Rimmer ad 'D overseas' 08 1/7/08 14:44 Page 1 FREE restoration … · 2012-12-18 · REpAIR ShOp...

Transcript of Rimmer ad 'D overseas' 08 1/7/08 14:44 Page 1 FREE restoration … · 2012-12-18 · REpAIR ShOp...

Ragtop I SpRIng I 2011 www.TorontoTriumph.com 33

FREECATALOGUES

Rimmer Bros tick all the boxes:- �� Competitive prices �� Great customer service �� Efficient mail order anywhere �� World’s largest Triumph stock �� Free catalogues �� Trade enquiries welcome�� Easy to use website

STAG . TR2-8 . SPITFIRE . GT6 . HERALD VITESSE . DOLOMITE . 2000/2500

ROVER SD1 . ROVER 75/45/25MGF/MGTF . MG ZT/ZS/ZRROVER 200/400/600/800

METRO/MINI . MAESTRO/MONTEGO

RANGE ROVER CLASSIC/P38A/SERIES 3DISCOVERY 1 & 2 . FREELANDERDEFENDER . ROVER V8 ENGINES

AUTHORISED PARTS DISTRIBUTOROriginal Parts & Accessories

LAND ROVER

AUTHORISED PARTS DISTRIBUTOROriginal Parts & Accessories

Great prices! Great service!

FULL RANGE OF PARTS & ACCESSORIES

PARTS SALES & ENQUIRIESTel: 01144 1522 568000

Trade Enquiries: 01144 1522 567111Fax: 01144 1522 567600

E-mail: [email protected]

Rimmer Bros. Triumph House, Sleaford Rd (A15),Bracebridge Heath, Lincoln, LN4 2NA, England.

75,000 SQ FT OF SPACE

PARTS PICKED FROM 1000’S OF LOCATIONS

BROWSE OURCATALOGUESON YOUR PCAll our Catalogues & current Price Guides are available on one CD.Small charge is made to cover burning & postage.

SALESCOUNTER & VISITORCENTRE

WANT A PROFESSIONAL PARTS SERVICE

AT THE RIGHT PRICE?COME TO THE EXPERTS

We stock MG Rover and Land Rover parts too.

VISITORS WELCOMEWe are open:- MON – FRI; 8.30am to 5.30pm,

SAT; 8.30am to 1pm.

SALES OFFICE

A BRITISH COMPANY SUPPORTING BRITISH CARS

Rimmer ad 'D overseas' 08 1/7/08 14:44 Page 1

restoration

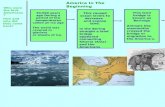

When I last left you on this proj-ect, I was at a tricky point of the restora-tion that would definitely test my newly learned welding skills. I had tacked the new inner passenger side sill in place and had repeatedly fit the front wing and door to check that the gaps and body lines were acceptable. Once I was satisfied that all was well, I finally found the courage to do my first bit of “structural” welding. With the in-ner sill solidly attached to the body tub, it was time to refit the outer sill after a quick spray of zinc primer. I punched the flange of the sill with my metal punch and used a series of plug welds to attach the outer sill to the inner. After yet another test fit of the door and fender to make sure that nothing moved or twisted during the welding process I moved on to com-plete the drivers side that I had left in-tact for structural integrity and refer-ence. The driver’s side took me about half the time.

The next step in the restoration was to weld the new floor pans in. It took a bit of fiddling to align the holes in the floor with the mating holes in the sill, before the top sides of the floors were welded in. A quick flip of the car and the bottom rear and front sections of the floor were welded . The floors were then connected to the driveshaft tun-nel in the center, before the car was once again flipped right side up.

With the structural welding taken care

by DavID tuShInghaM

Front Inner Fender Repair before and afters

restoration SIX & Two THREESand

a 250 – Part 8

34 www.TorontoTriumph.com Ragtop I SpRIng I 2011 Ragtop I SpRIng I 2011 www.TorontoTriumph.com 35

MERCEDES AUSTIN ALVIS BMW JENSEN TRIUMPH AUSTIN-HEALEY JAGUAR ASTON MARTIN

DAIMLER MG RALEIGH VAUXHALL BENTLEY ROLLS-ROYCE SUNBEAM LOTUS CORD TVR

LANDROVER WOLSELEY RELIANT BRISTOL PORSCHE ANGUS-SANDERSON ALLARD MORGAN

TROJAN INVICTA MORRIS ARGYLL AUDI ARMSTRONG-SIDDELEY LANCHESTER STRAKER-SQUIRELNER

905-953-0052 www.lnerautomotive.ca

European Classic Car SpecialistsMaintenance and ServiceComplete Mechanical RepairsComplete Electrical RepairsParts New and UsedParts FabricationRestoration of Body and Interior Br

ing

Us Y

our Dream

Ragtop 2009 - ¼ page - TRANSPORT BOOKS at DRB Motors Inc.

3.75”x 4.9375” 3 ¾ x 4 15/16 9.53cm x 12.55cm

Transport BooksCars, bikes, boats & planes...

trucks, tractors, tanks & trains

Our 37th year!

Canada's largest selection of motoring books & popular

motorsports videos.

Triumph books a specialty: historical, pictorial & technical.

Mon-Sat 10am-5pmfree parking – free mailing list

www.transportbooks.com

16 Elrose AvenueToronto, ON M9M2H6 Canada

(416)744-7675 (800)665-2665

Phone: 416-822-0096 or 905-616-0421Toll Free: 1-866-532-3630

Email: [email protected]: http://www.a-professional-appraisal.ca

of, I decided to continue to repair some of the other problem areas on the body tub. The rear wheel arches were showing a sig-nificant amount of rusted and thin areas that would need attention. This area, al-though fairly easy to repair, can be rather time consuming as the repair needs to be done in two steps. The metal in this area is “overlaid” so a repair first needs to be done to the base metal, followed by repair to the outer panel. To make it more interesting, there are a few cage nuts that need to be refitted to the inner tub where the access is a little tight for big hands and a MIG torch.

After the rear wheel well repairs were made, I decided to tackle the battery box area. I had previously partially re-moved the old battery box with a plan to cut the new box

and attach it to the remaining good metal. However, in the end I decided not to cut the box and fitted it after removing the old flange from below the scuttle. It is currently

tacked into place and will be finish welded at a later time.

I decided to take a break from welding at this point and concentrated on remov-ing the rest of the paint from

the body tub. The only paint remaining was in the trunk area, the engine bay and inner fenders. I started stripping the inner fend-

Rear wheel arch repair prior to plug welding

Small parts refinishing after sandblasting.. ... and after paint

36 www.TorontoTriumph.com Ragtop I SpRIng I 2011 Ragtop I SpRIng I 2011 www.TorontoTriumph.com 37

“I’ve always used your products for my 1998 Mustang Cobra. I used the NXT Generation Tech Wax on my wife’s 2004 Jeep Grand Cherokee (inferno red) and was so impressed I used it on my 1987 BMW 735i (mint condition). Just out of curiosity I did a fender on the Cobra with just some minor scratches. WOW....I couldn’t see them anymore and it left an incred-ible shine. I did the whole car and even under my fluorescent garage lighting the car looked unbelievable. The hazing and minor scratches don’t show anymore. Thanks for a great product.”

Wow! One word for your NXT Generation Tech Wax. I show a classic 1938 Cadillac V-16 oxblood maroon painted car. This past September we won a trophy for best Cadillac at the Concours d’Elegance and then won a Senior award from the AACA Southeastern meet at Asheboro NC. All this after only 2 coats of your NXT Generation Tech Wax 2 weeks earlier. Thanks Meguiars.”

“I just wanted to say thanks for your NXT Genera-tion Tech Wax. I won the Trans Am Show & Shine award at the Trans Am Nation

about 315 cars there. I used your NXT Generation Tech Wax and I have to say my car was awesome looking and your product helped me win the award. I had many people ask me what I used and I told them about your product. It’s the best shine on the market and believe me I’ve tried tons of them.”

4/24 tech wax palm reflection

J.D. AUTO SERVICES

Josip (Joe) Dukova

IMPORT, DOMESTIC & SPORTSCARS301 Rexdale Blvd. Unit C, Etobicoke, Ont. M9W 1R8TEL: (416) 746-1048 • FAX: (416) 746-9935

BRITISh CAR REpAIR ShOp• TRIUmph • mG• LOTUS • JAGUAR• SAFETY & E-TESTING

N

Rexdale Blvd.

Mar

tin

Gro

ve

2338 wyecroft rd., Unit K5-7, oakville, ontario L6L 6L4Tel: 905-825-2045 Fax: 905-825-0208

Your source for all your repairs

9 Forster Park DriveOakville, Ontario Canada L6K [email protected] www.winslowdelaney.com

Winslow Delaney | Creative Solutions 416.871.2358

• Parts Store• Complete Engine Machine Shop• Gasoline Injector Service• Engine Balancing & Blue Printing• Cylinder Head Porting & Flow Testing

• Diesel Engines• Gasoline Engines• Marine Engines• Race Engines• Vehicle Services

Telephone: (519) 833-COAT (2628) Fax: (519) 940-9798 www.fireballcoatings.com

27 Erinville Dr. Erin Ontario Canada N0B 1T0

ers and immediately found more issues with rust and areas to repair. Heavy repairs had been done in this area by the previous owner, as indi-cated by a lot of braising and heavy grinding marks. The passenger side inner fender had significant rust and was very thin in spots. I decided to

cut this area out completely and welded in new metal. I was actually impressed with my welding in this area and it was clear that I was getting better at welding the thinner body metal. Again, more cage nuts need to be welded in this area to secure the front wings.

In order to strip the paint from the bulk-head area of the engine bay, I finally de-cided to remove the throttle shaft from the

battery box and front wing paint stripping

New rear valence

car. If you have never had the pleasure of re-moving the throttle shaft from a TR3A I can tell you that, in my experience, it can be very difficult to locate and drift out the Mills pins that secure the shaft. New nylon bearings will be fitted before the shaft is reinstalled.

All in all, the trunk area looks pretty solid after stripping. However, I did find more issues with the front inner fend-ers where they attach to the bulkhead. I also decided to start stripping paint (and Bondo!) from the wings to see what I had to work with underneath. I do see some other areas of concern here that will need to be attended to in the future.

Unfortunately, I had a bit of a set back when my air compressor decided to pack it in. I turned from novice automotive me-chanic and restorer to novice air compres-sor repairman and managed to get it fixed within about a weeks time.

With the compressor breathing again, I decided to give it a work out and tested my

repair by continuing to media blast some small batches of parts. It is always nice to end up with nice clean and shiny parts to play with later during re-assembly. Seat racks, heater brackets, bumper brackets and numerous other small parts are ready to go when need be. (See photos p.35)

Now as you may recall, I had major is-sues with the rear valence of the car. I tried, with all my limited skills and tools, to repair the area, but it was not to be. I managed to find a new repair panel for sale on ebay and I have removed the old rear valance completely from the car. The new rear valence has been test fitted and looks like it will take a little bit of work to get it perfect.

I still have a lot of work to do on the car prior to sending it out to paint but I move a little closer to that milestone each week. Now, if I can only stay clear of “other dis-tractions”… ragtop

Rear Valence removed

Ragtop distribution provided by:

• Letter Shop Services• Order & Product Fulfillment

• Bulk Mail Service• List Management

(416) 755-9191

36 www.TorontoTriumph.com Ragtop I SpRIng I 2012 Ragtop I SpRIng I 2012 www.TorontoTriumph.com 37

restoration

It has been a little while since my last update… as a matter of fact it was a little over a year ago in the 2011 Spring Issue of Ragtop. Man, how time flies!

I can’t believe how long it is taking me to complete this restoration. Don’t get me wrong, I am no less motivated to get it done than I was in the beginning and I am still having a lot of fun working on this project. My first full restoration project of my ‘73 TR6 only took me 14 months to complete but then, I didn’t have a fun, two seat roadster to drive in the summer months!

Last spring and into early summer was a little difficult for me personally as labour issues at work and potential strikes at some of our facilities across Canada kept me away from home, in a management support role. Having another TR (or two!) can also throw a wrench into best-laid plans. As always, at the beginning of the driving season, I do a thorough inspection and follow up on some of the items on my “to do” list. The TR6 had some carb and other minor issues that needed attending to, so the TR3A would have to wait.

I didn’t really to get to work on the

Six and Two Three’sSix and Two Three’sSix and Two Three’s Part 9by DavID tuShInghaM

TR3A until I had some spare time towards the end of June and into early July. The first thing that needed to be tackled was to weld the new rear valance back on. I decided that it would be much easier to invest in a spot welder to do this job rath-er than use my MIG welder. Kijiji can be your friend when looking for lightly used equipment and I found a good heavy-du-ty spot welder and timing unit for a great price. This proved invaluable to replace all of the spot welds that I had cut out around the spare tire opening. It was also great to re-attach a new front driver’s side body to frame mount that was rusted beyond re-pair. The new floors that I installed did not come with cage nuts affixed, so new and improved cage nuts were purchased from Macy’s Garage and welded to the bottom of the floor pans.

For me, most weekends throughout the summer are dominated by one British Car event or another. I have driven my TR6 to these events without any major issues for the past 4 years. Unfortunately, this came to an end last July on my return trip from Ottawa having travelled to the 26th

Canadian Classic. I limped back to New-market, after a quick stop in Lindsay for the “Brits on the Lake” show having lost 2nd gear. Over the next two weekends, my focus was to remove the transmission

and complete a rebuild. Fortunately, my wallet was spared as I found that the culprit was a faulty/worn switch on the transmission top cover that was jam-ming the gear selector shaft. Long story short, the TR3A didn’t get touched again until late September.

I was getting tired of seeing the TR3A in state of disassembly for such a long period of time,

so I decided that I would put all the body panels and windscreen back on to make it look like a car again. This in the end was a good exercise as it served to motivate me to continue onwards with renewed vigor.

I continued to work with the welding to close panels on the rear of the car and made progress on patching holes on the wheel well arches and inside the body tub. At one point I counted the holes that need-ed to be filled inside the body tub… 36 if you must know!

Without a doubt, the single most mo-tivating factor for me thus far in the proj-ect has been getting the engine started.

engine bay bulk-head hole repair, before and after

test start temporary dash set-up . Great use of an old milk crate!

Front body to frame mount, plug welded

prior to grinding

When I bought the car it wasn’t running, although the previous owner stated that it was running before it was parked. At the end of December, plans were made to try and see if I could get it to fire. As I needed some assistance with wiring the car to test start, I asked Scott Douglas to give me a hand and he graciously accept-ed. With Syl Demers on fire extinguisher duty and John Morton in attendance for moral support, we cranked it over and despite our best efforts, we could not get it to start. We definitely had spark, but were having issues getting fuel from the carbs into the cylinders. After a cou-ple of days troubleshooting, changing

the intake manifold and rebuilding the carbs, I finally got it to start. First time that it had been running in about 9 years and it was like mu-sic to my ears. A great way to start the New Year.

I still have some welding to do, but I am almost ready to hang up the MIG and pick up a paint gun. That’s right… I have decided that I am go-ing to learn to do some bodywork and paint. Over the winter, I pur-chased a new Turbine Spray Paint

unit (again off Kijiji) and have been doing research on paint and body ever since. Kevin Tetz has a great 5 disc series avail-able for purchase called “Paintucation” that I highly recommend. Great resource for a bodyman/painter in the making. I have been prepping the tub for interior painting and have been media blasting in my garage over the winter months. Very effective, but also very very messy.

I hope that by next report, I will have the body primed and if all goes really well, it might even have some paint on it… watch this space! ragtopRear valence repair test fit Rear valence finished welded

Putting the panels back on to remember what the car looked like!