Role of In Vitro System as Continuous Betalain Sources - Retno Mastuti

Transcript of Role of In Vitro System as Continuous Betalain Sources - Retno Mastuti

Role of In Vitro System as Continuous Betalain Sources

Retno Mastuti

Biology Department, Faculty of Mathematics and Natural Sciences, University of Brawijaya,

Malang, Indonesia ([email protected])

Abstract

Plants are sources of many important secondary metabolites including pigments. Betalain, one of plant major

pigments is of growing interest for colorant of food and pharmaceutical industries. This natural colorant has

been concerned as an alternative for synthetic colorants due to its positive effects on health. Recent reports show

that betalains have high anti-oxidative, free radical scavenging activities and potential for anti malaria. In

higher plants betalain occurrence is restricted to 13 families of the order Caryophyllales. Their occurence is

mutually exclusive to that of the anthocyanins. Although the major pigment group shows wide occurence in

different plant tissues, the production is very affected by environmental conditions. Therefore, an in vitro system

under controlled conditions is one promising alternative pigments source for all seasons. Plant cells and tissue

cultures can be established routinely under sterile conditions from explants, such as plant leaves, stems, and

roots for both multiplication and extraction of secondary metabolites including pigments. Some in vitro

strategies have been applied to improve betalain production. Strain improvement, methods for the selection of

high-producing cell lines, and medium optimizations could enhance secondary metabolite production. In

addition, this paper will discuss hairy root cultures for pigment production, precursor addition for betalain

improvement, elicitation of in vitro products, and bioreactors scaling up of production.

Keywords: betalains, plant in vitro systems, optimization strategies

I. INTRODUCTION

The plant major pigments are chlorophyll,

carotenoids, anthocyanins and betalains. Except

chlorophyll, the three families of pigments play

important ecological functions, for example in the

attraction of pollinators and seed dispersal animals.

All of them are secondary metabolite which

economically important such as in food and

medicinal industry. Interest in betalains has grown

since their antiradical activity was characterized (1),

and they are widely used as additives in the food

industry because of their natural colorant properties

and absence of toxicity (2). Consequently, the

sustain availability of betalain pigments become

important. However, the distribution of secondary

metabolites in plants is far more restricted than that

of primary metabolites. Also, the secondary

metabolites often accumulate in the plant in small

quantities, sometimes in specialized cells which

caused the difficulty in their extraction. Although

extraction of secondary metabolites from plants is

still commercially important a large number of these

metabolites are difficult or impossible to synthesize

at economic values (3). Therefore, development of

alternatives to the intact plant for the production of

plant secondary metabolites has been intensively

approached. In the past three decades, research has

been concentrated on the use of plant cell and tissue

cultures. Biotechnological approaches, specifically

plant tissue culture plays a vital role in search for

alternatives to production of desirable compounds

from plants (4). This method can provide a

continuous, reliable source of natural products. In

vitro system offers several advantages over field

cultivation: it is independent of geographical and

seasonal variations, environmental factors, and

political interference; in addition, it allows optimal

and stable growth conditions, voluntary modulation

of growth parameters, and constant quality control

(5-6). It also eliminates negative biological

influences (microorganisms and insects) that affect

secondary metabolites production in nature; and

possibility to select cultivars with higher production

of secondary metabolites (7). Moreover, colourants

produced in this way are classified as 'natural' rather

than 'nature-identical', which increases their

desirability to customers. In some cases, the yield

per gram fresh weight of secondary metabolites in

plant cell culture may exceed that which is found in

nature. Therefore, a priority in current and future

efforts towards sustainable conservation and rational

utilization of biodiversity is searching for new plant-

derived chemicals (8). Plant-produced secondary

compounds have been incorporated into a wide

range of commercial and industrial applications.

Different strategies using cell cultures systems have

been extensively studies with the objective of

improving the production of bioactive secondary

metabolites.

Plant tissue cultures were first established in

1939. The success in isolated visnagin (9) and

diosgenin (10) respectively from cell cultures in

larger quantities than from the whole plant showed

the potential of plant cell cultures to produce useful

compounds. Increasing the effort to obtain high

amount of secondary metabolites in plant cell

cultures was accompanied by emphasizing the

biochemical and molecular research on the

secondary metabolism of plants (11-16). These lead

to the successful manipulation of secondary

metabolism and significantly increase the amounts

of the compound(s) production. Now, it seems that

any substances of plant origin can be produced by

plant cell culture techniques. Identification of cell

lines that can produce amounts of compounds equal

or even higher than those in the plant from which

they derived has been possible.

II. BETALAIN – BIOCHEMISTRY, DISTRIBUTION AND

CHARACTERS

Betalains, known for a long time as safe

colorants for food or other industrial purposes.

Betalains are water-soluble nitrogen-containing

pigments which also known as immonium

derivatives of betalamic acid (Fig. 1A) (17).

Fig. 1. Chemical structures of betalamic acid (A),

betalain and its resonance (B), betanidin (C), and

indicaxanthin (D) (17,18)

They are synthesized from tyrosine by the

condensation of betalamic acid (19) The structure

below the dashed line is present in all betalain

molecules (Fig. 1B). Betalains are commonly

classified based on their structural characteristics

and divided in two groups red-violet betacyanin and

yellow betaxanthin depending on the identity of the

R1 and R2 residues. They are immonium conjugates

of betalamic acid with cyclo-dopa and amino acids

or amines, respectively, respectively. The first

betalains identified by chemical means are:

betalamic acid (Fig. 1A), the chromophore of all

betalains, betanidin (Fig. 1C), the main aglycone of

all betacyanins, and indicaxanthin (Fig. 1D) (20), a

proline-containing betaxanthin. To date, in nature

comprise approximately 50 red betacyanins and 20

yellow betaxanthins (21), all with the same basic

structure.

Betalains are restricted to higher plants to most

families of the order Caryophyllales (old name

Centrospermae); 13 betalain producing families have

been identified: Achatocarpaceae, Aizoacea,

Amaranthaceae, Basellaceae, Cactaceae,

Chenopodiaceae, Didieraceae, Holophytaceae,

Hectorellaceae, Nyctaginaceae, Phytolaccaceae,

Portulacaceae and Stegnospermataceae (22) (Table

1). The other two families, the Caryophyllaceae and

Molluginaceae accumulate anthocyanins. The

betalain and anthocyanin pathways in flowering

plants has been known as evolutionary mechanisms

leading to the mutual exclusion (23-24). The

Caryophyllales-specific occurrence of betalains is a

prominent example of the chemotaxonomic

relevance of plant secondary products.

Table 1. Classification of Caryophyllales (22)

Suborder Family Examples of genus

Chenopodiinae (Betalain-producing anthocyanin-free taxa)

Achatocarpaceae Achataocarpus

Aizoaceae Dorotheanthus, Mesembryanthemum

Amaranthaceae Amaranthus, Celosia, Gomphrena

Basellaceae Basella

Cactaceae Mammilaria, Opuntia, Schlumbergera

Chenopodiaceae Beta, Chenopodium, Salicornia, Spinacia

Didiereaceae Decaryia, Didierea

Halophytaceae Halophytum

Hectorellaceae Hectorella

Nygtaginaceae Bougainvillea, Mirabilis

Phytolaccaceae Gisekia, Phytolacca

Portulacaceae Claytonia, Portulaca

Stegnospermataceae Stegnosperma

Chenopodiinae (Betalain-free anthocyanin-producing taxa)

Caryophyllaceae Dianthus, Melandrium, Silene

Molluginaceae Mollugo, Pharnaceum

Betalains are found in different plant organs

namely flowers, fruits and occasionally in vegetative

tissues of plants and they are accumulated in cell

vacuoles, mainly in epidermal and subepidermal

tissues (Table 2) (25). However, they are sometimes

accumulated in plant stalks such as in the

underground parts of red beet. Many plants

accumulate betalains but only two (Beta vulgaris

and the prickly pear Opuntia ficus-indica) are

approved to be used in food (26-27). Betalains are

also present in some higher fungi Amanita,

Hygrocybe, and Hygrosporus (28). The functions of

betalains in plant flower and fruit colouration are

obvious. Meanwhile, their role in fungi is unknown.

Betalain derived from red beetroot is approved to be

used in food industries as food additive in United

State (21 CFR 73.40) and in European Union

(E162).

Table 2. Betalain distribution in plant structure (25)

Plant Structures Color Produced Examples

Flowers Red, yellow, pink and orange

Aizoaceae and Potrulacaceae plants

Fruits Yellow, red and purple

Prickly pear

Roots Red-purple Red-beet root Bracts Wide ranges of

colors Bougainvillea sp.

Seeds Yellow and red, among others

Amaranthus spp.

Leaves and stems A range of colors Teloxis spp.

III. ACCUMULATION OF BETALAIN AND CELL

GROWTH

Many secondary metabolites accumulate in

specific tissues and cell of higher plants, or at

specific stages during the growth of cultured cells.

The accumulation of most secondary metabolites in

cultured cells is maximum during the stationary

phase of growth. On the contrary, peaks of

accumulation of secondary products during the

logarithmic phase of growth have been observed in

only a few cases. Accumulation of betacyanin was

suppressed when growth of cells in suspension

cultures of Phytolacca americana was inhibited by

aphidicolin (an inhibitor of DNA synthesis) (29).

Betacyanin content in cell suspension culture of B.

vulgaris also increased in parallel with the cell

growth during the log phase (30). Peaks of

accumulation of betalains during the logarithmic

phase were also observed in suspension cultures of

Chenopodium rubrum (31). Close correlation

between growth and accumulation of betacyanin was

also reported in suspension cultures of P. americana

(32). Subsequently, it was suggested a positive

correlation between the accumulation of betacyanin

and cell proliferation (29).

A similar results has been reported for cell

suspension from the violet callus of B. vulgaris (35).

Lack of phosphate or addition of aphidicolin to the

medium suppressed both the division of cells and the

accumulation of betacyanin. Conversely, re-addition

of phosphate and removal of aphidicolin initiated

both process. Tracer experiments using labeled

tyrosine revealed that the incorporation of

radioactivity from tyrosine to betacyanin was

inhibited while that from DOPA was not. Therefore,

it is concluded that the step from DOPA to

betacyanin is not coupled with cell division, but that

from tyrosine to DOPA is coupled (34). Furthermore

such a relationship between the betacyanin

accumulation and cell growth has been observed in

cell suspension culture of B. vulgaris (30) and

Portulacca (35).

IV. MAXIMIZATION OF SYNTHESIS AND

PRODUCTION

Many efforts have focused on the stimulation

of biosynthetic activities of cultured cells using

various methods. Since the tissue culture cells

typically accumulate large amounts of secondary

compounds only under specific conditions the

maximization of accumulation secondary

metabolites requires: manipulating the parameters of

the environment and medium; selecting high

yielding cell clones precursor feeding and elicitation.

A. Optimization of medium composition

Since the economically viable is prerequisite, it

is important to develop methods that would allow

for consistent generation of high yields of products

(36). Several products were found to be

accumulating in cultured cells at a higher level than

those in native plants through optimization of

cultural conditions (37). There is no similar trend of

availability of phosphate ion in affecting betalain

content. In B. vulgaris cv Detroit Dark Red hairy

root cultures there is phosphate ions reduction from

initial levels of 120 to 10-15 mg L-1

after the start of

the exponential phase of cultivation (38). However

the same culture in phosphate-free medium resulted

in total betalain contents rising to 19 g L-1

: 4.8 times

higher than the amounts accumulated in a standard

MS medium (39).

The concentration of nitrate ions exhibited

different color phenotypes of B. vulgaris cv. Bikores

Monogerm cell lines (33). While combination of

nitrogen concentrations with some concentrations in

microelement increased betacyanin production in red

beet cell suspension (40), there was no significant

effect on betalain accumulation in various nitrogen

concentrations (39). Ammonium ions are utilized

more rapidly than nitrate ions but no significant

amount of either ammonium or nitrate ions are

consumed in the first 5 days of B. vulgaris hairy root

cultures (41). In suspension cultures of P. americana

L., betacyanin accumulation per cell increased with

increasing total nitrogen concentration (initial

NH+

4:NO−

3 ratio 1:2) in the range 0–40 mM and then

remained almost constant in the range 40–80 mM.

(42).

Microelements in medium also influenced

betalain production. Increasing Fe2+

concentration

up to 20-fold higher than that in the standard LS

medium markedly increased betacyanin content

without any affect on cell growth of B. vulgaris cell

suspension (30). Apparently, concentration of

microelement was significantly affected by basal

medium. Removing of boron, iodine, manganese and

molybdenum was found to decrease both the cell

growth and betacyanin content whereas absence of

copper and cobalt did not show any negative effect

on red beet cell suspension using LS basal medium

(43). On the other hand in Gamborg B5 medium

except manganese the addition high concentration of

copper, iron, molybdenum, zinc and cobalt showed

positive effect on betalain production.

Exogenous supply of a biosynthetic precursor

to culture medium may also increase the yield of the

desired product. Attempts to induce or increase the

production of plant secondary metabolites by

supplying precursor or intermediate compounds

have been effective in many cases. Betacyanin

accumulation in red-violet cell suspension cultures

of C. rubrum could be increased up to 1% or 100 mg

betacyanins/l by feeding tyrosine (44). Meanwhile

adding DOPA (44) and specific amino acids (45)

does not increase the betacyanin content.

The type of inoculums strongly influences

betacyanin production. The cell culture of Portulaca

grandiflora derived from the basipetal cut of a

hypocotyls segment is superior to the cell culture of

acropetal origin with regard to betacyanin

concentration. These differences indicate the

polarization of physiological conditions in the

hypocotyls segments (46).

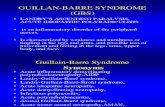

B. Selection of highly productively cell lines

Plant cell cultures represent a heterogenous

population in which physiological characteristics of

individual plant cells are different (37) Proper

selection of productive cells and cultural conditions

results in accumulation of products in high level.

Not all cells express the pigmented phenotype,

giving rise to variegated patches (47). The pattern of

patch formation is different from one callus to

another, although all calluses stem from the same

original clone. Therefore, the selection of high-

producing strains is necessary. Secondary

callogenesis of B. vulgaris cv. Bikores Monogerm,

on media with various ratios of auxin (2,4-D) and

cytokinin (BAP), showing white, green, yellow,

orange, red and violet pigmentations, a pattern of

coloration similar to that exhibited by the flowers of

betalain production species (Fig. 1). It represents the

overall pathways of betalain metabolism (48). It

shows that genetic pathways which repressed at the

whole plant level under given conditions may be

activated in tissue culture.

Fig 1. Five basis inherited stable phenotypes of red

beet cell cultures. Left to right: green, yellow, orange, red,

violet (48)

C. Hairy root cultures

Hairy root system based on inoculation with

Agrobacterium rhizogenes has become popular as a

method of producing secondary metabolites

synthesized in plant roots (49). They often grow as

fast as or faster than plant cell cultures (50) do not

require hormones in the medium. In contrast to

callus cultures, they are usually considered as

genetically stable. The secondary metabolites

produced by hairy roots are the same as those

usually synthesized in intact parent roots, with

similar or higher yields (51) The red beet hairy root

culture obtained from cv. Detroit Dark Red is a

prospective producer of betalain pigments because it

has stable morphological, growing and biosynthetic

characteristics and biosynthesizes 13.2 mg/g DW

pigments (4.4 mg/g DW are betacyanins and 8.8

mg/g DW betaxanthins, respectively) (52).

D. Elicitation

The accumulation of secondary metabolites in

plants is a common response of plants to biotic and

abiotic stresses. Their accumulation can be

stimulated by biotic and abiotic elicitors. Use of

elicitors of plant defense mechanisms, i.e.

elicitation, has been one of the most effective

strategies for improving secondary metabolites

production in plant tissue culture. The effect of

elicitors depends on many factors, such as the

concentration of the elicitor, the growth stage of the

culture at the time of elicitation and the contact time

of elicitation. Betacyanin levels in suspension

cultures of Portulaca sp. Cv. Jewel increased 2.6-

and 1.8-fold due to the addition of biotic elicitors

methyl jasmonate and B-glucan, respectively (53).

While in a wide range of biotic and abiotic elicitors

the Ca2+

was reported as the strongest abiotic elicitor

which induced a 2.92-fold increase in betalain

content in B. vulgaris L. hairy root cultures (54).

E. Bioreactors scaling up

The most important source of betalain

pigments is B. vulgaris root. Until now it has been

the only one commercially exploited for betalain

production. However, alternative sources are found

in plants from the Amaranthaceae and Cactaceae

families. Another alternative source is plant cell

culture in bioreactors, although optimization of

pigment production seems necessary (55). Many

different types of bioreactor systems for cultivating

plant cultures in vitro are available, and choosing the

most appropriate for specific applications is of great

importance (56). In hairy root culture bioreactors

can be roughly divided into three types: liquid-

phase, gas-phase, or hybrid reactors that are a

combination of both. Therefore, the ideal type of in

vitro system for producing betalains from any kind

of plant cells or tissues needs to be carefully

investigated on a case-by-case basis. Cell suspension

cultures and hairy roots of B. vulgaris have been

grown in shake flasks (40,57) and in several types of

reactors. Until recently, the shake flask method of

cultivation offered higher betalain yield than

cultivation of cells in bioreactors (58). Cultivation of

B. vulgaris cv. Bikores Monogerm suspension

cultures in shake flasks yields high betalain while

cultivation of B. vulgaris cv. Crosby Egyptian in a

stirred tank bioreactors resulted in 62.5% lower

betalain content sthan in shake flask (59). To date, it

is considered that betalain production by in vitro

system could be an excellent option in the future,

mainly because the production assures availability

and quality independently of environmental changes,

which is a big problem with agronomic production.

This technology can also produce novel metabolites

since new molecules which have not been found

previously in plants have been produced by cell

cultures. Plant tissue culture techniques offer the

rare opportunity to alter the chemical profile of a

phytochemical product, by manipulation of the

chemical or physical microenvironment, to produce

a compound of potentially more value for human

use.

REFERENCES

[1] J. Escribano, M. A. Pedreno, F. Garcıa-Carmona and R. Mun˜oz, “Characterization of the antiradical activity of betalains from Beta vulgaris L. roots”, Phytochem. Anal., no. 9, pp. 124–127, 1998.

[2] S. J. Schwartz, J. H. von Elbe, M. W. Pariza, T.

Goldsworthy and H. C. Pitot, “Inability of red beet

betalain pigments to initiate or promote

hepatocarcinogenesis”, Food Chem. Toxicol., no. 21,

pp. 531-535, 1983.

[3] A. Sasson, “Production of useful biochemicals by

higher-plant cell cultures: biotechnological and

economic aspects”. Options Méditerranéennes –

Sérié Séminaires, no. 14, pp. 59-74, 1991.

[4] R. S. Rao and G. A. Ravishankar, “Plant tissue

cultures; chemical factories of secondary

metabolites”, Biotechnol. Adv., no. 20, pp. 101-153,

2002.

[5] D.A. Moreno, C. García-Viguera, J.I. Gil, A. Gil-

Izquierdo, “Betalains in the era of global agri-food

science, technology and nutritional health”,

Phytochem. Rev., no. 7, pp. 261–280, 2008.

[6] S. Ramachandra Rao, G.A. Ravishankar, “Plant cell

cultures:Chemical factories of secondary

metabolites”, Biotechnol. Adv., no. 20, pp. 101–153,

2002.

[7] V. Mulabagal and H. Tsay, “Plant Cell Culture – An

Alternative and efficient source for the Production of

Biologically Important Secondary Metabolites”, Int.

J. Appl. Sci. Engineer., vol. 2, no. 1, pp. 29-48, 2004.

[8] Philipson JD (1990). Plants as source of valuable

products. In: B.V.Chalwood and M.J. Rhodes (Eds.),

Secondary products from plant tissue culture,

Oxford, Clarendon Press. pp.1-21.

[9] B. Kaul, and E. J. Staba, “Ammi visnaga L. Lam.

tissue cultures: multiliter suspension growth and

examination for furanochromones”, Planta Medica,

Journal of Medicinal Plant Research, pp.145-56,

1967.

[10] M. R. Heble, S. Narayanaswamy, and M.S. Chadha,

“Diosgenin and sitosterol isolation from Solanum

xanthocarpum tissue cultures”, Science, no. 161, pp.

1145, 1968. [11] M. Fowler, “Plant cell biotechnology to produce

desirable substances”, Chemistry and Industry, no. 7,

pp. 229-33, 1981.

[12] M. W. Fowler, “Time for plant cell culture?”, Nature,

vo1.307, no. 5951, pp. 504, 1984.

[13] M. W. Fowler, “Plant-cell culture: natural products

and industrial application”, Biotechnol. Genetic

Engineer. Rev., no. 2, pp. 41-67, 1984.

[14] M. Misawa, Production of useful metabolites. Adv.

Biochem. Eng./Biotech., no. 31, pp. 59-88, 1985.

[15] J. Berlin, S. Sieg, D. Strack, M. Bokern and H.

Harms, “Production ofbetalains by suspension

cultures of Chenopodium rubrum L.”, Plant Cell Tiss.

Org. Cult., no. 5, pp. 163–174, 1986.

[16] A. Stafford, P. Morris, M. W. Fowler, “Plant cell

biotechnology: a perspective”, Enzyme Microb.

Technol., no. 8, pp. 578-87, 1986.

[17] F. Delgado-Vargas and O. Paredes-López, Natural

colorants for food and nutraceutical uses. CRC

Press. Boca Raton, Florida, pp. 192 – 211, 2003.

[18] D. Strack, T. Vogt and W. Schliemann, “Recent

advances in betalain research”, hyrocem. No. 62,

pp.247-269, 2003 [19] E. Grotewold, “The genetics and biochemistry of

floral pigments”, Annual Review of Plant Biology, no.

57, pp. 761-780, 2006. [20] M. Piattelli, L. Minale, ”Pigments of centrospermae.

1. Betacyanins from Phyllocactus hybridus Hort. and

Opuntia ficus indica Mill.”, Phytochem., no. 3, pp.

307–311, 1964.

[21] F. J. Francis, Anthocyanins and betalains. In F.J

Francis (Ed.), Colorants (pp. 55–66). St Paul, MN:

Eagan Press. (1999).

[22] J. S. Clement and T. J. Mabry, “Pigment evolution in

the Caryophyllales: A systematic overview”, Bot

Acta, no. 109, pp. 360–367, 1996.

[23] Kimler L, Mears J, Mabry TJ, Roesler H (1970) On

thequestion of the mutual exclusiveness of betalains

andanthocyanis. Taxon 19:875–878

[24] H. A. Stafford, “Anthocyanin and betalain: evolution

of the mutually exclusive pathways”, Plant Science,

no. 101, pp. 91-98, 1994

[25] F. Delgado-Vargas, A. R. Jiménez, and O. Paredes-

López, “Natural pigments:carotenoids, anthocyanins,

and betalains — characteristics, biosynthesis,

processing and stability”, Critical Reviews in Food

Science and Nutrition, no. 40, pp. 173–289, 2000.

[26] R. L. Jackman, and J. L. Smith, Anthocyanins and

betalains, in Natural Food Colorants. G.A.F. Hendry

and J.D. Houghton, Eds. Chapman & Hall, New

York, pp. 244–310, 1996.

[27] T. J. Mabry, A. Taylor and B. I. Turner, “The

betacyanins and their distribution” Phytochemistry,

no. 2, pp. 61–64, 1963.

[28] D. Strack, W. Steglich, and V. Wray, “Betalains, in

Methods in Plant Biochemistry, Vol. 8. E.E. Conn,

Ed. Academic Press, Orlando, FL, pp. 421–450,

1993.

[29] M. Hirose, T. Yamakawa, T. Kodama and A.

Komamine, “Accumulation of Betacyanin in

Phytolacca americana Cells and of Anthocyanin in

Vitis sp. Cells in Relation to Cell Division in

Suspension Cultures”, Plant Cell Physiol., vol. 31,

no. 2, pp. 267-271, 1990.

[30] T. Akita, Y. Hina, T. Nishi, “Production of

betacyanins by a cellsuspension culture of table beet

(Beta vulgaris L.)”, BiosciBiotech Biochem no. 64,

pp.1807–1812, 2000.

[31] J. Berlin, S. Sieg, D. Strack, M. Bokern and H.

Harms, “Production of betalains by suspension

cultures of Chenopodium rubrum L.”, Plant Cell Tiss.

Org. Cult., no. 5, pp. 163-174, 1986.

[32] M. Sakuta, T. Takagi and A. Komamine, “Growth

related accumulation of betacyanin in suspension

cultures of Phytolacca Americana L.,” Journal of

Plant Physiol, no. 125, pp. 337-343, 1986.

[33] R. Leathers, C. Davin, and J. Zrÿd, “Betalain

producing cell cultures of Beta vulgaris L. (red

beet)”, In Vitro Cell Development Biology, no. 28,

pp. 39–45, 1992.

[34] M. Sakuta, H. Hirano, K. Kakegawa, J. Sunda, M.

Hirose, R. W. Joy, M. Sugyama and A. Komamine,

“Regulatory mechanism of biosynthesis of

betacyanin and anthocyanin in relation to cell

division activity in suspension cultures”, Plant Cell

Tis. Org. Cult., no. 38, pp. 167-169, 1994.

[35] M. Bhuiyan, K. Murakami and T. Adachi, “Variation

in betalain content and factors affecting the

biosynthesis in Portulaca sp. “Jewel’ ceel cultures”,

Plant Biotechnology, vol. 19, no. 5, pp. 369-376,

2002.

[36] J. Berlin and F. Sasse, “Selection and screening

techniques for plant cell cultures”, Advanced

Biochemistry and Engineering, no. 31, pp:99-132,

1985.

[37] V. Mulabagal and H. Tsay, “Plant Cell Culture – An

Alternative and efficient source for the Production of

Biologically Important Secondary Metabolites,

International Journal of Applied Science and

Engineering, vol. 2, no. 1, pp. 29-48, 2004

[38] A. Pavlov, V. Georgiev and M. Ilieva, “Betalain

biosynthesis by red beet (Beta vulgaris L.) hairy root

culture. Process Biochem., no. 40, pp. 1531-1533,

2005.

[39] M. Taya, K. Yakura, M. Kino-Oka and S. Tone,

Influence of medium constituent on enhancement of

pigment production by batch culture of red beet hairy

roots. J. Fermen Bioeng, no. 77, pp. 215-217, 1994.

[40] T. Akita, Y. Hina and T. Nishi, “New medium

composition for highbetacyanin production by a cell

suspension culture of table beet (Beta vulgaris L.)”,

Biosci Biotech Biochem., no. 66, pp. 902–905, 2002.

[41] K. S. Shin, D. Chakrabarty, Y. J. Ko, S. S. Han and

K. Y. Paek, “Sucrose utilization and mineral nutrient

uptake during hairy root growth of red beet (Beta

vulgaris L.) in liquid culture”, Plant Growth Reg. no.

39, pp. 187–193, 2003.

[42] M. Sakuta, T. Takagi and A. Komamine, “ Effects of

nitrogen source on betacyanin accumulation and

growth in suspension cultures of Phytolaca

americana”, Physiologia Plantarum, no. 71, pp. 459-

463., 1987

[43] T. Akita, Y. Hina and T. Nishi, “Effect of zinc

deficiency onbetacyanin production in a cell

suspension culture of table beet (Beta vulgaris L.)”,

Biosci Biotech Biochem., no. 65, pp. 962–965, 2001.

[44] J. Berlin, S. Sieg, D. Strack, M. Bokern and H.

Harms, “Production of betalains by suspension

cultures of Chenopodium rubrum L.”, Plant Cell Tiss.

Org. Cult., no. 5, pp. 163-174, 1986.

[45] J. Hempel and H. Bo¨hm, “Betaxanthin pattern of

hairy roots from Beta vulgaris var. lutea and its

alteration by feeding of amino acids”, Phytochem.,

no. 44, pp. 847–852, 1997.

[46] W. Schroeder and H. Bohm, “Betacyanin

concentrations in young cell cultures from Portulacca

grandiflora an analysis of variation. Plant Cell

Reports, no. 3, pp. 14-17, 1984

[47] P. A. Girod and J. P. Zryd, “Cloal variability and

light induction of betalain synthesisi in red beet cell

cultures. Plant Cell Rep., no. 6, pp. 27-30, 1987.

[48] P. A. Girod and J. Zrÿd, “Secondary metabolism in

cultured red beet (Beta vulgaris) cells: differential

regulation of betaxanthin and betacyanin

biosynthesis”, Plant Cell Tiss. Org. Cult., no. 25, pp.

1–12, 1991.

[49] J. Palazon, M. T. Pinol, R. M. Cusido, C. Morales

and M. Bonfill, “Application of transformed root

technology to the production of bioactive

metabolites. Recent Res. Dev. Plant Phys, no. 1, pp:

125-143, 1997.

[50] H. E, Flores, J. M. Vivanco, V. M. Loyola-Vargas,

“Radicle biochemistry: the biology of root-specific

metabolism”, Trends Plant Sci., no. 4, pp. 220–226,

1999.

[51] N. Sevon, K. M. Oksman-Caldentey, “Agrobacterium

rhizogenesmediates transformation: Root cultures as

a source of alkaloids”, Planta Med., no. 68, pp. 859-

868, 2002.

[52] A. Pavlov, P. Kovatcheva, V. Georgiev, I. Koleva

and M. Ilieva, “Biosynthesis and Radical Scavenging

Activity of Betalains during the Cultivation of Red

Beet (Beta vulgaris) Hairy root Cultures”, Z.

Naturforsch, no. 57c, pp. 640-644, 2022.

[53] N. H. Bhuiyan and T Adachi, “Stimulation of

betacyanin synthesis through exogenous methyl

jasmonate and other elicitors in suspension-cultured

cells of Portulaca”, J Plant Physiol., no. 160, pp.

1117–1124, 2003.

[54] Savitha BC, Thimmaraju R, Bhagyalakshmi N, G. A.

Ravishankar, “Different biotic and abiotic elicitors

influence betalain production in hairy root cultures of

Beta vulgaris in shake-flaskand bioreactor”, Process

Biochem., no. 41, pp. 50–60, 2006.

[55] D. Pavokovik and M. Krsnik-Rasol, “Complex

Biochemistry and Biotechnological Production of

Betalains”, Food Technol. Biotechnol., vo. 49, no. 2,

pp. 145–155, 2011.

[56] Eibl R, Eibl D (2002) Bioreactors for plant cell and

tissue cultures. In:Oksman-Caldentey KM, Barz WH

(eds) Plant Biotechnology and Transgenic Plants.

Marcel & Dekker, New York, pp 163–200.

[57] G. Trejo-Tapia, A. Jimenez-Aparicio, M. Rodriguez,

G. Sepulveda, G. Salcedo, B. Martinez, Influence of

medium constituents on growth and betalain

production in cell suspension cultures of Beta

vulgaris, Asia-Pacific J. Mol. Biol. Biotechnol., no. 7,

pp. 167–172, 1999.

[58] B. Neelwarne, R. Thimmaraju, “Bioreactor for

cultivation of red beet hairy roots and in situ recovery

of primary and secondary metabolites”, Eng. Life Sci.

no. 9, pp. 227–238, 2009.

[59] M. Rodriquez-Monroy and E. Galindo, “Broth

rheology, growth and metabolite production of Beta

vulgaris suspension culture: a comparative study

between cultre grown in shake flaks and in a stirred

tank”, Enzyme Mcrob. Technol., no. 24, pp. 687-693,

1999.