REPEATERS Repeaters Eng

-

Upload

dimon-sergeevich -

Category

Documents

-

view

313 -

download

58

description

Transcript of REPEATERS Repeaters Eng

-

NAVIGATION AUTOMATION.

Head Office and Freight: Stueckenstrasse 1-3, D-22081 Hamburg, GermanyCorrespondence Address: P.O. Box 760860, D-22058 Hamburg, Germany

Tel. ++ 49 - 40 - 299 00-0, Telex 2 15 202 a plat d, Fax ++ 49 - 40 - 299 00-298

Operator, Technical and Service Manual

0562613-139 PM.RECO-422

Repeater Compass System with Serial Interface RS 422

04 MAY 98 REV D

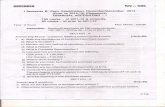

Bearing Repeater Compasswith a 360 Card

in a Bearing Stand

Console Repeater Compass with 360 Card

Steering Repeater Compass forConsole Mounting with 360 and 10 Cards

Bulkhead Repeater Compass with 360 Card

Bearing Repeater Compasswith a 360 Card

in a Bulwark Console

-

List of Contents

CHAPTER/ PAGESECTION

1 DESCRIPTION ........................................................................................ 1-011.1 Outline ...................................................................................................... 1-011.1.1 System Overview ....................................................................................... 1-011.1.2 Display ...................................................................................................... 1-011.1.3 Power Supply ............................................................................................ 1-01

1.2 Technical Description ............................................................................... 1-021.2.1 Standard Compass Card Assembly ......................................................... 1-021.2.2 Housing, Bulkhead Repeater Compass ................................................... 1-021.2.3 Housing, Bearing Repeater Compass ..................................................... 1-021.2.4 Console Repeater Compass and Steering Repeater Compass for

Console Mounting ..................................................................................... 1-031.2.5 Bearing Stand ........................................................................................... 1-031.2.6 Bulwark Console ...................................................................................... 1-031.2.7 Bearing Devices ........................................................................................ 1-031.2.8 Functional Description ............................................................................. 1-03

1.3 Technical Data .......................................................................................... 1-041.3.1 Operational Data ..................................................................................... 1-041.3.2 Mechanical Data ....................................................................................... 1-041.3.3 Electrical Data ........................................................................................... 1-05

2. OPERATION ............................................................................................. 2-012.1 Synchronization Switch and Alarm Conditions ........................................... 2-022.2 Synchronization of Repeater Compasses ................................................. 2-02

3. INSTALLATION AND INITIALIZATION ..................................................... 3-013.1 Before Installation ................................................................................... 3-013.2 Setting Dip Switches ................................................................................. 3-013.3 Dip Switch Information ............................................................................. 3-033.3.1 Delay Time ................................................................................................ 3-033.3.2 Repeater Address ...................................................................................... 3-043.3.3 Formats of the Serial Interface ................................................................ 3-043.3.4 Positions for Dip Switches S1 & S2 in Combination with other Equipment 3-063.4 Installation ............................................................................................... 3-073.4.1 Installation of the Bearing Stand and Bearing Repeater .......................... 3-073.4.2 Installation of the Bulwark Console and Bearing Repeater ........................ 3-103.4.3 Installation of the Bulkhead Repeater Compass ..................................... 3-113.4.4 Installation of the Console Repeater Compass ........................................ 3-11

NAVIGATION AUTOMATION.

056261

Contents I

-

NAVIGATION AUTOMATION. 056261

CHAPTER/ PAGESECTION

3.5 Switch-on .................................................................................................... 3-12

3.6 Trouble Shooting............................................................................................ 3-123.6.1 The "Sync." Switch ...................................................................................... 3-123.6.2 Repeater Compasses cannot be Synchronized with the Master Compass 3-133.6.3 The LEDs and the 7-Segment Display ........................................................ 3-133.6.4 Error Codes ................................................................................................. 3-16

4 MAINTENANCE ........................................................................................... 4-01

List of Contents

Contents II

-

1 DESCRIPTIONThe Repeater Compass System receives through an RS 422 serial interfaceangular information according to which the rotor of a step motor is driven to arelated position. The compass card system is coupled to the step motor througha gear train. The Repeater Compass System comprises basically two standardcompass card assemblies, one with a 360 card and a second with a 360 anda 10 card which, are supplied in a housing as demanded by the associatedapplication.

1. OutlineThe repeater compasses display the vessel's heading as supplied by agyrocompass, a transmitting magnetic compass system or an electronic compass.

1.1.1. System OverviewA suitable repeater compass is available for all applications and all locations. Bearing repeater compass with a 360 card, watertight, for installation in a

bearing stand or a bulwark console. Bulkhead repeater compass with a 360 card, watertight, for attachment to all

level vertical, horizontal and inclined surfaces. Console repeater compass with a 360 card for installation in a bridge console. Steering repeater compass with a 360 and 10 cards for installation in a

bridge console.A bearing stand and a bulwark console complete the system.

1.1.2 DisplayAll repeater compasses display the vessel's heading on a 360 compass card.An exception is the steering repeater, which has a 360 and a 10 card.Graduations and figures appear white on a matt black background during daylightand red illuminated during the hours of darkness. The luminous yellow lubberline facilitates exact reading.

1.1.3 Power SupplyThe repeater compasses are provided with power and heading information fromthe Electronic Power and Control Unit (EPCU) of the NAVIGAT X or NAVIGAT XIIgyrocompass systems. In addition to, or as an alternative for a gyrocompasssystem, the repeater compasses may also be used with a transmitting magneticcompass system.The heading signal in a C.PLATH, NMEA or Lehmkuhl format is received by therepeater through an RS 422 interface. The LED card illumination is provided with24 VDC.

NAVIGATION AUTOMATION. 056261

Page 1-01

-

1.2 Technical Description

1.2.1 Standard Compass Card AssemblyThe main element common to all repeater compasses is the standard compasscard assembly. In contains a 360 compass card (only the steering repeater hasan additional 10 card), a step motor, a gear train, LED illumination, three terminalblocks, a microcontroller, an EPROM, an EEPROM, two dip switch blocks, a7-segment LED display for trouble shooting and several red and green indicatorLEDs.The robust printed circuit board mounts not only the electronic components butalso the gear train and the step motor. The three hard-wearing plastic gear-wheels which make up the gear train run on bronze shafts and bushes.Red LEDs provide full compass card illumination.The compass cards are graduated as follows:Bearing repeater compass360 card: one graduation mark per 1

figured every 10, and figured every 5 with verysmall, mirror image numbers for use with a bearingdevice.360 compass card illumination.

Steering repeater compass360 card: one graduation mark per 5 and figured every 1010 card: one graduation mark per 0.5

figured every full degree.Compass card illuminated 60 each side of lubberline.

Bulkhead repeater / Console repeater360 card: one graduation mark per 1 and figured every 10

Compass card illuminated 60 each side of lubberline.

All repeater compasses are supplied with a prefabricated connection cable.

1.2.2 Housing, Bulkhead Repeater CompassThe bulkhead repeater compass is supplied in a rectangular, galvanized and blackenamelled steel housing. Three attachment feet are provided. The housing alsomounts a dimmer, a synchronization switch, a ground terminal and a cable gland.The bulkhead repeater compass is watertight to IP64.

1.2.3 Housing, Bearing Repeater CompassThe bearing repeaters are produced in a pressed stainless steel housing with aweight in the lower part. Two plastic bushes in the upper part of the housing acceptthe trunnion journals of the gimbal ring in the bearing stand or bulwark console.The bearing repeater can be attached to the gimbal ring at 000 or 90.Various bearing devices may used on this bearing repeater.

NAVIGATION AUTOMATION. 056261

Page 1-02

-

1.2.4 Console Repeater Compass and Steering Repeater Compass for ConsoleMountingFormat and design of the console repeaters are fully compatible with theC.PLATH "Equipment Family" - a comprehensive range of standardized bridgeequipment having front plate dimensions to DIN 43718. The main supportive partis the front plate. The entire compass card is visible through a circular window inthe square front plate. A dimmer and a synchronisation switch are located to theright and left below the compass card.

1.2.5 Bearing StandThe bearing stand is manufactured from an electrostatic powder coated alu-minium alloy and comprise one single part. A horizontal circular handle isprovided at the top of the stand, above which two bearing supports are attached.These accept the gimbal ring in which the bearing repeater is suspended. Analuminium connection box with cable glands, dimmer and a synchronisationswitch is attached to the lower half of the stand. Here, the repeater is connectedto the gyrocompass system. A watertight cover is provided to protect the standand the repeater from the effects of the weather.

1.2.6 Bulwark ConsoleThe bulwark console is an aluminium construction and is provided with four holesfor attachment to a bulwark console. A gimbal ring is attached to two bearingsupports. Fixed to the side of the console is a connection box with cable glands, adimmer and a synchronisation switch. Here, the repeater is junctioned to thegyrocompass system.

1.2.7 Bearing DevicesA selection of bearing devices, ranging from the conventional sight model to thetelescopic type, is available for bearing repeaters. All bearing devices locate in thebore in the center piece of the top glass and on the verge ring, allowing bearingsto be taken in relation to north and the ship's head.

1.2.8 Functional DescriptionThe angular information received through the serial interface is processed in an8 bit microcontroller and passed to the step motor control logic. In order to ensurethat the value displayed by the repeater is also the value received, the mechanicalposition of the compass card is monitored by a photoelectric cell every 10 and atthe 000 position. If the mechanical position does not coincide with the computedvalue, the microcontroller will correct the error. If the values are not within reason-able limits, a failure alarm is actuated. If a repeater is switched off or a powerfailure occurs, the last angular information is stored in an EEPROM to maintainsynchronisation when power is restored. Synchronisation can also be forced bymeans of a switch. Here, the compass card is brought to the 000 position regard-less of the current angular information. When 000 has been found, the compasscard returns to the value of the angular information currently received.

NAVIGATION AUTOMATION. 056261

Page 1-03

-

1.3 Technical DataUnless otherwise specified, the following data are effective for all repeater com-passes.

1.3.1 Operational DataAccuracy max. error between input signal and display

0.5 at 20/sec.Maximum rate of turn 25sec.Environmental requirements in accordance with IEC 945Equipment class X for equipment subjected to the effects of the weather.Equipment class B for equipment not subjected to the effects of the weather.Temperature range

operational -25C to +70C (X) -15C to 55C (B)non-operational -40C to +80C (X & B)

Humidity damp heat cycle IEC 945 /4.4.3Vibration 5 Hz to 50 Hz to IEC 945 /4.4.7Immunity to conducted audio 50 Hz to 10 kHz to IEC 945 /A3frequencies 10 kHz to 50 MHz to IEC 945 /A5

Immunity to conducted audio frequencies is notspecified for DC appliances.Test with power supply/rectifier and capacitorto IEC 945 /A7.

Conducted interference 10 kHz to 30 MHz IEC 945 /4.5.3Radiated interference 30 MHz to 300 MHz IEC 945 /4.5.4,Acoustic noise IEC 945/4.5.7

-

NAVIGATION AUTOMATION. 056261

1.3.3 Electrical DataMaximum current consumption 570 mAPower requirements 18 VDC to 36 VDCIllumination red, 16 or 4 LEDs, 24 VDCSteering and bearing repeaters 360 illuminationBulkhead and console repeaters 60 illumination each side of the lubber lineIllumination "Sync." switch red, 1 LED 24 VDCDrive step motor 18 VDC to 36 VDC,

300 microsteps / 1 AzimuthLength of connecting cable approx. 3 m. Bearing repeater only 1.2 m.

Page 1-05

-

056261NAVIGATION AUTOMATION.

Page 1-06

THIS PAGE LEFT BLANK

-

Item. Purpose

1. 360 compass card 2. 10 compass card indicate vessel's heading (10 card in steering repeater only). 3. Lubber line

4. Dimmer regulates the intensity of the compass card illumination.

5. Synchronization switch when pressed, starts synchronization procedure.indicates alarm conditions.

6. Connection box for for connection of bearing repeater to gyrocompass.bearing repeater

7. Dimmer for bearing regulates the intensity of the bearing repeater compass cardrepeater illumination.

8. Synchronization switch when pressed, starts synchronization procedure.for bearing repeater indicates alarm conditions.

NAVIGATION AUTOMATION. 056261

1

2

2. OPERATIONDuring normal operational conditions the repeater compasses require nooperation. The repeater compasses are self-aligning and consequently donot require synchronization after switch-on or as a result of an interim powerfailure.

3

45

7

6

8

Page 2-01

}

Figure 2-01

-

Continuous with short breaks Alternately on and off Short flashes for equal periods

2.2 Synchronization of Repeater CompassesAfter switch-on, the repeater compasses synchronize automatically with themaster compass. For the duration of this procedure the "Sync." switch willilluminate continuously in red with short breaks.

Alternate flashing on and off for equal periods of the "Sync." switch indicates thatthe repeater in no longer synchronized with the master compass.Press and hold for 5 seconds the "Sync." switch to synchronize the repeater withthe master compass. The compass card(s) will turn to the 000 position where it(they) will remain for 2 seconds. The compass card(s) will then return to theheading shown by the master compass. The synchronization procedure is nowcomplete.

If the repeater compass cannot be synchronized with the master compass, therepeater will rotate the card(s) clockwise at maximum speed for up to 55 seconds.The repeater will then switch back to master compass operation withouthaving synchronized. The "Sync." switch will flash alternately on and off for equalperiods to indicate this fault.

NAVIGATION AUTOMATION. 056261

2.1 Synchronization Switch and Alarm ConditionsThe synchronization switch (fig. 2-01, items 5,8) gives light signals to indicatealarm conditions. These are:

Light signal Cause Correction

Continuous Fatal Error See Trouble Shooting

Continuous with short Compass card rotates in searchbreaks function after switch-on or during synchronization

Alternately on and off Repeater is not synchronized Synchronize: press "Sync." switchfor equal periods for 5 sec.

Short flashes Interface error See trouble shooting

1 sec0.5 sec

0.5 sec

1 sec

0.1 sec 0.1 sec

light

dark

Page 2-02

-

NAVIGATION AUTOMATION. 056261

Figure 3-01 Page 3-01

3. INSTALLATION AND INITIALIZATION

3.1 Before InstallationLocated inside each repeater compass below the compass card(s) on thePCB are two blocks of 8 dip switches. These dip switches are factory set to theC.PLATH protocol format and to a time delay of 20 ms. The settings of these dipswitches are only to be changed when specified in the system connection diagramsupplied by C.PLATH.

3.2 Setting Dip Switches1. In order to gain access to the dip switches, the repeater compass is to be opened

in accordance with the following instructions.

a) Bulkhead repeater, console repeater, steering repeater (see fig. 3-01)

1. Unscrew and remove the four screws (socket head 3 mm AF) and washers(1) attaching the front plate. Lift out the repeater from its housing or console.Do not allow the seal (when fitted) to fall to the ground.NOTE: For repeaters in a C.PLATH "Equipment Family" frame open theconsole. At the rear of the repeater loosen but do not remove the screws (2)retaining the clamps (3). Turn the clamps (3) to one side and remove therepeater from its frame.

2. Set the dip switches as specified in the system connection diagram.

3. Fit the repeater with seal (when fitted) in its housing, console or frame.Secure in place with the attaching screws and washers.NOTE: For repeaters in C.PLATH "Equipment Family" frames, turn theclamps (3) into the clamping position and tighten the retaining screws (2).

1

3

2

-

NAVIGATION AUTOMATION.

b) Bearing Repeater Compass (see fig. 3-02)

1. Unscrew and remove the 8 nuts (5.5 mm AF) and washers (1) retainingthe verge ring (2).

2. Mark the position of the verge ring (2) on the housing (4) for laterattachment.

3. Remove the verge ring (2) complete with the compass card assemblyfrom the housing. Do not let the seal (3) fall to the ground.

4. Set the dip switches as specified in the system connection diagram.

5. Using the reference marking made during removal, fit the compass cardassembly with verge ring (2) into the housing. Ensure that the seal (3) iscorrectly positioned between the housing and the verge ring.

6. Screw on and tighten the 8 retaining nuts (5.5 mm AF) and washers (1).

1

2

3

Seite 3-02 Abbildung 3-02

4

056261

-

NAVIGATION AUTOMATION. 056261

3.3 Dip Switch Information

Dip Switch Block S1 Dip Switch Block S2

S1-1 delay time bit 0 (LSB) S2-1 display modeS1-2 delay time bit 1 S2-2 display modeS1-3 delay time bit 2 S2-3 display modeS1-4 delay time bit 3 (MSB)

S2-4 not connectedS1-5 repeater address bit 0 (LSB)S1-6 repeater address bit 1 S2-5 ON: heading plus 180S1-7 repeater address bit 2S1-8 repeater address bit 3 (MSB) S2-6 serial mode

S2-7 serial modeS2-8 ON: forced synchronization

by every reset of themicrocontroller.

3.3.1 Delay TimeThe delay in serial data transmission is taken into account by the softwareprogram in the repeater compasses. In this way, lag error caused by slow datatransmission is avoided.Delay time can be set in units of 20 milliseconds according to the following table.

S1-4 S1-3 S1-2 S1-1 decimal millisecondsMSB LSB0 0 0 0 0 00 0 0 1 1 200 0 1 0 2 400 0 1 1 3 600 1 0 0 4 800 1 0 1 5 1000 1 1 0 6 1200 1 1 1 7 1401 0 0 0 8 1601 0 0 1 9 1801 0 1 0 10 2001 0 1 1 11 2201 1 0 0 12 2401 1 0 1 13 2601 1 1 0 14 2801 1 1 1 15 300

C.PLATH recommends the following settings:

Page 3-03

-

3.3.2 Repeater Compass AddressWith the four dip switches S1-5 through S1-8 it is possible to set an individualaddress for each repeater compass. However, in a normal system configura-tion these dip switches remain in the OFF position.

3.3.3 Formats of the Serial Interface

Format C.PLATH NMEA 0183 Lehmkuhl NAVIPILOT notV & ADII used

Mode 0 - 1 2 3S2-6 OFF not required* ON OFF ONS2-7 OFF not required* OFF ON ONCP/NMEA open closed open open openbridge

Display Mode

Mode S2-1 S2-2 S2-3 Repeater Compass Displays

0 OFF OFF OFF Heading from Heading from 1200 bps Heading fromgyrocompass gyrocompass* gyrocompass

1 ON OFF OFF Heading from Heading from 2400 bps Heading frommagn. compass magn. compass* magn. compass

2 OFF ON OFF Rate of turn Rate of turn 4800 bps spare

3 ON ON OFF Roll spare 9600 bps spare

4 OFF OFF ON Pitch spare spare spare

5 ON OFF ON Heading from spare spare sparegyrocompassor magneticcompass

6 OFF ON ON spare Heading from spare sparegyrocompass**

7 ON ON ON spare Heading spare sparemagn. compass**

NAVIGATION AUTOMATION. 056261

Gyrocompass systems NAVIGAT X and XII S1-1 ONS1-2 OFFS1-3 OFFS1-4 OFF}

Multiple heading reference S1-1 ONmonitor NAVITWIN II S1-2 ON

S1-3 ONS1-4 OFF}

20 ms

140 ms

Page 3-04

* When the CP/NMEA bridge is closed, S2-6 and S2-7 are ineffective.

-

NAVIGATION AUTOMATION. 056261

Page 3-05

NOTE: * When a repeater compass is connected to interface 7 on NAVITWIN IIand display mode 0 or 1 is selected, the repeater will indicate theheading shown on NAVITWIN II (from a gyrocompass or a magnetic

compass).

** When a repeater compass is connected to interface 7 on NAVITWIN IIand display mode 6 or 7 is selected, the repeater will indicate theheading (from a gyrocompass or a magnetic compass) selected asthe display mode regardless of the heading shown on NAVITWIN II.(the NSD sentence is not taken into account.)

Spare Switch PositionsWhen dip switches are set to a non-specified combination for displaymode and interface format, the error code OFF will be shown on the7-segement display.

Lehmkuhl -FormatWith the Lehmkuhl format only heading is displayed.This format (LR22 or LR40 / LR60) is recognized automatically.The baud rate for this serial interface is set as the display mode, see3.3.3.

NMEA 0183The following sentences are processed:{ } substitute [ ] optional

Display Mode0 HDT {HDG}

[ROT][NSD]

1 HDM {HDG}[ROT][NSD]

2 ROT[HDT {HDG} {HDM}]

6 HDT {HDG}[ROT]

7 HDM {HDG}[ROT]

-

3.3.4 Positions for Dip Switches S1& S2 in Combination with other Equipment

NAVIGAT X & XII NAVITWIN II Lehmkuhl Format NAVIPILOTC.PLATH NMEA Interface 6* Interface 7 1200 2400 4800 9600 V & ADII Format Format (C.PLATH) (NMEA) Magn. com-

pass repeater

NAVIGATION AUTOMATION. 056261

Page 3-06

1 ON ON ON ON ON ON

2 OFF OFF ON ON OFF OFF

3 OFF OFF OFF ON OFF ON

4 OFF OFF OFF OFF OFF OFF

5 OFF OFF OFF OFF OFF OFF

6 OFF OFF OFF OFF OFF OFF

7 OFF OFF OFF OFF OFF OFF

8 OFF OFF OFF OFF OFF OFF

CP/NMEA Open Closed Open Closed Open Open Bridge

1 OFF OFF ON OFF OFF ON OFF ON ON

2 OFF OFF OFF OFF OFF OFF ON ON OFF

3 OFF OFF ON OFF OFF OFF

4 OFF OFF OFF OFF OFF OFF

5 OFF OFF OFF OFF OFF OFF

6 OFF OFF OFF OFF ON OFF

7 OFF OFF OFF OFF OFF ON

8 OFF OFF OFF OFF OFF OFF

S2

S1

*NAVITWIN II with bypass switch (Emergency Heading Selector Switch) only on Interface 6.

-

3.4 InstallationInformation regarding space required, attachment points and cable glands isgiven in the dimension drawings and wiring diagrams as listed below andcontained in the final section of this manual.

Repeater type Dimension drawing Wiring diagram

Bearing repeater in 4881-0112-02 4881-0115-03bearing stand 4662-0112-02

Bearing repeater in 4881-0112-02 4881-0115-03bulwark console 4890-0112-01

Connection box for 4884-0112-01 4884-0115-01bearing repeater

Bulkhead repeater 4881-0112-03 4881-0115-04

Steering repeater 4881-0112-01 4881-0115-02

Console repeater 4881-0112-01 4881-0115-01

NAVIGATION AUTOMATION. 056261

The following points are to be taken into consideration when selecting alocation:

the ambient temperature magnetic clearance the protection graderefer to the technical data in section 1.3.

Ensure that the system is deenergized before connecting repeater compasses.

All repeater compasses are supplied with a prefabricated cable which is to beconnected in accordance with the system connection diagram as supplied byC.PLATH.

3.4.1 Installation of the Bearing Stand and Bearing Repeater (see fig. 3-03)The bearing stand is to be attached to the deck by means of four M16 bolts.The bearing stand may be positioned amidships, port or starboard. Care is tobe taken that the bearing stand is positioned so that the horizon is not undulyobstructed by the superstructure of the vessel when bearings are taken. Alldimensions and electrical information is contained in the drawings anddiagrams specified in section 3.4.

Page 3-07

-

056261NAVIGATION AUTOMATION.

1. Prepare the place of location for installation.a) Weld four M16 bolts on their heads to the deck.

To ensure the accuracy of the bearing repeater in later use, the bolts mustbe positioned exactly parallel to the vessel's longitudinal axis.

b) Weld a cable inlet pipe 30 x 3 mm to the deck and cut an inlet hole for thecables.

c) Lay the connecting cables.2. Place the bearing stand over the attachment bolts.3. Fit the washers and screw on the retaining nuts but do not tighten them.4. Loosen the lock-nut (24 mm AF) securing one of the trunnion journals in the

gimbal ring.5. Screw back the trunnion journal (8 mm key) by approximately 2 cm.

CAUTION: The weight of the bearing repeater is 5.1 kg. Whenrequired, the following two assembly operations are to becarried out by two persons.

6. Lift the bearing repeater into the gimbal ring so that the lubber line points tothe ship's head and locate the fixed trunnion journal in the bush in therepeater.

7. Turn the loosened trunnion journal clockwise into the opposite bush so thatthe repeater is secured without play in the gimbal ring.

8. Check that the bearing repeater is positioned concentrically with the gimbalring. When necessary, adjust the trunnion journals to effect concentricity.

9. Tighten the trunnion journal lock-nuts.10. Fit an azimuth device to one of the bearing repeaters.11. Place a pin in the hole of the center piece of the opposite bearing repeater

compass.12. Using the azimuth device, take a bearing across the open bridge on the pin

in the opposite bearing repeater compass. The bearing taken is to be 90 (oraccordingly 270).NOTE: If it is not possible to take a bearing across the open bridge, carry out

steps 13, 14 and 15 instead of steps 11 and 12.13. Determine the distance between the longitudinal center line of the vessel and

the center point of the bearing repeater.14. Position as far away as practically possible a beam with a perpendicular

reference marking, see fig. 3-03.15. Take a bearing on the perpendicular reference marking through the azimuth

device. The bearing taken is to be 360 towards the ship's head or 180astern.

16. If the bearing taken is not 360 or 180, turn the bearing stand to obtainthese values.

17. Tighten the nuts securing the bearing stand.18. Unscrew the screws attaching the cover to the connection box and remove

the cover.19. Insert the cables from the bearing repeater and the gyrocompass system

through the cable glands into the connection box.20. Connect both cables to the terminal block in the connection box in

accordance with the system connection diagram.

Page 3-08

-

NAVIGATION AUTOMATION. 056261

Page 3-09

1 Bearing repeater compass2 Marking

Alignment of Bearing Repeaters

Figure 3-03

21. Tighten the cable glands.22. Fit the cover to the connection box and secure it with the attachment screws.23. As described above, align and connect all bearing repeater compasses.

-

NAVIGATION AUTOMATION. 056261

3.4.2 Installation of the Bulwark Console and Bearing RepeaterThe bulwark console is intended for attachment to a bulwark behind thewindshield on the wing of a bridge. Care is to be taken that the bulwark console ispositioned so that the horizon is not unduly obstructed by the superstructure of thevessel when bearings are taken.

1. Weld four M10 bolts to the bulwark at the place of location for the bulwarkconsole. Refer to the dimension drawing in the final section of this manual.

2. Fit the bulwark console to the attachment bolts and secure with lock washersand nuts.

3. Loosen the lock-nut (24 mm AF) securing one of the trunnion journals in thegimbal ring.

4. Screw back the trunnion journal (8 mm key) by approximately 2 cm.CAUTION: The weight of the bearing repeater is 5.1 kg. When

required, the following two assembly operations are to becarried out by two persons.

5. Lift the bearing repeater into the gimbal ring so that the lubber line points tothe ship's head and locate the fixed trunnion journal in the bush in therepeater.

6. Turn the loosened trunnion journal clockwise into the opposite bush so thatthe repeater is secured without play in the gimbal ring.

7. Check that the bearing repeater is positioned concentrically with the gimbalring. When necessary, adjust the trunnion journals to effect concentricity.

8. Tighten the trunnion journal lock-nuts.9. Fit an azimuth device to the bearing repeater.10. Determine the distance between the longitudinal center line of the vessel and

the center point of the bearing repeater.11. Position as far away as practically possible a beam with a perpendicular

reference marking, see fig. 3-03.12. Take a bearing on the perpendicular reference marking through the azimuth

device. The bearing taken is to be 360 towards the ship's head or 180astern.

13. CAUTION: Together, the bearing repeater and the bulwark consoleweigh 10.3 kg. When required, this step is to be carriedout by two persons.

If the bearing taken is not 360 or 180, fit spacers between the console andthe bulwark to obtain these values.

Page 3-10

14. Unscrew the screws attaching the cover to the connection box and removethe cover.

15. Insert the cables from the bearing repeater and the gyrocompass systemthrough the cable glands into the connection box.

16. Connect both cables to the terminal block in the connection box inaccordance with the system connection diagram.

17. Tighten the cable glands.18. Fit the cover to the connection box and secure it with the attachment screws.19. As described above, align and connect all bearing repeater compasses.

-

NAVIGATION AUTOMATION. 056261

Figure 3-04 Page 3-11

2

1

3.4.3 Installation of the Bulkhead Repeater CompassThe bulkhead repeater compass is attached by means of screws to a bulkhead orwall. For this purpose the repeater is fitted with three attachment feet each drilledto 7 mm diameter. All dimensions and the location of attachment holes are con-tained in the dimension drawing.

1. Weld three M6 bolts to the bulkhead or, alternatively, drill three holes in thebulkhead enabling the bolts to be inserted from the opposite side.

2. Fit the bulkhead repeater over the attachment bolts and secure it with lockwashers and M6 nuts.

3. Connect the prefabricated connection cable in accordance with the systemconnection diagram.

3.4.4 Installation of the Console Repeater Compass (see fig. 3-04)The console repeater is always supplied with four attachment columns (1) forinstallation in a C.PLATH "Equipment Family" frame. If the repeater is not to beinstalled in an "Equipment Family" frame but directly in a bridge console, theattachment columns (1) must be removed beforehand. A seal is provided forwatertight installation.

1. Unscrew the four retaining screws (2) and remove them together with theattachment columns (1).

2. Cut an opening in the bridge console as shown in the dimension drawing forinstallation of the console repeater.

3. Drill and tap four M4 holes for attachment of the repeater as shown in thedimension drawing.

4. Fit the seal when it is required) to the back of the repeater and fit it into theopening in the console.

5. Using the screws and washers (2) removed in step 1, secure the repeater to thebridge console.

6. Connect the prefabricated connection cable in accordance with the systemconnection diagram.

-

056261NAVIGATION AUTOMATION.

3.5 Switch-onThe repeater compasses are switched on together with the gyrocompass system.

Alternate flashing on and off for equal periods of the "Sync." switch indicates thatthe repeater in no longer synchronized with the master compass.Press and hold for 5 seconds the "Sync." switch to synchronize the repeater withthe master compass. The compass card(s) will turn to the 000 position where it(they) will remain for 2 seconds. The compass card(s) will then return to theheading shown by the master compass. The synchronization procedure is nowcomplete.

If the repeater compass cannot be synchronized with the master compass, therepeater will rotate the card(s) clockwise at maximum speed for up to 55 seconds.The repeater will then switch back to master compass operation withouthaving synchronized. The "Sync." switch will flash alternately on and off for equalperiods to indicate this fault.

3.6 Trouble ShootingInformation on suspected faults in the function of the repeater compasses is givenby the "Sync." switch on the front plate of the repeaters and in the connection boxof bearing repeaters as well as several LEDs and a 7-segment display inside therepeaters. To view the LEDs and the 7-segement display it is necessary to re-move the associated repeater from its housing, see 3.2.

3.6.1 The "Sync." Switch

Light signal Cause Correction

Continuous Fatal Error See error code no. on 7-segmentdisplay and compare with error codelist.

Continuous with short Compass card rotates in searchbreaks function after switch-on or during synchronization.

Alternately on and off Repeater is not synchronized. Synchronize: press "Sync." switchfor equal periods for 5 seconds.

See also 3.6.2.

Short flashes Interface error See error code no. on 7-segmentdisplay and compare with error codelist.

Page 3-12

After switch-on the repeater compasses synchronize automatically with the mastercompass. The "Sync." switch illuminates continuously in red with short breaks forthe length of the synchronization procedure.

-

If the repeater compass cannot be synchronized with the master compass, therepeater will rotate the card(s) clockwise at maximum speed for up to 55 seconds.The repeater will then switch back to master compass operation withouthaving synchronized. The "Sync." switch will flash alternately on and off for equalperiods to indicate this fault; read the error code number on the 7-segment displayand refer to the error code list.

3.6.3 The LEDs and the 7-Segment Display (see fig. 3-05)Located on the standard compass card assembly are a 7-segment display and 8LEDs. By displaying hexadecimal numbers, the 7-segment display provides errorcodes and information on dip switch positions and operational status.The LEDs illuminate to indicate the presence of various voltages and other func-tions required for normal operation.

Continuous with short breaks Alternately on and off Short flashesfor equal periods

NAVIGATION AUTOMATION. 056261

0.1 sec

1 sec0.5 sec

0.5 sec

1 sec

0.1 sec

3.6.2 Repeater Compasses cannot be Synchronized with the Master Compass

light

dark

Page 3-13

-

NAVIGATION AUTOMATION. 056261

Page 3-14

Fig. Item Description Purpose

3-05 1 IC13, 7-segment display by displaying numbers, provides error codesand information on dip switch positions andoperational status.

2 CR3, LED, red illuminates when the max. operationaltemperature has been exceeded and thepower supply switched off.

3 CR27, LED, green illuminates when the internal voltage +12 Vis present.

4 CR25, LED, red illuminates when the input voltage exceeds48 V DC and has been switched off.

5 CR28, LED, green illuminates when the +24 V input voltageis present.

6 CR30, LED, green illuminates when +5 V is present.

7 CR37, LED, green illuminates when -5 V is present.

8 CR33, LED, green illuminates when the 10 photoelectric cellhas been actuated.

9 CR34, LED, green illuminates when the 360 photoelectric cellhas been actuated.

10 CR35, 4 LEDs, red illuminate alternately when the four stepmotor voltages are present.

11 Dip switch block S1 see 3.3.

12 Dip switch block S2 see 3.3.

13 Bridge BR1 none.

-

NAVIGATION AUTOMATION. 056261

Figure 3-05Standard Compass Card Assembly PCB, Component Side

Page 3-15

12

1

2

3

4

513

6

7

8

9

1011

-

NAVIGATION AUTOMATION. 0562561

3.6.4 Error Codes

Page 3-16

Error codes in the form of two digit hexadecimal numbers are shown on a7-segment display. Since there is only one 7-segment display, the two digits ofeach code are shown consecutively.When more than one error code is present, the code numbers are displayed in anascending sequence.

Display of digits: 0.5 sec.Interval between digits: 0.1 sec.Interval between error codes: 1.0 sec.

The 16 hexadecimal digits are: 0 1 2 3 4 5 6 7 8 9 A b C d E F and allow errorcodes over a range of 00 to FF.

The numbers are displayed reading from left to right. Example: error code 27(twenty-seven) first the "2" then the "7".Orientation is arranged so that the edge of the PCB is the bottom of the display.

An exception is when all dip switches are set to ON or OFF. A display of two digiterror codes is no longer shown and a single "0" is displayed ten times when all dipswitches are set to ON. When all dip switches are set to OFF, a single "1" isdisplayed ten times. The numbers are displayed for 0.5 sec. Interval is 0.5 sec.

The error codes are divided into three groups:F = FaultW = WarningH = General information

Errors and warnings are displayed as long as the cause remains unresolved.General information is normally given when a change in the current operationalstatus occurs or when the positions of the dip switches are changed. Theassociated code is displayed five times. Example: when the external NMEA bridgeis closed, the code "db" is displayed five times. Because in this example theformat of the serial interface NMEA 0183 is concerned, the following will also bedisplayed: "80" = NMEA format on (5 times)

"84" = baud rate 4500 (5 times)

During normal operation (i.e. without faults) the following error codes in accord-ance with the selected interface format will be displayed:C.PLATH format: 00NMEA 0183: Codes of sentences recognized e.g. NAVIGAT X/XIIHDT + ROT):

20 70Lehmkuhl: 92 or 94

-

NAVIGATION AUTOMATION. 0562561

Page 3-17

ErrorCode(Hex) Type Cause Correction

00 H no error - - - - - - -01 F internal RAM test error switch repeater off and on. If fault is still

present, replace microcontroller (IC3).02 F external RAM test error switch repeater off and on. If fault is still

present, replace external RAM (IC14).03 F EPROM checksum error replace EPROM (IC 12).04 F 360 photoelectric cell failure replace repeater.05 F 10 photoelectric cell failure replace repeater.06 F angle at 360 photoelectric cell false synchronize.07 F angle at 10 photoelectric cell false synchronize.08 H reset of the controller - - - - - - - -09 W EEPROM data checksum error repeater is synchronized automatically.0A H power supply failed - - - - - - - -0b H revision of EEPROM varies from

revision of EPROM repeater is synchronized automatically.0C F no data from serial interface check polarity of RXD / RXDN,

check data source (compass).0d F unusable data from serial interface check S2-1 thru S2-3, S2-6 and S2-7 and

external NMEA bridge.check data source (compass).

0E F angle not synchronized synchronize.0F F invalid switch combination CHECK S2-1 thru S2-3, S2-6 and S2-7 and

(format of serial interface, display mode) external NMEA bridge.10 W index/actual difference (angle) too large - - - - - - - -11 H synchronizing phase 1 - - - - - - - -12 H synchronizing phase 2 - - - - - - - -13 H synchronizing phase 3 - - - - - - - -14 H synchronizing phase 4 - - - - - - - -15 H synchronizing phase 5 - - - - - - - -16 H synchronizing phase 6 - - - - - - - -17 F angle serial timeout check interface.18 H primary angle from interface timeout - - - - - - - -19 H rate of turn is accepted by the - - - - - - - -

serial interface1A H rate of turn is calculated in the - - - - - - - -

repeater (from change in angle)1b W runaway in angle - - - - - - - -1C F write error in EEPROM (byte-wise) replace EEPROM.1d F write error in EEPROM (block-wise) replace EEPROM1E H Sync. is pressed - - - - - - - -1F H dip switch S2-8 switched to on - - - - - - - -

NMEA 0183 HDT sentence:20 H NMEA HDT recognized - - - - - - - -21 F NMEA HDT: checksum error check interface / data source22 F NMEA HDT: field missing check interface / data source23 W NMEA HDT: empty field check interface / data source24 F NMEA HDT: internal error - - - - - - - -25 W NMEA HDT: invalid heading check interface / data source

(not T)

-

NAVIGATION AUTOMATION. 0562561

Page 3-18

NMEA 0183 HDM sentence:30 H NMEA HDM recognized - - - - - - - -31 F NMEA HDM: checksum error check interface / data source32 F NMEA HDM: field missing check interface / data source33 W NMEA HDM: empty field check interface / data source34 F NMEA HDM: internal error - - - - - - - -35 W NMEA HDM: invalid heading check interface / data source

(not M)

NMEA 0183 NSD sentence:39 H NMEA NSD recognized - - - - - - - -3A F NMEA NSD: checksum error check interface / data source3b F NMEA NSD: field missing check interface / data source3C H NMEA NSD: empty field - - - - - - - -3d F NMEA NSD: internal error - - - - - - - -3E H NMEA NSD: heading gyro - - - - - - - -3F H NMEA NSD: heading magnetic - - - - - - - -

NMEA 0183 HDG sentence:40 H NMEA HDG recognized - - - - - - - -41 F NMEA HDG: checksum error check interface / data source42 H NMEA HDG: type: mag. sensor heading - - - - - - - -43 H NMEA HDG: type: magnetic heading - - - - - - - -44 H NMEA HDG: type: true heading - - - - - - - -45 F magnetic sensor heading: field missing check interface / data source.46 W magnetic sensor heading: empty field - - - - - - - -47 F magnetic sensor heading: internal error - - - - - - - -

55 F deviation: field missing check interface / data source.56 H deviation: empty field - - - - - - - -57 F deviation: internal error - - - - - - - -58 F deviation sign (E or W): field missing check interface / data source.59 H deviation sign (E or W): empty field - - - - - - - -5A F deviation sign (E or W): neither E or W check interface / data source.

65 F variation: field missing check interface / data source.66 H variation: empty field - - - - - - - -67 F variation: internal error - - - - - - - -68 F variation sign (E or W): field missing check interface / data source.69 H variation sign (E or W): empty field - - - - - - - -6A F variation sign (E or W): neither E or W check interface / data source.

-

NAVIGATION AUTOMATION. 0562561

Page 3-19

NMEA 0183 ROT sentence:70 H NMEA ROT recognized - - - - - - - -71 F NMEA ROT: checksum error check interface / data source.72 F NMEA ROT status: field missing check interface / data source.73 H NMEA ROT status: empty field check interface / data source.74 H NMEA ROT status: invalid - - - - - - - -75 F NMEA ROT number: field missing check interface / data source.76 H NMEA ROT number: empty field - - - - - - - -77 F NMEA ROT number: internal error check interface / data source.

80 H NMEA format selected - - - - - - - -81 H baud rate 1200 - - - - - - - -82 H baud rate 2400 - - - - - - - -

84 H baud rate 4800 - - - - - - - -

89 H baud rate 9600 - - - - - - - -

Lehmkuhl repeater format (LR22 / LR40 / LR60) :90 H Lehmkuhl format not selected - - - - - - - -

(serial mode = 1)

92 H LR 22 format recognized - - - - - - - -

94 H LR 40/60 format recognized - - - - - - - -95 F digit address false check interface / data source.96 H alarm status set (LR40/60) - - - - - - - -97 F mode control bits not 0 in digit byte check interface / data source.

C.PLATH format:A0 H C.PLATH format selected - - - - - - - -

(serial mode = 0)A1 F checksum error check interface / data source.A2 H general device error bit set - - - - - - - -

NAVIPILOT V/AD II remote format:b0 H NAVIPILOT format selected - - - - - - - -

(serial mode = 2)b1 F NAVIPILOT checksum error check interface / data source.b2 H NAVIPILOT value invalid - - - - - - - -

Serial mode 3 format:C0 H serial mode 3 selected - - - - - - - -

d0 H display mode 0 selected - - - - - - - -d1 H display mode 1 selected - - - - - - - -d2 H display mode 2 selected - - - - - - - -d3 H display mode 3 selected - - - - - - - -d4 H display mode 4 selected - - - - - - - -d5 H display mode 5 selected - - - - - - - -d6 H display mode 6 selected - - - - - - - -d7 H display mode 7 selected - - - - - - - -

-

NAVIGATION AUTOMATION. 056261

Page 3-20

dA H yaw test on press "Sync." switch to stop test.db H external NMEA bridge closed - - - - - - - -dC W internal error - - - - - - - -dd W internal error - - - - - - - -dE W internal error - - - - - - - -dF H heading + 180 selected - - - - - - - -

E0 H repeater address = 0 - - - - - - - -E1 H repeater address = 1 - - - - - - - -E2 H repeater address = 2 - - - - - - - -E3 H repeater address = 3 - - - - - - - -E4 H repeater address = 4 - - - - - - - -E5 H repeater address = 5 - - - - - - - -E6 H repeater address = 6 - - - - - - - -E7 H repeater address = 7 - - - - - - - -E8 H repeater address = 8 - - - - - - - -E9 H repeater address = 9 - - - - - - - -EA H repeater address = a - - - - - - - -Eb H repeater address = b - - - - - - - -EC H repeater address = c - - - - - - - -Ed H repeater address = d - - - - - - - -EE H repeater address = e - - - - - - - -EF H repeater address = f - - - - - - - -

F0 H delay = 0 ms - - - - - - - -F1 H delay = 20 ms - - - - - - - -F2 H delay = 40 ms - - - - - - - -F3 H delay = 60 ms - - - - - - - -F4 H delay = 80 ms - - - - - - - -F5 H delay = 100 ms - - - - - - - -F6 H delay = 120 ms - - - - - - - -F7 H delay = 140 ms - - - - - - - -F8 H delay = 160 ms - - - - - - - -F9 H delay = 180 ms - - - - - - - -FA H delay = 200 ms - - - - - - - -Fb H delay = 220 ms - - - - - - - -FC H delay = 240 ms - - - - - - - -Fd H delay = 260 ms - - - - - - - -FE H delay = 280 ms - - - - - - - -FF H delay = 300 ms - - - - - - - -

-

NAVIGATION AUTOMATION. 056261

4. MAINTENANCE

The repeater compasses require no maintenance.

Page 4-01

-

NAVIGATION AUTOMATION.

Page 4-02

THIS PAGE LEFT BLANK