Rolling 2

Transcript of Rolling 2

8/2/2019 Rolling 2

http://slidepdf.com/reader/full/rolling-2 1/17

METAL FORMING

*Metals may be formed into useful shapes in two

basic ways:

1. By plastic deformation processes in which the

volume and mass of metal are conserved and the

metal is displaced from one location to another.

2. By metal removal or machining processes in which

material is removed in order to give it the required

shape.

8/2/2019 Rolling 2

http://slidepdf.com/reader/full/rolling-2 2/17

*Metal forming processes may be classified into

only a few categories on the basis of the type of

forces applied to the work-piece as it is formed

into shape.

• Direct-compression-type processes

• Indirect-compression processes

• Tension type processes

• Bending processes

• Shearing processes

8/2/2019 Rolling 2

http://slidepdf.com/reader/full/rolling-2 3/17

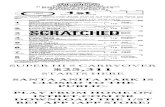

ROLLING

• The process of plastically deforming metal by

passing it between the rolls is known as rolling.• The work is subjected to high compressive stresses

from squeezing action of rolls.

• The frictional force between metal and rolls isresponsible for drawing the metal into the rolls.

Classification of Rolling Process

i) Hot Rollingii) Cold Rolling

iii) Powder Rolling

8/2/2019 Rolling 2

http://slidepdf.com/reader/full/rolling-2 4/17

Hot Rolling:

• Hot working ---- above the re-crystallizationtemperature

• It is employed where large reduction in cross-sectional area is required.

• Used for bars, rods, rails etc.

Cold Rolling:

• Cold working ---- below the re-crystallizationtemperature

• Employed for finishing the metal to givenspecification of sizes and surface quality.

• Produces sheets, strips and foils with good surface

finish and increased mechanical strength.

8/2/2019 Rolling 2

http://slidepdf.com/reader/full/rolling-2 5/17

Powder Rolling:

• Metal powder is introduced between the rolls and

turned into a “green strip” which is subsequentlysintered to high density.

• This produces a tough sheet with very fine grain size

or minimum of preferred orientation.

8/2/2019 Rolling 2

http://slidepdf.com/reader/full/rolling-2 6/17

ROLLED PRODUCTS

i) Bloom:

• First breakdown product of ingots with a minimum cross-

sectional area of 36 in2.

• Generally, square in cross-section.

ii) Billet:

• Further reduction of bloom by rolling results in a billet.

• Cross-sectional area 1.5 in. X 1.5 in.

iii) Slab:

• A hot rolled ingot with a width to thickness ratio of 2:1 atleast.

• Cross-sectional area over 16 sq. in.

**Blooms, billets and slabs are known as semi-finished productsbecause they are subsequently formed into other mill products.

8/2/2019 Rolling 2

http://slidepdf.com/reader/full/rolling-2 7/17

iv) Plate:

• It has thickness greater than ¼ in.

v) Sheet and Strip:

• Generally have thickness lesser than ¼ in.

vi) Foil:

• Thickness is very small just as 0.002 in.

* Billets and other unfinished rollings are further

rolled to I-sections, T-sections, Angles, Channels,

Girders etc.

8/2/2019 Rolling 2

http://slidepdf.com/reader/full/rolling-2 8/17

Rolling Process:

• In the process of rolling the billet is fed from oneside into the rolls and reduces in thickness

according to the section and gap between the rolls.

• The reduction ratios have maximum allowablevalues for different metals beyond which

reduction is not practicable in a single process.• Rolling sets in series may be employed.

** There are fundamentally two types of rolls:

i) Supporting rollsii) Driving rolls

** the rolls must be rigid or the rolled material will

have a loop like shape.

8/2/2019 Rolling 2

http://slidepdf.com/reader/full/rolling-2 9/17

ROLLING MILLS:

• A rolling mill consists basically of rolls, bearings,

a housing for containing these parts, and a drive

for applying power to the rolls and controlling

their speeds.

• High forces are involved ------ large motors

• Continuous mills ----- high initial investment

• Rolling mills can be conventionally classified

with respect to the number and arrangement of the

rolls.

8/2/2019 Rolling 2

http://slidepdf.com/reader/full/rolling-2 10/17

Classification of rolling mills:

i) Two-high mills

ii) Two-high reversing millsiii)Three-high mills

iv)Four-high mills

v) Cluster millsvi)Continuous mills

vii)Planetary mills

8/2/2019 Rolling 2

http://slidepdf.com/reader/full/rolling-2 11/17

8/2/2019 Rolling 2

http://slidepdf.com/reader/full/rolling-2 12/17

8/2/2019 Rolling 2

http://slidepdf.com/reader/full/rolling-2 13/17

8/2/2019 Rolling 2

http://slidepdf.com/reader/full/rolling-2 14/17

Two-high Mill: The simplest and most common type.

• Rolls of equals size are rotated in one direction.

• The stock is returned to entrance, or rear, of the rollsfor further reduction by hand carrying or by means

of a platform which can be raised to pass the work

above the rolls.

• Improvement --- a two-high reversing mill, in which

the work can be passed back and forth through the

rolls by reversing their direction of rotation.

Three-high Mill: consists of an upper and lower driven

roll and a middle roll which rotates by friction.

8/2/2019 Rolling 2

http://slidepdf.com/reader/full/rolling-2 15/17

Four-high Mill: four rolls ---- two small rolls

supported by large-diameter backup rolls.

** Very thin sheet can be rolled to very close

tolerance on a millwith small-diameter work rolls.

Cluster Mill: each of the work rolls is supported bytwo backing rolls.

Continuous Mill: high production

Planetary Mill: consists of a pair of heavy backing

rolls surrounded by a large number of small

planetary rolls.

8/2/2019 Rolling 2

http://slidepdf.com/reader/full/rolling-2 16/17

8/2/2019 Rolling 2

http://slidepdf.com/reader/full/rolling-2 17/17