Research Article Theoretical Model for Predicting Moisture...

Transcript of Research Article Theoretical Model for Predicting Moisture...

Hindawi Publishing CorporationModelling and Simulation in EngineeringVolume 2013 Article ID 491843 7 pageshttpdxdoiorg1011552013491843

Research ArticleTheoretical Model for Predicting Moisture Ratio duringDrying of Spherical Particles in a Rotary Dryer

F T Ademiluyi and M F N Abowei

Department of ChemicalPetrochemical Engineering Rivers State University of Science amp Technology PO Box 5080Port Harcourt 5005 Nigeria

Correspondence should be addressed to F T Ademiluyi ademuluyiyahoocom

Received 3 April 2012 Accepted 8 January 2013

Academic Editor Agostino Bruzzone

Copyright copy 2013 F T Ademiluyi and M F N Abowei This is an open access article distributed under the Creative CommonsAttribution License which permits unrestricted use distribution and reproduction in any medium provided the original work isproperly cited

Amathematical model was developed for predicting the drying kinetics of spherical particles in a rotary dryer Drying experimentswere carried out by drying fermented ground cassava particles in a bench scale rotary dryer at inlet air temperatures of 115ndash230∘Cair velocities of 083msndash155ms feedmass of 50ndash500 g drum drive speed of 8 rpm and feed drive speed of 100 rpm to validate themodel The data obtained from the experiments were used to calculate the experimental moisture ratio which compared well withthe theoretical moisture ratio calculated from the newly developed Abowei-Ademiluyi model The comparisons and correlationsof the results indicate that validation and performance of the established model are rather reasonable

1 Introduction

Rotary drying is a very complicated process that can beapplied not only to thermal drying but also movement ofparticles within the dryer Several authors have carried outinvestigations on the steady state modeling of the rotarydrying process Static models are in general differential equa-tions and they are suitable for investigation of static distribu-tions Myklestad [1] was the first to obtain an expression topredict product moisture content throughout a rotary dryerbased on drying air temperature initialmoisture content andproduct feed rate Thin layer drying equations contribute tothe understanding of the heat and mass transfer phenom-ena in agricultural products and computer simulations fordesigning new and improving existing commercial dryingprocesses [2] They are used to estimate drying times ofseveral products and also to generalize drying curves In thinlayer drying model the rate of change in material moisturecontent in the falling rate drying period is proportional to theinstantaneous difference between material moisture contentand the expected material moisture content when it comesinto equilibrium with the drying air [3]

Many authors have developed semiempirical modelsbased on the diffusion theory to predict the drying kinetics

of moist substances in thin layer as shown in Table 1 (whereMR is the moisture ratio) The constants 119886 119887 119888 119896 119896

119900 1198701

and 119899 in eight models by most authors have been found to befunctions of inlet air temperature inlet air velocity humidityand so forth the mass of feed was not accounted for by all theauthors and in the drying of substances with high moisturecontent like fermented ground cassava dairy products andsome pharmaceutical product in rotary dryer and the massof feed should be accounted for in the thin layer dryingequation It was observed that although several models havebeen proposed there is not a general theory to describe themechanismof rotary drying and it seems that specificmodelsfor an equipment and material are more useful than generalmodels [4]

Therefore the objective of this study is to develop a the-oretical model for predicting the drying kinetics of sphericalparticles in a rotary dryer accounting for the quantity ofmate-rials to be dried in the model

2 Materials and Method

21 Theoretical Development of Thin Layer Drying EquationFickrsquos diffusion equation (1) has been accepted for describing

2 Modelling and Simulation in Engineering

Table 1 Mathematical models given by various authors for the drying curves

Model number Model name Model equation References1 Newton MR = exp(minus119896119905) [5]2 Page MR = exp(minus119896119905

119899

) [6 7]3 Modified page MR = exp(minus(119896119905)

119899

) [8]4 Henderson and Pabis MR = 119886 exp(minus119896119905) [9]5 Logarithmic MR = 119886 exp(minus119896119905) + 119888 [10]6 Two-term MR = 119886 exp(minus119896

119900

119905) + 119887 exp(minus1198961

119905) [11]7 Wang and Singh MR = 1 + 119886119905 + 119887119905

2 [12]8 Ademiluyi-modified page model MR = 119886 exp(minus(119896119905)

119899

) [13ndash15]

Outlet air 120579(1198792 )

Lagging material

Inlet air(1198791 )

119903

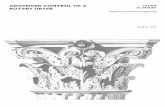

Figure 1 Showing hypothetical profile of moisture diffusion from aspherical particle in a rotary dryer

the drying characteristics of biological and chemical productsin the falling rate period [16] as follows

120597119872

120597119905

=

120597

120597119909

(119863

120597119872

120597119909

) +

120597

120597119910

(119863

120597119872

120597119910

) +

120597

120597119911

(119863

120597119872

120597119911

) (1)

where 119863 is the diffusion coefficient 119872 is moisture content(dry basis) at any time 119905 and 119905 is drying time The equationof diffusion for a spherical particle at constant diffusivity andradial (as shown in Figure 1) flux takes the following form

120597119872

120597119905

= 119863 (

1205972

119872

1205971199032

+

2

119903

120597119872

120597119903

) (2)

In order to solve (2) the following assumptions wereadopted

(1) moisture movement is only diffusion and unidirec-tional

(2) diffusion coefficient 119863 is independent of moistureconcentration

(3) drying process is isothermal that is adiabatic dryer(4) material to be dried is spherical in shape(5) shrinkage is neglected

Using minus1205822 as a separation constant we obtain from (2)

1

119863

119889119872

119889119905

= minus1205822

(3)

(

1205972

119872

1205971199032

+

2

119903

120597119872

120597119903

) = minus1205822

(4)

Integrating (3) using separation of variables gives

119879 = 1198621119890minus120582

2119863119905

(5)

Equation (4) is of the form

1199032

11987710158401015840

+ 21199031198771015840

+ 1205822

1199032

119877 = 0 (6)

Equation (6) is a Bessel equation of order zero the solutionof which is [17]

119877 (119903) = 1198622(120582119903)12

11986912

(120582119903) + 1198623(120582119903)12

119869minus12

(120582119903) (7)

But

11986912

(120582119903) = radic

2

120587 (120582119903)

sin (120582119903)

119869minus12

(120582119903) = radic

2

120587 (120582119903)

cos (120582119903)

(8)

119877 (119903) = radic2

120587120582

[

1198622

119903

sin (120582119903) +

1198623

119903

cos (120582119903)] (9)

Combining (5) and (9) gives 119872(119903 sdot 119905) = 119877(119903)119879(119905) so that

119872 (119903 119905) = 1198621119890minus120582

2119863119905

radic2

120587120582

[

1198622

119903

sin (120582119903) +

1198623

119903

cos (120582119903)]

(10)

and applying the boundary conditions in (11)The solution to(10) in the case of a sphere is expressed as

120597119872

120597119903

= 0 119903 = 0 119903 ge 0

119872 = 119872119890 119903 = 119886 119905 ge 0

119872 = 119872119900 0 le 119903 le 119886 119905 = 0

(11)

MR =

119872119894

minus 119872119890

119872119900

minus 119872119890

=

6

1205872

infin

sum

119899=1

1

1198992

explfloor

minus1198992

1205872

119863

1199032

rfloor 119905 (12)

where 119903 is the radius of sphere MR is moisture ratio 119872119900is

initial moisture content ( db) 119872119890is equilibrium moisture

content ( db) 119872119894is moisture content at time 119905 ( db) and

119905 is drying time (hr)

Modelling and Simulation in Engineering 3

From the work of Abowei [18] the mass of hydrocarbon119872 was accounted for when modeling one-dimensional dif-fusion of oil spill in water and obtain a general solution (see(13)) to predict the diffusion of known quantity of crude oilin water This equation is analogous to the diffusion equation(12) describing diffusion of moisture in porous sphericalparticles as follows

119862119901

=

119872119901

119860[4120587119863119898

119905]12

119890minus119909

24119863119898119905

(gcm3) (13)

where 119872119901is the quantity of oil spilled and 119862

119901is the concen-

tration of oil spilled at any time119860 is the area where oil is spill119863119898is the diffusion coefficient and 119905 is the timeComparing (12) with (13) the term 119872

119901119860[4120587119863

119898119905]12 in

(12) is analogous to the term (61205872

) suminfin

119899=1

(11198992

) in (13) andhence (12) can be rewritten as

MR =

119872119901

120588119860[4120587119863119898

119905]12

explfloor

minus1198992

1205872

119863119898

1199032

rfloor 119905 (14)

whereMR is the moisture ratio 119860 is surface area available formoisture transfer which for the rotary dryer is 120587(119877

2

+ 119877119871)119872119901in equation (14) is now the mass of fermented ground

cassava which is analogous to the119872119901in equation (13) 120588 is the

average density of sample to be dried and the density is added119905119901equation (14) to make the equation dimensionless since

moisture ratio MR is dimensionless so that (14) becomes

MR =

119872119901

120588 (120587 (1198772

+ 119877119871)) [4120587119863119898

119905]12

explfloor

minus1198992

1205872

119863119898

1199032

rfloor 119905

(15)

where 119903 is the average radius of particle to be dried 119877 is theradius of rotary dryer drum 119871 is the length of the rotarydryer and 119863

119898= 119863 is diffusion coefficient = 119863

119900exp(119864

119886119877119879)

where 119864119886is the activation energy Equation (15) is the

new theoretical Abowei-Ademiluyi model for predicting thedrying of any spherical particles in a rotary dryer Equation(15) was simulated to obtain the theoretically determinedmoisture ratio

211 Dimensional Analysis Approach In order to removemoisture from amoistmaterial in a rotary dryer themoistureratio (MR) can be taken to be a function of the change intemperature Δ119879 the quantity of fermented ground cassavato be dried 119872

119901 the latent heat 120582 diameter of particle 119863

to be dried inlet air velocity V and drum speed 119873 so thatmathematically the moisture ratio MR is dimensionless as

MR = 120601 lfloorΔ119879 119872119901

120582 119863 119881 119873rfloor (16)

where 120601 is a correction factorApplying dimensional analysis we have

119872

119872

= 120601 [119879119886

119872119887

(

119865119871

119872

)

119888

119871119889

(

119871

120579

)

119890

(

1

120579

)

119891

] (17)

Applying the Buckingham 120587 method gives

sum 119872 0 = 119887 minus 119888 (18)

sum 119879 0 = 119886 (19)

sum 119871 0 = 119889 + 119890 + 119888 (20)

sum 120579 0 = minus119890 minus 119891 (21)

sum 119865 0 = 119888 (22)

Solving (18) to (22) gives 119886 = 0 119887 = 0 119888 = 0 119889 = minus1 119890 = 1and 119891 = minus1 which

MR = 120601 [

119881119873

119863

] (23)

So that

120601 =

(MR) 119863

119881119873

(24)

The dimensionless constant 120601 can be evaluated theoreticallyand experimentally by substituting forMR in (14) into (24) togive the correction factor as

120601 =

(119872119901

120588119860[4120587119863119898

119905]12

) exp lfloorminus1198992

1205872

119863119898

1199032

rfloor 119905119863

119881119873

(25)

22 Experimental Work In order to validate the modelfermented ground cassava particles was dried in a bench scalerotary dryer (Figure 2)The developed theoretical model (15)was simulated with Microsoft Excel 2007 using the followingdata

(i) average density product (kgm3) = 400 [19](ii) drying time (120ndash1200 secs)-step 60(iii) 119903 = 00175m 119877 = 00508m 119871 = 046m

The diffusion coefficients (119863119879 119863119872 and 119863

119881in m2s) in (26)ndash

(28) were obtained experimentally at different inlet air tem-perature (119879 in ∘C) inlet air velocity (119881 in ms) and mass offeed (119872 in kg) from previous work [15] on fermented groundcassava as follows

119863119879

= 9747 times 10minus8 exp [

minus13892

8314119879

] 1199032

= 0994 (26)

119863119872

= 8938 times 10minus10

+ 5937 times 10minus11

lowast

log (119872)

119872

1199032

= 0986

(27)

119863119881

= 4702 times 10minus9

+ (minus849 times 10minus9

) exp (minus119881) 1199032

= 0990

(28)

221 Sample Preparation The cassava cultivar used in thisstudy is TMS 30572 obtained from Rivers State Agricultural

4 Modelling and Simulation in Engineering

1 2 3

4 5

6

7

8

9

10

11

1213

14

16

15

Figure 2 Schematic diagram of bench scale rotary dryer (1) cyclone (2 and 4) probe connections (3) rotary drum (5) feed hopper (6)feed drive (7) electric heater arrangement (8 and 15) sight glasses (9) air blower and orifice plate control (10) support (11) control box (12)chain drive (13 and 14) dried product receivers and (16) steel table

Development Project farm (ADP) at Rumuokoro Port Har-court The choice of this cassava cultivar TMS 30572 wasbased on its preference by farmers because of its high yieldand suitability for gari processing [20] The cassava cultivarwas peeled washed grated and packed in sack for pressingThe dewatered mash was allowed to ferment naturally for72 hrs sieved with a mesh of 35mm and then dried in abench rotary dryer (Figure 2)

222 Experimental Procedure At the beginning of eachexperiment the dryer was allowed to reach steady state at thedesired airflow rate inlet air temperature feed drive speedand drum drive speed When steady state condition hadbeen attained the fermented ground cassava mash of knownmoisture content was introduced into the dryer feed hopperThe drying conditions used in the experiments are inlet airtemperatures of 115∘C 140∘C 190∘C and 230∘C air velocitiesof 083 102 1397 and 155ms mass of feed of 50 g 100 g200 g and 500 g feed drive speeds 100 rpm and drum drivespeeds of 8 rpmThe decrease inmass of fermentedmash wasmonitored with time per pass The initial moisture contentof samples was determined separately before start of exper-iment The weight loss during drying was used to calculatethe moisture content The drying data obtained were used tocalculate the experimental moisture ratio (MR) to predict thekinetics of drying fermented ground cassava

3 Results and Discussion

31 Simulated Theoretical Results The theoretical moistureratio results are presented in Figures 3 5 and 7 The theo-retical moisture ratio decreases with drying time as inlet air

14

12

1

08

06

04

02

00 200 400 600 800 1000 1200

Drying time (s)

Theo

retic

al m

oistu

re ra

tio

115∘C

140∘C

190∘C

230∘C

Figure 3 Variation of moisture ratio with time at different air inlettemperatures using the theoretical model

temperature inlet air velocity and mass of feed increases Asimilar profile is also exhibited in Figures 4 6 and 8 for theexperimental moisture ratio The theoretical moisture ratioplots show a typical drying curve generally obtained duringdrying of moist materials [3 21]

It can be observed from the theoretical moisture ratioplots that the Abowei-Ademiluyi model does not give valuesfor moisture ratio at 119905 = 0 and this will not be a problemsince the initial moisture content from which the moistureratio at 119905 = 0 (ie 119872

119900) was calculated is always known at

start of drying Hence the Abowei-Ademiluyi model can beused to predict the drying kinetics of spherical particles at any

Modelling and Simulation in Engineering 5

14

12

1

08

06

04

02

00 2 4 6 8 10 12

Drying time (min)

Expe

rimen

tal m

oistu

re ra

tio

115∘C

140∘C

190∘C

230∘C

Figure 4 Experimental moisture ratio at different inlet tempera-ture

1412

1816

1

2

08060402

00 200 400 600 800 1000 1200 1400

Drying time (s)

Theo

retic

al m

oistu

re ra

tio

083ms102ms

1397ms155ms

Figure 5 Variation of moisture ratio with time at different inlet airvelocity using the theoretical model

14

12

1

08

06

04

02

00 10 20 30 40 50

Drying time (min)

083ms102ms

1397ms155ms

Expe

rimen

tal m

oistu

re ra

tio

Figure 6 Experimental moisture ratio at different inlet air velocity

known particle diameter rotary drum diameter and dryerlength once the diffusion coefficient is known

35

30

25

20

15

10

5

00 200 400 600 800 1000 1200 1400 1600

Drying time (s)

Theo

retic

al m

oistu

re ra

tio

100 g250 g

500 g1000 g

Figure 7 Variation of moisture ratio with time at different mass offeed using the theoretical model

100 g250 g50 g500 g

14

12

1

08

06

04

02

00

5 10 15 20 25 30Drying time (min)

Expe

rimen

tal m

oistu

re ra

tio

Figure 8 Experimental moisture ratio at different mass of feed

32 Comparison ofTheoretical and Experimented Results Thesimulated theoretical result compared favorably with thoseof the experimental results The similarity is shown from thehigh value (119903 close to 1) obtained for the coefficient ofmultipledeterminations 119877

2 at different inlet air temperature and inletair velocity as shown in Figures 9 and 10 However better fitcould be obtained if the average density particle is correctlychosenThe theoretical (Abowei-Ademiluyi model) moistureratio also compared well with experimentally moisture ratioat different mass of feed as shown in Figure 11

4 Conclusion

The new theoretical Abowei-Ademiluyi model has beendeveloped for predicting drying kinetics of spherical particlesat any known particle diameter rotary drum diameter anddryer length The new model also account for the mass offeed Model validation was carried out by drying fermentedground cassava particles in a bench scale rotary dryer atinlet air temperatures of 115ndash230∘C air velocities of 083msndash155ms feed mass of 50ndash500 g drum drive speed of 8 rpm

6 Modelling and Simulation in Engineering

14

14

12

12

1

1

08

08

06

06

04

04

02

020

0

Theo

retic

al m

oistu

re ra

tio

Experimental moisture ratio

1198772= 09828

1198772= 09955

1198772= 09962

1198772= 09997

115∘C

140∘C

190∘C

230∘C

Figure 9Theoretical (Abowei-Ademiluyi model) and experimentalmoisture ratios at different inlet air temperature

083ms102ms1397ms155ms

14

14

12

12

1

1

08

08

06

06

04

04

02

020

0

Theo

retic

al m

oistu

re ra

tio

Experimental moisture ratio

1198772= 09974

1198772= 09978

1198772= 09839

1198772= 099

Figure 10 Theoretical (Abowei-Ademiluyi model) and experimen-tal moisture ratios at different inlet air velocity

14

14

12

12

1

1

08

08

06

06

04

04

02

020

0

Theo

retic

al m

oistu

re ra

tio

Experimental moisture ratio

500 g250g100 g50g

1198772= 09934

1198772= 09887

1198772= 09991

1198772= 09934

Figure 11 Theoretical (Abowei-Ademiluyi model) and experimen-tal moisture ratios at different mass of feed

and feed drive speed of 100 rpm The theoretical moistureratio calculated from the model compared favorably withexperimental moisture ratio

References

[1] O Myklestad ldquoHeat and mass transfer in rotary dryersrdquo Chem-ical Engineering Progress Symposium Series vol 59 no 41 pp129ndash137 1963

[2] D S Jayas S Cenkowski S Pabis and W E Muir ldquoReview ofthin-layer drying and wetting equationsrdquo Drying Technologyvol 9 no 3 pp 551ndash588 1991

[3] H O Menges and C Ertekin ldquoMathematical modeling of thinlayer drying of Golden applesrdquo Journal of Food Engineering vol77 no 1 pp 119ndash125 2006

[4] A Iguaz A Esnoz G Martınez A Lopez and P VırsedaldquoMathematical modelling and simulation for the drying processof vegetable wholesale by-products in a rotary dryerrdquo Journal ofFood Engineering vol 59 no 2-3 pp 151ndash160 2003

[5] Q Liu and FW Bakker-Arkema ldquoStochastic modelling of graindrying part 2 Model developmentrdquo Journal of AgriculturalEngineering Research vol 66 no 4 pp 275ndash280 1997

[6] Y C Agrawal and R P Singh ldquoThin layer drying studies onshort grain rough icerdquo ASAE Paper 3531 1977

[7] Q Zhang and J B Litchfield ldquoOptimization of intermittent corndrying in a laboratory scale thin layer dryerrdquoDrying Technologyvol 9 no 1 pp 233ndash244 1991

[8] G M White T C Bridges O J Loewer and I J Ross ldquoThinlayer drying model for soybeansrdquo Transactions of the AmericanSociety of Agricultural Engineers vol 24 no 6 pp 1643ndash16461981

[9] M S Chhinnan ldquoEvaluation of selected mathematical modelsfor describing thin-layer drying of in-shell pecansrdquoTransactionsof the American Society of Agricultural Engineers vol 27 no 2pp 610ndash615 1984

[10] A Yagcıoglu A Degirmencioglu and F Cagatay ldquoDrying char-acteristics of laurel leaves under different drying conditionsrdquoin Proceedings of the 7th International Congress on AgriculturalMechanization and Energy pp 565ndash569 Adana Turkey May1999

[11] M S Rahman C O Perera and C Thebaud ldquoDesorptionisotherm and heat pump drying kinetics of peasrdquo Food ResearchInternational vol 30 no 7 pp 485ndash491 1997

[12] C Y Wang and R P Singh ldquoUse of variable equilibrium mois-ture content in modelling rice dryingrdquo ASAE Paper 78-6505ASAE Press St Joseph Mich USA 1978

[13] T Ademiluyi K Oduola and J Eke ldquoMathematical modelingof drying different Cassava Chips in thin layersrdquo Journal ofNigerian Society of Chemical Engineers vol 22 p 148 2007

[14] T Ademiluyi E O Oboho and M Owudogu ldquoInvestigationinto the thin layer dryingmodels ofNigerian popcorn varietiesrdquoLeonardo Electronic Journal of Practices and Technologies vol 7no 13 pp 047ndash062 2008

[15] T Ademiluyi Development of predictive models for drying fer-mented ground cassava [PhD thesis] River State University ofScience and Technology Port Harcourt Nigeria 2009

[16] W L McCabe J C Smith and P Harriott Unit Operations ofChemical EngineeringMcGraw-Hill BookCompanyNewYorkNY USA 4th edition 1987

[17] K A Stroud Advance Engineering Mathematics Palgrave Mac-milian Hampshire UK 4th edition 2003

Modelling and Simulation in Engineering 7

[18] M F N Abowei Prediction model development for simulationof petroleum weathering process in aquatic environment [PhDthesis] Department of Chemical Engineering University ofLagos Lagos Nigeria 1991

[19] T Ademiluyi M F N Abowei Y T Puyate and S CAchinewhu ldquoEffect of variety on the drying and engineeringproperties of fermented ground cassavardquo Journal of Newviewsin Engineering analysis and Modelling pp 80ndash79 2006

[20] E Joy physicochemical and pasting properties of tapioca fromdifferent cassava cultivars in food science and technology [PhDthesis] River State University of Science and Technology PortHarcourt Nigeria 2006

[21] O Bozkir ldquoThin-layer drying and mathematical modelling forwashed dry apricotsrdquo Journal of Food Engineering vol 77 no 1pp 146ndash151 2006

International Journal of

AerospaceEngineeringHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

RoboticsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Active and Passive Electronic Components

Control Scienceand Engineering

Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

International Journal of

RotatingMachinery

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporation httpwwwhindawicom

Journal ofEngineeringVolume 2014

Submit your manuscripts athttpwwwhindawicom

VLSI Design

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Shock and Vibration

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Civil EngineeringAdvances in

Acoustics and VibrationAdvances in

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Electrical and Computer Engineering

Journal of

Advances inOptoElectronics

Hindawi Publishing Corporation httpwwwhindawicom

Volume 2014

The Scientific World JournalHindawi Publishing Corporation httpwwwhindawicom Volume 2014

SensorsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Modelling amp Simulation in EngineeringHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Chemical EngineeringInternational Journal of Antennas and

Propagation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Navigation and Observation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

DistributedSensor Networks

International Journal of

2 Modelling and Simulation in Engineering

Table 1 Mathematical models given by various authors for the drying curves

Model number Model name Model equation References1 Newton MR = exp(minus119896119905) [5]2 Page MR = exp(minus119896119905

119899

) [6 7]3 Modified page MR = exp(minus(119896119905)

119899

) [8]4 Henderson and Pabis MR = 119886 exp(minus119896119905) [9]5 Logarithmic MR = 119886 exp(minus119896119905) + 119888 [10]6 Two-term MR = 119886 exp(minus119896

119900

119905) + 119887 exp(minus1198961

119905) [11]7 Wang and Singh MR = 1 + 119886119905 + 119887119905

2 [12]8 Ademiluyi-modified page model MR = 119886 exp(minus(119896119905)

119899

) [13ndash15]

Outlet air 120579(1198792 )

Lagging material

Inlet air(1198791 )

119903

Figure 1 Showing hypothetical profile of moisture diffusion from aspherical particle in a rotary dryer

the drying characteristics of biological and chemical productsin the falling rate period [16] as follows

120597119872

120597119905

=

120597

120597119909

(119863

120597119872

120597119909

) +

120597

120597119910

(119863

120597119872

120597119910

) +

120597

120597119911

(119863

120597119872

120597119911

) (1)

where 119863 is the diffusion coefficient 119872 is moisture content(dry basis) at any time 119905 and 119905 is drying time The equationof diffusion for a spherical particle at constant diffusivity andradial (as shown in Figure 1) flux takes the following form

120597119872

120597119905

= 119863 (

1205972

119872

1205971199032

+

2

119903

120597119872

120597119903

) (2)

In order to solve (2) the following assumptions wereadopted

(1) moisture movement is only diffusion and unidirec-tional

(2) diffusion coefficient 119863 is independent of moistureconcentration

(3) drying process is isothermal that is adiabatic dryer(4) material to be dried is spherical in shape(5) shrinkage is neglected

Using minus1205822 as a separation constant we obtain from (2)

1

119863

119889119872

119889119905

= minus1205822

(3)

(

1205972

119872

1205971199032

+

2

119903

120597119872

120597119903

) = minus1205822

(4)

Integrating (3) using separation of variables gives

119879 = 1198621119890minus120582

2119863119905

(5)

Equation (4) is of the form

1199032

11987710158401015840

+ 21199031198771015840

+ 1205822

1199032

119877 = 0 (6)

Equation (6) is a Bessel equation of order zero the solutionof which is [17]

119877 (119903) = 1198622(120582119903)12

11986912

(120582119903) + 1198623(120582119903)12

119869minus12

(120582119903) (7)

But

11986912

(120582119903) = radic

2

120587 (120582119903)

sin (120582119903)

119869minus12

(120582119903) = radic

2

120587 (120582119903)

cos (120582119903)

(8)

119877 (119903) = radic2

120587120582

[

1198622

119903

sin (120582119903) +

1198623

119903

cos (120582119903)] (9)

Combining (5) and (9) gives 119872(119903 sdot 119905) = 119877(119903)119879(119905) so that

119872 (119903 119905) = 1198621119890minus120582

2119863119905

radic2

120587120582

[

1198622

119903

sin (120582119903) +

1198623

119903

cos (120582119903)]

(10)

and applying the boundary conditions in (11)The solution to(10) in the case of a sphere is expressed as

120597119872

120597119903

= 0 119903 = 0 119903 ge 0

119872 = 119872119890 119903 = 119886 119905 ge 0

119872 = 119872119900 0 le 119903 le 119886 119905 = 0

(11)

MR =

119872119894

minus 119872119890

119872119900

minus 119872119890

=

6

1205872

infin

sum

119899=1

1

1198992

explfloor

minus1198992

1205872

119863

1199032

rfloor 119905 (12)

where 119903 is the radius of sphere MR is moisture ratio 119872119900is

initial moisture content ( db) 119872119890is equilibrium moisture

content ( db) 119872119894is moisture content at time 119905 ( db) and

119905 is drying time (hr)

Modelling and Simulation in Engineering 3

From the work of Abowei [18] the mass of hydrocarbon119872 was accounted for when modeling one-dimensional dif-fusion of oil spill in water and obtain a general solution (see(13)) to predict the diffusion of known quantity of crude oilin water This equation is analogous to the diffusion equation(12) describing diffusion of moisture in porous sphericalparticles as follows

119862119901

=

119872119901

119860[4120587119863119898

119905]12

119890minus119909

24119863119898119905

(gcm3) (13)

where 119872119901is the quantity of oil spilled and 119862

119901is the concen-

tration of oil spilled at any time119860 is the area where oil is spill119863119898is the diffusion coefficient and 119905 is the timeComparing (12) with (13) the term 119872

119901119860[4120587119863

119898119905]12 in

(12) is analogous to the term (61205872

) suminfin

119899=1

(11198992

) in (13) andhence (12) can be rewritten as

MR =

119872119901

120588119860[4120587119863119898

119905]12

explfloor

minus1198992

1205872

119863119898

1199032

rfloor 119905 (14)

whereMR is the moisture ratio 119860 is surface area available formoisture transfer which for the rotary dryer is 120587(119877

2

+ 119877119871)119872119901in equation (14) is now the mass of fermented ground

cassava which is analogous to the119872119901in equation (13) 120588 is the

average density of sample to be dried and the density is added119905119901equation (14) to make the equation dimensionless since

moisture ratio MR is dimensionless so that (14) becomes

MR =

119872119901

120588 (120587 (1198772

+ 119877119871)) [4120587119863119898

119905]12

explfloor

minus1198992

1205872

119863119898

1199032

rfloor 119905

(15)

where 119903 is the average radius of particle to be dried 119877 is theradius of rotary dryer drum 119871 is the length of the rotarydryer and 119863

119898= 119863 is diffusion coefficient = 119863

119900exp(119864

119886119877119879)

where 119864119886is the activation energy Equation (15) is the

new theoretical Abowei-Ademiluyi model for predicting thedrying of any spherical particles in a rotary dryer Equation(15) was simulated to obtain the theoretically determinedmoisture ratio

211 Dimensional Analysis Approach In order to removemoisture from amoistmaterial in a rotary dryer themoistureratio (MR) can be taken to be a function of the change intemperature Δ119879 the quantity of fermented ground cassavato be dried 119872

119901 the latent heat 120582 diameter of particle 119863

to be dried inlet air velocity V and drum speed 119873 so thatmathematically the moisture ratio MR is dimensionless as

MR = 120601 lfloorΔ119879 119872119901

120582 119863 119881 119873rfloor (16)

where 120601 is a correction factorApplying dimensional analysis we have

119872

119872

= 120601 [119879119886

119872119887

(

119865119871

119872

)

119888

119871119889

(

119871

120579

)

119890

(

1

120579

)

119891

] (17)

Applying the Buckingham 120587 method gives

sum 119872 0 = 119887 minus 119888 (18)

sum 119879 0 = 119886 (19)

sum 119871 0 = 119889 + 119890 + 119888 (20)

sum 120579 0 = minus119890 minus 119891 (21)

sum 119865 0 = 119888 (22)

Solving (18) to (22) gives 119886 = 0 119887 = 0 119888 = 0 119889 = minus1 119890 = 1and 119891 = minus1 which

MR = 120601 [

119881119873

119863

] (23)

So that

120601 =

(MR) 119863

119881119873

(24)

The dimensionless constant 120601 can be evaluated theoreticallyand experimentally by substituting forMR in (14) into (24) togive the correction factor as

120601 =

(119872119901

120588119860[4120587119863119898

119905]12

) exp lfloorminus1198992

1205872

119863119898

1199032

rfloor 119905119863

119881119873

(25)

22 Experimental Work In order to validate the modelfermented ground cassava particles was dried in a bench scalerotary dryer (Figure 2)The developed theoretical model (15)was simulated with Microsoft Excel 2007 using the followingdata

(i) average density product (kgm3) = 400 [19](ii) drying time (120ndash1200 secs)-step 60(iii) 119903 = 00175m 119877 = 00508m 119871 = 046m

The diffusion coefficients (119863119879 119863119872 and 119863

119881in m2s) in (26)ndash

(28) were obtained experimentally at different inlet air tem-perature (119879 in ∘C) inlet air velocity (119881 in ms) and mass offeed (119872 in kg) from previous work [15] on fermented groundcassava as follows

119863119879

= 9747 times 10minus8 exp [

minus13892

8314119879

] 1199032

= 0994 (26)

119863119872

= 8938 times 10minus10

+ 5937 times 10minus11

lowast

log (119872)

119872

1199032

= 0986

(27)

119863119881

= 4702 times 10minus9

+ (minus849 times 10minus9

) exp (minus119881) 1199032

= 0990

(28)

221 Sample Preparation The cassava cultivar used in thisstudy is TMS 30572 obtained from Rivers State Agricultural

4 Modelling and Simulation in Engineering

1 2 3

4 5

6

7

8

9

10

11

1213

14

16

15

Figure 2 Schematic diagram of bench scale rotary dryer (1) cyclone (2 and 4) probe connections (3) rotary drum (5) feed hopper (6)feed drive (7) electric heater arrangement (8 and 15) sight glasses (9) air blower and orifice plate control (10) support (11) control box (12)chain drive (13 and 14) dried product receivers and (16) steel table

Development Project farm (ADP) at Rumuokoro Port Har-court The choice of this cassava cultivar TMS 30572 wasbased on its preference by farmers because of its high yieldand suitability for gari processing [20] The cassava cultivarwas peeled washed grated and packed in sack for pressingThe dewatered mash was allowed to ferment naturally for72 hrs sieved with a mesh of 35mm and then dried in abench rotary dryer (Figure 2)

222 Experimental Procedure At the beginning of eachexperiment the dryer was allowed to reach steady state at thedesired airflow rate inlet air temperature feed drive speedand drum drive speed When steady state condition hadbeen attained the fermented ground cassava mash of knownmoisture content was introduced into the dryer feed hopperThe drying conditions used in the experiments are inlet airtemperatures of 115∘C 140∘C 190∘C and 230∘C air velocitiesof 083 102 1397 and 155ms mass of feed of 50 g 100 g200 g and 500 g feed drive speeds 100 rpm and drum drivespeeds of 8 rpmThe decrease inmass of fermentedmash wasmonitored with time per pass The initial moisture contentof samples was determined separately before start of exper-iment The weight loss during drying was used to calculatethe moisture content The drying data obtained were used tocalculate the experimental moisture ratio (MR) to predict thekinetics of drying fermented ground cassava

3 Results and Discussion

31 Simulated Theoretical Results The theoretical moistureratio results are presented in Figures 3 5 and 7 The theo-retical moisture ratio decreases with drying time as inlet air

14

12

1

08

06

04

02

00 200 400 600 800 1000 1200

Drying time (s)

Theo

retic

al m

oistu

re ra

tio

115∘C

140∘C

190∘C

230∘C

Figure 3 Variation of moisture ratio with time at different air inlettemperatures using the theoretical model

temperature inlet air velocity and mass of feed increases Asimilar profile is also exhibited in Figures 4 6 and 8 for theexperimental moisture ratio The theoretical moisture ratioplots show a typical drying curve generally obtained duringdrying of moist materials [3 21]

It can be observed from the theoretical moisture ratioplots that the Abowei-Ademiluyi model does not give valuesfor moisture ratio at 119905 = 0 and this will not be a problemsince the initial moisture content from which the moistureratio at 119905 = 0 (ie 119872

119900) was calculated is always known at

start of drying Hence the Abowei-Ademiluyi model can beused to predict the drying kinetics of spherical particles at any

Modelling and Simulation in Engineering 5

14

12

1

08

06

04

02

00 2 4 6 8 10 12

Drying time (min)

Expe

rimen

tal m

oistu

re ra

tio

115∘C

140∘C

190∘C

230∘C

Figure 4 Experimental moisture ratio at different inlet tempera-ture

1412

1816

1

2

08060402

00 200 400 600 800 1000 1200 1400

Drying time (s)

Theo

retic

al m

oistu

re ra

tio

083ms102ms

1397ms155ms

Figure 5 Variation of moisture ratio with time at different inlet airvelocity using the theoretical model

14

12

1

08

06

04

02

00 10 20 30 40 50

Drying time (min)

083ms102ms

1397ms155ms

Expe

rimen

tal m

oistu

re ra

tio

Figure 6 Experimental moisture ratio at different inlet air velocity

known particle diameter rotary drum diameter and dryerlength once the diffusion coefficient is known

35

30

25

20

15

10

5

00 200 400 600 800 1000 1200 1400 1600

Drying time (s)

Theo

retic

al m

oistu

re ra

tio

100 g250 g

500 g1000 g

Figure 7 Variation of moisture ratio with time at different mass offeed using the theoretical model

100 g250 g50 g500 g

14

12

1

08

06

04

02

00

5 10 15 20 25 30Drying time (min)

Expe

rimen

tal m

oistu

re ra

tio

Figure 8 Experimental moisture ratio at different mass of feed

32 Comparison ofTheoretical and Experimented Results Thesimulated theoretical result compared favorably with thoseof the experimental results The similarity is shown from thehigh value (119903 close to 1) obtained for the coefficient ofmultipledeterminations 119877

2 at different inlet air temperature and inletair velocity as shown in Figures 9 and 10 However better fitcould be obtained if the average density particle is correctlychosenThe theoretical (Abowei-Ademiluyi model) moistureratio also compared well with experimentally moisture ratioat different mass of feed as shown in Figure 11

4 Conclusion

The new theoretical Abowei-Ademiluyi model has beendeveloped for predicting drying kinetics of spherical particlesat any known particle diameter rotary drum diameter anddryer length The new model also account for the mass offeed Model validation was carried out by drying fermentedground cassava particles in a bench scale rotary dryer atinlet air temperatures of 115ndash230∘C air velocities of 083msndash155ms feed mass of 50ndash500 g drum drive speed of 8 rpm

6 Modelling and Simulation in Engineering

14

14

12

12

1

1

08

08

06

06

04

04

02

020

0

Theo

retic

al m

oistu

re ra

tio

Experimental moisture ratio

1198772= 09828

1198772= 09955

1198772= 09962

1198772= 09997

115∘C

140∘C

190∘C

230∘C

Figure 9Theoretical (Abowei-Ademiluyi model) and experimentalmoisture ratios at different inlet air temperature

083ms102ms1397ms155ms

14

14

12

12

1

1

08

08

06

06

04

04

02

020

0

Theo

retic

al m

oistu

re ra

tio

Experimental moisture ratio

1198772= 09974

1198772= 09978

1198772= 09839

1198772= 099

Figure 10 Theoretical (Abowei-Ademiluyi model) and experimen-tal moisture ratios at different inlet air velocity

14

14

12

12

1

1

08

08

06

06

04

04

02

020

0

Theo

retic

al m

oistu

re ra

tio

Experimental moisture ratio

500 g250g100 g50g

1198772= 09934

1198772= 09887

1198772= 09991

1198772= 09934

Figure 11 Theoretical (Abowei-Ademiluyi model) and experimen-tal moisture ratios at different mass of feed

and feed drive speed of 100 rpm The theoretical moistureratio calculated from the model compared favorably withexperimental moisture ratio

References

[1] O Myklestad ldquoHeat and mass transfer in rotary dryersrdquo Chem-ical Engineering Progress Symposium Series vol 59 no 41 pp129ndash137 1963

[2] D S Jayas S Cenkowski S Pabis and W E Muir ldquoReview ofthin-layer drying and wetting equationsrdquo Drying Technologyvol 9 no 3 pp 551ndash588 1991

[3] H O Menges and C Ertekin ldquoMathematical modeling of thinlayer drying of Golden applesrdquo Journal of Food Engineering vol77 no 1 pp 119ndash125 2006

[4] A Iguaz A Esnoz G Martınez A Lopez and P VırsedaldquoMathematical modelling and simulation for the drying processof vegetable wholesale by-products in a rotary dryerrdquo Journal ofFood Engineering vol 59 no 2-3 pp 151ndash160 2003

[5] Q Liu and FW Bakker-Arkema ldquoStochastic modelling of graindrying part 2 Model developmentrdquo Journal of AgriculturalEngineering Research vol 66 no 4 pp 275ndash280 1997

[6] Y C Agrawal and R P Singh ldquoThin layer drying studies onshort grain rough icerdquo ASAE Paper 3531 1977

[7] Q Zhang and J B Litchfield ldquoOptimization of intermittent corndrying in a laboratory scale thin layer dryerrdquoDrying Technologyvol 9 no 1 pp 233ndash244 1991

[8] G M White T C Bridges O J Loewer and I J Ross ldquoThinlayer drying model for soybeansrdquo Transactions of the AmericanSociety of Agricultural Engineers vol 24 no 6 pp 1643ndash16461981

[9] M S Chhinnan ldquoEvaluation of selected mathematical modelsfor describing thin-layer drying of in-shell pecansrdquoTransactionsof the American Society of Agricultural Engineers vol 27 no 2pp 610ndash615 1984

[10] A Yagcıoglu A Degirmencioglu and F Cagatay ldquoDrying char-acteristics of laurel leaves under different drying conditionsrdquoin Proceedings of the 7th International Congress on AgriculturalMechanization and Energy pp 565ndash569 Adana Turkey May1999

[11] M S Rahman C O Perera and C Thebaud ldquoDesorptionisotherm and heat pump drying kinetics of peasrdquo Food ResearchInternational vol 30 no 7 pp 485ndash491 1997

[12] C Y Wang and R P Singh ldquoUse of variable equilibrium mois-ture content in modelling rice dryingrdquo ASAE Paper 78-6505ASAE Press St Joseph Mich USA 1978

[13] T Ademiluyi K Oduola and J Eke ldquoMathematical modelingof drying different Cassava Chips in thin layersrdquo Journal ofNigerian Society of Chemical Engineers vol 22 p 148 2007

[14] T Ademiluyi E O Oboho and M Owudogu ldquoInvestigationinto the thin layer dryingmodels ofNigerian popcorn varietiesrdquoLeonardo Electronic Journal of Practices and Technologies vol 7no 13 pp 047ndash062 2008

[15] T Ademiluyi Development of predictive models for drying fer-mented ground cassava [PhD thesis] River State University ofScience and Technology Port Harcourt Nigeria 2009

[16] W L McCabe J C Smith and P Harriott Unit Operations ofChemical EngineeringMcGraw-Hill BookCompanyNewYorkNY USA 4th edition 1987

[17] K A Stroud Advance Engineering Mathematics Palgrave Mac-milian Hampshire UK 4th edition 2003

Modelling and Simulation in Engineering 7

[18] M F N Abowei Prediction model development for simulationof petroleum weathering process in aquatic environment [PhDthesis] Department of Chemical Engineering University ofLagos Lagos Nigeria 1991

[19] T Ademiluyi M F N Abowei Y T Puyate and S CAchinewhu ldquoEffect of variety on the drying and engineeringproperties of fermented ground cassavardquo Journal of Newviewsin Engineering analysis and Modelling pp 80ndash79 2006

[20] E Joy physicochemical and pasting properties of tapioca fromdifferent cassava cultivars in food science and technology [PhDthesis] River State University of Science and Technology PortHarcourt Nigeria 2006

[21] O Bozkir ldquoThin-layer drying and mathematical modelling forwashed dry apricotsrdquo Journal of Food Engineering vol 77 no 1pp 146ndash151 2006

International Journal of

AerospaceEngineeringHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

RoboticsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Active and Passive Electronic Components

Control Scienceand Engineering

Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

International Journal of

RotatingMachinery

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporation httpwwwhindawicom

Journal ofEngineeringVolume 2014

Submit your manuscripts athttpwwwhindawicom

VLSI Design

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Shock and Vibration

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Civil EngineeringAdvances in

Acoustics and VibrationAdvances in

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Electrical and Computer Engineering

Journal of

Advances inOptoElectronics

Hindawi Publishing Corporation httpwwwhindawicom

Volume 2014

The Scientific World JournalHindawi Publishing Corporation httpwwwhindawicom Volume 2014

SensorsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Modelling amp Simulation in EngineeringHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Chemical EngineeringInternational Journal of Antennas and

Propagation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Navigation and Observation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

DistributedSensor Networks

International Journal of

Modelling and Simulation in Engineering 3

From the work of Abowei [18] the mass of hydrocarbon119872 was accounted for when modeling one-dimensional dif-fusion of oil spill in water and obtain a general solution (see(13)) to predict the diffusion of known quantity of crude oilin water This equation is analogous to the diffusion equation(12) describing diffusion of moisture in porous sphericalparticles as follows

119862119901

=

119872119901

119860[4120587119863119898

119905]12

119890minus119909

24119863119898119905

(gcm3) (13)

where 119872119901is the quantity of oil spilled and 119862

119901is the concen-

tration of oil spilled at any time119860 is the area where oil is spill119863119898is the diffusion coefficient and 119905 is the timeComparing (12) with (13) the term 119872

119901119860[4120587119863

119898119905]12 in

(12) is analogous to the term (61205872

) suminfin

119899=1

(11198992

) in (13) andhence (12) can be rewritten as

MR =

119872119901

120588119860[4120587119863119898

119905]12

explfloor

minus1198992

1205872

119863119898

1199032

rfloor 119905 (14)

whereMR is the moisture ratio 119860 is surface area available formoisture transfer which for the rotary dryer is 120587(119877

2

+ 119877119871)119872119901in equation (14) is now the mass of fermented ground

cassava which is analogous to the119872119901in equation (13) 120588 is the

average density of sample to be dried and the density is added119905119901equation (14) to make the equation dimensionless since

moisture ratio MR is dimensionless so that (14) becomes

MR =

119872119901

120588 (120587 (1198772

+ 119877119871)) [4120587119863119898

119905]12

explfloor

minus1198992

1205872

119863119898

1199032

rfloor 119905

(15)

where 119903 is the average radius of particle to be dried 119877 is theradius of rotary dryer drum 119871 is the length of the rotarydryer and 119863

119898= 119863 is diffusion coefficient = 119863

119900exp(119864

119886119877119879)

where 119864119886is the activation energy Equation (15) is the

new theoretical Abowei-Ademiluyi model for predicting thedrying of any spherical particles in a rotary dryer Equation(15) was simulated to obtain the theoretically determinedmoisture ratio

211 Dimensional Analysis Approach In order to removemoisture from amoistmaterial in a rotary dryer themoistureratio (MR) can be taken to be a function of the change intemperature Δ119879 the quantity of fermented ground cassavato be dried 119872

119901 the latent heat 120582 diameter of particle 119863

to be dried inlet air velocity V and drum speed 119873 so thatmathematically the moisture ratio MR is dimensionless as

MR = 120601 lfloorΔ119879 119872119901

120582 119863 119881 119873rfloor (16)

where 120601 is a correction factorApplying dimensional analysis we have

119872

119872

= 120601 [119879119886

119872119887

(

119865119871

119872

)

119888

119871119889

(

119871

120579

)

119890

(

1

120579

)

119891

] (17)

Applying the Buckingham 120587 method gives

sum 119872 0 = 119887 minus 119888 (18)

sum 119879 0 = 119886 (19)

sum 119871 0 = 119889 + 119890 + 119888 (20)

sum 120579 0 = minus119890 minus 119891 (21)

sum 119865 0 = 119888 (22)

Solving (18) to (22) gives 119886 = 0 119887 = 0 119888 = 0 119889 = minus1 119890 = 1and 119891 = minus1 which

MR = 120601 [

119881119873

119863

] (23)

So that

120601 =

(MR) 119863

119881119873

(24)

The dimensionless constant 120601 can be evaluated theoreticallyand experimentally by substituting forMR in (14) into (24) togive the correction factor as

120601 =

(119872119901

120588119860[4120587119863119898

119905]12

) exp lfloorminus1198992

1205872

119863119898

1199032

rfloor 119905119863

119881119873

(25)

22 Experimental Work In order to validate the modelfermented ground cassava particles was dried in a bench scalerotary dryer (Figure 2)The developed theoretical model (15)was simulated with Microsoft Excel 2007 using the followingdata

(i) average density product (kgm3) = 400 [19](ii) drying time (120ndash1200 secs)-step 60(iii) 119903 = 00175m 119877 = 00508m 119871 = 046m

The diffusion coefficients (119863119879 119863119872 and 119863

119881in m2s) in (26)ndash

(28) were obtained experimentally at different inlet air tem-perature (119879 in ∘C) inlet air velocity (119881 in ms) and mass offeed (119872 in kg) from previous work [15] on fermented groundcassava as follows

119863119879

= 9747 times 10minus8 exp [

minus13892

8314119879

] 1199032

= 0994 (26)

119863119872

= 8938 times 10minus10

+ 5937 times 10minus11

lowast

log (119872)

119872

1199032

= 0986

(27)

119863119881

= 4702 times 10minus9

+ (minus849 times 10minus9

) exp (minus119881) 1199032

= 0990

(28)

221 Sample Preparation The cassava cultivar used in thisstudy is TMS 30572 obtained from Rivers State Agricultural

4 Modelling and Simulation in Engineering

1 2 3

4 5

6

7

8

9

10

11

1213

14

16

15

Figure 2 Schematic diagram of bench scale rotary dryer (1) cyclone (2 and 4) probe connections (3) rotary drum (5) feed hopper (6)feed drive (7) electric heater arrangement (8 and 15) sight glasses (9) air blower and orifice plate control (10) support (11) control box (12)chain drive (13 and 14) dried product receivers and (16) steel table

Development Project farm (ADP) at Rumuokoro Port Har-court The choice of this cassava cultivar TMS 30572 wasbased on its preference by farmers because of its high yieldand suitability for gari processing [20] The cassava cultivarwas peeled washed grated and packed in sack for pressingThe dewatered mash was allowed to ferment naturally for72 hrs sieved with a mesh of 35mm and then dried in abench rotary dryer (Figure 2)

222 Experimental Procedure At the beginning of eachexperiment the dryer was allowed to reach steady state at thedesired airflow rate inlet air temperature feed drive speedand drum drive speed When steady state condition hadbeen attained the fermented ground cassava mash of knownmoisture content was introduced into the dryer feed hopperThe drying conditions used in the experiments are inlet airtemperatures of 115∘C 140∘C 190∘C and 230∘C air velocitiesof 083 102 1397 and 155ms mass of feed of 50 g 100 g200 g and 500 g feed drive speeds 100 rpm and drum drivespeeds of 8 rpmThe decrease inmass of fermentedmash wasmonitored with time per pass The initial moisture contentof samples was determined separately before start of exper-iment The weight loss during drying was used to calculatethe moisture content The drying data obtained were used tocalculate the experimental moisture ratio (MR) to predict thekinetics of drying fermented ground cassava

3 Results and Discussion

31 Simulated Theoretical Results The theoretical moistureratio results are presented in Figures 3 5 and 7 The theo-retical moisture ratio decreases with drying time as inlet air

14

12

1

08

06

04

02

00 200 400 600 800 1000 1200

Drying time (s)

Theo

retic

al m

oistu

re ra

tio

115∘C

140∘C

190∘C

230∘C

Figure 3 Variation of moisture ratio with time at different air inlettemperatures using the theoretical model

temperature inlet air velocity and mass of feed increases Asimilar profile is also exhibited in Figures 4 6 and 8 for theexperimental moisture ratio The theoretical moisture ratioplots show a typical drying curve generally obtained duringdrying of moist materials [3 21]

It can be observed from the theoretical moisture ratioplots that the Abowei-Ademiluyi model does not give valuesfor moisture ratio at 119905 = 0 and this will not be a problemsince the initial moisture content from which the moistureratio at 119905 = 0 (ie 119872

119900) was calculated is always known at

start of drying Hence the Abowei-Ademiluyi model can beused to predict the drying kinetics of spherical particles at any

Modelling and Simulation in Engineering 5

14

12

1

08

06

04

02

00 2 4 6 8 10 12

Drying time (min)

Expe

rimen

tal m

oistu

re ra

tio

115∘C

140∘C

190∘C

230∘C

Figure 4 Experimental moisture ratio at different inlet tempera-ture

1412

1816

1

2

08060402

00 200 400 600 800 1000 1200 1400

Drying time (s)

Theo

retic

al m

oistu

re ra

tio

083ms102ms

1397ms155ms

Figure 5 Variation of moisture ratio with time at different inlet airvelocity using the theoretical model

14

12

1

08

06

04

02

00 10 20 30 40 50

Drying time (min)

083ms102ms

1397ms155ms

Expe

rimen

tal m

oistu

re ra

tio

Figure 6 Experimental moisture ratio at different inlet air velocity

known particle diameter rotary drum diameter and dryerlength once the diffusion coefficient is known

35

30

25

20

15

10

5

00 200 400 600 800 1000 1200 1400 1600

Drying time (s)

Theo

retic

al m

oistu

re ra

tio

100 g250 g

500 g1000 g

Figure 7 Variation of moisture ratio with time at different mass offeed using the theoretical model

100 g250 g50 g500 g

14

12

1

08

06

04

02

00

5 10 15 20 25 30Drying time (min)

Expe

rimen

tal m

oistu

re ra

tio

Figure 8 Experimental moisture ratio at different mass of feed

32 Comparison ofTheoretical and Experimented Results Thesimulated theoretical result compared favorably with thoseof the experimental results The similarity is shown from thehigh value (119903 close to 1) obtained for the coefficient ofmultipledeterminations 119877

2 at different inlet air temperature and inletair velocity as shown in Figures 9 and 10 However better fitcould be obtained if the average density particle is correctlychosenThe theoretical (Abowei-Ademiluyi model) moistureratio also compared well with experimentally moisture ratioat different mass of feed as shown in Figure 11

4 Conclusion

The new theoretical Abowei-Ademiluyi model has beendeveloped for predicting drying kinetics of spherical particlesat any known particle diameter rotary drum diameter anddryer length The new model also account for the mass offeed Model validation was carried out by drying fermentedground cassava particles in a bench scale rotary dryer atinlet air temperatures of 115ndash230∘C air velocities of 083msndash155ms feed mass of 50ndash500 g drum drive speed of 8 rpm

6 Modelling and Simulation in Engineering

14

14

12

12

1

1

08

08

06

06

04

04

02

020

0

Theo

retic

al m

oistu

re ra

tio

Experimental moisture ratio

1198772= 09828

1198772= 09955

1198772= 09962

1198772= 09997

115∘C

140∘C

190∘C

230∘C

Figure 9Theoretical (Abowei-Ademiluyi model) and experimentalmoisture ratios at different inlet air temperature

083ms102ms1397ms155ms

14

14

12

12

1

1

08

08

06

06

04

04

02

020

0

Theo

retic

al m

oistu

re ra

tio

Experimental moisture ratio

1198772= 09974

1198772= 09978

1198772= 09839

1198772= 099

Figure 10 Theoretical (Abowei-Ademiluyi model) and experimen-tal moisture ratios at different inlet air velocity

14

14

12

12

1

1

08

08

06

06

04

04

02

020

0

Theo

retic

al m

oistu

re ra

tio

Experimental moisture ratio

500 g250g100 g50g

1198772= 09934

1198772= 09887

1198772= 09991

1198772= 09934

Figure 11 Theoretical (Abowei-Ademiluyi model) and experimen-tal moisture ratios at different mass of feed

and feed drive speed of 100 rpm The theoretical moistureratio calculated from the model compared favorably withexperimental moisture ratio

References

[1] O Myklestad ldquoHeat and mass transfer in rotary dryersrdquo Chem-ical Engineering Progress Symposium Series vol 59 no 41 pp129ndash137 1963

[2] D S Jayas S Cenkowski S Pabis and W E Muir ldquoReview ofthin-layer drying and wetting equationsrdquo Drying Technologyvol 9 no 3 pp 551ndash588 1991

[3] H O Menges and C Ertekin ldquoMathematical modeling of thinlayer drying of Golden applesrdquo Journal of Food Engineering vol77 no 1 pp 119ndash125 2006

[4] A Iguaz A Esnoz G Martınez A Lopez and P VırsedaldquoMathematical modelling and simulation for the drying processof vegetable wholesale by-products in a rotary dryerrdquo Journal ofFood Engineering vol 59 no 2-3 pp 151ndash160 2003

[5] Q Liu and FW Bakker-Arkema ldquoStochastic modelling of graindrying part 2 Model developmentrdquo Journal of AgriculturalEngineering Research vol 66 no 4 pp 275ndash280 1997

[6] Y C Agrawal and R P Singh ldquoThin layer drying studies onshort grain rough icerdquo ASAE Paper 3531 1977

[7] Q Zhang and J B Litchfield ldquoOptimization of intermittent corndrying in a laboratory scale thin layer dryerrdquoDrying Technologyvol 9 no 1 pp 233ndash244 1991

[8] G M White T C Bridges O J Loewer and I J Ross ldquoThinlayer drying model for soybeansrdquo Transactions of the AmericanSociety of Agricultural Engineers vol 24 no 6 pp 1643ndash16461981

[9] M S Chhinnan ldquoEvaluation of selected mathematical modelsfor describing thin-layer drying of in-shell pecansrdquoTransactionsof the American Society of Agricultural Engineers vol 27 no 2pp 610ndash615 1984

[10] A Yagcıoglu A Degirmencioglu and F Cagatay ldquoDrying char-acteristics of laurel leaves under different drying conditionsrdquoin Proceedings of the 7th International Congress on AgriculturalMechanization and Energy pp 565ndash569 Adana Turkey May1999

[11] M S Rahman C O Perera and C Thebaud ldquoDesorptionisotherm and heat pump drying kinetics of peasrdquo Food ResearchInternational vol 30 no 7 pp 485ndash491 1997

[12] C Y Wang and R P Singh ldquoUse of variable equilibrium mois-ture content in modelling rice dryingrdquo ASAE Paper 78-6505ASAE Press St Joseph Mich USA 1978

[13] T Ademiluyi K Oduola and J Eke ldquoMathematical modelingof drying different Cassava Chips in thin layersrdquo Journal ofNigerian Society of Chemical Engineers vol 22 p 148 2007

[14] T Ademiluyi E O Oboho and M Owudogu ldquoInvestigationinto the thin layer dryingmodels ofNigerian popcorn varietiesrdquoLeonardo Electronic Journal of Practices and Technologies vol 7no 13 pp 047ndash062 2008

[15] T Ademiluyi Development of predictive models for drying fer-mented ground cassava [PhD thesis] River State University ofScience and Technology Port Harcourt Nigeria 2009

[16] W L McCabe J C Smith and P Harriott Unit Operations ofChemical EngineeringMcGraw-Hill BookCompanyNewYorkNY USA 4th edition 1987

[17] K A Stroud Advance Engineering Mathematics Palgrave Mac-milian Hampshire UK 4th edition 2003

Modelling and Simulation in Engineering 7

[18] M F N Abowei Prediction model development for simulationof petroleum weathering process in aquatic environment [PhDthesis] Department of Chemical Engineering University ofLagos Lagos Nigeria 1991

[19] T Ademiluyi M F N Abowei Y T Puyate and S CAchinewhu ldquoEffect of variety on the drying and engineeringproperties of fermented ground cassavardquo Journal of Newviewsin Engineering analysis and Modelling pp 80ndash79 2006

[20] E Joy physicochemical and pasting properties of tapioca fromdifferent cassava cultivars in food science and technology [PhDthesis] River State University of Science and Technology PortHarcourt Nigeria 2006

[21] O Bozkir ldquoThin-layer drying and mathematical modelling forwashed dry apricotsrdquo Journal of Food Engineering vol 77 no 1pp 146ndash151 2006

International Journal of

AerospaceEngineeringHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

RoboticsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Active and Passive Electronic Components

Control Scienceand Engineering

Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

International Journal of

RotatingMachinery

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporation httpwwwhindawicom

Journal ofEngineeringVolume 2014

Submit your manuscripts athttpwwwhindawicom

VLSI Design

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Shock and Vibration

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Civil EngineeringAdvances in

Acoustics and VibrationAdvances in

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Electrical and Computer Engineering

Journal of

Advances inOptoElectronics

Hindawi Publishing Corporation httpwwwhindawicom

Volume 2014

The Scientific World JournalHindawi Publishing Corporation httpwwwhindawicom Volume 2014

SensorsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Modelling amp Simulation in EngineeringHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Chemical EngineeringInternational Journal of Antennas and

Propagation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Navigation and Observation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

DistributedSensor Networks

International Journal of

4 Modelling and Simulation in Engineering

1 2 3

4 5

6

7

8

9

10

11

1213

14

16

15

Figure 2 Schematic diagram of bench scale rotary dryer (1) cyclone (2 and 4) probe connections (3) rotary drum (5) feed hopper (6)feed drive (7) electric heater arrangement (8 and 15) sight glasses (9) air blower and orifice plate control (10) support (11) control box (12)chain drive (13 and 14) dried product receivers and (16) steel table

Development Project farm (ADP) at Rumuokoro Port Har-court The choice of this cassava cultivar TMS 30572 wasbased on its preference by farmers because of its high yieldand suitability for gari processing [20] The cassava cultivarwas peeled washed grated and packed in sack for pressingThe dewatered mash was allowed to ferment naturally for72 hrs sieved with a mesh of 35mm and then dried in abench rotary dryer (Figure 2)

222 Experimental Procedure At the beginning of eachexperiment the dryer was allowed to reach steady state at thedesired airflow rate inlet air temperature feed drive speedand drum drive speed When steady state condition hadbeen attained the fermented ground cassava mash of knownmoisture content was introduced into the dryer feed hopperThe drying conditions used in the experiments are inlet airtemperatures of 115∘C 140∘C 190∘C and 230∘C air velocitiesof 083 102 1397 and 155ms mass of feed of 50 g 100 g200 g and 500 g feed drive speeds 100 rpm and drum drivespeeds of 8 rpmThe decrease inmass of fermentedmash wasmonitored with time per pass The initial moisture contentof samples was determined separately before start of exper-iment The weight loss during drying was used to calculatethe moisture content The drying data obtained were used tocalculate the experimental moisture ratio (MR) to predict thekinetics of drying fermented ground cassava

3 Results and Discussion

31 Simulated Theoretical Results The theoretical moistureratio results are presented in Figures 3 5 and 7 The theo-retical moisture ratio decreases with drying time as inlet air

14

12

1

08

06

04

02

00 200 400 600 800 1000 1200

Drying time (s)

Theo

retic

al m

oistu

re ra

tio

115∘C

140∘C

190∘C

230∘C

Figure 3 Variation of moisture ratio with time at different air inlettemperatures using the theoretical model

temperature inlet air velocity and mass of feed increases Asimilar profile is also exhibited in Figures 4 6 and 8 for theexperimental moisture ratio The theoretical moisture ratioplots show a typical drying curve generally obtained duringdrying of moist materials [3 21]

It can be observed from the theoretical moisture ratioplots that the Abowei-Ademiluyi model does not give valuesfor moisture ratio at 119905 = 0 and this will not be a problemsince the initial moisture content from which the moistureratio at 119905 = 0 (ie 119872

119900) was calculated is always known at

start of drying Hence the Abowei-Ademiluyi model can beused to predict the drying kinetics of spherical particles at any

Modelling and Simulation in Engineering 5

14

12

1

08

06

04

02

00 2 4 6 8 10 12

Drying time (min)

Expe

rimen

tal m

oistu

re ra

tio

115∘C

140∘C

190∘C

230∘C

Figure 4 Experimental moisture ratio at different inlet tempera-ture

1412

1816

1

2

08060402

00 200 400 600 800 1000 1200 1400

Drying time (s)

Theo

retic

al m

oistu

re ra

tio

083ms102ms

1397ms155ms

Figure 5 Variation of moisture ratio with time at different inlet airvelocity using the theoretical model

14

12

1

08

06

04

02

00 10 20 30 40 50

Drying time (min)

083ms102ms

1397ms155ms

Expe

rimen

tal m

oistu

re ra

tio

Figure 6 Experimental moisture ratio at different inlet air velocity

known particle diameter rotary drum diameter and dryerlength once the diffusion coefficient is known

35

30

25

20

15

10

5

00 200 400 600 800 1000 1200 1400 1600

Drying time (s)

Theo

retic

al m

oistu

re ra

tio

100 g250 g

500 g1000 g

Figure 7 Variation of moisture ratio with time at different mass offeed using the theoretical model

100 g250 g50 g500 g

14

12

1

08

06

04

02

00

5 10 15 20 25 30Drying time (min)

Expe

rimen

tal m

oistu

re ra

tio

Figure 8 Experimental moisture ratio at different mass of feed

32 Comparison ofTheoretical and Experimented Results Thesimulated theoretical result compared favorably with thoseof the experimental results The similarity is shown from thehigh value (119903 close to 1) obtained for the coefficient ofmultipledeterminations 119877

2 at different inlet air temperature and inletair velocity as shown in Figures 9 and 10 However better fitcould be obtained if the average density particle is correctlychosenThe theoretical (Abowei-Ademiluyi model) moistureratio also compared well with experimentally moisture ratioat different mass of feed as shown in Figure 11

4 Conclusion

The new theoretical Abowei-Ademiluyi model has beendeveloped for predicting drying kinetics of spherical particlesat any known particle diameter rotary drum diameter anddryer length The new model also account for the mass offeed Model validation was carried out by drying fermentedground cassava particles in a bench scale rotary dryer atinlet air temperatures of 115ndash230∘C air velocities of 083msndash155ms feed mass of 50ndash500 g drum drive speed of 8 rpm

6 Modelling and Simulation in Engineering

14

14

12

12

1

1

08

08

06

06

04

04

02

020

0

Theo

retic

al m

oistu

re ra

tio

Experimental moisture ratio

1198772= 09828

1198772= 09955

1198772= 09962

1198772= 09997

115∘C

140∘C

190∘C

230∘C

Figure 9Theoretical (Abowei-Ademiluyi model) and experimentalmoisture ratios at different inlet air temperature

083ms102ms1397ms155ms

14

14

12

12

1

1

08

08

06

06

04

04

02

020

0

Theo

retic

al m

oistu

re ra

tio

Experimental moisture ratio

1198772= 09974

1198772= 09978

1198772= 09839

1198772= 099

Figure 10 Theoretical (Abowei-Ademiluyi model) and experimen-tal moisture ratios at different inlet air velocity

14

14

12

12

1

1

08

08

06

06

04

04

02

020

0

Theo

retic

al m

oistu

re ra

tio

Experimental moisture ratio

500 g250g100 g50g

1198772= 09934

1198772= 09887

1198772= 09991

1198772= 09934

Figure 11 Theoretical (Abowei-Ademiluyi model) and experimen-tal moisture ratios at different mass of feed

and feed drive speed of 100 rpm The theoretical moistureratio calculated from the model compared favorably withexperimental moisture ratio

References

[1] O Myklestad ldquoHeat and mass transfer in rotary dryersrdquo Chem-ical Engineering Progress Symposium Series vol 59 no 41 pp129ndash137 1963

[2] D S Jayas S Cenkowski S Pabis and W E Muir ldquoReview ofthin-layer drying and wetting equationsrdquo Drying Technologyvol 9 no 3 pp 551ndash588 1991

[3] H O Menges and C Ertekin ldquoMathematical modeling of thinlayer drying of Golden applesrdquo Journal of Food Engineering vol77 no 1 pp 119ndash125 2006