our conceptualization of architectural capability appears somewhat similar to what

marketing scholars have referred to as the “product-line breadth” (Kekre and Srinivasan, 1990) or

“product variety” (Lancaster, 1990), although theoretically there are important differences in the

knowledge that architectural capability and product variety capture. For example, the marketing literature

defines product variety as “the number of variants within a specific product group” (Lancaster, 1990;

p.189) and uses the PIMS database to measure the product line breadth of a firm. Using this database, for a

firm like Honda the product variety from manufacturing Accord sedans is = 1. However, architectural

capability for Honda from Accord sedan is = 3 because Accords are manufactured in three different HPs:

177, 190, and 271 HPs. Because our intention in this paper was to explore the role of a firm’s knowledge

30

of linking components in different ways to manufacture a product, architectural capability better captures

that knowledge than product variety does. As Sahal (1981) observed, changes in size create structural

challenges, because as the geometric proportions of a product change, so too do properties such as its

capacity to bear weight and dissipate heat. In the case of the Accord, manufacturing each product with a

different HP gives Honda the capability to combine similar components differently, which is not captured

when all Accords with different HP are treated as a single “product-line.” Nonetheless, statistically, we

would expect a positive and high correlation between a firm’s architectural capability and its product line

breadth. We would also expect the correlation to be exceptionally high in the MT industry, inasmuch as

the manufacturers in this industry typically use different model numbers for all products with different

HPs, thereby increasing their product line breadth with every change in product architecture. We develop

the variable “product count” which is the number of MT products a firm had in the market in the pre-

fusion years. As expected, the new variable is highly correlated to architectural capability (corr = 0.79). To

check the robustness of our finding, we did our analyses by substituting product line breadth for

architectural capability. The results with product count as I.V. are in table 7, models 5 and 6, and these

results, as expected, are similar for the results shown in models 2 and 4 of table 6.

Additionally, it may be argued that the presence of both component and architectural capability

together in a firm would help it to exploit the two capabilities in exploring the performance frontier. To

test this alternative hypothesis, we created the variable Component*Architectural Capability and used it as

a control variable in our analyses. The results are in models 7 and 8 of table 7. Component*architectural

capability does not have a significant effect on either type of performance frontier exploration. These

results are similar to those reported in models 2 and 4 of table 6.

Taken together, the results of our analyses suggest that the more pre-existing technological

capabilities that firms can exploit during PMF, the more likely it is that they can better explore the

31

performance frontier of the fused product-market. Moreover, our predictions are robust to a variety of

alternative explanations.

DISCUSSION

Our motivation for this paper was to investigate performance frontier exploration by firms that

exploit their pre-existing technological capabilities during PMF. We find that exploiting different

technological capabilities lead to the exploration of the frontier in different ways. Our results suggest that

firms exploit component capability to explore the performance frontier in terms of improving multiple

performance features simultaneously, and exploit architectural capability to explore the performance frontier

in terms of the proportions of the various performance features.

Although PMF is increasingly becoming a dominant force shaping the evolution of various

technologies, scholars have yet to investigate how pre-existing capabilities affect firm responses during

these changes. Ours is one of the first studies to investigate systematically the effects of pre-existing

technological capabilities on firms’ exploration of the performance frontier during such a change. We use

a panel dataset of MT manufacturers in the US who were challenged by Japanese new entrants with new

products that fused previously distinct market segments. In the process, we extend both the Strategic

Management and the Technology Management literatures.

Our study adds to the firm exploration/exploitation literature by addressing a long-standing

tension among Strategy scholars. It builds a bridge across the chasm by pointing out that while firms do

need pre-existing capabilities that they can exploit during PMF (consistent with March, 1991 and Levinthal

and March, 1993), these capabilities help firms to explore new performance frontiers (consistent with

Klepper and Simons, 2000). Our paper is one of the first one to distinguish between upstream and

downstream exploitation and exploration from a firm’s value chain perspective (Porter, 1980). The reader

might refer to exploiting pre-existing technological capabilities as an upstream activity (or the cause) and

exploring performance frontier as a downstream activity (or the effect).

32

We also extend the technology literature that explains the establishment of a dominant design and

the cyclical nature of technology evolution (Tushman and Anderson, 1986). While scholars have paid

more attention to the causal mechanisms that establish a dominant design (Klepper, 1997), they have paid

relatively less attention to the substitution of one dominant design for another. Recently, Argyres et al

(2011) have investigated how conpositio desiderata, a product design that has unexpectedly high demand,

leads to the dominant design. Similar to Argyres et al., CNC MTs introduced by the Japanese

manufacturers may be regarded as the conpositio desiderata- a product design all the US manufacturers

imitate. However, our findings take an additional step by suggesting that the followers imitate the

performance frontier created by the conpositio desiderata.

Our study is also one of the first to study systematically PMF by using a panel dataset. Most prior

research (e.g., Yoffie, 1997; Gambardella and Torrisi, 1998) has been case studies. Our paper

complements existing studies on “technological convergence,” which investigate how firms integrate

multiple technologies into a product to improve a product performance feature. In contrast to those

studies (e.g., Gambardella and Torrisi, 1998), ours investigates a situation in which a new product is a

perfect substitute for several products that were previously used in different product-markets.

The results of our analyses have important implications for practitioners. Our results suggest that

during PMF in consumer electronics, firms such as Apple, with relatively few component and architectural

capabilities to exploit compared with manufacturers such as Samsung, are likely to be at a disadvantage in

exploring the performance frontier of fused products such as the iPhone which combines stand-alone

products such as the cell phone, camera, MP3 players, and GPS. Indeed, the Financial Times reported on

7/6/2011 that Samsung’s new smartphone has taken a technological lead over Apple’s iPhone by

introducing the first smartphone with a dual-core processor. Our results also suggest that the recent

problems of Nokia can partly be explained by its lack of component and architectural capabilities, since

the cell phone market is undergoing rapid fusion with other technologies and Nokia was a standalone cell

33

phone manufacturer that had limited component capability (lack of non-cell phone products that

companies such as Apple or Samsung have) and architectural capability (due to lack of different product

architectures and Nokia’s past record of manufacturing no-frills cell phones) to explore the performance

frontier of the rapidly evolving cell phone market.

The limitations of this paper are the assumptions that we have made. At the same time, the

limitations however open up new avenues for research. For example, we assumed perfect substitution of

the fused product for the previous stand-alone products. It would be interesting to explore whether our

findings hold for contexts in which, despite the availability of the fused product, the stand-alone products

can still cater to certain niche markets.

Given the recent attention to PMF in the popular business press, our study is pertinent for both

managers and practitioners, who face a formidable challenge of PMF because of the rapid rate of

technological innovations in the past few decades.

Figure 1: Pcost C (combinati

Figure 2: Ivarious ye

0.1

0.2

0.3

0.4

0.5

0.6

19

ProductivityProductivityons of F1 an

Import penears)

975

C

y frontier ofy frontier nd F2)

etration in th

1980

f a fused prof fused

he US mach

Import

0

F2

34

roduct with product-ma

hine tool ma

Penetration

1985

Year

two perforarket show

arket (Sourc

n (%)

F1

rmance featuwn in dash

ce: AMT Ec

1990

Source:

ures F1 andhed line fo

conomic Ha

199

: AMT Economic Hand

d F2 and or three

andbook,

95

dbook

35

Figure 3: Comparison of rapid traverse (IPM) of the newly introduced U.S. and Japanese MTs

Figure 4: Comparison of spindle rpm in newly introduced U.S. and Japanese MTs

Figure 5: Sales of CNC and traditional MTs in the US since 1987

0

5 0 0

1 0 0 0

1 5 0 0

2 0 0 0

1 9 7 5 1 9 8 0 1 9 8 5 1 9 9 0 1 9 9 5

Y e a r

M a x J a p . I P M M a x U . S . I P M

1000

10000

100000

1975 1979 1983 1987 1991 1995

Year

Spi

ndle

RP

M

Max Spindle RPM (Japanese) Max Spindle RPM (U.S.)

36

Figure 6: Market share of CNC MTs in lathe market

Figure 7: Illustrative PRODPERF and TRADEOFF (Distance from origin of (x,y)=PRODPERF; = TRADEOFF)

Table 1: Components and subsystems used in various MTs Gears, Bearings, Spindle, Spring, Hydraulic subsystem, Pneumatic subsystem, Cam, Index Centers, Crank, Pulley, Abrasives, Bonding, Vice, Ram, Clamp, Ionization subsystem, Heat treatment subsystems, Heat transfer subsystems, Servo controls, Ball screw, Tribology related subsystems, Transducers, Resolver/ encoder, Circular/ Parabolic/ Cubic interpolation subsystems, Switches, Acoustic sensors, Dynamometers, Capacitator, Pressure sensor, Torsional rigidity subsystems, Thermal stability subsystems. Table 2: Components, subsystems, and performance of MTs Components and Subsystems Function Performances affected

Recirculating ballscrew Slideway motion Rapid ipm; number of axes Bearings Friction reduction Spindle rpm, rapid ipm, number of axes

Hydraulic subsystems Tool release Number of axes; number of spindles Pneumatic subsystems Work holding devices Spindle rpm, number of axes, number of spindles

Resolver/ encoder Table and tool positioning Rapid ipm, number of axes Tribology related subsystems Friction reduction Rapid ipm, number of axes

Thermal stability subsystems Thermal drift reduction Spindle rpm, rapid ipm, number of spindles

Rapid traverse

Spindle RPM

American product (x2, y2)

Versatile product by entrant (x1, y1)

45o

37

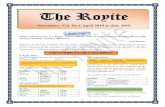

Torsional rigidity subsystems Flexure reduction Spindle rpm, number of axes Table 3(a): Correlation matrix for variables in hedonic regression 1975-1980 (N=238)

Mean S.D. 1 2 3 4 5

1 Log Price 11.18 1.33 1.00

2 Log Spindle 0.09 0.29 0.13 1.00

3 Log Axes 1.02 0.28 0.42 0.11 1.00

4 Log RPM 7.69 0.68 -0.10 0.28 0.23 1.00

5 Log IPM 5.27 0.56 0.54 0.01 0.34 0.24 1.00

6 Log HP 2.44 1.07 0.72 -0.11 0.02 -0.54 0.29 Table 3(b): Correlation matrix for variables in hedonic regression 1981-1987 (N=148)

Mean S.D. 1 2 3 4 5

1 Log Price 10.61 1.30 1.00 2 Log Spindle 0.05 0.19 -0.13 1.00 3 Log Axes 0.99 0.24 0.08 0.12 1.00 4 Log RPM 8.03 0.76 0.30 0.00 0.30 1.00

5 Log IPM 5.52 0.78 0.55 -0.14 0.15 0.51 1.00

6 Log HP 2.03 1.09 0.77 -0.35 -0.17 0.07 0.42 Table 3(c): Estimates of hedonic panel regressions for 1975-1980 and 1981-1987 with year fixed effects

Model 1 Model 2 Pre-fusion Period Fusion Period

Log Spindle 0.26 † 0.78 * (0.14) (0.32)

Log Axes 1.00 *** 0.79 *** (0.17) (0.26)

Log RPM 0.25 *** 0.23 * (0.08) (0.09)

Log IPM 0.36 *** 0.30 ** (0.09) (0.10)

Log HP 0.79 *** 0.94 *** (0.05) (0.07)

Cons 4.43 *** 4.43 *** (0.64) (0.66)

Year fixed effects *** *** N 238 148

R-squared within 0.65 0.71 † p<0.1; * p<0.05; ** p<0.01; *** p<0.001; Standard errors in parentheses

38

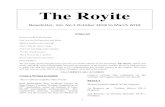

Table 4: Subcategories of category 8 and category 12 MTs

AMT Category Subcategories of MTs

12 Sub-category 1: Lathes, Turning Centers, Turret Lathes 12 Sub-category 2: Bar and Chuckers 12 Sub-category 3: Vertical Turning Centers, Vertical Boring Machines 8 Sub-category 4: Horizontal Machining Centers 8 Sub-category 5: Horizontal Milling Machines 8 Sub-category 6: Horizontal Boring Machines 8 Sub-category 7: Vertical Machining Centers 8 Sub-category 8: Vertical Milling Machines

Table 5: Descriptive variables and correlation matrix (N=264)

Variable Mean Std. Dev. 1 2 3 4 5 6 7 8 9

1 PRODPERF 0.974 0.033 1.00

2 Initial