RELEASE 516 - Maintenance

Transcript of RELEASE 516 - Maintenance

DisclaimerThis document contains Honeywell proprietary information. Information contained herein is to beused solely for the purpose submitted, and no part of this document or its contents shall bereproduced, published, or disclosed to a third party without the express permission of HoneywellInternational Sàrl.

While this information is presented in good faith and believed to be accurate, Honeywell disclaimsthe implied warranties of merchantability and fitness for a purpose and makes no expresswarranties except as may be stated in its written agreement with and for its customer.

In no event is Honeywell liable to anyone for any direct, special, or consequential damages. Theinformation and specifications in this document are subject to change without notice.

Copyright 2020 - Honeywell International Sàrl

- 2 -

Contents 3

Chapter 1 - About this guide 11.1 Revision history 1

1.2 Terms and Definitions 1

Chapter 2 - Introduction 72.1 Overview 7

2.1.1 The Common Industrial Protocol (CIP™) 7

2.1.2 Ethernet/IP™ 7

2.1.3 Interoperability 8

2.1.4 Essential CIP Concepts and Terms 8

Chapter 3 - Experion EIP Solutions Overview 123.1 Summary of Experion EIP Solutions 12

3.2 EtherNet/IP Topologies Supported 14

3.3 Major Classification of EtherNet I/P Devices 16

3.4 Common EIP I/O Device Structures 16

3.4.1 Generic I/O Devices: 17

3.4.2 Modular I/O Devices: 17

3.4.3 DeviceNet Devices: 18

3.5 EIP Device Types and Interface Methods 18

3.6 Solution Configuration in Control Builder 20

3.7 Ethernet/IP Device Templates Present in Experion Library 20

Chapter 4 - EIP Network Details 234.1 C300 Direct EIP Solution 23

4.1.1 Prerequisites 23

4.1.2 C300 DIRECT Solution - FTE Topology 24

4.1.3 Assigning EIP to the C300 25

4.1.4 C300 Direct Solution - Rules and Caveats 26

4.1.5 C300 Direct Solution – Sample EIP Topologies 28

4.2 C300 EIM EIP Solution 29

4.2.1 Prerequisites 29

4.2.2 Assigning EIP Capability to the C300 29

Chapter 5 - EIM Block Configuration 315.1 EIM Redundancy Option 34

5.2 C300 EIM FTE Topologies and Overview 35

- 3 -

5.3 C300 EIM Solution - Rules and Caveats 36

5.3.1 EIM EIP Solution – Sample Topologies Using Stratix 8000 38

5.3.2 EIM EIP Solution – Sample DLR Using 1783-ETAPs 39

5.3.3 EIM EIP Solution – Sample DLR Using the Stratix 5700 40

Chapter 6 - Creating Ethernet/IP™ Device, Drive, and I/O Module Types 416.1 Prerequisites 41

6.2 Creating Ethernet/IP™ device types using EDS files 41

6.4 Creating Ethernet/IP™ drive types using EDS files 42

6.4.1 To create device types using EDS files 42

6.5 Creating Ethernet/IP™ drive types without EDS files 50

6.6 Creating Ethernet/IP™ I/O module types using EDS files 53

6.7 Creating Ethernet/IP™ I/O module types without EDS files 56

6.8 Configuring data link parameters 58

Chapter 7 - Introduction to UDT Concepts 617.1 What is a ControlLogix UDT and How is it Used? 61

7.2 UDT – Input Parameters & Output Parameters 62

7.3 UDT - Data Types Supported in Experion R511 62

7.4 UDT Template vs. Instance Concept 64

7.5 CPU Loading Due to UDT Points 64

7.6 C300 and ControlLogix integration 65

7.7 Configuring ControlLogix Tags in peer references fromExperion strategies 66

7.7.3 Configuring the ControlLogix Gateway block 70

7.7.4 Creating Control Logix Aggregate UDT Type 71

7.7.5 Creating Control Logix Scalar UDT Type 74

7.7.6 Defining the ControlLogix tag access 88

7.7.7 Using Aggregate or Scalar Tag Instance for Read and Write Operations 91

Chapter 8 - Planning and Design 938.1 Planning EtherNet/IP implementation 93

8.1.1 Network requirements 93

8.1.2 Ethernet/IP™ implementation architecture and topology 97

Chapter 9 - Ethernet/IP™ Device Configuration in CEE 1079.1 Guidelines for Ethernet/IP™ device configuration 108

9.2 Known limitations 111

- 4 -

9.3 Configuring the ArmorPoint Ethernet/IP™ adapter block 115

9.3.5 Consolidate connections 116

9.3.6 Configuring the IP address of an Ethernet/IP™ device 117

9.4 Configuring ArmorPoint I/O module blocks 118

9.5 Configuring ArmorBlock I/O module blocks 119

9.6 Configuring the EIP GenAdapter Block 121

9.7 Configuring the IP address of an EIP device 128

9.8 Configuring GenAdapter I/O module blocks 128

9.9 Slot 0 Diagnostic Information 130

9.10 Slot 0 Configuration 131

9.11 Configuring PowerFlex drive blocks 132

9.12 Configuring E3 relay blocks 133

9.13 Assigning Ethernet/IP™ devices to the CEE C300 block 135

9.14 Configuring channels in Ethernet/IP™ devices 136

9.15 Ethernet/IP™ device configuration references 136

9.15.1 Advance Configuration or Statistics 137

9.15.2 Alarms tab 138

9.15.3 Channel Configuration tab 138

9.15.4 Configuration tab 142

9.15.5 Data/Status tab and Data/Command tab in PowerFlex drive block 142

9.15.6 Data/Status tab and Data/Command tab in E3/E3 plus relay blocks 145

9.15.7 Sensor Type and PV Low and High Signal range for RTD module - ArmorBlock 1732E-IR4IM12R 149

9.15.8 Sensor Type and PV Low and High Signal range for Thermocouple module -Armor Block 1732E-IT4IM12R 150

9.15.9 Cold junction configuration for thermocouple module - Armor Block 1732E-IT4IM12R 151

9.15.10 Digital Filter configuration for thermocouple and RTD modules of theArmor block family 154

9.15.11 PV scaling factor configuration in thermocouple modules 154

9.16 Through EIM Ethernet/IP™ Different Topology ExampleScenarios 155

9.16.1 EIM primary and secondary downlinks are connected to single switch 155

9.16.2 EIM primary and secondary downlinks are connected to different switches 156

9.16.3 EIM primary and secondary downlinks are directly connected to DLR 156

9.16.4 Multiple EIMs are sharing same device network through switch 157

9.16.5 Multiple EIMs are sharing same device network through DLR 158

- 5 -

9.16.6 ControlLogix SCADA access 158

9.17 On Demand Connect Feature for EIP blocks 159

9.17.1 Connect On-Demand 159

9.17.2 User Scenarios 161

9.17.3 Scenarios specific to Non-Chassis, Adapter/Chassis with Direct connectionsand Adapter Modules 163

9.17.4 Scenarios specific to Adapter based Modules 167

9.17.5 Scenarios specific to Adapter based Modules, being used withoutconsolidation of connections 168

9.17.6 Scenarios specific to Adapter based Modules, being used with consolidationof connections 169

Chapter 10 - Configuring ControlNet IOMs in Ethernet/IP™ 17310.1 UOC vUOC supported topologies with ControlNet IOMs 173

10.1.1 Non-Redundant Star IO Network with UOC 173

10.1.2 DLR IO Network with UOC 174

10.2 Cascaded network support in UOC to ControlNet IOModules 175

10.2.1 Cascaded network support in ControlNet IOMs 176

10.2.2 Cascaded network support with Redundant Chassis 176

10.2.3 Ethernet IP Network with ControlNet IOMs 177

10.2.4 Non-Redundant Star IO Network with vUOC 178

10.2.5 Design for Cascaded network support 179

10.3 Configuring ControlNet IO 179

10.4 ControlNet Alarms 184

Chapter 11 - Ethernet/IP™ Supportability 18511.1 Ethernet/IP™ device configuration 186

11.2 Parameter Definition Editor (PDE) Grid Tabs 187

11.3 Device type modification 190

11.3.3 Modifying device types 191

Chapter 12 - EIP IO behavior during C300 or EIM switchover 194

Chapter 13 - Simulate Control Strategy 19513.1 For UDT Blocks 195

13.2 For IO Blocks 195

Chapter 14 - Troubleshooting Scenarios (Hardware and Software) 196

Chapter 15 - CIP Error code 19715.1 Status Codes 197

- 6 -

15.2 Connection Manager Service Error Codes 202

15.3 Honeywell specific Extended error code 230

Chapter 16 - Appendix - A 23116.1 Third Party EIP Network Component Details 231

16.2 Configuring a Stratix switch for Ethernet/IP™ integration 231

16.2.1 Prerequisites 231

16.2.2 To configure the Stratix switch for Ethernet/IP™ integration 231

16.2.3 Connecting locally to the switch 232

16.2.4 Checking the version of the switch IOS 232

16.2.5 Accessing switch configuration files 233

16.2.6 Configuring switch interface options 237

16.2.7 Loading the switch configuration file 240

16.2.8 Switch Maintenance 241

16.3 Tofino firewall configuration 242

16.3.1 Software and hardware requirements for Tofino firewall configuration 243

16.3.2 Configuring the Tofino firewall 244

- 7 -

ABOUT THIS GUIDE

This document provides an overview and implementation details related to the Experion C300 andUOC controller integration with Ethernet/IP™ networks and Ethernet/IP conformant devices.

The following EtherNet/IP solutions are covered in this guide:

l C300 Direct solution: First released with Experion R430

l C300 EIM (Ethernet Interface Module) solution: First released with Experion R500

l UOC Downlink solution: First released with Experion R505

NOTE

The Experion SCADA EtherNet/IP solution is covered in a separate document.

1.1 Revision history

Revision Date Description

A August 2020 Initial release of the document

1.2 Terms and Definitions

Term Definition

EtherNet/IPDevice

A CIP protocol concept. An Adapter device (or I/O Adapter) isa device on the EtherNet/IP network that connects to theprocess and performs some process related function. Someexamples include I/O subsystems (typical AI, AO, DI, and DOI/O modules), field instruments (like valves and transmitters),Variable Frequency Drive controllers, motor starters, and thelike. Scanner devices connect to adapter devices to transfer(read and write) data. Relative to this document, the C300,UOC and EIM are considered a scanner device.

Adapter Block A Control Builder concept. A function block configured inControl Builder to represent the Adapter Module of a modularIO station such as Rockwell AB’s Armor Point IO.

- 1 -

CHAPTER

1

Term Definition

AdapterModule

A communication device which connects to the Ethernet/IP™network to serve data from a set of devices or modulesunderneath it. Adapter Modules typically support IOconnectivity from Scanners via implicit Ethernet/IP™connections.

Assembly A CIP protocol concept. Provides the mechanism to pass databetween the Scanner and Adapter device over theEtherNet/IP network.

An assembly is a pre-defined set of data (parameters) residingin an Adapter device. Each assembly can consist of multipleparameters that can be of different data types. Assemblies areidentified by a unique instance number and are usuallydefined by the Adapter vendor.

Three types of assemblies are:

l Input (data to be sent from adapter to scanner)

l Output (data to be sent from scanner to adapter), and

l Configuration (a data area reserved for information abouthow consumed and produced data is to be interpreted).

The user entered RPI setting determines the update rate forthe input and output assemblies. Input and output assembliesutilize Implicit messaging.

CIP Common Industrial Protocol (CIP™). CIP is the protocollanguage used to enable communication between all nodeson the network. CIP is physical media and data link layerindependent. This media independence provides the ability tochoose the CIP Network best suited for your application. CIPvariants include ControlNet, CompoNet, DeviceNet, andEthernet/IP. CIP and all of its variants are managed andcontrolled by ODVA. More information can be found at thefoundation website. WWW.ODVA.org

ControlLogixUDT Tag

A unique Tag name is assigned to each UDT. UDTs are used totransfer data between the ControlLogix PLC and theC300/UOC. See UDT definition below.

A named data item resident in a Rockwell AB ControLogixPLC. Individual, scalar data items can be named with Tags orgroups of data called structures can be named with Tags. Thetransport of tagged data between Honeywell Controllers/EIMand ControlLogix is accomplished using User Defined DataType (UDT) Blocks.

- 2 -

Chapter 1 - About this guide

Chapter 1 - About this guide

Term Definition

Custom BlockType

A Control Builder concept. A block type in Control Builder andCEE which is created to integrate specific Adapter typedevices. These blocks provide all of the information requiredto connect to a particular Adapter device, transfer assemblyinformation, and adapt data types to the expected Experiondata formats.

More details related to adding and managing EtherNet/IPcompliant devices is provided in later sections of thisdocument.

Device Block An Experion block which enables the Honeywell controllers ( C300 & UOC ) and EIM controller to communicate with anEthernet/IP™ device.

A specific Device Block must be created for every uniqueDevice (and major device revision). Many device types havealready been added (see list in later section). The solutionprovides the tools to add new devices without the need toincrement the Experion release.

DLR (DeviceLevel Ring)

A commonly used EtherNet/IP network topology whereEtherNet/IP devices are connected in ring. This topologyimproves availability by tolerating single cable faults.

EDS(ElectronicData Sheet)

A CIP protocol concept: The Electronic Data Sheet (EDS) is atext file which specifies the properties and capabilities of aspecific Adapter device.

Adapter device vendors are required to provide an EDS file foreach of their devices.

ExperionEtherNet/IP™Solutions

In this document, this term includes all Experion solutionscovered in this document (C300 Direct, C300 EIM, and UOCDownlink solutions).

EtherNet/IP™Devices

In this document, this term will identify that set ofEtherNet/IP™ devices that physically connect to the processand perform some process related task. Some examplesinclude: • VFDs (Variable Frequency Drives) • Motor startersand smart relays • I/O systems and traditional I/O modules(AIs, AOs, DIs and DOs) • Field Instruments (such as vales,transmitters, analyzers, and the like) Visit the ODVA website(WWW.ODVA.org) for a full list of conformant EtherNet/IP™devices.

ImplicitMessaging(Class-1)

A CIP protocol concept: One of two primary messagingmethods used to transfer data between an Adapter device andScanner device on the EtherNet/IP network

- 3 -

Term Definition

Implicit messaging is well suited for data that must betransferred in a cyclic manner. This data transfer mechanismis fast, deterministic, and well suited for data that is used fordirect control and logic applications. Data transfer with allEtherNet/IP™ I/O Devices uses Implicit messaging.

ExplicitMessaging(Class-3)

A CIP protocol concept: One of two primary messagingmethods used to transfer data between an Adapter device andScanner device on the EtherNet/IP network.

Explicit messaging is used to transfer non-time criticalinformation (like device configuration parameters). It is wellsuited for data that does not need to be cyclic andapplications that can tolerate a lower level of determinism.

UDTs use Explicit messaging to transfer data betweenControlLogix and C300/UOC controllers.

InputAssembly

A CIP protocol concept. Provides the mechanism to pass databetween the Scanner and Adapter device over theEtherNet/IP network.

An assembly is a pre-defined set of data (parameters) residingin an Adapter device. Each assembly can consist of multipleparameters that can be of different data types. Assemblies areidentified by a unique instance number and are usuallydefined by the Adapter vendor.

In this manual, Input Assemblies are used to transfer datafrom EIP I/O Devices to the C300/EIM and UOC. The RPIsetting determines the update rate.

OutputAssembly

A CIP protocol concept. Provides the mechanism to pass databetween the Scanner and Adapter device over theEtherNet/IP network.

An assembly is a pre-defined set of data (parameters) residingin an Adapter device. Each assembly can consist of multipleparameters that can be of different data types. Assemblies areidentified by a unique instance number and are usuallydefined by the Adapter vendor.

In this manual, Output Assemblies are used to transfer datafrom C300/EIM and UOC to EtherNet/IP™ I/O Devices. TheRPI setting determines the update rate.

ConfigurationAssembly

A CIP protocol concept. An Assembly which transportsconfiguration data from the Scanner to the Adapter device.

Configuration Assemblies are sent at the time that a

- 4 -

Chapter 1 - About this guide

Chapter 1 - About this guide

Term Definition

connection is initially established with the Adapter device.

A Configuration Assembly byte size of zero is sent when theConfiguration Assembly is not supported for the givenAdapter device. In this case, configuration must be providedby a separate Ethernet/IP™-connected tool.

IO ModuleBlock

A Control Builder and CEE tagged block is used to interfacewith traditional AI, AO, DI, and DO modules and channels.Each of the I/O modules may have their own dedicated EIPinterface (also referred to as block I/O), or may have amodular I/O architecture where a single EtherNet/IP™interface is shared by a number of assigned I/O modules. Achassis I/O solution is one example of a Modular I/O solution.

Modular IO A modular IO is a typical chassis with adapter module and aset of Input Output Modules (IOMs). The adaptor moduleprovides the interface to the chassis for Input OutputModules (IOMs). One IP address is required to communicatewith the chassis. One Implicit connection may be required foreach IOM.

The Adopter consolidates IOM data and sends data toscanner. Scanner in turn parses the data.

PDE(ParameterDefinitionEditor)

Control Builder Tool: The Parameter Definition Editor (PDE)tool is invoked within Control Builder.

With respect to the Honeywell EtherNet/IP™ solutions, thetool is used for the following:

• To complete EtherNet/IP™ I/O Device configurationconfiguration and information that was not contained in thevendor EDS file.

• To complete parameter entries for UDT points

RPI(RequestedPacketInterval)

Requested Packet Interval: A user entered value (inmilliseconds). It determines the update rate for the following:

l Input Assemblies via Implicit messaging

l Output Assemblies via Implicit messaging

l UDT data transfer between the C300 and ControlLogixPLC via Explicit messaging

Note: Always check vendor device specifications forsupported range of RPI settings.

Scanner A CIP protocol concept. Scanner devices connect to the

- 5 -

Term Definition

Device Ethernet/IP™ network and communicate with Adapter typedevices. See Adapter device definition.

Relative to this document, the C300, EIM, and UOC areconsidered to be Scanner devices. They can directly connectto Adapter devices to read and write data that can be used forcontrol, logic, and to provide information for the operatorinterface.

UDT (UserDefined DataType)

A Rockwell PLC term and concept: User Defined-Data Type.(UDT) is a mechanism for transferring data (as reads andwrites) between the C300 and a ControlLogix PLC.

In concept the user creates UDTs on the ControlLogix sidethat consist of a set of user defined parameters of userdefined data types. The UDT is then assigned a unique Tagname. The user then creates an identical UDT (and Tagreference) in Control Builder and downloads the UDT to theC300.

Data transfer (as inputs and outputs) then commence andcontinue according to the user entered RPI setting. Explicitmessaging is used for UDT points.

UDT types supported: (UDTs are fully defined by the user)

l Multi-Parameter or Aggregate: Can have multipleparameters of different data types.

l Scalar: Has one parameter of a given data type

UDT Block A Control Builder concept: A block created in Control Builder.The user creates a UDT block on the Experion side thatexactly matches a UDT that has been created on theControlLogix side.

In concept, the user will create a UDT template on theControlLogix side. They must then create an identical UDTtemplate on the Control Builder side. Each UDT Blockrepresents one of these UDT templates. One UDT Block isrequired for every different UDT template. Instances of thetemplate can then be created and assigned unique TagNames. The Tag Names must match on the ControlLogix andC300/EIM/UOC side.

See UDT definition for more details.

IO Modules The input/output module (I/O module) is normally connectedto the computer system on one end and one or moreinput/output devices on the other.

UOC Unit Operations Controller

- 6 -

Chapter 1 - About this guide

INTRODUCTION

2.1 Overview

2.1.1 The Common Industrial Protocol (CIP™)

EtherNet/IP™ DeviceNet™, ControlNet™, and CompoNet™, are commonly used industrial networksolutions. These network solutions are all linked by one common protocol, the Common IndustrialProtocol (CIP™).

It’s important to separate CIP (the communication protocol) from the network infrastructureselected to transport the digital packets from node to node.

CIP is a media independent protocol and is currently implemented on the following networks…

l CompoNet™ …………. CIP on TDMA technology

l ControlNet™ ………… CIP on CTDMA technology

l DeviceNet™ …………. CIP on CAN technology

l EtherNet/IP™…....... CIP on ETHERNET technology

EtherNet/IP is the primary focus of this document.

CIP encompasses a comprehensive suite of messages and services to fully support a broadspectrum of applications including control, safety, energy, synchronization & motion, informationand network management. CIP is applicable to both process and factory automation in bothcontinues and batch operations.

CIP is a modern, mature, and object oriented protocol that provides connections betweenindustrial devices (sensors, actuators, drives, motors, I/O, etc.) and higher-level devices(controllers and user interfaces). CIP is the protocol language used to enable communicationbetween all nodes on the network. It is physical media and data link layer independent. This mediaindependence provides the ability to choose the CIP Network best suited for your application.

CIP and the network variants above are promoted, controlled, and managed by ODVA. Refer to theODVA website for more information and a list of ODVA conformant CIP devices and vendors.

WWW.ODVA.org

2.1.2 Ethernet/IP™

In the simplest terms, Ethernet/IP™ is CIP as implemented over standard Ethernet. This enablesthe user to realize all of the benefits of both CIP and the Ethernet technology (IEEE 802.3combined with the TCP/IP Suite).

Ethernet/IP networks can host a variety of different I/O devices (such as Variable FrequencyDrive controllers, motor starters, typical I/O modules, field instruments, to name a few) from alarge list of vendors. The user can satisfy a broad spectrum of process control needs over onenetwork and using one protocol.

Additional EtherNet/IP details and a full list of conformant EtherNet/IP devices can be found onthe ODVA website.

- 7 -

CHAPTER

2

The Experion EIP solutions provide a comprehensive and effective integration to EtherNet/IPnetworks and conformant EtherNet/IP I/O devices. These smart networked I/O devices along withthe large amount of valuable process and device data resident in each, can be used to……..

l Augment control and logic

l Augment plant operations

l Improve maintenance

l Simplify engineering, and

l Extend asset life cycles

2.1.3 Interoperability

To become an ODVA conformant device, all EIP devices must comply with all CIP and EtherNet/IPspecifications and mandatory behaviors.

Strict adherence to specifications and device conformance testing ensures interoperabilitybetween all devices connected on the EtherNet/IP network. This enables multiple devices, ofdifferent types and from different vendors, to interoperate on the same network without issues. Italso allows host systems, like Experion, to seamlessly interface with any conformant device toeffectively monitor and control the process.

Visit the ODVA website for more details on ODVA conformance requirements and device testing.

The Experion EIP solutions provide tools in Control Builder that allows for the addition of newconformant EIP devices without the need to increment the Experion release.

All three solutions (C300 direct, C300 EIM, and UOC Downlink) use the same tool set andprocedures to add a new EIP device. A device that has been added for one solution will work withthe other two.

ATTENTION

At this time, only Honeywell personnel can perform the task of adding new EIP devices.Please contact your Honeywell representative for an up to date list of supported devices orto request the addition of a new device.

2.1.4 Essential CIP Concepts and Terms

This section will provide some key CIP and EIP concepts and terms. This information will be veryhelpful to your understanding of the Experion EIP solutions and the sections that follow.

Message Types

The CIP protocol provides for two major messaging methods, as follows:

1. Implicit Messaging

This messaging type is used for cyclic data transfer. It is designed to be fast and deterministic. Thisdata transfer mechanism is well suited for data that is used for primary control and logicapplications.

Implicit messaging uses Producer/Consumer transactions.

2. Explicit Messaging

- 8 -

Chapter 2 - Introduction

Chapter 2 - Introduction

This messaging type is used for acyclic data transfer. It is used to transfer non-time criticalinformation. One example would be parameter reads/writes related to device configuration. It iswell suited for data that does not need to be cyclic and applications that can tolerate some variationin determinism.

Explicit messaging uses Request/Reply transactions.

Input and Output Assemblies

Input and Output Assemblies are used as the data transfer mechanism for Implicit data transfersbetween EIP I/O devices and the Experion EIP solutions.

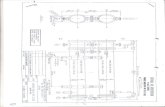

Assembly Concepts: Refer to figure Input and Output Assembly Concept.

l All EIP I/O devices have a large amount of process and device data (parameters) resident intheir memory.

l An assembly is a pre-defined set of data (parameters of a given data type) selected from thetotal parameters available in the I/O device.

l Assemblies are defined by the I/O device vendor. The device vendor determines what deviceparameters will be assigned to a given assembly.

l The device vendor assigns a unique identification number to each assembly. This uniqueinstance number is used to identify the assembly to be transferred in each Implicit transaction.

l Depending on the device type and its function, it may have an Input Assembly or OutputAssembly or both.

NOTE

You can usually do a search in the vendor document for the terms Input Assembly or OutputAssembly to determine available assemblies, assigned parameters, assembly structure, andtheir assigned instance numbers.

Input and Output Assemblies are utilized by Implicit data messaging as follows:

Refer to figure Input and Output Assembly Concept.

Input Assemblies

The following are the Implicit messaging steps:

1. Experion EIP Solution connects to the EIP I/O device.

2. Experion EIP Solution indicates the assembly instance (by number) to be transferred.

Also indicates the update rate per the user entered RPI setting in milli-seconds.

3. Data Flow: EIP I/O device then continuously transmits the entire Input Assembly (allparameters) to the C300, EIM, or UOC in one packet. This cyclic transaction continues (per theRPI) until the connection is either lost or terminated.

Output Assemblies

The following are the Implicit messaging steps:

1. Experion EIP solution connects to the EIP I/O device.

2. Experion EIP solution indicates the assembly instance (by number) to be transferred.

Also indicates the update rate per the user entered RPI setting in milli-seconds.

- 9 -

3. Data Flow: The Experion EIP Solution then continuously transmits the entire Output Assembly(all parameters) to the EIP I/O Device in one packet. This cyclic transaction continues (per theRPI) until the connection is either lost or terminated.

Input and Output Assemblies enable the Experion EIP Solutions to monitor and control theprocess through the associated EIP I/O Device. Implicit data transfer is fast and deterministic.

Requested Packet Interval (RPI)

Requested Packet Interval is a user entered value (in milli-seconds) that sets the update rate fordata transmission for Input Assemblies, Output Assemblies, and UDTs.

NOTE

The RPI range is determined by the vender and Experion will support range from 50ms to2sec in multiple of 50. user can use the vender supported range which is falling in Experionrange.

Figure 2.1 Input and Output Assembly Concept

Configuration Assembly

An Assembly which transports configuration data from the C300, EIM, or UOC to the EIP I/Odevice. Configuration Assemblies are sent at the time that a connection is initially established. AConfiguration Assembly byte size of zero indicates that this assembly is not supported.

Electronic Data Sheet (EDS)

The Electronic Data Sheet (EDS) is a text file which specifies the properties and capabilities of aspecific EIP I/O Device. ODVA mandates that the vendor must provide an EDS file for every device(and major device revision). EDS files are used by the Experion EIP Solutions to add new devices.

- 10 -

Chapter 2 - Introduction

Chapter 2 - Introduction

NOTEAlthough the EDS file can contain all information needed to create a full I/O Device Block(connection, input assembly, output assembly, and configuration assembly information),ODVA only mandates that an EDS file provide device ID information. The solution providesthe PDE tool to allow the user to manually enter any data that is missing in the EDS file. Youshould always check with your selected device vendor to determine if they provide acomplete EDS file. When using the PDE tool you will need access to detailed vendordocumentation that describes all information required to create the device I/O Block.

- 11 -

EXPERION EIP SOLUTIONS OVERVIEW

NOTE

Any references in this document to specifications or limits are provided for concept only.Always consult the appropriate specifications document for any project planning.

3.1 Summary of Experion EIP Solutions

It is important to distinguish between the various Experion EIP Solutions. The table belowprovides a high level description and some distinguishing characteristics for each.

ExperionSolutionName(Note-1)

FirstReleasedwithExperion

High level Solution Description

C300DIRECTEIPSolution

R430 Refer to Figure-3.1. This solution can be characterized by the way theC300 control processor is interfaced with the EtherNet/IP network andEIP devices. As shown, The C300 communicates over FTE Level-2,through a Tofino firewall, to the EIP network and devices. The Tofinofirewall provides protection between the FTE and EtherNet/IP networkand devices. Only the C300 can be redundant. The FTE cable and Tofinocannot be redundant. This solution can be implemented on C300 modelCC-PCNT01 or CC-PCNT02. Although this solution is still supported, theC300 EIM solution is preferred and has enhanced functionality andimproved specifications and limits. Use of this solution will reduce themax limit of FTE nodes from 330 to 200.

C300EIM EIPSolution

R500 Refer to Figure-3.2. This solution can be characterized by the way theC300 control processor is interfaced with the EtherNet/IP network andEIP devices. As shown, The C300 communicates over FTE Level-2,through the Ethernet Interface Module (EIM), to the EIP network anddevices. The EIM is a new module in the Series C form factor that wasfirst released with Experion R500. The EIM provides both the FTE firewall(embedded CF9-like functions) and the EIP firewall function. This solutioncan be implemented on C300 model CC-PCNT02 only. The EIM solutionprovides optional redundancy from the C300, through the EIM, to a DLREIP network. The EIM can be implemented at FTE Level-1 or Level-2.

UOCDownlinkEIPSolution

R505 Refer to Figure-3.3. This solution can be characterized by the way theUOC (Unit Operations Controller) is interfaced with the EtherNet/IPnetwork and EIP devices. As shown, The UOC has EtherNet/IP downlinksdirectly on the UOC processor. Refer to the UOC Users Guide for moredetails and EIP network topologies.

SCADAEIP

Note-2 Note-2

- 12 -

CHAPTER

3

ExperionSolutionName(Note-1)

FirstReleasedwithExperion

High level Solution Description

Solution

Note-1: All of these solutions can be used simultaneously on the same ServerCluster. However, the specification limits of one solution can affect the limitsof the others. Always consult the appropriate specification documents.

Note-2: The SCADA solution is covered in a separate document. No furtherSCADA coverage is provided in this document.

Figure 3.1 C300 Direct EIP Solution

Figure 3.2 C300 EIM Solution

Figure 3.3 UOC EIM Solution

- 13 -

Chapter 3 - Experion EIP Solutions Overview

Chapter 3 - Experion EIP Solutions Overview

3.2 EtherNet/IP Topologies Supported

This section will provide a high-level overview of the three EtherNet/IP network topologies. Thetopologies can be implement individually or in any combination of the three.

The tree topologies are as follows:

l Liner Bus

l Star

l DLR (Device level Ring)

DLR (Device Level Ring): The DLR is a very popular topology. It provides an added level ofrobustness and availability. The DLR can tolerate single cable faults. Devices may have an EIPinterface that can natively support and participate in the DLR. Native DLR devices have two EIPcable connectors and fully understand how to connect and participate in the ring. Non-nativedevices are connected to the ring using the Rockwell 1783 ETAP module.

Basic Topology Diagrams

Figure 3.4 Linear Bus

Figure 3.5 Linear Bus

- 14 -

Figure 3.6 DLR Topology

The table below summarizes the topologies supported by EIP solution and identifies the qualifiedhardware for each.

EIP Network Topologies Supported EIP Network Hardware Supported

SolutionLinearBus

Star DLRStratix8000

Stratix5700

Rockwell1783ETAP

TofinoXenonFirewall

C300Direct(1)

Yes Yes Yes (3) Yes No Yes Yes

C300 EIMSolution(1)

Yes Yes Yes (3) Yes Yes Yes N\A

UOCDownlink(2)

Yes Yes Yes Yes Yes Yes N\A

Note-1: Additional networking details are provided later in the document.

Note-2: For networking details for this solution, refer to the UOC User’s Guide.

Note-3: For DLR - C300 Direct and C300 EIM, Rockwell 1783 ETAP must beconnected to enable DLR topology. For UOC, Embedded DLR is supported inController and no ETAP is required.

- 15 -

Chapter 3 - Experion EIP Solutions Overview

Chapter 3 - Experion EIP Solutions Overview

3.3 Major Classification of EtherNet I/P Devices

The manner in which control strategies are configured in the C300 for Ethernet/IP™ connectionwith respect to this document and the Honeywell EIP solutions (C300-Direct, C300-EIM, and UOC-Downlink), all EIP network connected devices can be placed into two major categories, as follows:

1. EIP Devices: This includes a category of devices that directly connect to the process andperform some type of process related function.

Some devices that fall into this category include:

l Variable Frequency Drives (VFDs),

l Motor starters and smart relays,

l Typical I/O modules (AI, AO, DI, DO and PI),

l Field instruments (such as valves, transmitters, analyzers, etc.),

l See ODVA website for a complete listing of conformant devices.

The C300 and UOC can connect to and read/write data with these devices to perform primarycontrol and logic.

CIP Implicit messaging is used to ensure that the data transfer is fast and deterministic.

A device-specific EIP I/O Block must be created in Control Builder for every different device typeand major device revision.

EIP I/O Blocks utilize the CIP concept of Input Assemblies, Output Assemblies, and ConfigurationAssemblies.

Update rates are determined by the user entered RPI setting in milli-seconds.

Solution tools provided in Control Builder to create device-specific EIP I/O Blocks:

l EDS parser tool: Processes the EDS file to create the initial I/O Block.

l PDE tool: Allows the user to modify the I/O Block.

2. PLCs: Currently this category only includes the Rockwell ControlLogix PLC. User created UDTsare used to identify and transfer the desired data between the C300/UOC and theControlLogix PLC.

UDTs are used to establish a supervisory control relationship between the C300/UOC and theControlLogix PLC. In this relationship the C300/UOC is considered the supervisor and the PLC isconsidered to be the primary controller.

UDTs can be of type Multi-parameter (Aggregate) or Single-parameter (Scalar).

UDTs are fully defined by the user (Structure, naming, number of parameters, and assignment ofdata types).

UDTs (Class 3) use CIP Explicit messaging.

Update rates are determined by the user entered RPI setting in milli-seconds.

Solution tools provided in Control Builder to create UDTs:

l PDE tool: Allows the user to create the UDT Template.

3.4 Common EIP I/O Device Structures

EIP I/O device requires the creation of a (device specific templates) Device Block. The Device Blockdescribes the attributes related to …

- 16 -

l Device connection

l Input and Output Assemblies

l Configuration Assemblies

Once the block exists in the Control Builder library, it can be used create instances of that device.

The following is a summary of the common devices structures that you may encounter with regardto adding new devices.

3.4.1 Generic I/O Devices:

Figure-3.7 shows the structure of a generic IO device. This example shows the Rockwell E300smart relay. EIP drive such as the Rockwell PF 755 would also have this structure. These devicesuse one IP address and one CIP Implicit connection to establish communication with the device.This one connection provides access to both the input and Output Assemblies. EIP drive may alsosupport the Configuration Assembly.

Figure 3.7 Generic IO Devices

3.4.2 Modular I/O Devices:

Figure-3.8 shows a typical modular device structure. An I/O chassis is a good example of a modulardevice. The adapter module provides the interface to the chassis and each of the Input OutputModules (IOMs). One IP address is required to communicate with the chassis. One Implicitconnection may be required for each IOM. Input Assemblies are used for input type I/O moduleand Output Assemblies are required for output type I/O modules.

Usually, one Device Block must be created for every unique I/O module.

Consolidation option: Some I/O vendors only support the concept of consolidation. The Adopterconsolidates IOM data and sends data to scanner. Scanner in turn parses the data.This can saveon Implicit connections used by the I/O chassis.

Some vendors support the Configuration Assembly.

Figure 3.8 Complex Devices

- 17 -

Chapter 3 - Experion EIP Solutions Overview

Chapter 3 - Experion EIP Solutions Overview

3.4.3 DeviceNet Devices:

As shown in Figure-2.9, some devices, like the Rockwell E3 and E3+ smart relay, only support aDeviceNet interface. In this case, an EtherNet/IP to DeviceNet converter is required. For the E3and E3+, the Rockwell 193-DNENCATR has been qualified for this purpose. When interfacing adevice that has a DeviceNet interface, the EIP to DeviceNet adaptor must be considered as part ofthe integration.

Figure 3.9 DeviceNet Devices

3.5 EIP Device Types and Interface Methods

The three Experion EIP solutions (C300 direct, C300 EIM, and UOC Downlink) view devicesconnected to EtherNet/IP Networks in two distinct categories, as follows:

EIP I/O Device: This includes a category of devices that directly connect to the process and performsome type of process related function.

Some devices that fall into this category include:

l Variable Frequency Drives (VFDs),

l Motor starters and smart relays,

l Typical I/O modules (AI, AO, DI, DO and PI),

l Field instruments (such as valves, transmitters, analyzers, etc.),

l See ODVA website for a complete listing conformant devices.

PLCs: Currently this category only includes the Rockwell ControlLogix PLC. Data transfers (readsand writes) between the ControlLogix PLC and the Experion EIP Solutions is accomplished usingUDTs

UDTs (User-define-data Types) are a Rockwell PLC concept. UDTs are used to transfer data (asinputs and outputs) between the Experion controller and the ControlLogix PLC. A UDT is atemplate that contains one or more user defined parameters of user defined data types.

The user fully defines the structure (parameter usage, naming, and data type) of every UDT. Inthat way, UDTs provide a very flexible and effective method for data transfer with Rockwell PLCs.

There are two types of UDTs, as follows:

1. Multi-parameter (or aggregate) UDTs: Can have multiple parameters of different data types.

2. Scalar UDTs: Have a single parameter of some data type

UDT structure is fully defined by the user. UDT templates must exactly match on the ControLogixand Control Builder side.

The user creates a UDT template and then creates instances of that template under unique tagnames. Tag names must match on the Control Builder and ControlLogix side.

The table below provides some additional information related to EIP device types:

- 18 -

Device Type TypicalUsage

Access Method Typical Usage Control Builder Tasks

EIP I/O Device ( I/O Modules,Drives, Relays,Motors Starter,Transmittersetc)

Uses Implicitmessaging and theconcept of …. InputAssemblies andOutput AssembliesA given device mayalso support theConfigurationAssembly

Experioncontroller (C300or UOC) candirectly connectto the I/O deviceto:

l Monitor theprocess anddeviceconditions.

l Manuallychangeoutputs.

l Use deviceinputs andoutputs inprimarycontrol andlogic strategiesrunning in theC300 or UOC.

For every unique device(and major devicerevision) a device-specificdevice template must becreated and tested.

This is done using toolsprovided in ControlBuilder. CB Tools Used:

l EDS file parser(1)

l PDE (ParameterDefinition Editor) tool

ControlLogix PLC Uses Explicitmessaging and theconcept of UDTs(User-define DataTypes)

Experioncontroller (C300or UOC) candirectly connectto theControlLogixPLC to:

l Read and writePLC data.

l Establish asupervisorycontrolarrangementwhere theHoneywellcontroller isthe supervisorand theControlLogix isthe primarycontroller.

The user must create aUDT Block (template) forevery UDT template to beaccessed from a givenControlLogix PLC. TheControl Builder andControlLogix UDTstructure (parameternaming, order, datatypes) must exactlymatch. CB Tool Used:

l PDE (ParameterDefinition Editor) tool

Note-1: The Honeywell parser tool will analyze and process the vendor supplied EDS file andattempt to create a device specific template. ODVA mandates that every vendor must provide anEDS file for every different device (and major device revision). However, only a minimal amountof information is mandated for inclusion into an EDS. In some cases, and when an EDS hasinformation gaps, the user will need to use the PDE tool to manually complete any informationthat was not in the EDS. A complete EDS file and clear and complete device vendordocumentation is essential to successfully adding a new EIP I/O device. You should check withyour device vendor to determine the completeness of the EDS and the device documentation.

- 19 -

Chapter 3 - Experion EIP Solutions Overview

Chapter 3 - Experion EIP Solutions Overview

3.6 Solution Configuration in Control Builder

Experion Control Builder is used to complete the following major engineering tasks:

1. Configure major modules and components (C300, EIM, UOC, ControlLogix connections, etc.).

2. Creation of EIP I/O Device Blocks (add new device types and manage device revision changes).

3. Creation of UDT Templates (Multi-parameter and single-parameter Scalar UDTs).

4. Instantiation of UDT Templates and assignment of UDT Tags

5. Control Strategy: Configuration and use of EIP I/O Block data with Control Modules (CM) &Sequence Control Modules (SCM).

6. Control Strategy: Configuration and use of UDT Block data with Control Modules (CM) &Sequence Control Modules (SCM).

Except for things that are specific and unique to a given solution, all three solutions (C300 Direct,C300 EIM, and UOC Downlink) utilize many of the same engineering tools, utilities, and basicprocesses.

Work product that is common across solutions:

1. The same EIP I/O Blocks created for one solution can be used with all three solutions. Once ablock exists in the library, it can be instantiated any number of times. Refer to Chapter-5 fordetails about how to add and manage devices.

2. The same UDT Templates created for one solution can be used with all three solutions. Once aUDT Template exists in the library, it can be instantiated any number of times. Refer toCreating Control Logix Aggregate UDT Type for more details about how to create UDTTemplates.

3. Create a ControlLogix Block.

Work product with differences:

1. For details about how to Configure a C300 for use with the C300 Direct solutions refer tosection 4.1.

2. For details about how to configure a C300 and EIM module for use with the C300 EIM solutionrefer to section 4.2.

3. For details about how to configure a UOC module for use with the UOC Downlink solution referto section 4.3.

4. For details about how to assign UDT Tags and use data with the C300 Direct and C300 EIMsolution refer to (reference goes here)

5. For details about how to assign UDT Tags and use data with the UOC solution refer to(reference goes here)

NOTE

Due to the differences that exist between the three solutions, manual intervention and workeffort will be required to move a control strategy from one solution to the other.

3.7 Ethernet/IP Device Templates Present in ExperionLibrary

The following table lists the devices supported and EIP I/O Blocks available at the time thisdocument was released.

- 20 -

As new devices may have been added since, you should always consult your Honeywellrepresentative for the most up to date list or to request to have a new device added.

Vendor EIP Device UseEmbedded

(Note-1)

RequiredImport

(Note-2)Rockwell 1738 ArmorPoint

I/OTypical I/O Seefull module listbelow

√

Rockwell 1732EArmorBlock I/O

Typical I/O Seefull module listbelow

√

Rockwell E3 Solid StateOverload Relay(Note-3)

Motor control 2-states Start/Stop

√

Rockwell E3 + Solid StateOverload Relay(Note-3)

Motor control 3-statesStop/State-1/State-2

√

Rockwell PF 755 Drive Command motordirection andspeed

√

Rockwell PF 753 Drive Command motordirection andspeed

√

Rockwell E300 Smart Relay Motor control 3-statesStop/State-1/State-2

√

Rockwell PF 525 Drive √

Note - 1: These device blocks are embedded and loaded with the Experionsoftware. No additional steps are required to use these block types.

Note - 2: These device blocks are not loaded with the Experion software. Theymust be downloaded from Honeywell Process Solutions support website at:

http://www.honeywellprocess.com/support and then manually imported bythe user.

Note - 3: The E3 and E3+ are DeviceNet devices. They require the use of anEtherNet/IP to DeviceNet converter device. The Rockwell 193-DNENCATR isqualified for this purpose.

Module Type Channels Signal Type

1738-AENT Adaptor N/A N/A

1738-IB4DM12 DI 4 Sinking 24 Vdc

1738-IB8M12 DI 8 Sinking 24 Vdc

- 21 -

Chapter 3 - Experion EIP Solutions Overview

Chapter 3 - Experion EIP Solutions Overview

Module Type Channels Signal Type

1738-OB2EPM12 DO 2 24 Vdc

1738-OB8EM12 DO 8 24 Vdc

1738-OA2M12AC3 DO 2 120V ac, 220V ac

1738-OE2CM12 AO 2 (4-20 ma)

1738-OE4CM12 AO 4 (4-20 ma)

1738-IE2CM12 AI 2 (4-20 ma)

1738-IE4CM12 AI 4 (4-20 ma)

1738-IT2IM12 AI 2 TC, Milli-volt

1738-IR2M12 AI 2 RTD, resistance

1732E ArmorBlock I/O Module List

Module Type Channel Signal Type

1732E-IB16M12DR DI 16 with diagnostics

1732E-IF4M12R AI 4 High Level Current/voltage

1732E-OF4M12R AO 4 High Level Current/voltage

1732E-IT4IM12R AI 4 T/C, MV

1732E-IR4IM12R AI 4 RTD, resistance

- 22 -

EIP NETWORK DETAILS

Experion supports three types of topology for connecting to Ethernet/IP™ networks:

l C300 Direct EIP Solution

l C300 EIM EIP Solution

l UOC Downlink Solution

NOTE

For more information on details of the UOC downlink topologies refer to the UOC UserGuide.

ATTENTION

It is important to be aware of these three solutions and any rules or limits that may need tobe considered when implementing them on the same Server Cluster. These solutions aresupported in Experion R500.

4.1 C300 Direct EIP Solution

4.1.1 Prerequisites

The following is required to use the C300 Direct solution:

Honeywell Components and Model Numbers:

l Experion R430 or higher.

l C300 model CC-PCNT01 or CC-PCNT02.

l License model TC-EPLX01 (one per C300 or redundant pair).

Using Honeywell CTools (Series C Firmware Load Tool) to ensure the following:

l C300 is loaded with the appropriate Firmware level for the Experion release in use.

l The C300 is loaded with the appropriate 50ms CEE personality.

l To establish C300 Direct solution Tofino Firewall should be configured.

See Series C Firmware Load Tool (CTool) for Series C Components in the Control Hardware.

Troubleshooting and Maintenance Guide for the procedure to capture diagnostic data.

EtherNet/IP network components that have been validated with the C300 Direct solution are:

- 23 -

CHAPTER

4

l Rockwell 1783 ETAP (used to enable the EIM to be used with a Device Level Ring topology)

l Rockwell Stratix 8000 switch

l Tofino (Xenon) firewall module

Supported EtherNet/IP network topologies:

l Liner bus

l Star

l DLR (Device Level Ring)

The following solutions differ primarily in their topologies and the manner in which they interfacethe C300 to the associated Ethernet/IP network and Ethernet/IP devices. The topologies are asfollows:

1. C300 Direct Ethernet/IP Solution - Released in R430

2. C300 Ethernet Interface Module (EIM) EIP Solution - Released in R500

3. UOC Direct Connectivity to EIP Devices

4.1.2 C300 DIRECT Solution - FTE Topology

As shown in the diagram below, the C300 Direct EIP solution connects the C300 directly to the EIPnetwork and associated EIP nodes. This enables data transfers (as reads/writes) to and from theC300 and EIP resident nodes.

Some key characteristics:

l Only the C300 can be redundant. Media and Tofino firewall are non-redundant.

l Solution should be implemented over FTE A (Yellow) cable and switches.

l Use of this solution will limit the maximum number of FTE nodes to 200.

l Both the FTE and EIP subnet must be the same. This will limit the IP addresses available forEIP devices, across the entire Experion Cluster (all controllers), to a max of 200.

NOTE

The C300 EIM solution is the preferred solution. It provides better redundancy, improvedspecifications, and enhanced functions and features.

- 24 -

Chapter 4 - EIP Network Details

Chapter 4 - EIP Network Details

4.1.3 Assigning EIP to the C300

The screen capture below shows the typical C300 Block configuration form and tabs. The items inred indicate the assignments related to the C300 Direct EIP solution.

Make the following assignments:

l Network Address Configuration: Assigns the C300 FTE IP address. Primary must be an oddaddress and redundant partner is Odd address + 1.

ATTENTION

The EIP subnet must be the same as the FTE subnet.

l Enter Protocols Supported: Select “EtherNet/IP” to enable EIP for this C300.

l EtherNet/IP Communication Mode: In this case select “Direct Connection”.

NOTE

This can be a configuration form for either a C300 model CC-PCNT01 or CC-PCNT02.

- 25 -

4.1.4 C300 Direct Solution - Rules and Caveats

The use of EIP below,to be used as a shorthand for EtherNet/IP™:

l When using C300 Direct EIP solution, the maximum number of FTE Nodes per Community isreduced from 330 FTE Nodes to 200 FTE Nodes.

l C300 Direct EIP communication is only supported through the C300’s FTE ports. So, the EIPnetwork must use the same subnet assignment as the Experion FTE Server Cluster.

l This solution can use C300 model CC-PCNT01 or CC-PCNT02. Standard C300 redundancy issupported on a C300 that is EIP capable

l A Tofino Xenon Firewall must be used to isolate and protect EIP communications from FTEcommunications.

l C300-EIP communication is supported between a C300 and EIP devices that are connected ina switched star topology

l C300-EIP communication is supported between a C300 and EIP devices that are connected ina linear bus topology

l C300-EIP communications is supported between a C300 and EIP devices that are connected ina ring topology

l Each connected EIP Device or PLC counts as a Non-FTE Node towards the Non-FTE Nodecount limit per FTE Community

l Any Ethernet I/O connected and used by the Rockwell Allen Bradley ControlLogix PLC shouldbe connected on an isolated separate downlink ENET card on the Rockwell Allen BradleyControlLogix, and not be connected directly to the Stratix switch network that connects to FTEthrough the firewall.

l Rockwell tools should be located on a separate PC connected directly to the Stratix switch.

- 26 -

Chapter 4 - EIP Network Details

Chapter 4 - EIP Network Details

l The CF9 used by the C300 communicating with EIP Devices or PLCs must be upgraded to R430compatibility level (Rev JJ or higher) to enable the proper TCP and UDP ports used for EIPCommunications.

l The Rockwell 1758 ETAP should be configured for Ring supervisor in DLR network to maintainthe connection between the EIP-compatible devices and the Stratix switch.

l C300 direct EIP solution must use the Honeywell qualified 3rd party EIP network switches forEIP network integration.

l The EIP network must be connected through a Tofino (Xenon) firewall to the yellow FTE Level-2 CISCO switch. Cisco switch must be a model 2960 or newer.

ATTENTION

For project planning, always consult the latest specifications document for the most up-to-date information.

- 27 -

Chapter 4 - EIP Network Details

4.2 C300 EIM EIP Solution

4.2.1 Prerequisites

The following is required to use the C300 EIM solution:

Honeywell Components and Model Numbers:

l Experion R500 or higher.

l C300 model CC-PCNT02 (The CC-PCNT01 cannot be used).

l EIM module model CC-PEIM01 (two required for redundant configuration).

l EIM IOTA model CC-TEIM01 (two required for redundant configuration).

l EIM license model TC-EPLX02 (one per EIM or redundant pair).

Using the Honeywell Firmware Manager tool ensure the following:

l EIM is at an appropriate Firmware revision level for the Experion release being used.

l EIM is loaded with the EtherNet/IP personality.

See the Firmware Manager User Guide for more details.

Using Honeywell CTools (Series C Firmware Load Tool) to ensure the following:

l The CC-PCNT02 is at an appropriate Firmware revision level for the Experion release beingused.

l The CC-PCNT02 controller is loaded with the 50ms (Extended) personality.

See Series C Firmware Load Tool (CTool) for Series C Components in the Control Hardware.

Troubleshooting and Maintenance Guide for the procedure to capture diagnostic data.

EtherNet/IP network components that have been validated with the EIM solution:

l Rockwell 1783 ETAP (used to enable the EIM to be used with a Device Level Ring topology)

l Rockwell Stratix 8000 switch

l Rockwell Stratix 5700 switch

l 1756-ENET or 1756-EN2TR for CLX

Supported EtherNet/IP network topologies:

l Liner bus

l tar

l DLR (Device Level Ring)

4.2.2 Assigning EIP Capability to the C300

The screen capture below shows the typical C300 Block configuration form and tabs.

The items in red indicate the assignments related to the C300 EIM EIP solution.

Make the following assignments….

l Network Address Configuration: Assigns the C300 FTE IP address. Primary must be odd addressand redundant partner is Odd address + 1.

- 29 -

ATTENTIONFTE and EIP subnets must be different. EIP subnet assignment is made on the EIM Block

l Enter Protocols Supported: Select “EtherNet/IP” to enable EIP for this C300.

l EtherNet/IP Communication Mode: In this case select “Through EIM”.

ATTENTION

This must be a configuration form associated with a C300 model CC-PCNT02 that is loadedwith the 50 ms “Extended Functionality” firmware.

For more information to assign EIP capability to the C300 refer to UOC User Guide-EPDOC-X512.

- 30 -

Chapter 4 - EIP Network Details

EIM BLOCK CONFIGURATION

The screen capture below shows the typical EIM Block configuration form and tabs.

The items in red indicate the assignments related to the C300 EIM EIP solution.

Make the following assignments:

l FTE Address Configuration: Assigns the EIM FTE IP address. Primary must be an odd addressand redundant partner is Odd address + 1.

l Downlink Address Configuration: Assigns the EIM EIP IP address. Primary must be oddaddress and redundant partner is Odd address + 1.

ATTENTION

FTE and EIP subnets must be different.

l Protocols: Select the protocol to assign to this EIM. IEC 61850 or EtherNet/IP. Select“EtherNet/IP” in this case.

ATTENTION

EIM must be loaded with the EtherNet/IP personality using the Firmware Manager tool.

l Downlink Configuration: Select Non-redundant media. HSR and PRP are only usable whenthe IEC 61850 personality is loaded into the EIM.

- 31 -

CHAPTER

5

EIM IOTA Layout and Connectors

IOTA model CC-TEIM01 (9 inch IOTA). Connector summary when EIM is loaded with theEtherNet/IP personality.

- 32 -

Chapter 5 - EIM Block Configuration

+24Vdc Screw connection to the 24 volt DC carrier bus bar. Provides24Vdc to the IOTA and the EIM module.

Com Screw connection to the common side of the 24Vdc bus barpower system.

Fuse Fuse for the 24Vdc power supply.

FTE Index Thumb wheels used to set the FTE index. The index is the lastoctet of the FTE IP address. FTE IP = ###.###.###.Index First3 octets are set in Control Builder. IP address is administered bythe BootP service running in Experion Sever. Primary EIM indexmust be odd Backup EIM is Primary address + 1

Redundancy An RJ45 connector used to support optional redundancybetween two IOTAs and two EIMs. A CAT5 cable connects thetwo IOTAs and provides the redundancy sync path between thetwo EIMs. Standard cable lengths are 36, 48, 60, 84 inches.Maximum cable length allowed is 100 meters. Redundancycable usually has an Orange boot.

FTE A/FTEB

RJ45 connectors. Connects the EIM to the Honeywell FTE(Fault Tolerant Ethernet) network. FTE A is referred of as theYellow FTE cable. FTE B is referred to as the Green FTE cable.

ETH 1 RJ45 connector. Provides the downlink to the EtherNet/IPnetwork. Note: The EIM IP address on the EtherNet/IP networkis set in Control Builder an as an entry in the EIM Block.Supported topologies…. Star, Linear Bus, DLR (Device LevelRing)

ETH 2 RJ45 connector. This connector is disabled (unusable) when theEIM is loaded with the EtherNet/IP personality. It is only activewhen the IEC 61850 personality is loaded.

5.1 EIM Redundancy Option

As shown in the diagram below, EIM redundancy is implemented by using two IOTAs (CC-TEIM01)and two EIM modules (CC-PEIM01) connected by a redundancy sync cable. The CAT5 Sync cableenables the primary and backup EIM to maintain synchronization of their database andconfiguration.

Available cable models and lengths:

51305980-8## (CAT5 cable with orange boot) … ## = inches (options: 36, 48, 60, and 84)

FTE Device Index Setting (Establishes the FTE IP Address): One IOTA is assigned the Odd Indexwhile the other IOTA is assigned the (Odd + 1) Index. Either IOTA can be set to the Odd Index aslong as the partner is set to (Odd + 1).

- 34 -

Chapter 5 - EIM Block Configuration

Chapter 5 - EIM Block Configuration

NOTEDuring switchover of a redundant EIM pair, the odd IP address follows the primary moduleeven though the Index setting on the IOTA does not change. The EIM 4-character localdisplay will indicate the current primary [-OK-] and backup [BKUP].

Compatible Partners: To synchronize and transition to a normal Primary/Backup state, both EIMmodules must be compatible. The following criteria is compared:

l Factory data, such as, vendor ID, product type, and product code must be identical to ensureplatform hardware compatibility.

l Firmware level and personality must be identical. Firmware level should be appropriate for theExperion release in use and in this case, both EIMs should be loaded with the EtherNet/IPpersonality.

l IOTA Device Index settings must be correct. One IOTA Index is Odd and the other is Odd+1.

l A Firmware version difference can be tolerated during an OPM (On Process Migration)procedure. For further information, see the document, “On Process Migration.”

EIM Module Replacement: When replacing a failed EIM, a functioning Primary EIM willautomatically connect to and synchronize the database of the (compatible) replacement EIMmodule. When replacing a non-redundant EIM, the database will need to be loaded manually asan additional step.

Switchover: A transfer of control between the primary and backup EIM can occur as follows:

l Automatic: Triggered by a fault in the primary

l Manual: User commanded from the user HMI

5.2 C300 EIM FTE Topologies and Overview

As shown in the diagram below, the C300 EIM solution can be implemented at FTE Level-1 and/orFTE Level-2.

Some key characteristics:

l Solution can be optionally redundant from the C300, over FTE, and down to the EIP DLRnetwork.

l EIM can be optionally redundant (IOTA-to-IOTA).

l CF9 functionality is embedded into the EIM. In some cases, the CF9 can be eliminated. Onesuch case is the EIM implement at Level-2. In this case, the EIM can connect directly to theLevel-2 switch.

- 35 -

l EtherNet/IP firewall is embedded into the EIM downlink. This protects the FTE network fromtraffic on the EIP network. No 3rd party firewalls are required.

l Up to five C300s can be configured to access one EIM.

l Up to five EIMs can be accessed by one C300.

l Solution requires C300 model the CC-TCNT02 loaded with the “Extended” personality.

5.3 C300 EIM Solution - Rules and Caveats

The use of EIP below, will be used as a shorthand for EtherNet/IP™

l When using the EIM EIP solution, the maximum number of FTE Nodes per FTE Community is330.

ATTENTION

One occurrence of a C300 Direct EIP solution on the FTE community will reduce thisnumber to a max of 200.

l Communication with EIP enabled devices and Rockwell Allen Bradley ControlLogix PLC issupported through separate downlink ports of EIM module. EIP ports are isolated from FTEports.

l The EIM EIP network should exist on its own subnet to isolate the EIP network from the FTEcommunity. The use of different EIP/FTE subnets will decouple the EIP node IP addressassignments from the IP addresses used for FTE and non-FTE nodes on the Experion FTEcommunity.

l EIM provides an embedded EIP firewall on the downlink (ETH 1). A 3rd party firewall is notrequired. This built-in firewall capability protects the FTE network from EIP network traffic.

l The EIM module must be loaded with EIP firmware personality to communicate with EIPdevices located on the EIP network.

l The associated C300 must be model CC-PCNT02 and loaded with the 50ms “ExtendedFunctionality” firmware personality.

l An EIM loaded with the EtherNet/IP personality supports only the ETH 1 IOTA downlinkconnector. ETH2 is disabled and is not usable.

- 36 -

Chapter 5 - EIM Block Configuration

Chapter 5 - EIM Block Configuration

l EIP communication is supported between an EIM and EIP devices that are connected in aswitched star, Linear, and/or Device Level Ring topology.

l The Rockwell 1783 ETAP or Stratix 5700 switch is required to connect the EIM ETH 1 port to aDLR (Device Level Ring) Topology. EIM does not support native DLR connection.

l Ring supervisor should be configured in DLR network either on EIP taps (ETAP) or EIP StratixSwitch before physically connecting the ring to maintain the connection between the EIP-compatible devices and the Stratix switch.

l DLR network requires at least one node to be configured as ring supervisor. ETAPs can be usedas a Ring Supervisor and also as a non-supervisor based on Ring supervisor support of Stratixswitch.

l EIP Device Level Ring (DLR) network should be connected only to the DLR ports configured onthe switch

l EIM EIP Ring- Switch Network Topology is supported only with EIP Stratix Switches (Eg: Stratix-5700) with Ring supervisor capability and join as EIP node on the network.

l Multiple EIMs can be connected to a single Device Level Ring (DLR), Linear, and Star, topologynetwork.

l EIM EIP cannot be used to bridge EIP devices across EIP networks.

l The CF9 used by the EIM solution be upgraded to R430 compatibility level (Rev JJ or higher) toenable the proper TCP and UDP ports used for EIP Communications.

l Any Ethernet I/O connected to and used by the Rockwell Allen Bradley ControlLogix PLCshould be connected on an isolated separate downlink ENET card on the Rockwell Allen BradleyControlLogix, and not be connected directly to the Stratix switch network.

l C300- EIM EIP solution and C300 direct EIP solution may co-exist in the same Experion system(but cannot be configured in the same C300 Controller.) Also, the C300 Direct EIP solutionlimits the maximum number of FTE nodes in FTE community to 200.

l Simultaneous use of C300 EIM- EIP and C300- Direct EIP solution in the same C300 controlleris not supported.

l Load of an EIM-EIP application firmware image is required when an EIM is received from thefactory or if it is desired to repurpose an EIM-61850 to server as an EIM-EIP

l Dedicated Network Time source may be required to synchronize clocks across devices andswitches operating on the EIP network. Diagnostics of EIP devices configured through EIM areprocessed in C300 controller and send notifications to Experion server using C300 time source.

l All EIP node display data access is through the C300 (for both solutions). The EIM when loadedwith the EIP personality cannot be directly accessed by the Server or Console station.

l EIM EIP solution must use the approved and mandated Honeywell qualified 3rd party EIPnetwork switches.

l Redundant Rockwell Allen Bradley ControlLogix PLC controller configured in EIM-EIP networktopology must be configured using floating IP mechanism (backup PLC assumes the IPaddress of the failed primary).

ATTENTION

For project planning, always consult the latest specifications document for the most up-to-date information.

- 37 -

5.3.1 EIM EIP Solution – Sample Topologies Using Stratix 8000

- 38 -

Chapter 5 - EIM Block Configuration

5.3.3 EIM EIP Solution – Sample DLR Using the Stratix 5700

- 40 -

Chapter 5 - EIM Block Configuration

CREATING ETHERNET/IP™ DEVICE, DRIVE, AND I/OMODULE TYPES

You can create Ethernet/IP™ device, drive, and I/O module types by using Electronic Data Sheets(EDS) files or without the EDS files. This section provides the high-level tasks for creatingEthernet/IP™ device, drive, and I/O module types.

6.1 Prerequisites

l If you want to create the Ethernet/IP™ devices, drives, or I/O modules by using the EDS,ensure that you have the appropriate EDS file.

l Ensure that you have all the required device-related specifications, which are available withthe device, before you create the device, drive, or I/O module type.

6.2 Creating Ethernet/IP™ device types using EDS files

Stepnumber

Tasks

1. Open the Parameter Definition Editor (PDE) tool from ControlBuilder. For more information on PDE refer to Parameter DefinitionEditor Reference guide .

2. Select the appropriate EDS file and import it to create a view of theinitial block type / template within PDE.

3. Modify the block parameter definitions as needed.

4. Modify the input, output and configuration assembly definitions asneeded.

- 41 -

CHAPTER

6

6.3 Creating Ethernet/IP™ device types without usingEDS files

Stepnumber

Tasks

1. Open the Parameter Definition Editor (PDE) tool from ControlBuilder. For more information on PDE refer to Parameter DefinitionEditor Reference guide .

2. Specify the input parameters as specified in the device specifications.

3. Specify the output parameters as specified in the devicespecifications.

4. Specify details for configuration parameters as specified in the devicespecifications.

5. Specify assembly details for input, output, and configurationassemblies, which are used for device communication.

6. Define the mapping between the parameters and the assemblies.

6.4 Creating Ethernet/IP™ drive types using EDS files

Prerequisites

l To configure the Ethernet/IP™ device and drive types by using EDS files, ensure that you havethe appropriate EDS file.

l The following sections in the EDS file are critical for device type creation. Ensure that thesedetails are available before using the EDS file.

o Device and Vendor information

o Parameter information

o Assembly information

o Connection information

6.4.1 To create device types using EDS files

1. Click File > New > Type > Ethernet/IP™ Device.

The Library & Type dialog box appears.

2. Select one of the following device types from the Device Type Category list:

l Generic Device

Ethernet/IP™-compatible devices, which are not-I/O devices or drives are categorized asGeneric devices.

l Generic Drive

- 42 -

Chapter 6 - Creating Ethernet/IP™ Device, Drive, and I/O Module Types

Chapter 6 - Creating Ethernet/IP™ Device, Drive, and I/O Module Types

3. Specify the required details depending on the device type and click OK.

l Library name - Indicates the name of the library.

l Type name - Indicates the name of the device type.

l Alarms Support - Enables alarm supportability.

l EDS File - Enables you to select the EDS file to create the device type.

l No. of Input/Output Channels - (Only for I/O) Indicates the number of I/O channels.

l Needs Adapter — Indicates whether the I/O module requires an associated adapter or not.If the I/O module requires an adapter, select the Needs Adapter box.

The following figure displays a sample Library & Type dialog box for reference:

NOTE

In a scenario where multiple I/O modules share a single communication adapter tocommunicate with an Ethernet/IP™ protocol, the Needs Adapter option must beselected. When you select Needs Adapter, while creating the I/O module type, theModule Slot number in Chassis option is enabled in the configuration form the I/Omodule instance. If you are using an adapter, which is not from the AENT1738series, you can specify the unique slot number details in the Module Slot numberin Chassis field and avoid creating a separate adapter.

4. Click Browse (... icon) to select the EDS file.

5. Select the EDS file and click Open.

6. In the Device Type Configuration dialog box, select the following Assembly types, as shown inthe figure, and click OK:

l Input

l Output

l Configuration

- 43 -

NOTE

There might be more than one Input, Output, and Configuration Assembly types.However, ensure that you select one instance of Input, one instance of Output, andone instance of Configuration Assembly types per your requirement.

The Parameter Definition Editor (PDE) grid for configuring the device type parametersappears. The PDE grid consists of the following tabs with the relevant details, which arepopulated from the EDS file.

l Forms layout

l Enumerations

l Input Parameters

l Output Parameters

l Configuration Parameters

l Assemblies

l Alarms

Scaling Configuration Tab

The following image illustrates the Scaling Configuration tab.

- 44 -

Chapter 6 - Creating Ethernet/IP™ Device, Drive, and I/O Module Types

Chapter 6 - Creating Ethernet/IP™ Device, Drive, and I/O Module Types

Parameter name: It is the custom parameter defined for input and output.o Type: It defines the parameter type.o Low Range: It defines the lowest limit for the parameter value.o High Range: It defines the highest limit for the parameter value.o Scale Factor: It defines the ratio of the value for scalingo Bias: It defines the calibrated engineering units.

Configuration

Configure custom parameters using the PDE (Parameter Definition Editor) tool. For moreinformation on PDE refer to Parameter Definition Editor Reference guide .

By default, scaling parameters are not available in the configuration form. To display it inthe configuration form, manually add the scaling parameters in the form layout of the EIPgeneric device PDE.

Form layout configuring for custom output scaling parameters

1. Create a generic device.

2. Add and configure custom parameters.

3. Configure scaling parameters for custom output parameters under Data Command tab,in the Form Layout page.

4. Save and close the PDE.

- 45 -

To view and modify the scaling parameters in EIP generic device instances

1. Create an instance of the generic device.

2. Open the configuration form of the generic device instance from Control Builder’sProject Tree view.

3. Select the Data/Command tab to view scaling parameters.

NOTE

You can modify scaling parameters from the configuration form.

Configuration Parameters for scalar (non-arrayed) custom parameters

o PARAMNAME.HIGHRANGEo PARAMNAME.LOWRANGEo PARAMNAME.SCALEFACTORo PARAMNAME.BIASo PARAMNAME.FLOATVALUE

For more information, see Control Builder Parameter Reference Guides_EPDOC-XX18-en-505A.pdf.

Configuration Parameters for arrayed custom parameters

For arrayed parameters, the array size will be defined based on the custom parameter’ssize.

- 46 -

Chapter 6 - Creating Ethernet/IP™ Device, Drive, and I/O Module Types

Chapter 6 - Creating Ethernet/IP™ Device, Drive, and I/O Module Types

Parametername:

PARAMNAME [Index].HIGHRANGE

Specific to Block: Generic Device

Description: Scaling parameter for setting high range

Data Type: FLOAT64

Range: -1.7E+308 to +1.7E+308

# Enumtext

Size inbytes

Min. RawValue

Max. Rawvalue

Default: NaN

Config Load:

Access Lock: Engineer

Residence: CEE

RelatedParameters:

Remarks:

Parametername:

PARAMNAME [Index].LOWRANGE

Specific to Block: Generic Device

Description: Scaling parameter for setting low range

Data Type: FLOAT64

Range: -1.7E+308 to +1.7E+308

Generic Device

# Enumtext

Size inbytes

Min. RawValue

Max. Rawvalue

Default: NaN

Config Load:

Access Lock: Engineer

Residence: CEE

- 47 -

Parametername:

PARAMNAME [Index].LOWRANGE

RelatedParameters:

Remarks:

Parametername:

PARAMNAME [Index].SCALEFACTOR

Specific toBlock:

Generic Device

Description:

Data Type: FLOAT32

Range: -1.7E+308 to +1.7E+308

# Enumtext

Size inbytes

Min. RawValue

Max. Rawvalue

Default: 1

Config Load:

Access Lock: Engineer

Residence: CEE

RelatedParameters:

Remarks:

- 48 -

Chapter 6 - Creating Ethernet/IP™ Device, Drive, and I/O Module Types

Chapter 6 - Creating Ethernet/IP™ Device, Drive, and I/O Module Types

Parametername:

PARAMNAME [Index].BIAS

Specific to Block: Generic Device

Description:

Data Type: FLOAT32

Range: -1.7E+308 to +1.7E+308

# Enumtext

Size inbytes

Min. RawValue

Max. RawValue

Default: 0

Config Load:

Access Lock: Engineer

Residence: CEE

RelatedParameters:

Remarks:

Parameter name: PARAMNAME [Index].FLOATVALUE

Specific to Block: Generic Device

Description:

Data Type: FLOAT64

Range: -1.7E+308 to +1.7E+308

# Enumtext

Size inbytes

Min. RawValue

Max. Rawvalue

Default: 0

Config Load:

Access Lock: Engineer

Residence: CEE

RelatedParameters:

Remarks:

- 49 -

Where ‘PARAMNAME’ is the Custom parameter name and ‘Index’ is the index of arrayedcustom parameter.