Reverse rotaion of co2 compressor

-

Upload

prem-baboo -

Category

Engineering

-

view

147 -

download

0

Transcript of Reverse rotaion of co2 compressor

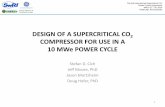

REVERSE ROTATION IN CO2 COMPRESSOR

Author

Prem Baboo

Sr. Manager (Prod)

National Fertilizers Ltd., Vijaipur, India

Reverse rotation phenomenon in CO2 Compressors during stopping of turbine was

observed in 1997. In our unit Vijaipur unit CO2 Compressors were installed for four

streams of urea plant namely (11, 21, 31, and 41). CO2 Compressors are of BHEL (India)

design. In our case line-I urea plant (11, 21 streams) were commissioned in 1987

whereas line-II urea (31, 41 streams) were commissioned in 1997. Reverse rotation is

an unwanted phenomenon as it is always associated with severe radial vibration and

axial displacement of the rotor which may lead to damage of the bearings and rubbing

of seals with the stationary components. This paper describes how the reverse rotation

of CO2 compressor trains provided in line-II urea plants at Vijaipur was diagnosed by

the analysis of post trip data picked up by Data Manager in house approach to find the

solution.

Description of CO2 Compressor Urea Plant

Both the Urea line-I & Line-II plants CO2 compressor were supplied by BHEL,

Hyderabad, India. Line –I Compressor turbine designed for 40 ata and line-II turbine

designed for 100 ata steam. The CO2 supplied by Ammonia plant at the pressure of 0.5

kg/cm2.The compressor having four stages. The low pressure casing is horizontally

split having two stages 1st discharge at 5.5 kg/cm2, Temperature 1900C and 2nd

discharge 22.5 kg/cm2,Temperature 1850C The high pressure casing is barrel type, the

speed of high pressure side isstepped up from 8400 to 12600 rpm by a speed increasing

gear. The pressure of third discharge is 88 kg/cm2 Temperature 1800Cand that of final

discharge is 162 kg/cm2 and final discharge temperature is 1150C, Flow diagram as

shown in the fig 1. And Lube oil circuit as shown in fig-2.

The speed of the steam turbine is controlled by an electronic governor (Woodward,

505E).in line-II where as urea line-I there is no electronic governor. The Antisurge

control system is supplied by Compressor Control Corporation (CCC) U.S.A. which

operates the control valve (Antisurge valve HV-62) to recycle gas from 4th discharge to

1st section. In addition to this, there are following recycle valves and vent valves to keep

each stage out of surge limit at different speed and pressure ratio:

Manual recycle valve from 1st discharge to 1st suction.

2. Manual vent valve at 1st discharge.

3. Recycle control valve from 2nd discharge to 1st suction (HV-63).

4. Vent control valve at 2nd discharge (HV-61).

5. Vent control valve at 4th discharge (PV-3).

An emergency shutdown system trips the machine in case of any abnormality with

simultaneous opening of the vent control valve at 2nd stage discharge (HV-61) and

recycle control valve connecting 4th stage discharge and 1st stage suction (HV-62).

Fig-1

Reverse rotation was observed in 31/41 Unit CO2 Compressors. Following were

observations:

1. During stopping it was observed that in 8-10 seconds time speed comes down

and then it again increases to around 2900 rpm. Then after 20-150 seconds the

speed comes down to minimum.

2. It had been physically observed that shaft rotates in reverse rotation as observed

from turbine rear side.

3. The Chart of rpm Vs Time as shown in the fig-3

Fig-2

Reason for reverse rotation in CO2 Compressor and their harms

When centrifugal compressor tripped the higher pressure existing at the discharge side

of the centrifugal compressor is allowed to overcome the lower pressure that is always

present at the suction side of the compressor. This is a situation that is possible of

reverse flow some plants reported reverse rotation phenomena in CO2 centrifugal

compressor. Reverse rotation is an unwanted phenomenon in a centrifugal machine as

it is always associated with severe radial vibration and axial displacement which may

lead to damage of the bearings and rubbing of seals with the stationary components

Bearing failure is a definite possibility Seals were not rated for this rotational speed.

Internal compressor components may become dislodged. High possibility of damaging

vibration at just reverse position. Coupling is rated for the rotational speed as long as

the train does not become energized. Rotor over speed can cause overstressing in bearing (journal/thrust) causing fits to loosen or parts to even be thrown low damped

critical speeds not normally of interest in rotor analysis may cause damage during runaway

event. Seals this case has packing less boxes Throttle sleeve pushed off the fit and welded to

throat Throttle sleeve thrust rings.

1. Standard face seals may be adversely affected by over speed.

2. Rings may be rotation sensitive.

Fig-3

Compressor internals 1. Slow roll in either direction can damage wear parts.

2. Reverse flow creates internal differential pressures that were NOT considered in the

pump design. Sleeves and wear parts can be displaced.

High runaway rotational speed

1. Balance issues.

2. Impeller stresses can be exceeded.

To safeguard against reverse rotation in CO2 Compressors following changes have

been affected.

1. During shutdown Antis urge valve (HV-62) provided from 4th discharge to 1st

suction opens and also 2nd Stage vent (HV-61) provided from 2nd discharge to

atmosphere opens. In addition to these HV-63 provided from 2nd discharge to 1st

suction logic is changed and now this opens through solenoid during tripping.

Further the timing of opening of HV-61 has been decreased. This change has

been done in 21/31/41 units.

2. In addition to above in 21 unit CO2 Compressor, the final discharge vent (PV-3)

logic changed to open it during tripping of machine.

It was being observed that these machines rotate in reverse direction as & when these

were tripped or emergency shutdown was taken at full load. Matter was brought in the

notice of M/s BHEL. All the four compressors suction is interconnected via

interconnection between CO2 line from Ammonia to Urea Plants

Matter had been studied in-house and experience shared with other Indian Urea

manufactures. In the process, it had come to be known that reverse rotation of CO2

8250

2908

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

0 1 2 3 4 5 6 7 8 9

10

10

20

30

40

50

60

70

80

90

10

0

11

0

12

0

13

0

14

0

15

0

16

0

17

0

18

0

RP

M

Time in Sec

REVERSE ROTATION OF CO2 COMPRESSOR

RPM Vs Time

compressors under similar conditions had also been observed at IFFCO, Aonla &

Phulpur plants, whereas similar phenomenon is not observed at NFCL, Kakinada(AP)

and BACL, Shahjahanpur(U.P.) During reverse rotation, shaft of the machine has been

physically observed to rotate in reverse direction (as observed from turbine rear side).

The rise & fall of inter stage pressures as observed and recorded does not indicate

malfunctioning of any control valve or NRV in interconnecting pipeline of Low pressure

Casing (MCL) & high pressure Casing (BCL).

As per the original trip interlock, various loading/vent valves provided in the surge

protection system of the compressor used to operate in following manner:

With the implementation of above changes improvement was observed in speed charts

in 31/41 unit’s range of speed has come down. In our CO2 Compressors NRV is installed

in between low pressure side (MCL) and high pressure side (BCL). Also a final stage

discharge knock out drum (MV-8) with upstream / downstream NRV is provided just

before the entry point of CO2 into the urea reactor. From CO2 Compressors platform

final discharge line to MV-8 length is around 100 meters.

Fig-4

The efforts however have not been able to prevent reverse rotation of 31/41Tk-1/K-1.

It is with this intent to prevent reverse rotation in 31/41 CO2 compressors that we

attract your kind attention to this problem. We hope that with vast experience behind

you it will be possible to find a solution of this problem. For your ready reference, three

8250

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

RP

M

Time in Sec

AFTER MODIFICATIONS RPM Vs Time

annexure containing data of two different tripping taking places under different

operating surge control interlock in operation are being enclosed.

Reverse rotation can be practically seen from rear end of turbine as shown by torch in

the figure-5

Fig. 5

Conclusion

A simple modification of the trip interlock to include the post trip opening of second

discharge recycle control valve permitted the recycle of high pressure gas to save the

whole train from rotating in reverse direction. The total net effect of the above

modification was in the form of drastic reduction in reverse gas flow torque on the LP

rotor immediately after trip due to sudden increase in first suction pressure together

with simultaneous increase in quantity of gas released from second stage discharge.

Although the gas reversal through the third stage remained Unchanged, the reverse

torque generated on the whole train due to reversal of gas through MCL and BCL

combined together substantially reduced due to reduction of gas reversal through MCL.

As a result, at any point of time during coast down, the residual forward torque of the

whole train due to inertia of rotation in the forward direction prevailed over the reverse

torque created due to reversal of gas through both BCL & MCL and the resultant

forward torque forced the rotor train to continue rotation in forward direction.