REFINERY OPERATIONS PLANNING Dunham, Luhila, Odunuga.

-

Upload

johanna-egle -

Category

Documents

-

view

217 -

download

5

Transcript of REFINERY OPERATIONS PLANNING Dunham, Luhila, Odunuga.

REFINERY OPERATIONS PLANNING

Dunham, Luhila, Odunuga

Overview

Refinery Overview Production Planning Linear model with complex and

simplified utilities Results Conclusions

Model Refinery: Bangchak Refinery (Thailand)

HDS

FOVS

FO2

GASOLINEPOOL

DIESELPOOL

CDU2

CDU3

MB

FG

LPG Naphtha FO

Kero DO

NPU

LN

HN

ISOU

CRU

HN

FG

REF

LPG

KTU

ISO

LN

Kero

IHSD

MTBET

DCCT

ISOG

SUPG

HSD

JP1

FO1

Products

Intermediates

PHET

SLEB

LB

TP

OM

Crudes

Kero

FO

Kero

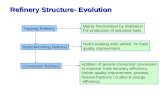

What is Refinery Operations Planning?

How much crude should be purchased?

What kind/quality of crude should be purchased?

How much does the refinery want to produce?

Consists of crude oil unloading, production planning and distribution

Problems in Refinery Operations Uncertainty in prices and demand

Effects of uncertainty are minimized by using models

Historically, models have been linear Use of average operating conditions Linear models are non-ideal

Currently Non-linear models are ideal Linear Model with Complex Utilities

Features of Current Models

Shah N1996

Moro et al.2004

Gathe-Lundgen et al.2002

Glismann et al.2001

Pongsakdi et al2006

Lee et al.1996

Zhang et al2001

Crude oil distillation and blending

X X X

NLP X X

P.planning, inventory mgt, shipment

X X

Coordination of feedstock & pdt with markets

X X X

Uncertainty X X X X

Financial risk X

Decomposition Strategy X X

Production Planning

Production Planning Processing of crude oil

through different units Decisions

Crude oil Purchase Processing Inventory

management

Bangchak Refinery

Production Planning

Routine process which guides purchasing Departments

Crude oil acquisition, product sales & refinery operations

Based on Market demands and prices Uncertainty

Production Planning

Winter High fuel oil

demand → more fuel oil produced

Summer High demand for

light crudes → more gasoline produced

Linear Modeling Method

Inside Unit is a black box (inside box doesn’t matter)

Input and output can be related

F1

F2

F3

Reactor Feed

Light Ends

Desulfurized Product

CRU

Linear Modeling Method

Linear Equation Relating Inputs and Outputs:

F3 =α31*F1

What is α31?

It depends on the system!

F1

F2

F3

Reactor Feed

Light Ends

Desulfurized Product

CRU

Finding Alpha (α)

Really, αij is the result of solving an ODE Example: Concentration of Aromatics

leaving a CRU

Thus αij will depend on Inlet concentrations and flows Process parameters: Temperature, Pressure

2** HAroAroAro

AroCCkr

dW

dC

Hydrotreating

Process to remove impurities in the stream

Aromatics

Hydrotreating for sulfur → hydrosulfurization

Reduces the aromatic content in crudes Hydrogenation

NitrogenSulfur

Hydrotreating PFD

Hydrotreating Model

Operating Conditions Reactor Temperatures range from 250°F –

550°F Main Variables

Pressure Temperature Velocity H2/HC ratio

KTU Aromatics Flow Rate

aroar rWfF *

ƒo = Initial Flow Rate

550.5200

081.1

__

_

E

E

oilweightmolecular

weightAromaticW

Hydrotreating Empirical Model

harar CCLHSVr **

Totalar f

TRP

C

*1000*

Totalh fTR

PC

885000*

*

1000*

Aromatics:

hr

mLHSV

3

66.2

KTU Equation Comparison

Linear Equation: Far =α1*Ftotal

Actual Equation:

totaltotal

oar FTR

P

FTRP

LHSVWfF885000

**

*1000**

*1000

**

2

45.0

22*1

**60*SHSH

hsss

CK

CCkr

Non linearity

TR

ks*

132000exp0127.4 9

fMwfTR

PCs /*)*5.1242(*

*

1000*

45.0

100000*

88500*

*

1000*

fTR

PCh

TRSH eK

2761

417702

100000*

88500*

*

1000*2 fTR

PC SH

Catalytic Reforming

Process of increasing octane number of NPU by converting napthenes & paraffins

Outputs Aromatics, light hydrocarbons (C1-C5) &

hydrogen Operating conditions

Variables Range

Temperature °F 900 – 950

Pressure (atm) 30 – 40

Catalytic Reformer PFD

TP

PPK

N

HAp

4604515.46exp

* 3

1

CRU -Empirical Kinetic ModelConversion of napthenes to aromatics

Amount of product X1 Produced

Reaction Rate

Kinetic Reaction Constant

Equilibrium Constant

Tk p

3475021.23exp1

1

3

11

*

p

HANp K

PPPkr

11 X

F

Wr

T

Reformer Temperature Modeling

5,000 10,000 15,000 20,000 25,000 30,000 35,000

-135

-130

-125

-120

-115

-110

-105

Reactor 1Mass Flow Rate (lb/hr)

Delt

a T

(R

)

Process Industry Modeling Systems

Allows user to analyze results graphically and to adjust variables

Adds capabilities for global optimization, solution ranging, and goal programming

Requires refinery-specific inputs to determine an acceptable starting point

PIMS

PIMS and Non-linearities

Benefits Identifies the solution that maximizes

global profitability

Validates solution and enhances planners’ confidence and gives an estimate on how close results are to optimal solution

Eliminates need to manually search for improved solutions

PIMS and Non-linearities

SLP is the primary non-linear modeling feature

Flexibility in the types of equations that can be used in models

Builds derivatives which eliminates potential errors

Non-linear terms can reference existing Aspen PIMs variables or define new variables

PIMS Modeling

PIMS finds maximum by calculating objective function gradient

Maximum found by PIMS depends on initial condition

0 10 20 30 40 50 600

102030405060708090

100 Objective ...

X

X

Start 1

Max 1

Max 2

Start 2

x

x

Linear Model with Utilities

Alternative Method

Model Super tables

Product flow of Paraffi ns(psi) Pressure 400 400 400(F) Temp. 800 820 840

Concentration Flow Rate0.31 15500 2547.928 2547.928 2547.9280.31 16000 2630.119 2630.119 2630.1190.31 16500 2712.31 2712.31 2712.310.31 17000 2794.502 2794.502 2794.5020.31 17500 2876.693 2876.693 2876.6930.31 18000 2958.884 2958.884 2958.8840.31 18500 3041.075 3041.075 3041.0750.31 19000 3123.266 3123.266 3123.2660.31 19500 3205.458 3205.458 3205.4580.31 20000 3287.649 3287.649 3287.649

Product flow of Paraffins

X=f(C,T,P,F)Conc = 0.31Temp = 800 FPressure = 400 psiFlowrate = 16000 m3/dayX= 2630 bbl/hr

Model Super tablesProduct flow of Paraffins

(psi) Pressure 400 400 400 400 400 400 400 400 400 400 450 450 450 450 450 450 450 450 450 450 500 500 500 500

(F) Temp. 800 820 840 860 880 900 920 940 960 980 800 820 840 860 880 900 920 940 960 980 800 820 840 860

Concentration Flow Rate

0.31 15500 2571.22 2596.69 2647.74 2747.85 2940.15 3302.30 3971.58 5186.33 7353.35 11155.62 2577.40 2609.65 2674.26 2800.97 3044.36 3502.73 4349.85 5887.40 8630.25 13442.95 2584.32 2624.13 2703.90 2860.34

0.31 16000 2653.41 2678.88 2729.93 2830.04 3022.34 3384.49 4053.77 5268.52 7435.54 11237.81 2659.59 2691.84 2756.45 2883.16 3126.55 3584.92 4432.04 5969.59 8712.44 13525.14 2666.51 2706.32 2786.09 2942.53

0.31 16500 2735.60 2761.07 2812.13 2912.24 3104.53 3466.68 4135.96 5350.72 7517.73 11320.01 2741.79 2774.03 2838.65 2965.35 3208.74 3667.12 4514.24 6051.78 8794.64 13607.33 2748.70 2788.51 2868.28 3024.72

0.31 17000 2817.79 2843.27 2894.32 2994.43 3186.72 3548.87 4218.15 5432.91 7599.92 11402.20 2823.98 2856.22 2920.84 3047.54 3290.93 3749.31 4596.43 6133.97 8876.83 13689.52 2830.89 2870.70 2950.48 3106.91

0.31 17500 2899.98 2925.46 2976.51 3076.62 3268.91 3631.06 4300.34 5515.10 7682.11 11484.39 2906.17 2938.41 3003.03 3129.74 3373.12 3831.50 4678.62 6216.16 8959.02 13771.71 2913.08 2952.89 3032.67 3189.10

0.31 18000 2982.17 3007.65 3058.70 3158.81 3351.10 3713.25 4382.53 5597.29 7764.30 11566.58 2988.36 3020.60 3085.22 3211.93 3455.31 3913.69 4760.81 6298.35 9041.21 13853.90 2995.27 3035.08 3114.86 3271.29

0.31 18500 3064.36 3089.84 3140.89 3241.00 3433.30 3795.44 4464.73 5679.48 7846.49 11648.77 3070.55 3102.80 3167.41 3294.12 3537.51 3995.88 4843.00 6380.54 9123.40 13936.09 3077.46 3117.27 3197.05 3353.48

0.31 19000 3146.55 3172.03 3223.08 3323.19 3515.49 3877.64 4546.92 5761.67 7928.69 11730.96 3152.74 3184.99 3249.60 3376.31 3619.70 4078.07 4925.19 6462.74 9205.59 14018.29 3159.66 3199.47 3279.24 3435.68

0.31 19500 3228.75 3254.22 3305.27 3405.38 3597.68 3959.83 4629.11 5843.86 8010.88 11813.15 3234.93 3267.18 3331.79 3458.50 3701.89 4160.26 5007.38 6544.93 9287.78 14100.48 3241.85 3281.66 3361.43 3517.87

0.31 20000 3310.94 3336.41 3387.46 3487.57 3679.87 4042.02 4711.30 5926.05 8093.07 11895.34 3317.12 3349.37 3413.98 3540.69 3784.08 4242.45 5089.57 6627.12 9369.97 14182.67 3324.04 3363.85 3443.62 3600.06

0.31 20500 3393.13 3418.60 3469.66 3569.77 3762.06 4124.21 4793.49 6008.25 8175.26 11977.54 3399.31 3431.56 3496.17 3622.88 3866.27 4324.65 5171.77 6709.31 9452.17 14264.86 3406.23 3446.04 3525.81 3682.25

0.33 15500 2735.60 2761.07 2812.13 2912.24 3104.53 3466.68 4135.96 5350.72 7517.73 11320.01 2741.79 2774.03 2838.65 2965.35 3208.74 3667.12 4514.24 6051.78 8794.64 13607.33 2748.70 2788.51 2868.28 3024.72

0.33 16000 2823.09 2848.57 2899.62 2999.73 3192.02 3554.17 4223.45 5438.21 7605.22 11407.50 2829.28 2861.52 2926.14 3052.85 3296.23 3754.61 4601.73 6139.27 8882.13 13694.82 2836.19 2876.00 2955.78 3112.21

0.33 16500 2910.59 2936.06 2987.11 3087.22 3279.52 3641.67 4310.95 5525.70 7692.72 11494.99 2916.77 2949.02 3013.63 3140.34 3383.73 3842.10 4689.22 6226.77 8969.62 13782.32 2923.69 2963.50 3043.27 3199.71

0.33 17000 2998.08 3023.56 3074.61 3174.72 3367.01 3729.16 4398.44 5613.20 7780.21 11582.49 3004.27 3036.51 3101.13 3227.83 3471.22 3929.60 4776.72 6314.26 9057.12 13869.81 3011.18 3050.99 3130.77 3287.20

0.33 17500 3085.57 3111.05 3162.10 3262.21 3454.51 3816.65 4485.94 5700.69 7867.70 11669.98 3091.76 3124.01 3188.62 3315.33 3558.72 4017.09 4864.21 6401.75 9144.61 13957.31 3098.68 3138.49 3218.26 3374.70

0.33 18000 3173.07 3198.54 3249.60 3349.70 3542.00 3904.15 4573.43 5788.19 7955.20 11757.48 3179.25 3211.50 3276.11 3402.82 3646.21 4104.58 4951.70 6489.25 9232.11 14044.80 3186.17 3225.98 3305.75 3462.19

0.33 18500 3260.56 3286.04 3337.09 3437.20 3629.49 3991.64 4660.92 5875.68 8042.69 11844.97 3266.75 3298.99 3363.61 3490.32 3733.70 4192.08 5039.20 6576.74 9319.60 14132.29 3273.66 3313.47 3393.25 3549.68

0.33 19000 3348.06 3373.53 3424.58 3524.69 3716.99 4079.14 4748.42 5963.17 8130.19 11932.46 3354.24 3386.49 3451.10 3577.81 3821.20 4279.57 5126.69 6664.24 9407.09 14219.79 3361.16 3400.97 3480.74 3637.18

0.33 19500 3435.55 3461.03 3512.08 3612.19 3804.48 4166.63 4835.91 6050.67 8217.68 12019.96 3441.74 3473.98 3538.60 3665.30 3908.69 4367.07 5214.19 6751.73 9494.59 14307.28 3448.65 3488.46 3568.24 3724.67

0.33 20000 3523.04 3548.52 3599.57 3699.68 3891.98 4254.12 4923.41 6138.16 8305.17 12107.45 3529.23 3561.48 3626.09 3752.80 3996.19 4454.56 5301.68 6839.22 9582.08 14394.77 3536.14 3575.95 3655.73 3812.16

0.33 20500 3610.54 3636.01 3687.06 3787.17 3979.47 4341.62 5010.90 6225.65 8392.67 12194.94 3616.72 3648.97 3713.58 3840.29 4083.68 4542.05 5389.17 6926.72 9669.57 14482.27 3623.64 3663.45 3743.22 3899.66

0.35 15500 2899.98 2925.46 2976.51 3076.62 3268.91 3631.06 4300.34 5515.10 7682.11 11484.39 2906.17 2938.41 3003.03 3129.74 3373.12 3831.50 4678.62 6216.16 8959.02 13771.71 2913.08 2952.89 3032.67 3189.10

0.35 16000 2992.78 3018.25 3069.30 3169.41 3361.71 3723.86 4393.14 5607.89 7774.91 11577.18 2998.96 3031.21 3095.82 3222.53 3465.92 3924.29 4771.41 6308.96 9051.81 13864.51 3005.88 3045.69 3125.46 3281.90

0.35 16500 3085.57 3111.05 3162.10 3262.21 3454.51 3816.65 4485.94 5700.69 7867.70 11669.98 3091.76 3124.01 3188.62 3315.33 3558.72 4017.09 4864.21 6401.75 9144.61 13957.31 3098.68 3138.49 3218.26 3374.70

0.35 17000 3178.37 3203.85 3254.90 3355.01 3547.30 3909.45 4578.73 5793.49 7960.50 11762.78 3184.56 3216.80 3281.42 3408.13 3651.51 4109.89 4957.01 6494.55 9237.41 14050.10 3191.47 3231.28 3311.06 3467.49

0.35 17500 3271.17 3296.64 3347.69 3447.80 3640.10 4002.25 4671.53 5886.28 8053.30 11855.57 3277.35 3309.60 3374.21 3500.92 3744.31 4202.68 5049.80 6587.35 9330.20 14142.90 3284.27 3324.08 3403.85 3560.29

0.35 18000 3363.96 3389.44 3440.49 3540.60 3732.90 4095.04 4764.33 5979.08 8146.09 11948.37 3370.15 3402.40 3467.01 3593.72 3837.11 4295.48 5142.60 6680.14 9423.00 14235.70 3377.07 3416.88 3496.65 3653.09

0.35 18500 3456.76 3482.24 3533.29 3633.40 3825.69 4187.84 4857.12 6071.88 8238.89 12041.17 3462.95 3495.19 3559.81 3686.51 3929.90 4388.28 5235.40 6772.94 9515.80 14328.49 3469.86 3509.67 3589.45 3745.88

0.35 19000 3549.56 3575.03 3626.08 3726.19 3918.49 4280.64 4949.92 6164.67 8331.69 12133.96 3555.74 3587.99 3652.60 3779.31 4022.70 4481.07 5328.19 6865.74 9608.59 14421.29 3562.66 3602.47 3682.24 3838.68

0.35 19500 3642.35 3667.83 3718.88 3818.99 4011.28 4373.43 5042.72 6257.47 8424.48 12226.76 3648.54 3680.78 3745.40 3872.11 4115.50 4573.87 5420.99 6958.53 9701.39 14514.08 3655.45 3695.26 3775.04 3931.47

0.35 20000 3735.15 3760.63 3811.68 3911.79 4104.08 4466.23 5135.51 6350.27 8517.28 12319.56 3741.34 3773.58 3838.20 3964.90 4208.29 4666.67 5513.79 7051.33 9794.19 14606.88 3748.25 3788.06 3867.84 4024.27

0.35 20500 3827.95 3853.42 3904.47 4004.58 4196.88 4559.03 5228.31 6443.06 8610.08 12412.35 3834.13 3866.38 3930.99 4057.70 4301.09 4759.46 5606.58 7144.13 9886.98 14699.68 3841.05 3880.86 3960.63 4117.07

Linear Model with Utilities

Our model finds the maximum by testing many discrete points

Optimum value will be close to the global optimum

0 10 20 30 40 50 600

10

20

30

40

50

60

70

80

90

100Objective Function

GAMS Software

Algebraic modeling interface capable of solving linear and mixed integer models

Non-linear equations cause problems

Comparison

Linear or Mixed Integer Programming

Discretizes continuous values

Always finds best test point (near global maximum)

Successive Linear Programming

Uses gradient of objective function

May find local maximum (depends on starting point)

Linear Model (in GAMS) PIMS

Utility Calculations

Steam and Power are produced within the refinery

Steam is produced by fired steam boilers, which burn refinery fuel gas and fuel oils to create steam

Electricity is produced by running high pressure steam through a turbine

Utility Table Equations

Water Cost (Heat exchangers)

Unit Fuel Gas Consumption (Heaters)

ww

vaplbcondensers

wW

ppplbcoolers CpT

m

CpT

TCpm

$$

fg

pp

H

TCpm

Utility Equations in GAMS

Results

LP Model (Individual Units)

CRU Reactor Temperature

Isothermal

Non-Isothermal

Utilities

No Utilities

Simplified Utilities

Complex Utilities

Linear Model Development

Utility Models

Linear Model with Complex Utilities: Uses tables to coordinate output values

with functions of Temperature, Pressure, and Flow rate

Linear Model with Simplified Utilities: Assumes Temperature and Pressure to

be the average of operating conditionsLinear Model without Utilities: Does not calculate utility cost

Results - Gross Refinery Margin

Model GRM

Linear Model with Complex Utilities

$34,103,151

Linear Model with Simplified Utilities

$31,168,455

Results - Total Utility Cost

Model Utility Cost

Linear Model with Complex Utilities

$2,980,761

Linear Model with Simplified Utilities

$3,411,319

Purchasing Recommendations

Linear Model with Complex Utilities

Crude Purchasing Recommendations (m3/day)

Month

1 2 3

OM 250361 265445 267700TP 35313 42245 43073LB 0 0 12997SLEB 95392 95392 95392PHET 57235 57235 57235

MB 95392 95392 95392

Linear Model with Simplified Utilities

Crude Purchasing Recommendations (m3/day)

Month

1 2 3

OM 244486

262303

267899

TP 32853 41126 47392

LB 0 0 9041

SLEB 95392 95392 95392

PHET 57235 57235 57235

MB 95392 95392 95392

Unit Operating Conditions

No Utility Model Complex Utility Model

Month: 1 2 3 1 2 3NPU2 NPU2

Temperature 600 600 600 600 600 600Pressure 600 600 600 600 600 600

NPU3 NPU3Temperature 700 700 700 700 700 700Pressure 600 680 680 680 680 680

ISOU ISOUTemperature N/A 275 275 275 275 275Pressure N/A 1.9 1.9 2 2.1 2.1

CRU2 CRU2Temperature 980 980 980 980 980 980Pressure 850 850 800 850 850 400

CRU3 CRU3Temperature 980 980 980 980 980 980Pressure 500 800 550 400 600 750

DiscussionCatalytic Reforming Unit

Isothermal Model

Reactors are isothermal

All reactor temperatures are the same

Produces more Fuel Gas

Varying Temperature Model

Each reactor operates at a different temperature

Temperature changes in each reactor

Produces more Hydrogen

Produces almost 50% more Reformate

Hydrogen and Refinery Fuel Gas Both utility models calculated a net

production of Hydrogen and Refinery Fuel Gas

Assume these are usable and can be transported around the refinery where make-up is needed

Since excess is produced, no Hydrogen or RFG is purchased

Conclusions

The Linear Model with Complex Utilities processes more crude and gives a larger GRM than a model with Simplified Utilities and a model with no utility cost calculation

The Non-isothermal CRU model produces more reformate and increases overall GRM

Linear models in GAMS always find a value close to the global optimum, where PIMS may find only a local optimum depending on starting point

Questions?