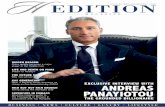

Rematecnews Edition 3 2015

-

Upload

rai-amsterdam -

Category

Documents

-

view

240 -

download

17

description

Transcript of Rematecnews Edition 3 2015

Remanufacturingfor highflyers

Direct Group - Serving fleet operators

Sustainability on 4 wheels - Volvo’s XC90

ReMaTec2015 welcomes theworld’s remanufacturers

REMANUFACTURING INTERNATIONAL MAY 2015 | NO 3 | VOLUME 15

www.rematecnews.com

ReMaTecNews | 3CONTENTS

www.rematecnews.com

52 | Helping fleet ownersstay on the road

Several of Europe’s largest public transport

operators rely on a UK remanufacturer when it

comes to keeping their vehicles on the road.

By meeting their requirements, Direct Parts in

Staffordshire in central England has created a solid

business that seems destined for further growth.

12 | Volvo launches a reman dream: the new XC90

Famed for its attention to safety, Volvo also has a

long history of producing environmentally sound

cars. The Swedish manufacturer’s most recent

model is no exception. In fact, it could be described

as one of the world’s most remanufacturable cars.

We take a peek under the bonnet.

28 | Amsterdam ready forReMaTec2015

The remanufacturing show of the year,

ReMaTec2015, is only a few weeks away. Soon

remanufacturers from across the world, their

suppliers and the entire supply chain will gather for

the biennial “Olympic Games of remanufacturing”.

In 2015: 6 editions ReMaTecNews Magazine | Special pages on Transmissions in Editions 1, 3, 5 | Special pages on Heavy Duty/Trucks in Editions 2, 4, 6

“Volvo has been remanufacturing parts for more than 50 years ... “Gunnar Magnusson, Head of Remanufacturing, Volvo Cars

Editorial 4

OEs benefit from remanufacturing 5

Remanufacturer of the Year 6

Reman takes to the skies 24

ReMaTec2015 show special 28

WaiGlobal opens up in Poland 41

World Reman Summit 43

Electronics lead HD market surge 46

The broadening horizons of reman 50

APRA 56

FIRM 57

International exhibitions 58

Page 12

EDITOR’S LETTER ReMaTecNews | 4

A week for the reman industryBy the time you read this, there will only be a few weeks left before the largest single event in the

2015 reman calendar - ReMaTec2015 in Amsterdam, the Netherlands, gets underway from June 14 to

16. Co-locating with the fourth World Remanufacturing Summit, the eighth edition of the ReMaTec

show also hosts the 11th anniversary of the Remanufacturer of the Year award as well as a number of

side-shows and events. Amsterdam is set to attract audiences from across the world. In importance, no

other event designed specifically for the remanufacturing industry can match it.

For anyone that has been involved since the early days in 2001 and the small-scale beginnings of

the ReMaTec exhibitions, this is a good time for reflection. Not so much perhaps about the ever-

growing need for professional events that bring industry players together for networking, exchange

of views and experiences - but rather on the general development of an industry that for so long was

somewhat fragmented, underrated and even relatively unknown outside its own narrow circles.

How different from today. When ReMaTec2015 opens for business in only a few short weeks, the

remanufacturing industry is recognised and respected worldwide for its job creation, its innovative

approach to complex technical issues and above all for its contribution to a better environment and for

saving the earth’s resources.

Yes, much remains to be done – but the achievements of the remanufacturing industry thus far have

been nothing less than remarkable.

The evidence is there for all to see. In the US, recognition is now given to remanufacturing at the

highest levels. In Europe, different associations are working with the authorities to create better

awareness of the benefits of reman. In China, the world’s largest car market, the government

continues to promote remanufacturing as one solution to the country’s vast environmental challenges.

Whether in the financial sector or among environmental lobby groups, companies are increasingly

active in promoting reman. ReMaTec2015 and the events surrounding it will provide much evidence of

this. It’s all heading in a positive direction.

In one way or another, most of those attending the upcoming events in June play a role in moving the

remanufacturing industry forward. They should take pride in what they do – and enjoy their three or

four days in Amsterdam. It’s all worthwhile – today and in the future.

William Schwarck, Editor-in-Chief

May 2015 | Number 3 | Volume 15

Published by Amsterdam RAI B.V. P.O. Box 77777, 1070 MS Amsterdam The Netherlands In association with

Editor-in-ChiefWilliam SchwarckPhone +44 (0)778 652 [email protected]

US CorrespondentDenise RondiniOffice +1 (0) 773 334 5740Cell +1 (0) 773 951 [email protected]

Marketing Communications & PRSanne van DartelenPhone +31 (0)20 549 [email protected]

Advertising SalesEwoud Barink Phone +31 (0)20 549 1431 Fax +31 (0)20 549 [email protected] PublisherNiels Klarenbeek (responsible under Dutch Press Law) [email protected] Production & ArtworkMaaike van DijkPhone +31 (0)20 549 [email protected] DesignJenb, Graphic design, Hilversum, The Netherlandswww.jenb-online.nl PrintingSDA Print + Media CopyrightAmsterdam RAI, Amsterdam, The Netherlands Reproduction No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise, without the prior written permission of the publisher, Amsterdam RAI B.V. Subscription magazine and e-newsletterwww.ReMaTecnews.com Change of addressE-mail [email protected] Website / ReMaTecNews magazine onlinewww.ReMaTecnews.com Circulation Approx.13,500 readers per edition. The magazine is delivered on a controlled circulation basis to recipients in Western Europe, Eastern Europe, Africa, North America, South America and Asia.

ReMaTecNews

WWW.AEROFORCE.DE

5 YEARWARRANTY

2 YEARWARRANTY

CRO

SSLI

ST

Original / OE RegulatorBosch, Magneti Marelli, Denso, Valeo

CRO

SSLI

ST

Ignition Modules, -CoilsMotor-Management

CRO

SSLI

ST

Voltage RegulatorAlternator Components

CRO

SSLI

ST

ABS Sensor WheelspeedMotor-Management

CRO

SSLI

ST

RectifiersAlternator Components

CRO

SSLI

ST

Engine ManagementCamshaft SensorIdle Air Control ValveEGR ValveOil Level Sensor

Complete Database in our Webshop

WWW.AUTOPULLEY.COM

■ Approved and Tested by all main OE Players

■ We can Develop any new Type according your OEM Sample

■ Worldwide Distribution Network

Original/OE Regulator

Ignition Module/Coil

Voltage Regulator

ABS Sensors

Rectifi er

Engine Management

ReMaTecNews | 5News

The not uncommon perception that

manufacturers damage – or “cannibalise”

sales prospects if and when they engage in

remanufacturing, is given a clear “thumbs

down” by a major financial institution

operating in world markets.

Contrary to the common belief that businesses that

engage with second life assets put sales of their

new products at risk, a major European financial

institution concludes that remanufactured second

life assets may enhance financial performance.

DLL, an affiliate of Dutch banking giant Rabobank,

has carried out a survey among fourteen large

industrial customers.

The white paper presents a range of arguments

in favour of companies entering the reman field

even if, on the surface, remanufactured products

would seem to compete with the manufacturers’

own new lines.

DLL lists three distinct groups of benefits from

remanufacturing:

• Financial - where trade-ins create additional

value support, generate new sales and increased

revenues from parts and service.

• Competitiveness – leading to increased resale

values, industry competitiveness and protection

of brand value from third parties as well as

alleviating problems in saturated export markets.

• Customer needs – in terms of improving

customer solutions and meeting demand for

second life assets.

The traditional linear economy model is based on

a take, make, dispose system where raw materials

are extracted from the earth, assets are made,

sold and eventually discarded by the user to

potentially end up in landfill or for incineration.

The circular economy model is aimed at keeping

raw materials in closed loops. This model relies

on usage rather than ownership of the asset. It

enables manufacturers to keep more control of

their assets throughout the technical cycle and

makes services around the product an increasingly

important profit centre for manufacturers.

The findings of the report will significantly

strengthen the arguments in favour of

remanufacturing within manufacturing companies

where the pros and cons of remanufacturing are

often a hotly contested issue.

The findings may also contribute to a better

understanding of the value of remanufacturing

and how to offer the best financial terms to

the reman industries from financial institutions.

In the past, some attempts have been made to

direct attention to remanufacturing by financial

institutions but so far with modest success. The

white paper from DLL may help change that. n

OEs benefit from remanufacturing

ReMaTecNews | 6

An Oscar for remanufacturers

VISIT US ATR E M A T E CAmsterdam, Stand 11.620ATo find out how Melett precision engineered turboparts can benefit you and your customers, visit theRematec Theatre on Monday 15th June at 15.15hrswhere Martyn Howorth, Melett Sales Director, willpresent ‘Trends in the Turbocharger Aftermarket’,or alternatively visit our multilingual team atHall 11, Stand 11.620A.

Melett is the market leader in quality replacement turbocharger partsand will be showcasing an extensive range of turbo components,repair kits and VSR balanced CHRA.

Melett - Quality Matters

QUALITY REPLACEMENT TURBOCHARGER PARTS

Remetec 290415-half-Rem-4i.qxp_Layout 1 29/04/2015 17:07 Page 1

On the evening of Sunday 14 June,

ReMaTecNews will announce the winner of its

Remanufacturer of the Year award for 2015.

As in previous years, the announcement will

be made during the Industry Reception that

marks the opening of the ReMaTec exhibition

at the RAI Convention Centre in Amsterdam.

Inaugurated in 2005 for the purpose of honouring

individuals or businesses that have served

automotive and heavy duty remanufacturing

with particular distinction, the award has since

established an unrivalled position as the global

reman industry’s most prestigious honour.

Instigated by ReMaTecNews and awarded by a

panel of judges representing a cross-section of the

industry, the Remanufacturer of the Year award is

an independent choice made by the judges and

their decision is free from commercial or personal

interests. Their decision is made exclusively on the

basis of what they believe is in the interests of the

industry as a whole.

The panel of judges consists of Volker Schittenhelm

of FIRM, the European Engine Remanufacturers

Association; Fernand Weiland, former Chairman

of the European Division of APRA, the Automotive

Parts Remanufacturers Association; Doug Wolma,

Head of Remanufacturing at DANA Corporation

and a board member of MERA, MEMA’s reman

division and with William Schwarck, Editor-in-Chief

Last time in Amsterdam: The winner of the Remanufacturer of the Year Award 2013, Alan Smart of

ATP in the UK, with the panel of judges. From left Fernand Weiland, APRA Europe, William Schwarck,

Editor-in-Chief, ReMaTecNews, Alan Smart, and Volker Schittenhelm, FIRM

ReMaTecNews | 7

at ReMaTecNews, as Chairman. Candidates can

be nominated by anyone, including themselves,

and are considered by the judges on the basis

of the following criteria: Technical excellence,

dedication to quality, innovation and impact on

the reman industry.

Other criteria include outstanding customer

service, pioneering activities and commitment to

the cause and promotion of automotive and

heavy duty remanufacturing.

“Year after year over the past decade,

remanufacturing has gained in acceptance in

keeping with social demands for environmental

solutions, preservation of resources, jobs and

affordable prices for parts. This trend will see

continual growth and ReMaTecNews is delighted

that the award recognises some of the excellent

companies that drive the industry forward,” said

William Schwarck, Editor of ReMaTecNews. n

alternators | starters

Specializing in alternators, starter motors and electrical repair components for the automotive, agricultural, industrial, heavy duty, mining, forestry and marine aftermarket applications – Wilson offers customers an extensive range of these products. Over 15,000 individual part numbers are listed in our most comprehensive electronic cataloguing system available in the industry.

All of Wilson products undergo extensive quality control measures and meet or exceed O.E.M. specifications.

When you buy Wilson, you’re buying a full-featured, quality product – one with enhanced reliability, a longer service life, less chance of premature failure, and the best guarantee in the business.

S TA R T I N G CHARGINGTHE WORLD

&

Contact: Jeff BellPh: 44 (0)1772 490679 Email: [email protected]

Dorian Drake Europe11/15 William RoadLondon NW1 3ER

www.wilsonautoelectric.com

Winners of the Remanufacturer of the Year Award2014: Jack Stack, SRC, Missouri, US

2013: Alan Smart, ATP UK

2012: Doug Wolma, Meritor, US

2011: Philippe James, Remy Automotive Europe

2010: Francois Augnet, TRW Europe

2009: Carsten Bücker, BU Drive Group, Germany

2008: Johan van Gerven, MRT Engines, the Netherlands

2007: Martin Detzen, MD Rebuilt, Germany

2006: Alexander Schäfer, MS Motor Service Int, Germany

2005: Jens Lindholm, Holger Christiansen, Denmark

When part specifications and surface tolerances cannot change, the only blasting abrasive to use

is ARMEX. The gentle physical propriety of baking soda but yet aggressive cleaning ability is

what makes ARMEX the only choice. Other blasting abrasives can remove surface materials

damaging parts. Additionally, since ARMEX is also soluble it will never leave particles behind in

critical passageways like other blasting abrasives which increase the risk of part failure when

placed back into service. ARMEX for when non-destructive cleaning is critical.

Is non-destructivecleaning critical?

For more information visit www.armex.com

ARMEX and ARM & HAMMER are trademarks of Church & Dwight Co., Inc.

ARMEX is the only choice

BEFORE

AFTER

ReMaTecNews | 9News

When part specifications and surface tolerances cannot change, the only blasting abrasive to use

is ARMEX. The gentle physical propriety of baking soda but yet aggressive cleaning ability is

what makes ARMEX the only choice. Other blasting abrasives can remove surface materials

damaging parts. Additionally, since ARMEX is also soluble it will never leave particles behind in

critical passageways like other blasting abrasives which increase the risk of part failure when

placed back into service. ARMEX for when non-destructive cleaning is critical.

Is non-destructivecleaning critical?

For more information visit www.armex.com

ARMEX and ARM & HAMMER are trademarks of Church & Dwight Co., Inc.

ARMEX is the only choice

BEFORE

AFTER

You are invited!

Join our 18th Technical Seminar on Saturday 13th of June,

prior to ReMaTec.Topics include 0B5; A6MF1; ZF8HP, ZF6HP,

Mercedes 722.9 and many more.

Don´t miss out! Register on

www.automaticchoice.com

We would love to meet you at our booth 11.602

Automatic Choice ReMaTecNews2015 ChoiceTech.indd 1 23/04/2015 09:52:17

Well-known UK remanufacturerreorganises distribution systemA reorganisation of its distribution network

means that AMK, one of the UK’s long-

standing remanufacturing companies, will

now supply UK automotive trade customers

from a single site at Dewsbury, in Yorkshire.

Managing Director Alan Griffiths says the closing

of the last of the five other branches in April,

consolidates the company’s position and makes

it more competitive. ‘Our distribution structure is

now more comparable with those of our closest

rivals,’ he said. It’s also understood that invoicing

from a single location will be a benefit to some

customers, which includes national distributors as

well as smaller independents.

Griffiths is one of the original founders of the £12

million turnover business and bought the business

back from OSL Group in July 2013. OSL had

acquired it in 2007.

Founded by the late Harry Wicks, a prominent

name in UK remanufacturing, the AMK-branded

range is largely remanufactured but contains

some OE products. Its major product lines include

transmission parts, brake products, steering

and suspension, A/C compressors and rotating

electrics. Income is generated from UK sales,

although a small amount of revenue comes from

sales of coil springs to customers on mainland

Europe.

Steering pumps

The reorganisation releases resources for

investment in stock and the development of new

product areas. The electric power steering pumps

market is one product area that might suit AMK’s

more streamlined operation, although no firm

decisions have been made as yet, Alan Griffith

says. n

Alan Griffiths

ReMaTecNews | 10

FSEG launches OES turnkey platform

ORPAV Via Milano, 1B 21020 Ternate (VA) - ItalyP. +39 0332 961886 [email protected]

ORPAV

WWW.EMMETEC.COM

WWW.ORPAV.COM

Spare parts for shock absorbers,repair tools and test benches

EPS-C (electric columns)

EPS-P (electric pumps)

EPS-R (electric racks)

Vinci R EPS Universal benchesEuropean patent no. 2259041-31/10/2013(published in European bulletin 13/48 of 27/11/2013)

WWW.EMMETEC.COM

Power steering, pumps, EPS and power brake booster spare parts

Precisão Meraviglião mod. «Hector»

revolutionarytest bench that allows to test open shock absorbers

International patent in progress

MangustaINOX

Repairmachine

for shocksCutting •

Welding •Threading •Gas filling •

with automatedprocesses

Hydraulic pump benchNew version with controlling pulpit

Z-27002 + Z-27300

Please visit us at

ReMaTecAmsterdamJune 14-16 2015

Booth 11.120

FSEG, Flight Systems Electronics Group, has

announced a new OES Turnkey Contract

Remanufacturing Services Platform.

The service will officially launch at the

ReMaTec2015 remanufacturing show in

Amsterdam on June 14th to 16th.

“Expanding into Engineering Consulting was a

logical progression based on our Reman business

experience”, said Marc Baines, Managing

Director of Flight Systems Europe. “The overall

reception was immediate and positive, once we

introduced this technical support service to our

OEM customer base. It has been a natural fit for

the growing European Reman markets, as they

need strong experienced technical partners to

grow their businesses and product lines.” The OES

operating division of Flight Systems Automotive

Group, FSEG, has its European headquarters in

Vrchlabi in the Czech Republic and is part of the

Cignet Group of companies, with locations in

Lewisberry, Pennsylvania, USA and Vrchlabi.

Electronics and mechatronics

The other operating divisions of the Flight Systems

Automotive Group comprise Flight Diesel, Reman

Auto Electronics and CTS Reman. In total, FSAG

and Flight Systems Europe remanufacture and

manufacture over 500,000 electronic, mechatronic

and mechanical parts per year, making it one

of the largest independent remanufacturing

companies in the world.

“For over 40 years FSEG has been a leading

remanufacturer in North America and Europe for

mechatronic products, catering to the automotive

and heavy duty markets,” commented Mark

DiGiampietro, Automotive Group Business Leader

of FSAG, and President of the FSEG Division. “This

year FSEG hopes to expand on its knowledge and

expertise by adapting to the changes we are

seeing in the reman market,” he added. “More

than ever, Tier 1 and 2 OEs are seeing the benefit

of expanding their internal and external reman

operations. Our reman turnkey solutions business

offers customers a choice of either external or

internal - or a hybrid version - through assistance

from our staff of 20+ electronic and mechanical

engineers. We realized over time there was a

serious gap in our customer’s resources that we

could fill on a practical level.” n

Flight Systems Europe’s Marc Baines

makes all these parts and more.makes all these parts and more.PLA EPLA EPLA EPLA EPLA EPLA Emakes all these parts and more.makes all these parts and more.PLA EPLA EPLA EPLA EPLA EPLA EPLA EPLA EPLA EPLA EPLA EPLA EPLA EPLA EPLA EPLA EPLA EPLA EPLA EPLA EPLA ENLYNLYNLYNLYNLYNLY

PLA EPLA EPLA EPLA EPLA EPLA ENLYNLYNLYNLYNLYNLYNLYNLYNLYNLYNLYNLY

GFX CORPORPATE HEADQUARTERS4810 NW 74 Avenue Miami, FL 33166T/ 305.499.9789 www.gfxcorp.com

AVAILABLE EXCLUSIVELY THROUGH GFX

Onlyoneplace_ReMaTec.indd 1 11/11/2014 1:17:06 PM

10 l ReMaTecNews

timely delivery, high quality• Transmission Parts Warehouse• Torque converters and Valve bodies• Technical assistance• Daily shipping all over Europe

Phone: +31(0)546 819 510 [email protected] www.ganzeboom.net The Netherlands

Visit our booth at ReMaTec2013

11.710Visit us at booth 11.101

ReMaTecNews | 12

Remanufacturing the Volvo way - safe, solid - and sustainable

Not long ago “safe” and “solid” were the

characteristics that would most often come

to mind when discussing Volvo, the brand

from Europe’s far north that has become a

global byword for sensible, if not spectacular,

motoring. The Swedish tractor, as some

motor writers used to call it – rather unfairly.

Volvo’s latest top-of the-range model, the XC90,

out this year, puts a nail in the coffin of this long-

standing perception. Without compromising on

the old safety virtues, this stylish model illustrates

how the acquisition of the company by China’s

giant Geely car maker in 2010 has had no negative

impact whatsoever on Volvo’s global reputation.

At the same time, the fundamental part of Volvo’s

philosophy, its commitment to sustainability and

to remanufacturing, remains second to none.

In fact, you can argue that the XC90 is the world’s

most “remanufacturable” vehicle. Although Volvo

itself prefers to put it in somewhat milder terms,

it is undeniable that the new XC90 continues

Volvo’s half century of reman expertise by offering

substantial opportunities for remanufacturing

when it is time for an overhaul. More than that,

in recent years Volvo has been steadily extending

its range of remanufactured components in its

Exchange System - partly because of the addition

of new product areas for the Volvo V60 Plug-In

Hybrid model.

In full, Volvo’s remanufactured parts currently

account for 15 per cent of all the group’s parts

– or as the company likes to put it: “In 2013,

the 350 tonnes of aluminium and 980 tonnes of

steel saved by Volvo through remanufacturing

corresponded to the CO2 emissions from driving

1,326 times around the world in a V40 D2 model.

Parts for a new generation of cars

As the XC90 T8 starts hitting the markets this

year, the launch widens the range of exchange

parts even more. Thus the XC90 marks the start of

a new era for Volvo cars, with a new generation

of cars built on a new platform and with a

new line of innovative, fuel-efficient engines. The

Gunnar Magnusson, Head of remanufacturing at Volvo, discusses technical details with Janos Vörös

who is responsible for Engines

ReMaTecNews | 13

top-of-the-line product among the XC90 model

versions is the XC90 T8 Twin Engine, which is a

plug-in electric car, hybrid and high-performance

model rolled into one. This 7-seater SUV delivers

400hp/640Nm combined with ultra-low emissions

(59g/km) and high fuel efficiency (2.5 l/100km).

Designed for remanufacturing

“Throughout the development of the new XC90

T8, there has been an ongoing dialogue between

the remanufacturing and R&D departments at

Volvo Cars in order to ensure that key components

are optimally prepared for remanufacturing,”

says Gunnar Magnusson, the 57-year-old

mechanical engineer who has been in charge of

Volvo’s remanufacturing processes and product

development for the past decade.

“For Volvo it is important to always consider the

total life cycle as well as aftermarket service costs

and long-term environmental concerns. This may

often involve design solutions that not merely

focus on what may be most efficient when the

component is manufactured, but also on what

may simplify its disassembly when the day comes

for it to be remanufactured,” he explains. “For

example, Volvo is now using screws instead of

glue or welded joints when sealing the casing

of certain components, such as the high voltage

battery casing itself and electronic control modules

for optimising the high voltage batteries functions

such as BECM (Battery Electronic Control Unit).”

“Volvo has been remanufacturing parts for more than 50 years so we’re clearly committed to a sustainable environment”

Critical components

In addition, Volvo Cars has put significant effort

into ensuring that all critical components – such

as the high voltage battery, the integrated starter-

generator, the electric rear axle drive, including

the electric motor, planetary gears differential and

several other components, can be handled safely

within Volvo Cars’ general Exchange System flow.

“For Volvo Cars, it is imperative to be able to

retain responsibility for these types of components

throughout their lifecycle, and during both their

first and second life,” Gunnar Magnusson told

ReMaTecNews.

All this is linked to all three of Volvo’s core

values: safety, quality and the environment. For

example, many safety aspects are considered

when handling, transporting, storing, diagnosing

and replacing the XC90 T8 high-voltage battery

packs.

“This requires a system without any weak links,

where everything is prepared and everyone knows

what to do,” Magnusson says. “There are, of

course, also quality aspects, with Volvo wanting

to ensure that the highly advanced components

of the XC90 T8 and other coming hybrids are

always remanufactured according to Volvo Cars’

high standards and specifications, so that the

long-term safety and quality of Volvo cars are not

put to risk.

Research projects

“Lastly, there are the environmental aspects,”

he continues. “Again, high voltage batteries for

electrified cars complicate the issue, since it is not

yet obvious which will be the best way to take

Exchange systemAll Volvo dealers are connected to its

Exchange System and have a return

obligation for replaced parts included in

the Exchange product range. Currently, the

Volvo Cars Exchange System offers one of

the widest exchange part ranges in the

automotive industry, including everything

from gearboxes to injectors and electronic

components:

• Diesel Particulate Filters

• Automatic Transmission

• Combined Instruments

• Manual Transmissions

• Catalytic Converters

• Audio Equipment

• AC Compressors

• Turbo Chargers

• Cylinder Heads

• Steering Gears

• Servo Pumps

• Drive Shafts

• EGR Valves

• Alternators

• Starters

• Engine

ReMaTecNews | 14

ATP has the facilities and parts to re-manufacture large ZF welded converters up to 470mm

These services are available to you and can often deliver a saving of 70% off the price of a new torque converter.

• Re-balanced

• Crack Tested • New Frictions • New Steels • New ‘O’ Rings

• New Bearings • One Way Clutch • All units pressure tested

ATP Industries Group Ltd. Cannock Wood Industrial Estate, Cannock Wood Street, Cannock, Staffordshire, WS12 0PL, [email protected] +44 (0) 1543 870 336

[email protected] +44 (0) 1543 870 330 www.atp-group.com

VOLVO BELL CASE LIEBHERR MOXY TEREX

care of them when they reach the end of their

useful life and can no longer be remanufactured,

reused or repurposed. There is, unfortunately, still

no good way to recycle them in an economically

and environmentally sensible manner. “

For this reason, Volvo Cars is participating in

several research projects together with universities

and auto industry stakeholders aimed at driving

the development towards optimal recycling

methods. Until such methods become reality,

Volvo Cars takes full responsibility for the safe

handling of high-voltage batteries, as well as

other hybrid car components, via Volvo dealers

and the Volvo Exchange System, throughout the

entire lifecycle.

50 years of reman

“Volvo has been remanufacturing parts for more

than 50 years so we’re clearly committed to

a sustainable environment,” explains Gunnar

Magnusson.

That, however, is not the end of the story by any

means. At its historic headquarters in Torslanda

outside Gothenburg in western Sweden,

technicians and engineers continue the quest

for ever more fuel-efficient and environmental-

friendly processes for the next generation of cars.

“There are new challenges in the handling of

remanufactured parts because of increasing use

of electrification and hybrid technologies ,” says

Gunnar Magnusson. “This is something that

Volvo Cars has spent several years preparing for.”

Quality standards

“Remanufactured spare parts have always been

a cost-efficient and environmentally-friendly

alternative to newly manufactured parts,”

Magnusson says. The remanufactured spare parts

meet the same quality standards, specifications

and warranty as newly made components, and

Transmission products are an integral part of Volvo’s reman range. Dick Cruslock who has responsibity

for all Reman Transmission Products and Gunnar Magnusson, exchange views about an ERAD, Electric

Rear Axle Drive

ReMaTecNews | 15

OEM Surplus New Core Reman

Core Sold

Matthew Carbo: 00-1-417-827-9600 [email protected] www.GlobalRecoveryCo.com

2065 E Pythian Springfield, MO

Compared to Dealers

Axles, cylinder heads, crankshafts, camshafts,

hydraulics, injectors, differentials, transmissions,

and more!

this also means that they can be even better

during their “second life”, as they are upgraded

to the latest and improved specifications. The

remanufactured product line is an environmentally

good choice because a remanufactured part

requires up to 85 per cent less raw material and

80 per cent less energy compared with a newly

made product.”

Comprising almost any part under the hood, the

list of components that can be remanufactured in

Volvo’s new XC model provides a clear illustration

of a global car-maker’s dedication to reman.

Other car makers may be catching up – but

no-one is likely to exceed the environmentally-

aware Swedes within this field for the foreseeable

future.

The ownership of Volvo Cars may have relocated

to China. The commitment to safety, quality

and remanufacturing clearly remains where it has

always been - at Gothenburg in Sweden. Seems

it’s pretty safe there. n

Volvo and remanVolvo’s reman history goes back to the end of the Second World War when the company first began renovating gearboxes in the town of Köping in

central-southern Sweden. At that time, the post-war shortages of raw material made it a sensible choice to invest in remanufacturing; and it has been

ever since, even if material shortage is no longer the reason.

“Today, the environmental benefits, together with the ambition of offering high availability of top quality Volvo genuine parts for Volvo cars long after the

end of production, are the main motives behind Volvo Cars’ focus on remanufacturing,” says Gunnar Magnusson, head of remanufacturing at Torslanda.

ReMaTecNews | 17

Garrett appoints Dutch master dealerDutch customers for Garrett turbochargers

will have greater choice following the

appointment by Garrett of turbo specialist

Turbo Direct of Almere, as master distributor

for the renowned American turbocharger

manufacturer. Late in March and with

effect from 1 April 2015, Garrett signed an

agreement with Turbo Direct, a five year-

old business in central Netherlands, under

which Turbo Direct becomes Garrett’s main

distributor for both new and remanufactured

turbochargers from Garrett’s range.

“We are very happy with this,” said Erwin Visser,

one of Turbo Direct’s two founders. “The deal

confirms that we have pursued the right strategy

since we started Turbo Direct in early 2009 -

a strategy based on 100 per cent quality and

reliability.” Turbo Direct, which also supplies

products from Mitsubishi as well as for industrial

and maritime applications, claims to be the only

company in the Netherlands that delivers original

turbos exclusively. This also applies to Garrett’s

remanufactured programme, which the company

makes available as an alternative to cheap and/or

copied units from low-cost countries.

Lack of technical information

“The turbo market keeps growing” says Visser’s

partner, Frans Wiegmans. “More and more

suppliers are offering reconditioned turbochargers,

but most of the manufacturers have not supplied

parts for them for many years now. Technical

information, necessary for delivering a flawless

working reconditioned turbocharger, has also

not been released for many years while, at the

same time, the number of Chinese copy products

has been increasing. By making Garrett’s reman

programme available, we allow customers to

sidestep non original reconditioned or copied

turbos on their engines. As we all know, you

cannot judge the quality of a turbocharger from

the outside. n

Bas Pappot, Erwin Visser and Frans Wiegmans – the trio behind Turbo Direct

Garage

Core handling

Remanu-facturing

Packaging

Assembly & testing& testing

facturing

Core handlingCore handling

Garage

Logistics

www.trwaftermarket.com/remanufacturing

TRW-Safety

TRW Remanufacturing. As New.

Remanufacturing old parts to become exchange parts that are ‘as new’ not only saves precious resources, but especially for older vehicles it may be the only repair method that makes sense fi nancially. Perfect function and safety at lower prices – it is a repair solution to suit the times, especially as vehicles are spending even longer on the road.

Almost all electrical, electronic and mechanical components are remanufactured to ‘as new’ condition in the ‘TRW Original Exchange Parts Program‘. Here we benefi t from our experience as an original equipment supplier and our close cooperation with the vehicle manufacturers. In terms of qua lity, service life and appearance, the fi nished products are as good as new parts. At two locations in Europe, TRW is ensuring that used parts are turned into exchange parts for vehicle manufacturers, Independent Aftermarket and Industry garages.

braking. steering. suspension.

TRW at: hall 11 | stand: 11.10214-16 June

2015

ReMaTecNews | 19

Call for more collective expertiseHeavy-duty engine remanufacturers could

offer the automotive industry more of the

specialist services that they need by working

more closely together, says Ken Worsdale,

President of the UK Federation of Engine

Remanufacturers.

He says that in the UK, there are a lot of smaller

companies offering their own specialist services to

the industry. Collectively, under the banner of the

FER, they could provide a more comprehensive

service. Ken Worsdale, who succeeded Alan

Johnson as President at the end of 2014, is the

current Managing Director of Foxwood Diesel.

Foxwood Diesel offers two types of

remanufacturing service from separate sites

just down the road from each other in the

Derbyshire town of Chesterfield. One strand of

the business is a heavy-duty facility that specialises

in the remanufacturing and fitting of engines for

buses operated by big fleets such as Arriva or

Stagecoach as well as some of the more local

operators like Trent Barton. The other branch of

the business is more of a jobbing shop, machining

engine components and offering crank grinding

and re-boring services to retail customers on the

passenger car side.

“One of the biggest problems when you start

[remanufacturing] engines is [knowing] how to

test them. At Foxwood Diesel, we specialise in

Cummins and Mercedes-Benz engines. We have

invested in the diagnostic technology and we can

test them on a dyno rig,” Worsdale says.

He adds he would like to hear from engine

remanufacturing specialists of other marques,

who would be interested in providing a more

collective expertise for the benefit of the industry.

n

Electronic Power Steering

Testing System

We offer:▪ EPS testing system▪ EPS sensors ▪ Hydraulic power steering test bench▪ Components to rebuild steering

system

C

M

Y

CM

MY

CY

CMY

K

Phone: +001 513-771-8000Email: [email protected]

www.JNelectric.com

Ken Worsdale, new President of the UK Federation of Engine Remanufacturers

D&V’s full range of alternator & starter testers are ready for the latest generation of LIN/BSS alternators, start/stop and COM starters. D&V’s testers include industry leading high-speed data acquisition technology and intuitive measuring software.

To find out more about our full line of testers visit www.dvelectronics.com or watch us on YouTube www.youtube.com/dvelectronics

See us in Hall 11, Stand 104

All materials © 2015 D&V Electronics Ltd.

D&V ELECTRONICS LTD.T: +1 905-264-7646 F: +1 [email protected] www.dvelectronics.com

DESIGNED FOR THE FUTURE, BUILT FOR EUROPE

ALT-198 ADVANCED ALTERNATOR TESTER

ADVANCED ALTERNATOR & STARTER TESTING

JBT-1 ALTERNATOR & STARTER TESTER

ST-120 PRODUCTION STARTER TESTER

ReMaTecNews | 21

Eco austerity drives demand for remanufactured partsThe global market for remanufactured

automotive parts is projected to reach US$

139.8 billion by 2020, driven by the era of

eco austerity and growing concerns over

the environmental impact of mainstream

manufacturing. Consumers show growing

awareness of the environmental and cost

benefits offered by remanufactured parts. A

key trend in the market is the diversification

of OEMs into the remanufacturing business.

Remanufacturing enables auto OEMs to

compete against low-cost manufacturers and

also to adhere to their corporate social and

environmental responsibilities.

These are some of the conclusions in an updated

report on automotive remanufacturing by the

research institute Global Industry Analysts,

Inc. in California. In 2013, GIA published

a comprehensive report on the global reman

industry and the new version brings the findings

of the initial report up to date, the authors state.

“Production of remanufactured automotive parts

and components is rapidly migrating to low-cost

countries in Asia-Pacific and Eastern Europe, due

to the availability of low-cost labour,” states

“Automotive Parts Remanufacturing: A Global

Strategic Business Report”.

Key trend

“A key trend in the market is the diversification

of OEMs into the remanufacturing business.

Remanufacturing enables auto OEMs to compete

against low-cost manufacturers and to adhere

to their corporate social and environmental

responsibilities.” The report points out that auto

parts accounts for about two-thirds of the global

remanufacturing activity. “The environmental

benefits of remanufacturing are significant in

the automotive industry, since vehicle parts and

components are subject to significant wear and

tear, and require frequent repairs or replacements

during the operating life of the vehicle,” the

report says. “Remanufacturing, in this regard,

offers huge economic benefits as compared to

mainstream manufacturing.” n

Major reman playersMajor players covered in the report include Andre

Niermann, ATC Drivetrain Inc., ATSCO Remanufacturing

Inc., BORG Automotive A/S, Cardone Industries Inc.,

Caterpillar Inc., Detroit Diesel Corporation, Genuine

Parts Company, Jasper Engines and Transmissions,

Marshall Engines Inc., Maval Manufacturing Inc.,

Motorcar Parts of America Inc., Remy International

Inc., Robert Bosch GmbH, Standard Motor Products

Inc., Teamec BVBA, TRW KFZ Ausrustung GmbH, and

ZF Friedrichshafen AG.

[email protected] KEEP YOU RUNNING

www.arrowheadep.com Call: 1-800-328-5454

SHIPPING WORLDWIDE!

WWW.XTREMEOPE.COM

ReMaTecNews | 22

Ewoud BarinkTel.: 0031 (0)6 5144 8367

• APRA News• FIRM News• International events

• Spain’s Sercore: Broader horizons

ReMaTecNews2014 - NO 1 - VOLUME 14REMANUFActURING INtERNAtIONAL

Keeping legends alive

• Reman award in Las Vegas in 2014

• LKQ acquires MM Knopf

www.rematecnews.com

ReMaTecNews_2014_NO1_cs5_3.indd 1 03-02-14 14:56

Make your reservation for the upcoming edition! For advertising or more information, please

contact your Sales Manager

The no. 1 news magazine dedicated to Automotive and Heavy Duty

remanufacturing worldwide.

Or email to: [email protected] your company – more exposure – more leads

Singapore: Asia’s rising reman star

Former car factory remanufactured

Meritor Taking reman to a higher level

REMANUFACTURING INTERNATIONAL APRIL 2014 | NO 2 | VOLUME 14

www.rematecnews.com

RemaTecNews_2014_E2_3.indd 1 09-04-14 16:15

Or email to: [email protected]

Meritor Meritor Taking reman to a higher levelTaking reman to a higher levelTaking reman to a higher level

Taking reman to higher levels: Caterpillar

Ganzeboom: Making customers happy

New chairman of MERA

Reman alliance for Middle East TransAxle partners OWS in Dubai

REMANUFACTURING INTERNATIONAL JUNE 2014 | NO 3 | VOLUME 14

www.rematecnews.com

RemaTecNews_2014_E3_6.indd 1 11-06-14 15:05

Stopper 90x133 Rematec.indd 1 05-05-15 15:28

®

Hall 10&11 Stand number: 11524

Fraunhofer and Bayreuth University celebrate world class reman centreAfter three years of preparation and

construction, Fraunhofer at Bayreuth

University in Germany is about to open its

new state-of-the-art research and education

centre.

Already Europe’s most advanced centre for research

into remanufacturing, Bayreuth University and the

Fraunhofer Project Group Process Innovation now

boasts an EUR 8 million facility that will reaffirm

Bayreuth’s position as a pre-eminent hub for

the science-based development of processes and

services for the reman industry.

In addition, the facilities are set to play a key

role in the education and training of students,

once they have completed their degrees, and

engineers who will contribute to the expansion

of remanufacturing knowledge over the coming

decades.

Further expansion

Over the coming two months, the staff of 40

engineers and all machinery and equipment

will relocate from their current location at the

Bayreuth University campus to the new building.

Later in the year, the official inauguration will

take place in the presence of senior politicians,

academics and administrators from the state of

Bavaria as well as leading representatives from the

European remanufacturing industry.

“We’re proud of the fact that this large-scale

construction project came in on time – and on

budget,” says Dr. Stefan Freiberger who has been

in charge of the project from the outset.

“For us, the university, and hopefully, for the

remanufacturing industry in general, this presents

a major step forward in that we’re now able

to offer a much broader range of services to Dr. Stefan Freiberger

ReMaTecNews | 23

remanufacturers in Europe and, indeed, across

the world.”

Advances in research

The building comprises 1,000 sq m office space

for a staff of 50, 850 sq m workshops and

laboratories as well as a number of storage rooms,

teaching facilities and meeting rooms. The project

has been under way since its inception close to

four years ago and in the words of Dr. Freiberger

marks “a significant advance in remanufacturing

research with the huge workshop space”.

Part of the renowned Fraunhofer Project Group

Process Innovation, the centre will contribute

significantly to meeting rising demands for

“regenerative (sustainable) production processes.”

Headed by Professor Rolf Steinhilper and

Dr. Stefan Freiberger, it has over the past decade

established a position as Europe’s leading research

institution for remanufacturing.

In the short and mid-term the new building

will focus on the specific areas of service

engineering and remanufacturing, resource–

efficient production and factory planning and

logistics of which the latter aims to deliver

sustainable solutions for production hall planning

to rationalising the production flows for reman

processes etc.

High demand

“The industry is seeing high demand for

sustainable processes and with the new centre,

we expect to add more engineers to the current

40 employed by the Fraunhofer Project Group,”

Freiberger said. “This probably means that within

the foreseeable future, we’ll bring the total

number of specialists working for the Fraunhofer

Project Group to around 60.” n

The new reman centre in Bayreuth

ReMaTecNews | 24

Reman takes to the skies

On a spotlessly clean hangar floor at the

private Cuyahoga County Airport just outside

Cleveland in Ohio, an assortment of aircraft

parts lies scattered alongside the dismantled

body of a business jet. Not long ago, they

were cruising the skies above the North

American continent. Before long, they will do

so again – extending the working life of this

hugely expensive private jet. Welcome to the

new world of business jet remanufacturing.

The international aviation industry, airlines

and component manufacturers, such as Rolls

Royce, have a long record of remanufacturing

components for airliners. Over the years this

has made an enormous contribution to saving

resources, keeping fleets operating at lower costs

and meeting international safety regulations.

Owners of private business jets are now heading

in the same direction. The proof is on the floor

of the hangar in Cuyahoga. Here a young

company named Nextant is busy carving a niche

in a market that promises to spearhead a new

chapter in the history of remanufacturing. Already

Nextant Aerospace is well on the way, seeing

huge opportunities in a market that until now

has appeared to be the sole preserve of global

corporations or super-rich individuals.

Pioneering force

Established in 2007 by aerospace entrepreneur

Kenneth Ricci, it is not the only company of its

kind. The market is increasingly attracting other

players that can see its potential. It is, however,

the pioneering force in this highly specialised field,

a position that allows it to expand sales to markets

across the world: Asia, the Middle East and

Europe. On the day when ReMaTecNews visited

its head office in Cleveland, it was preparing to

dispatch another completed project to a buyer

in the UK. The specifications – and the business

model – are impressive indeed. Nextant’s first

product, the Nextant 400XT, a modified and

modernised Beechjet 400A/XP sells for half the

price of other models with comparable features

and specifications.

For the technically minded, the 400XT is equipped

with 3,050-pound-thrust Williams FJ44-3AP

Full Authority Digital Engine Controls (FADEC)

turbofan engines and a Rockwell Collins Pro Line

21™ integrated avionics suite, which provides

a cruising speed of 850 km per hour and a

range of 3,713 km with four passengers. And

here is an interesting illustration of the power

of remanufacturing - compared to the original

Beechcraft 400A, the remanufacturing process

increases range by 50 per cent, improves fuel

efficiency by 32 per cent, reduces climb times

by one-third and reduces operating costs by 29

per cent.

6000 man hours

Achieving this is no ordinary repair task. When

Nextant’s engineers have completed the reman

process, they will have finished more than 500

individual inspections, replaced all life-limited

components and invested 6,000 man hours during

the process. Not surprising, perhaps, that the

finished product appears brand new, including

Nextant in Cleveland, Ohio has brought world class remanufacturing to the aerospace industry

ReMaTecNews | 25

exquisite interior leathers, passenger cabins that

resemble those of a Hollywood film and boast

every conceivable convenience for passengers and

pilots.

“When you deliver a good product, you take care of the customer and that turns into two more customers - just like any other business.”

And yet, only a few years ago, it was all a dream

in the mind of the serial avionics entrepreneur,

Ken Ricci, who had been involved with aeroplanes

most of his professional life and realised that, in

tune with the times, remanufacturing could give

new life to older aircraft. From inception to the

first commercial product took four years.

“The question was how do you make a good

aircraft great?” explains Jay Heublein, Nextant

Executive Vice President for Global Sales and

Marketing, in a conversation with ReMaTecNews.

“Take an aircraft already in service, then have a

sample group of pilots, mechanics, engineers and

customers come together to work through their

wish list and then put it through a remanufacturing

process. This is exactly what Nextant Aerospace

does.”

Next generation

Following the success of the Nextant 400XT,

the company is now working on a successor,

the Nextant G90XT turboprop, powered by

next-generation GE H75-100 engines for which

expectations are high. Within a few short years,

avionics remanufacturing has gained a significant

foothold in a highly sophisticated market and

Heublein is confident that the upward curve is set

to continue.

“If we made any mistake in our planning, we

probably underestimated how quickly the market

would become global for what we were doing.

We’re a US based company and for the first

five years, we were expecting the majority of

product to stay domestic, but in reality a very

large percentage, probably over 50% right now,

is being exported to different countries around

the world. To date, we’ve delivered more than

40 aircraft to more than eight different countries

around the world. So in a very short period of

time we were able to prove without a doubt that

there is a global demand for this remanufactured

product that we brought to aviation. Every month

it seems we are going somewhere new.”

Market penetration

Looking at the most recent developments,

Heublein reports strong market penetration,

with China as a new customer, which is due to

it receiving its first remanufactured Nextant jet

shortly. Other recent sales include Singapore, New

Zealand and South Africa. The Middle East is also

expected to perform well, which is why Nextant

has established a sales force there.

Jay Heublein, VP Global Sales and Marketing, Nextant

ReMaTecNews | 26

So what is the outlook for Nextant?

“We think the market has the ability to absorb,

without any improvement, 15 to 25 aircraft a

year. For at least the next five years, there are

some indications that our market is starting to

pick up after five years where business aviation has

been somewhat depressed. There are indications

that we may be heading towards some type of

sustained recovery and if the markets improve,

our ability to deliver products will improve. Right

now we feel very good about the number of units

we’re delivering, given the reality of the current

environment.

“At the end of the day we have created an industry

that didn’t exist until now. Remanufacturing exists

in other categories, but nobody outside of the

military – which has been doing it for a long time

– has been doing this in the civilian space before.

As we get more and more happy customers

and as our product gets out there in greater

numbers, this will grow exponentially. We have

a saying that “success breeds success” and when

you deliver good product, you take care of the

customer and that turns into two more customers

– just like any other business, right?” n

Second Life. First Choice.Overhaul of turbochargers – an all-round business

Did you know that you can give defective turbo -chargers a new lease of life, and also generate a profi table business from it?

The key to this are our two balancing machines, the TBcomfort and the TBsonio. Take your chance and get into this rapidly expanding market and fi nd out all you need to know in Hall 11, Stand 11.728 at ReMaTec 2015.

www.turbobalancer.com

Second Life. First Choice.

RT4

054

M

AR

KE

NR

AU

M

rz_anz_rematec_2015_150429.indd 1 30.04.15 15:23

E-Mail: [email protected]

Phone: Sales on 0208 848 9911

We are a main distributor for all the leading automatic transmission parts manufacturers and supply premium quality transmission parts

Automatic Transmission Parts SuppliersAnd Torque Converter Remanufacturers

We are a main distributor for all the leading automatic transmission

Vanmatic Repair PackagesPackages that are designed to cost effectively put all the usual parts required for a repair at a better price than buying the individual components.

We are a main distributor for all the leading automatic transmission We are a main distributor for all the leading automatic transmission

Vanmatic Repair PackagesPackages that are designed to cost effectively put all the usual parts required for a repair at a better price than buying the individual components.

We can supply parts for any type of automatic gear box including:-

overhaul kits, friction clutch plates, brake bands, filters, steel clutch plates, oil seals, gaskets, thrust washers, thrust bearings, bushes,

solenoids, sensors, pistons, hard parts, valve body’s and much more.

We can supply parts for any type of automatic gear box including:-

RELY ON ZF.BECAUSE TRUST HAS A NAME.

ZF Services. If you‘re looking for a reliable source for spare parts, there‘s no substitute for brand-name products. You get quality with a guarantee. Original equipment by SACHS, LEMFÖRDER and ZF Parts gives you the leading edge. You know you‘ll be providing your customers with original equipment quality. For cars as well as commercial vehicles.www.zf.com/services

Visit us at ReMaTec, booth 11.208.

ZFS_Ad_Rematec_90x277mm_1502_EN_136956_0.indd 1 04.02.15 11:13

ReMaTecNews | 28ReMaTec Events show special

The world’s remanufacturers gather in Amsterdam

A huge selection of professional activities,

a record number of exhibitors and visitors

from across the globe, larger floor space than

ever before, two important conferences,

events focussing on remanufacturing’s role

in the circular economy, presentations aimed

exclusively at the reman supply chain and

the most extensive networking opportunities

offered in one place.

Those are the key reasons why the world-wide

leaders and operators within the automotive

and heavy duty reman industries gather at the

Amsterdam RAI Exhibition Centre between 14 and

16 June for the eighth ReMaTec Remanufacturing

Exhibition. At the time of writing no less than 225

exhibitors have announced their participation in

the world’s largest remanufacturing exhibition

with visitor attendance expected to exceed 3,500.

Visitors will be travelling to Amsterdam from over

60 countries.

“Pre-show interest has been overwhelming and

we expect numbers to increase even further

in the weeks prior to the show,” says Niels

Klarenbeek of Amsterdam RAI, the organiser of

ReMaTec2015. “That remanufacturing is growing

by leaps and bounds is beyond dispute and we’re

proud of being part of a rapidly rising trend.” The

trend is evidenced by the number of international

delegations attending or directly participating

in the show. China, the rising power in the

motor industry, is represented by two high level

delegations and the US Commercial Service, the

export promotion arm of the US Department of

Commerce, has organised visits by from number

of delegation via its world-wide embassies, all

of which will be looking for information about

remanufacturing and links to reman suppliers. n

ReMaTec appA service that will be appreciated by exhibitors

and visitors alike is the comprehensive

ReMaTec app for smartphones, a convenient

guide through the floor plan, exhibitor lists

and all the new products on display.

Visitor registrationOnline registration is now open and visitors

can register for a free entrance badge until

5 June. After this date, fees apply unless

visitors can show an invitation from an

exhibitor. For further information, please visit

www.rematec.com.and all the new products

on display.

InnovationLABInnovation takes centre-stage with the

introduction of the InnovationLAB. In Hall 10

special attention will be given to the latest

trends and developments in the industry,

introducing a selection of industry-firsts.

Powerful Chinese delegations

ReMaTecNews | 29ReMaTec Events show special

The delegation:

Key people in China’s march towards

remanufacturing. From left: Zhang

Shaobo, Deputy General Manager, Beijing

Chengwaicheng International Autoparts

Center, Li Baomin, Vice Director of Auto &

Motorbike Parts & Accessories Chamber of

Commerce, All-China Federation of Industry

& Commerce, Ma Rong, Vice Director of

Environment & Resource Department,

National Development and Reform

Commission, General, Professor Xu Binshi,

Academician of China Engineering Academy

and Father of China’s remanufacturing

industry, Wang Pingsheng, President of

China Economic Herald, Yu Guang, Director

of Technical Department, China Association

of Automobile Manufacturers and Zhu

Yonggang, COO of Ping An Property &

Casualty Insurance Company of China Ltd.

Vice Director Ma Rong will head the Chinese

delegation to ReMaTec2015.

One of China’s most influential economic

government agencies will use ReMaTec2015

to gain insight into Europe’s automotive and

heavy duty remanufacturing sector.

The aim of a delegation from the powerful National

Development and Reform to ReMaTec2015 is

to acquire knowledge and create contacts to

European players as remanufacturing, circular

economy issues and sustainability are rapidly

gaining ground in China.

During its European tour the delegation, led by

the Deputy Director Ma Rong and Yao Xin will

also visit remanufacturing plants, including Italy’s

Sermec and AutopLanet Transmissions and French

core dealers and EIT. The World Reman Summit

is another item on the delegation’s agenda. The

National Development and Reform Commission

is the hugely influential macroeconomic

management agency under the Chinese State

Council, and has wide-ranging administrative and

planning control over China’s economy.

In recent years NDRC, has been tasked with

restructuring the country’s economic development,

and been instrumental in the promotion of the

circular economy in China. In particular, the NDRC

has been responsible for approving a number

of important pilot schemes for remanufacturing,

thus laying the groundwork for Chibna’s future

reman industry.

CAAM

The visit by the NDRC group is the organised in

conjunction with a second Chinese delegation,

as announced in Edition 2 of ReMaTecNews, by

members of the Chinese Aftermarket Association,

CAAM, which represents the country’s

remanufacturing industry.

“NDRC has an important role in launching and

updating policies for remanufacturing in China

and CAAM’s reman committee is pleased to be

involved in NDRC’s European trip,” a spokesman

for CAAM said. “In view of the importance

of NDRC to China’s automotive industry, we

welcome NDRC’s decision to visit ReMaTec.” n

Mixing business with pleasure“All work and no play makes Jack a dull boy”,

runs an old English saying. There is no risk of

that at ReMaTec2015.

While most of the hard work will take place at hall

10 and hall 11, the show will also offer a wealth

of networking opportunities away from the trade

show floor. A repeat of the similar – and very

successful - event at ReMaTec2013 two years ago,

a top attraction will be the ReMaTec cruise along

Amsterdam’s famous canals. Enjoying drinks

in the early summer evening, over a hundred

exhibitors and visitors spent a few very pleasant

hours on the water.

“The cruise two years ago was a kind of

experiment,” said Niels Klarenbeek, ReMaTec2015

organiser. “When we were back on terra firma

again, there was no doubt that this event should

be repeated in 2015. It was so popular that the

trip was heavily oversubscribed last time so we

would encourage everyone to sign up in good

time to avoid disappointment.”

The canal cruise is scheduled for Saturday 13

June, with departure from the Amsterdam RAI

marina at 17.30. Tickets are priced at EUR 55 (ex.

VAT) and can be purchased from the online visitor

registration site or the exhibitor web shop. n

ReMaTecNews | 30ReMaTec Events show special

Organised by Circle Economy, the symposium

features lectures and seminars from

experts in the automotive industry on best

practice leadership styles, technological

developments, new business models,

logistical solutions, as well as marketing and

sales strategies that might be applicable in

the reman sector as a whole will all come

under the microscope.

“Our main goal is to show how some of the

principles of the circular economy are already

happening,” says communications manager

Arjanne van der Plas. “Circle Economy is a non-

profit cooperative based in Amsterdam. Together

with members we look at their role in the circular

future and how we can back them in taking the

first steps. Sometimes this involves technological

pilots such as exploring ways for dairy companies

to use manure as a resource or in the textiles

industry, how to better recycle polyester and

achieve greater consumer acceptance of polyester

clothing.

“The primary focus of our seminar will be the

lessons that can be learnt from the – mainly

automotive – frontrunners in remanufacturing.

These different topics will be spread across various

time slots. In addition, we will offer guidelines for

looking around the exhibition to help those who

are not directly involved in the remanufacturing

business gain a good overview of what is on offer.

“Our target group is a combination of our

members and other companies interested in

the circular economy, from R&D and innovation

experts to CEOs from SMEs. There’s a lot of talk

about the circular economy which is holistic and

inspirational, but we hope to make it very practical

in line with our motto: ‘Change is good. You go

first!’. We want to showcase the people who

have already gone ahead and reveal why there’s

no excuse not to change. ReMaTec is technology-

focussed and our aim is to zoom out and show

the kind of movement in which this fits.”

See www.circle-economy.com/events for more

information. n

Circular Economy Seminar

Trade shows provide opportunities for

industry players to showcase products,

present methods and processes and exchange

news and views within their professional

communities. Good trade shows also enable

exhibitors and visitors to look into the future

of their industries – to get a sense of what

lies ahead.

At ReMaTec2015, three major events allow for

just that: the World Remanufacturing Summit,

where world-class scientists and reman executives

come together to exchange knowledge, the ICoR

conference, which transcends the boundaries

of academic research and the Circle Economy

Symposium that focuses on environmental

challenges and their impact on reman industries.

You can read about the World Remanufacturing

Summit of which ReMaTecNews is a founding

partner on page 43. Below, ICor and Circle

Economy explain how attendees will benefit. n

Side events offer inspiration at RAI

ReMaTecNews | 31ReMaTec Events show special

ICoR 2015Organised by the universities of Strathclyde

in the UK and Linköping in Sweden, ICoR

2015 gathers global knowledge and expertise

in remanufacturing practice and research.

ICoR offers a chance to learn how innovative

experiences can facilitate developments

in technology and research in sustainable

manufacture and waste management.

“We chose to hold ICoR 2015 in Amsterdam as it

links what is largely an academic conference with

the most well-known reman trade exhibition,”

says Dr James Windmill, Strathclyde University.

“Those of us in the academic world who are

busy in remanufacturing want to research what is

happening in the sector to the best of our ability

and ReMaTec is an excellent opportunity for us to

attend the conference and to discover what the

industry at large is up to at first hand.

“As leader in the academic conference field, we

bring a sense of purpose and a very specific focus.

There is no specific remit for a particular kind of

remanufacturing as we will be offering a very

broad range of presentations. They will reflect a

clear shift from the reasons why remanufacturing

is a good idea to a focus on the various ways to

optimise remanufacturing as a process, and the

decision-making and business models involved.”

“ICoR is a rare chance for researchers around the

world to come together and share knowledge

and experiences. In the past, academics active

in remanufacturing tended to visit sustainability

conferences where there might be at best half a

dozen papers on remanufacturing. At ICoR 2015

there will be forty reman papers in two days,

combined with the opportunity to visit the trade

show and ask questions of the industrialists. We

also hope that ReMaTec exhibitors come and see

what the academic community is doing.”

See www.remanufacturing-conference.com for

more information. n

ReMaTec - from strength to strengthThe organiser of the ReMaTec shows,

Niels Klarenbeek, Amsterdam RAI, gives a

rundown of June’s event.

ReMaTec2015 is the show’s largest edition

so far. What sets this edition apart from its

predecessors?

The key difference is the increased presence of

global players. The industry is clearly becoming

a worldwide industry, which is reflected by the

exhibitors on the show floor. Within a few short

years, remanufacturing has become a major

player on the world stage.

What are the key benefits for exhibitors and

visitors to the show?

For exhibitors, the benefits are undoubtedly the

number of quality visitors. We have invested a

lot of time and resources in attracting the right

audience. There is no doubt that the figures are

well up on previous years. I’m confident that

this year will once again see a record number of

visitors with the willingness and power to buy. As

for the visitors, the main benefit for them lies in

the fact that all the world’s important suppliers are

gathered in one place. In addition, the ReMaTec

Theatre and the other side events are strong

attractions that offer genuine opportunities for

new learning.

To what do you ascribe the present upsurge

of the reman industry?

Growing public understanding of sustainability

and conservation of resources, is obviously a

key driver. This is one of the main reasons why

remanufacturing is such an attractive business

to be in right now. Reman is not just a business,

it’s an industry. It offers genuine value for our

society and, indeed, the individual consumer.

It’s also a proven job creator. Last but not least,

the financial crisis has driven the demand for

cost-effective, quality alternatives. Sustainability,

employability and cost awareness have created

the “perfect storm” that drives the reman industry

forward.

How do you see the future direction of the

ReMaTec concept?

With our annual sister show BigR/ReMaTecUSA in

Las Vegas, we cover all the world’s major markets.

This provides us with very significant potential for

developing these shows further. I can even see

opportunities for extending the show model into

other parts of the motor industry as learning and

updated knowledge become ever more crucial for

remanufacturers – as well as offering them new

opportunities. We live in a world where continued

learning is paramount and we would like to be

part of extending such opportunities to everyone.

We’re doing this within reman.

Could there be similar opportunities in other

areas?

We have seen a significant increase in exhibitors

and visitors from China and Southeast Asia,

especially during the last two editions of ReMaTec.

This June, there will be a large pavilion from the

Remanufacture Committee of China Association

of Automobile Manufacturers and various

delegations will be welcomed. It’s clear that

countries like Japan, China and Singapore have

a powerful agenda in terms of remanufacturing,

which could possibly lead to a new ReMaTec

event in that region. n

Niels Klarenbeek, Domain Manager ReMaTec

ReMaTecNews | 32ReMaTec Events show special

Milestones in 15 years of progress

2001The ReMaTec exhibition is founded by a small

Danish exhibition organiser and trade magazine

publisher named Visholm. First show takes place

at Amsterdam RAI Exhibition and Conference

centre. ReMaTecNews is launched as an

international trade magazine for the automotive

remanufacturing industry.

2003Second ReMaTec edition is held in Amsterdam.

Visholm is taken over by the Aller group, one of

Scandinavia’s largest magazine publishers.

2004Amsterdam RAI, one of Europe’s largest exhibition

centres, buys the rights to the ReMaTec shows,

which are then merged into RAI’s diverse

exhibition activities. ReMaTecNews becomes part

of RAI Langfords, RAI’s publishing house, which

owns a series of Dutch trade titles.

2005First ReMaTec show organised by Amsterdam RAI.

ReMaTecNews launches its Remanufacturer of

the Year award. The first winner is Jens Lindholm,

Managing Director of renowned Danish starter and

alternator remanufacturer, Holger Christiansen.

2007The first APRA European Symposium is held in

conjunction with the show.

2011

2007

2005 2005

ReMaTecNews | 33ReMaTec Events show special

2009The financial crisis severely affects the automotive

aftermarket. ReMaTec2009 is the smallest

ReMaTec event since the inaugural show in 2001.

2010To further strengthen the ReMaTec concept,

Amsterdam RAI appoints Niels Klarenbeek,

head of its reman activities and organiser of the

ReMaTec shows.

2011Michael Cardone Jr., owner of the world’s largest

private remanufacturing company, Cardone

Inc., gives a keynote speech at ReMaTecNews’

Remanufacturer of the Year award. The 2011

winner is Philippe James of Remy Europe.

Launch of the ReMaTec Theatre for presentations

of products, methods and innovation.

ReMaTec obtains Trade Show Certification by the

US Department of Commerce.

Record breaking visitor numbers: 60% up on

2009.

New entrants such as Meritor, Caterpillar,

Cummins and Valeo take large custom-built

stands at the show.

2013First ReMaTec social event (150 people tour the

Amsterdam canals).

Following successful negotiations, APRA, the

Automotive Parts Remanufacturers Association,

and Amsterdam RAI agree to join forces to

organise APRA’s annual Big R exhibition in Las

Vegas, Nevada. The revived show is named the

Big R/ReMaTecUSA.

2014The first BigR/ReMaTecUSA show rolls out in

November 2014 at the Rio Hotel and Conference

Centre, Las Vegas. The show is double the size

of the previous year’s event. Strong growth in

international attendees and exhibitors.

ReMaTecNews names Jack Stack, founder and

head of SRC, Springfield, Missouri Remanufacturer

of the Year.

2015The eighth edition of the ReMaTec show in

Amsterdam is set to exceed all previous records

in terms of exhibitor and visitor numbers as well

as activities.

The exhibition organisers add another large

exhibit hall, Hall 10 and launch InnovationLAB, a

special section for innovative products,

The fourth World Remanufacturing Summit is

held in connection with the show. The conference

programme also includes ICoR2015 and Circle

Economy Symposiums. n

2013

2009

20112013

2015

ReMaTecNews | 34ReMaTec Events show special