ref. 3 ecoli

description

Transcript of ref. 3 ecoli

646 lEEE Transactions on Dielectrics and Electrical Insulation Vol. 7 No. 5, October 2000

Streamer Discharges in Liquids and their Applications

H. Akiyama Graduate School of Science and Technology

Kumamoto University Kumamoto, Japan

ABSTRACT Industrial applications using pulsed power technologies have been developed in many fields. One of them is the treatment of exhaust gas by using uniformly produced streamer discharges. Streamer discharges in liquid also generate extremely high electric fields at the tip of stream- ers, as well as high energy electrons, ozone, other chemically active species, ultraviolet rays and shock waves. All of these may be utilized to sterilize microorganism and to decompose mole- cules and materials. Large-volume streamer discharges in water have been produced in order to realize industrial applications. A wire to plane electrode configuration has been used. The discharge in water shows similar optical radiation to that in an atmospheric gas as provided by evidence from still photographs. The influence of polarity, conductivity, electrode geometry and hydrostatic pressure on the streamers in liquid, the mechanism of streamer discharges and possible industrial applications of streamers in liquids, are discussed in the present work.

1 INTRODUCTION

NUUSTRIAL applications of pulsed power technology have been de- I veloping rapidly in many fields, such as the treatment of exhaust gases such as nitrogen oxides, sulfur oxides and dioxin; the sterilization of microorganism; the removal of biological wastes; the fragmentation of rocks; the recycling of concrete and electric appliances; and the sur- face treatment of material [l-81. The application of electric fields with a short pulse width allows direct interaction with biological cells without heating the tissues [l , 9,101.

Pulsed power may be used to produce nonthermal plasmas in at- mospheric pressure gases that generate a high electric field at the tips of streamer discharges and produce high energy electrons, free radi- cals, ultraviolet rays and ozone [Z, 3,ll-131. These manifestations of streamer discharges have been used in the treatment of exhaust gases, removal of volatile and toxic compounds such as dioxin, and the steril- ization of microorganisms.

The breakdown phenomena in liquids have been studied for a long time, in particular its relation to electrical insulation [14-171. Large volume streamer discharges can be produced not only in atmospheric pressure gases but also in liquids using the most recent development in pulsed power technology [14,18,20]. These streamer discharges in liq- uids are able to produce a high electric field, high energy electrons, ozone, chemically active species, ultraviolet rays and shock waves, which readily sterilize microorganisms and decompose molecules and materials.

Pulsed electric field treatment has been used for cleaning of wa- ter containing organic chemical impurities and in water-air mixtures (aerosol) [ZO]. The streamer discharge in water has a thermal nature, and the streamers are gas discharges in thin vapor bubbles, which oc- cur in water [14,21]. Although streamer discharges in liquids and in aerosols generally have similar features, the streamers in liquids are denser than those in aerosols. The large volume streamer discharges have large commercial applications, such as the treatment of sludge water, the dissociation of toxic chemicals like dioxin, the cleaning of contaminated water, the sterilization of milk and juices and others.

First of all the method to produce large volume streamer discharges is described in this review. It is very important to make streamers over a large volume of the liquid for commercialization of these systems. Then, after describing the influence of polarity, conductivity, electrode geometry and pressure on the streamers, the mechanism of streamer discharges and their applications are summarized.

2 CHARACTERISTICS OF

2.1 PRODUCTION OF LARGE STREAMER DISCHARGES

VOLUME STREAMER DISCHARGES

A small-volume streamer discharge has been produced by using a point to plane electrode [ZZ-251. As stated already, the production of large volume streamer discharges is important in order to realize their industrial applications.

1070-9878101 $3.00 0 2000 IEEE

IEEE Transactions on Dielectrics and Electrical Insulation Vol. 7No. 5, October 2000 647

Figure 3. Framing photographs with the frame gate of 20 ns and the interframe time of 100 ns

Polyethylene insulators Outer ring electrode 10

8 t r r i 5 r

~~~' z:: Y

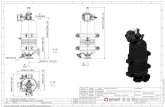

Figure 1. Cross section of the reactor to produce a large volume streamer discharge

Y 36 Figure 1 shows a cross section of a reactor to produce a large vol-

ume streamer discharge [14,18]. It consists of a HV cable input, a wa- 4+ c 4 100 8

O O

E ter inlet and outlet, a plastic vessel with an acrylic window for optical measurements and an electrode system. The inner electrode has a disk shape, radius 1 cm, and thickness 1 mm, is made of stainless steel, and is attached to the HV cable. The outer, grounded, electrode is made of stainless steel and has a variable inner diameter (40 to 88 mm)

able number of stages The stage capacitance and the charging voltage are 0.22 pF and 40 kV, respectively The number of stages can be varied from 3 to 12, providing a peak output voltage in the range of 120 to

5 2 - 50 g \- - - - - - -

-2 -50 -0.5 0 0.5 1 1.5 2 2.5

(a) Time(*) Positive HV pulses are obtained from a Marx generator with a vari- 10

% 150 9 100 'iii c

c 4

50 g 0 8

E 5 2

.*---e? O O

-2 -50 -0.5 0 0.5 1 1.5 2 2.5

(b) Time(*)

Figure 4. Voltage and current waveforms in distilled water (a) and tap water (b) with 39 mm electrode separation

are 20 and 100 ns, respectively The streamer discharges expand uni- formly The streamers shown in Figure 2 are ultrahigh-speed luminous positive tertiary streamer (PTS) or third mode [26], which usually have a filamentary structure and can be obtained in highly overstressed gaps and fast rise time voltage pulses [15]. Figure 4 shows the voltage and current waveforms in distilled water (a) and tap water (b) with 39 mm electrode separation.

The uniformity of the streamer discharge is dependent on water conductivity, electrode separation and applied voltage. Examples of uniform and nonuniform discharges are summarized in Table 1 The streamer pattern radius showing the final radius of the streamer cloud was measured on the open shutter photographs. This radius corre- sponds to the maximum streamer length before an arc discharge occurs. After arcing, the streamers do not propagate anymore The good uni- formity means that the streamer discharges have a radius >90% of the electrode separation. The poor uniformity corresponds to a streamer pattern radius t70% of the interelectrode distance. The uniformity of

Figure 2. Time-integrated photograph of the discharge at Marx output voltage of 200 kV in distilled water

In order to achieve a large volume streamer discharge, it must be equally distributed azimuthally in space between electrodes, and have a length close to the electrode gap separation. Figure 2 shows the time- integrated photograph of the discharge at a Marx output voltage of 200 kV in distilled water with a resistivity of 1 0 4 a m. A uniform streamer discharge with a volume of N 200 to 300 cm3 is obtained between the electrodes N 20 arc channels are observed with stream- ers Framing photographs taken with Imac0n-790~~ (Hadland Photon- ics Ltd.) are shown in Figure 3 The frame gate and the interframe times

648 Akiyama: Streamer Discharges in Liquids and their Applications

Table 1. Estimates of the uniformity of large-volume streamer dis- charges under various experimental conditions. The circle, triangle, cross and bar marks mean the good uniformity, fair uniformity, poor uniformity and no data, respectively. 0: uniform, A: nearly uniform, x: not uniform, -: no data.

the streamer discharge improves with decreasing applied voltage, in- creasing electrode separation, and increasing water conductivity

Wire electrode Plane electrode

Figure 5. Time-integrated photograph of discharges in tap water un. der a thin wire to plane electrode configuration.

The volume of the streamer discharges was greatly increased by us- ing a thin wire electrode placed in parallel with a plane electrode. Fig- ure 5 shows a time-integrated photograph of discharges in tap water, which were produced by 9 stages of the Marx bank. The diameter of the thin wire was 1 mm, and the electrode separation and the length of plane electrode were 45 and 150 mm, respectively. The thin wire elec- trode was positive. The number of streamers per unit length increased with the intensity of the electric field on the surface of the thin wire electrode. Coaxial electrodes, i.e. a thin wire electrode in parallel with four plane electrodes and a thin wire electrode surrounded by a spiral or a mesh electrode, are necessary in order to get large volume streamer discharges.

2.2 POLARITY EFFECTS ON STREAMERS

Polarity effects on the structure and the velocity of streamers were summarized in [15,26]. Figure 6 shows schematic structures of positive (a) and negative (b) streamers for a point to plane electrode [26]. In the case of a positive point electrode, the 1st anode mode with a velocity of - 2x102 m/s appears, and then a bushy streamer, defined as the 2nd anode mode, propagates with a velocity of 4x103 m/s. Finally, the 3rd anode mode with a velocity of 4x104 m/s propagates until it reaches the grounded plane electrode. After the streamer connects between two electrodes, an arc discharge occurs.

In the case of a negative point electrode as shown in Figure 6(b), the 1st cathode mode, with 100 pm length, propagates with a velocity of 2x102 m/s, and then a more bushy 2nd cathode mode grows with a velocity of 2x102 m/s. The 3rd and 4th cathode modes propagate with velocities of 2x105 m/s and 4x106 m/s, respectively. An arc discharge occurs after the streamer arrives at the plane electrode. Streamers from

1 s t 2 n d 3rd

(a) Anode mode

Q Q 8 7 1st 2 n d 3rd 4th

Cathode mode (b)

Figure 6. Schematic structures of positive (a) and negative (b) stream- ers for the point to plane electrode.

a negative electrode are more bushy than that from a positive electrode, and streamers from a positive electrode are more filamentary

Although a typical example is shown in Figure 6, these structures may change with the applied voltage waveform. Also, the electrode configuration [15], the hydrostatic pressure [27-291, the characteristics of the liquid [30-321 and additives [33,34] have large effects on the structure of streamers. If we apply a negative pulsed voltage with a fast risetime to a point-plane electrode, the second cathode mode disap- pears. The same suppression has been observed in hexane and toluene when the pressure is increased 2 10 MPa [26]. In the case of a positive pulsed voltage, the 3rd anode mode becomes dominant [la]. In satu- rated n-hexane and cyclohexane, the shapes of the streamer are only bush-type for a negative point, but both bush-type and tree-type are observed for the positive electrode. In unsaturated 1-hexane, there is only bush-type for a negative point and tree-type for the positive elec- trode. In benzene, there are both bush-type and tree-type streamers for the negative point, but only a radial-type for the positive electrode [30].

The polarity effect in insulating oil was summarized by Beroual et al. [15]. The positive streamer can be classified in three consecutive stages: the 1st anode mode (positive primary streamer), the 2nd an- ode mode (positive secondary streamer), and the 3rd anode mode (ter- tiary streamer). The primary positive streamer with a velocity of 2 to 3x103 m/s has an umbrella-like structure and reaches to near the op- posite electrode. At a higher applied voltage, the 2nd anode mode with a velocity of 3 . 2 ~ 1 0 ~ m/s appears in the form of bright stems witha top ionization zone in the shape of brush-type structures [3]. Further higher applied voltage causes a short 1st anode mode growth, an earlier 2nd anode mode inception, and an ultra-high speed 3rd anode mode with a velocity >lo5 m/s. The 3rd anode mode is less branched and often fil- amentary The structure of negative streamers in insulating oil appears to change depending on the applied electric field. The structures of the 1st cathode mode (negative primary streamer) changes from the shape of a leafless treetop to a compact bushy structure with many branches as the applied voltage increases. At very high fields, the streamer shape changes again. Only one branch bridges the gap with a velocity that can exceed lo5 m/s. For larger gaps (>40 mm), a secondary stage could be detected.

The disk to circular electrode shown in Figure 1 produced multi- ple positive streamers. Figure 7 shows the dependence of the streamer length of the 3rd anode mode (tertiary streamers) on time for various applied voltages in distilled water. The streamer expansion velocity

IEEE Transactions on Dielectrics and Electrical Insulation Vol. 7 No. 5,OctoberZOOO 649

Figure 7. Dependence of the streamer length of the 3rd anode mode (tertiary streamers) on time for various applied voltages in distilled water.

10 - 50 60 70 80 90 100

E b d (ICv/") Figure 8. Dependence of the breakdown time lag on the breakdown voltage in distilled water, 0.001 and 0.01 M sodium chloride solutions.

is independent of the voltage pulse amplitude for a fast rising pulsed voltage and is x 3 to 4x104 m/s. The number of major visible posi- tive streamers increases with increasing applied voltage [14,18]. The number of negative streamers is much less than that of the positive streamers.

2.3 INFLUENCE OF LIQUID CONDUCTIVITY

Electronic conduction processes in dielectric liquids have been stud- ied for many years [35-411. The voltage and current waveforms for both distilled and tap water are shown in Figure 4. Although the prebreak- down current in distilled water, just before the rapid voltage drop cor- responding to breakdown, is significantly less than that in tap water, the time lag to breakdown is almost similar in both experiments. The framing photographs of the streamer discharge in distilled water taken with the image converter camera are shown in Figure 3. The voltage applied to the inner positive electrode is 200 kV A number of major filamentary self-luminous streamers propagate between the electrodes with almost constant velocity of 3x104 m/s, which is calculated from

the increase of streamer pattern radius with time. The streamer 17eloc- ity is similar for both distilled and tap water despite the 2.5 order of magnitude difference in their conductivities.

The dielectric breakdown in water has been investigated by chang- ing the conductivity and using high amplitude electric fields of sub mi- crosecond duration [21]. Figure 8 shows the dependence of the break- down time lag on the breakdown voltage in distilled water, and 0.001 and 0.01 M (molar) sodium chloride solutions. The influence of con- ductivity on discharges is small, and therefore bulk heating via ionic current contributes little to the initiation of the breakdown process.

2.4 EFFECTS OF ELECTRODE GEOMETRY

The characteristics of streamers depend on the electric field. The electric field E, on the surface of the wire in a wire to plane electrode is expressed by the following equation [42]

where h, Rand V are the distance between the center of the wire elec- trode and the plane electrode, the radius of wire, and applied voltage to the wire, respectively For example, in the case of the 5 cm gap sepa- ration and 50 pm wire electrode, the electric field on the surface of the wire is enhanced by - 240x the average field.

This enhancement factor is determined by the electrode geometry, and is one of the important factors to initiate the streamer and to shape the streamer structure. The electrode geometry is also one of the impor- tant factors to determine whether streamer remains single or spreads into multiple forms.

2.5 INFLUENCE OF HYDROSTATIC PRESSURE

The hydrostatic pressure has a large effect on the structure and the velocity of streamers. The streamer volume and the number of streamer branches decrease with increasing hydrostatic pressure. These phenom- ena are shown clearly in Figure 9 [15]. These photographs are taken for negative streamers in cyclohexane, and changing pressure. The num- ber and amplitude of current and light pulses and the average streamer velocity are reduced. Consequently, there is a decrease in the number and amplitude of microdischarges which contribute to the propagation of streamers [15]. A further increase in the pressure causes the dis- appearance of the streamer, and the corresponding current and light pulses [16]. Therefore the breakdown strength of liquids increases with increasing hydrostatic pressure. These phenomena have been investi- gated on a microsecond time scale [43-45]. The influence of pressure decreases as the pulse duration is reduced to the sub-microsecond time scale [27].

A short pulse with 3 ns risetime and 100 ns duration was used to in- vestigate the breakdown in water. Gap separations from 0.4 to 2.1 mm were used, and the pressure was changed from atmospheric to 40 MPa. The time lag to breakdown has been found to increase with increasing pressure. Figure 10 shows the propagation velocity of the ionizing front in distilled water as a function of pressure [21]. The gap separation is

650 Akiyama: Sfreamer Discharges in Liquids and their Applications

V V

Figure 9. Structure of streamers at different hydrostatic pressure.

$ o L 0 Pressure (MPa)

Figure 10. Propagation velocity of ionizing front in distilled water as a function of pressure.

1.1 mm, and the applied voltage is 66 kV. Since the statistical time lag is much smaller than the formative time lag, the velocity is calculated from the gap distance divided by the time lag to breakdown. The veloc- ity also decreases with the pressure in the case of 100 ns pulse voltage.

3 MECHANISM OF STREAMER DISCHARGES

Two main concepts of electrical breakdown in liquid [46] have been studied; i.e. a bubble process [47-511 and an electronic process.

As one example of a bubble process, a bubble is formed by vapor- ization of liquid by local heating in the strong field region at the tips of asperities on the electrodes. The bubble will grow and breakdown will take place in the low-strength vapor within the bubbles. Accord- ing to the electronic process, breakdown will occur when an electron makes a suitable number of ionizing collisions in its transit across the breakdown gap. The use of new optical and measuring techniques has permitted significant progress in understanding of the phenomena that can occur in the prebreakdown phase and then in the breakdown [52- 561.

It has been confirmed by recent work carried out on ultra purified cyclohexane that the physical nature of the streamers is gaseous [16, 511. In that case, the cavitation mechanisms induced by electrohydrody- namic phenomena are the most evoked, particularly for the slow bush- like streamers [16]. The time lag to water breakdown, using 100 ns pulse voltage, has been found to increase with increasing pressure. These ex- perimental results indicate that the bubble mechanism is a contributing factor to the sub-microsecond discharge formation in water [21]. The time to form these bubble was 3 to 13 ns, depending on field and pres- sure. The field emission currents from asperities [57], which can pro- vide the necessary heating and free electrons, were considered as the most probable agent contributing to bubble nucleation.

The streamer is increasing in length with time. Taking the measured velocity of a streamer v, the rate of increase of the water mass d m l d t (in kg/s) involved in the streamer propagation process is

(2) dm - = nr'vp, d t

where T and w are the radius of the streamer tip and the density of water. The radius of the streamer tip is assumed to be constant during the streamer propagation process, according to the literature data [58]. The power P necessary to evaporate the water during the streamer propagation can be estimated from the specific heat of evaporation (Wv = 2 . 3 ~ 1 0 ~ J/kg) as follows [14]

dm d t P = W,- = W,nr2vp, (3) I"

Substituting 31.6 p m streamer radii into Equation (3) gives a power of P,,, = 2170 kW that must be released into a single streamer to ensure its propagation in the form of vapor channels.

In the case of multiple streamers shown in Figure 2, the calculated power of a single streamer is multiplied by the total number of visible streamers of N 50 and the total power Pt for 50 streamers becomes 10.85 MW. This power is in good agreement with the power calculated from the discharge current and voltage.

The influence of small concentrations of electronic scavenger addi- tives on the shape and velocity of negative streamers [31,59] and the spectroscopic analysis of the light emitted by streamers [32] indicate that electronic processes are present also. With regards to the positive streamers, the electronic scavenger additives have negligible effect on the shape and velocity It is thought that both gaseous and electronic processes occur simultaneously in the prebreakdown phase, even if one of them is dominant in one case and the second in another [16].

4 APPLICATION OF STREAMER

4.1 PRODUCTION OF CHEMICAL

DISCHARGES

REACTANTS

Several methods, such as oxidation using ozone and high-energy electron irradiation, have been tried for the treatment of pollutants in liquids. Recently, another method using streamer discharges in liquid was considered [60-621. The streamer discharges in liquid produced by pulsed HV generate reactants such as OH, H, HO2, H202, 0, 02, 02- and 03. These reactants treat organic compounds by oxidation. Espe- cially, the OH and 0 radicals and 03 are known to play an important role in oxidative purification of water and in degrading organic com- pounds [24,63].

Figure 11 shows a typical example of the emission spectra of radicals from a pulsed streamer discharge in distilled water [64,65]. Several peaks were observed. The peaks were identified as follows: at 282 nm (A%+ (v=l) + XzH (v=O) and at 309 nm (A2Cf (v=O) + X211 (v=O)) are from OH radicals. Peaks in the visible region are H, (656.3 nm), Ho (486.1 nm) and H, (434.0 nm), respectively [64,65]. Peaks at 777.1 nm (3p5P0 + 3s5S0) and 844.6 nm (3p3P + 3s3S0) are from the emission lines of atomic oxygen.

IEEE Transactions on Dielectrics and Electrical Insulation

t 1

200 300 400 500 600 700 800 900 1000

Wavelenglb [nm]

Figure 11. Typical emission spectra of radicals from a pulsed streamer discharge in distilled water.

4.2 REACTION MECHANISMS

The 0 radical reacts directly with pollutants in water by oxidation. In addition, the 0 radical reacts with liquid to produce the OH radical by the following reaction

0 t HzO + 20H Also, the OH radicals are produced by the reaction with hydrogen per- oxide as follows

0 t HzOz + OH t H02 The OH radicals oxidize organic compounds directly. The primary

oxidation products are oxidized to form secondary products, and finally it is expected that carbon dioxide is formed.

Ozone can react with organic compounds directly and also decom- poses into other radicals, which react with the organic compounds. Wa- ter decomposition by ozone produces many transient oxidizing species such as OH, HOz, O,O-, O;, 0; [64]. These oxidizing species destroy organic compounds effectively.

(4)

(5)

4.3 REMOVALS OF PHENOL AND TRlCH LOROETHYLEN E

The initial reaction rate constants for the formation of hydroxyl rad- icals, hydrogen peroxide and aqueous electrons produced by pulsed streamer discharges were described by Joshi e t al. [66]. The degrada- tion of phenol in aqueous solution was studied by Sharma e t al. [60] using a pulsed streamer discharge. It was observed that a variety of waste water contaminants could be destroyed using this reactor. The transient and final byproducts of phenol treated by a pulsed streamer discharge were studied by Sato e t al. [25].

The experimental apparatus for the treatment of phenol with a pulsed streamer discharge is shown in Figure 12(a) [25]. A point-to- plane geometry electrode system was used with a separation distance of 21 mm. The electrodes are a sharp platinum point and a 20 mm di- ameter stainless steel disk. A rotating double spark-gap switch was used to generate a HV pulse. Typical oscillograms of the pulse voltage and current are shown in Figure 12(b). The liquid was circulated with a peristaltic pump and was cooled through a coiled-pipe heat exchanger to ambient temperature. The liquid circulation rate was adjusted from 20 to 200 ml/min. The concentration of the phenol and byproducts in

! Vol. 7 No. 5, October 2000 651

the solution were measured by using gas chromatography and high- performance liquid chromatography The liquid chromatography ul- traviolet detwtnr was wt a t a w vplpndh of 7% Carbon dioxide -L

1 1 Phenol solution fi m 1. (a)

GND

GND

Time (50 ps/div) ( W

Figure 12. (a) Experimental apparatus for the treatment of phenol with a pulsed streamer discharge, and (b) voltage and current wave- forms.

was measured by absorption in barium hydroxide followed by back titration with standardized HCI.

-0- +20 kV 4-+17.2 kV 2oF, , . 1

0 0 10 2c

Resldence time [min]

Figure 13. Phenol removal with increasing residence time.

Phenol with an initial concentration of 50 ppm was removed by pulsed streamer discharges. The phenol removal increased with in- creasing residence time, as shown in Figure 13 [25]. The interme- diate main byproducts were hydroquinone, pyrocatechol and 1,4- benzoquinone. The phenol and intermediate products were removed completely after increasing the residence time. The hydrogen peroxide and carbon dioxide are considered the candidates for final byproducts.

Trichloroethylene is a toxic substance. It was difficult to remove it by common water treatment techniques. The pulsed streamer discharge is an effective candidate to remove it. Trichloroethylene with an initial concentration of 100 ppm was reduced by 90% using pulsed streamer discharges [64].

652 Akiyama: Streamer Discharges in Liquids and their Applications

4.4 OTHER POSSIBLE

Large volume streamer discharges can be produced in liquids, and generate extremely high electric fields [67], high energy electrons, ozone, chemically active species, ultraviolet rays and shock waves [68], which sterilize microorganisms and decompose molecules and mate- rials. Possible applications of large volume discharges are as follows; (a) sewage treatment, (b) water treatment, (c) ozone water production, (d) treatment of dioxin, (e) treatment of volatile organic compounds, (0 sterilization of food, (g) deodorization and (h) free radical sources.

APPLICATIONS

5 CONCLUSIONS large volume streamer discharge in water was produced by using A a wire to plane electrode configuration. A Marx bank was used to

supply the pulsed HV of 120 to 480 kV between two electrodes. The streamer discharges in water generate extremely high electric fields at the tips of the streamers, high-energy electrons, ozone, chemically active species, ultraviolet rays and shock waves. An increase in the streamer discharge volume is important in order to realize industrial applications, such as the sterilization of microorganisms and the de- composition of molecules. The influence of polarity, conductivity, elec- trode geometry and pressure on liquid streamers, the mechanism of streamer discharges, and the applications of streamers have been dis- cussed and summarized.

REFERENCES [l] C. Polk, "Biological Applications of Large Electric Fields: Some History and Funda-

mentals", IEEE Trans. Plasma Sci., Vol. 28, pp, 2-14,2000. [2] T. Namihira, S. Tsukamoto, D. Wang, S. Katsuki, R. Hackam, H. Akiyama, Y. Uchida

and M. Koike, "Improvement of NO, Removal Efficiency Using Short Width Pulsed Power", IEEE Trans. Plasma Sci., Vol. 28,2000 (in print).

[3] S. Masuda and H. Nakao, "Control of NO, by Positive and Negative Pulsed Corona Discharges", IEEE Trans. Industry Applications, Vol. 26, pp. 374383,1990,

[4] Pulsed Power Discharge and its Application, Ed. H. Akiyama, IEE of Japan, 2000 (in print).

[5] H. Inone, I. V Lisitsyn, H. Akiyama and 1. Nishizawa, "Pulsed Electric Breakdown and Destruction of Granite", Japan J. Appl. Phys., Vol. 38, pp. 6502-6505,1999,

[6] I. V. Lisitsyn, H. Inoue, I. Nishizawa, S. Katsnki and H. Akiyama, "Breakdown and Destruction of Heterogeneous Solid Dielectrics by HV Pulses", J. Appl. Phys., Vol. 84, pp. 6262-6267,1998.

[7] H. Inoue, I. V. Lisitsyn, H. Akiyama and I. Nishizawa, "Drilling of Hard Rocks by Pulsed Power", IEEE Electrical Insulation Magazine, Vol. 16,2000 (in print).

[8] A. Abou-Ghazala, Efecf ofpulsed Electric Fields on Aquatic Nuisance Species, Disser- tation, Old Dominion University, Norfolk, VA, 1998.

[9] S. Katsuki, T. Majima,K. Nagata, I. Lisitsyn, H. Akiyama, M. Furuta, T. Hayashi, K. Takahashi and S. Wirkner, "Inactivation of Bacillus Stearothermophilus by Pulsed Electric Field, IEEE Trans. Plasma Sci., Vol. 28, pp. 155-160,2000,

[lo] Q. Zhang, G. V Barbosa and B. G. Swanson, "Engineering Aspects of Pulsed Electric Field Pasteurization", J. Food Eng., Vol. 25, pp, 261-281,1995.

[ l l] F, Hegeler and H. Akiyama, "Spatial and Temporal Distributions of Ozone After a Wire-to-Plate Streamer Discharge", IEEE Trans. Plasma Sci., Vol. 25, pp. 115&1165, 1997.

[12] F. Hegeler and H. Akiyama, "Ozone Generation by Positive and Negative Wire-to- Plate Streamer Discharges", Japan J, Appl. Phys., Vol. 36, pp. 5335-5339,1997.

[13] S. Tsukamoto, T. Namihira, D. Wang, S. Katsuki, H. Akiyama, E. Nakashima, A. Sato, Y. Uchida and M. Koike, "Pollution Control of Actual Flue Gas Using Pulsed Power at a Thermal Power Plant", Trans. of IEE Japan, Vol. 119-A, pp. 984-989,1999 (in Japanese).

[14] 1. V Lisitsyn, H. Nomiyama, S. Katsuki and H. Akiyama, "Thermal Processes in a Streamer Discharges", IEEE Trans. Dielectr. Electr. Insul, Vol. 6, pp. 351-356,1999.

[15] A. Beroual, M. Zahn, A. Badent, K. Kisi, A. J. Schwabe, H. Yamashita, K. Ya- mazawa, M. Danikas, W. G. Chadband, Y and Torshin, "Propagation and Structure of Streamer in Liquid Dielectrics", IEEE Electr. Insul. Magazine, Vol. 14, pp, 6-17, 1998.

[16] A. Bbronal, "Electronic and Gaseous Processes in the Prebreakdown Phenomena of Dielectric Liquids", J. Appl. Phys., Vol. 73, pp. 45284534,1993.

(171 H. M. Jones, E. E and Kunhardt, "Prebreakdown Currents in Water and Aqueous Solutions and Their Influence on Pulsed Dielectric Breakdown", J. Appl. Phys., Vol. 78, pp. 330&3314,1995.

[18] I. V. Lisitsyn, H. Nomiyama, S. Katsuki and H. Akiyama, "Streamer discharge reac- tor for water treatment by pulsed power", Rev. Sci. Instrum., Vol. 70, pp. 3457-3462, 1999.

1191 H. Akiyama, H. Nomiyama, S. Katsuki and I. Lisitsyn, "Large Volume Discharges in Water and Application to Sludge Treatment", 27th IEEE International Conference on Plasma Science, New Orleans, 2000.

[20] V M. Bystritskii, T. K. Wood, Y. Yankelevich, S. Chaunan, D. Yee and E Wessel, "Pulsed Power for Advanced Waste Water Remedialion", Proc. 11th International Pulsed Power Conference, Baltimore. IEEE Catalog Number 97 CH36127, pp. 79- 84,1997.

1211 H. M. Jones and E. E. Kunhardt, "The Influence of Pressure and Conductivity on the Pulsed Breakdown in Water", IEEE Trans. Dielectr. Electr. Insnl., Vol. 1, pp, 1016- 1025,1994.

[221 I. M. Gavrilov, V. R. Knkhta, V V Lopatin and l? G. Petrov, "Dynamics of Prebreak- down Phenomena in a Uniform Field in Water", IEEE Trans. Dielectr. Electr. Insul., Vol. 1, pp. 496-502,1994,

1231 E. V Yanshin, 1. T. Ovchinnikov and Yn. N. Vershinin, "Mechanism of the Pulsed Electric Breakdown of Water", Sov. Phys.-Doklady, Vbl. 19, pp. 95-96,1974.

[24] J. S. Clements, M. Sato and R. H. Davis, "Preliminary Investigation of Prebreak- down Phenomena and Chemical Reactions Using a Pulsed HV Discharge in Liquid Water", IEEE Trans. Ind. Appl., Vol. 23, pp. 224-235,1987.

[25] Bing Sun, M. Sato and J. S. Clement, "Use of a pulsed HV discharge for removal of organic compounds in aqueous solution", J. Phys. D: Appl. Phys., Vol. 32, pp. 1908-1915,1999,

[26] R. E. Hebner, "Measurements of Electrical Breakdown in Liquids", in The Liquid Stale and ifs Electrical Properties, Eds. E. E. Kunhart, L, G. Christophoreau, and L H. Luessen, Plenum Press, New York, pp, 519-537.1988.

1271 K. C. Kao and J. B. Higham, "The Effects of Hydrostatic Pressure, Temperature, and Voltage Duration on the Electric Strengths of Hydrocarbon Liquids", J. Electrochem. Soc., Vol. 108, pp. 522-528,1961.

[281 K. C. Kao and J, F. C. McMath, "Time-dependent Pressure Effects in Liquid Di- electrics", IEEE Trans. Electr. Insul., Vol. 5, pp. 6448,1970,

1291 Jones, H. M. and E. E. Kunhardt, "Pulsed Dielectric Breakdown of Pressurized Wa- ter and Salts Solutions", J. Appl. Phys., Vol. 77,pp. 795-805,1995,

[30] H. Yamashita and H. Amano, "Prebreakdown Phenomena in Hydrocarbon Liq- uids", IEEE Trans. Electr. Insul., Vol. 4, pp. 739-750,1988.

[311 A. BCoual and R. Tobazhon, "Prebreakdown Phenomena in Liquid Dielectrics", IEEE Trans. Electr. Insnl., Vol. 4, pp. 613-627,1986.

[32] I? I? Wong and E. 0. Foster, "The Dynamics of Electrical Breakdown in Liquid Hy- drocarbons", IEEE Trans. Electr. Insul., Vol. 17, pp, 203-220,1982.

1331 Y Nakao, H. Itoh, S. Hoshino, Y. Sakai and H. Tagashira, "Effects of additives in Prebreakdown Phenomena in n-Hexane", IEEE Trans. Dielectr. Electr. Insnl., Vol. 1, pp. 383-390,1994,

[34] R. E. Hebner, E. F, Kelley, E. 0. Forster and G. J, FitzPatrick, "Observation of Pre- breakdown Phenomena in Liquid Hydrocarbons 11, Non- Uniform Field Condi- tions", IEEE Trans. Electr. Insnl., Vol. 20, pp. 281492,1985,

[35] W. E Schmidt, "Electronic Conduction Processes in Dielectric Liquids", IEEE Trans. Electr. Insul. Vol. 19, pp, 389418,1984.

[36] J, I? Gosse, "Electric Conduction in Dielectric Liquids", in The Liquid Sfnfe and its Electrical Properties, Eds. E. E. Kunhart, L. G. Christophoreau, and L H. Luessen, Plenum Press, New York, pp, 519-537.1988.

1371 N. Gee, M. A. Floriano, T. Wada, S. S:S. Hnang and Gorton, "Ion and Electron Mobilities in Cryogenic Liquids: Argon, Nitrogen, Methane, and Ethane", J, Appl. Phys., Vol. 57, pp. 1097-1101,1985,

IEEE Transactions on Dielectrics and Electrical Insulation Vol. 7"o. 5, October 2000 653

[38] S. Sakamoto and H. Yamada, "Optical Study of Conduction and Breakdown in Di- electric Liquids", IEEE Trans. Electr. Insul., Vol. 15, pp. 171-181,1980,

[39] K. Yoshino, "Electrical Conductionand Dielectric Breakdown in Liquid Dielectrics", IEEE Trans. Electr. Insul., Vol. 21, pp, 847-853,1986.

[40] S. Theoleyre and R. Tobazkon, "Ion Injection by Metallic Electrodes in Highly Polar Liquids of Controlled Conductivity", IEEE Trans. Electr. Insul., Vol. 20, pp. 213-220, 1985.

[41] M. Hilaire, C. Marteau and R. Tobazbon, "Apparatus Developed for Measurement of the Resistivity of High Insulating Liquids", IEEE Trans. Electr. Insul., Vol. 23, pp. 779-787,1988.

[42] M. Hara and H. Akiyama, High Voltoge Pulsed Power Engineering, Morikita, Capter 1, 1991 (in Japanese).

[43] A. E Alkhimov, V V Vorobev, V. F, Klimkin, A. G. Ponomarenko and R. 1. Soloukhin, "The Development of Electrical Discharge in Water", Sov. Phys.-Doklady, Vol. 15, pp, 959-961,1971,

[44] E. A. Abramyan, V. A. Kornilov, V M. Lagunov, A. G. Ponomarenko and R. I. Soloukhin, "Megavolt Energy-concentrating Device", Sov. Phys.-Doklady, Vol. 16, pp, 983-985,1972.

[45] K. C. Kao and J. B. Higham, "The Effects of Hydrostatic Pressure, Temperature, and Voltage Duration on the Electric Strengths of Hydrocarbon Liquids", J. Electrochem. Soc., Vol. 108, pp, 522-528,1961.

[46] A. H. Sharbaugh, J. C. Devins and S. J. Rzad, "Progress in the Field of Electrical Breakdown in Dielectric Liquids", lEEE Trans. Electr. Insul., Vol. 13, pp. 249-276, 1978.

[47] I? K. Watson, "Electrostatic and Hydrodynamic Effects in the Electrical Breakdown of Liquid Dielectrics", IEEE Trans. Electr. Insul., Vol. 20, pp. 395-399,1985.

1481 I? K. Watson, W. G. Chadband and M. Sadeghzadeh-Araghi, "The Role of Electro- static and Hydrodynamic Forces in the Negative-point Breakdowm of Liquid Di- electrics", IEEE Trans. Electr. Insul., Vol. 26, pp, 543-559,1991.

[49] I? K. Watson and W. G. Chadband, "The Dynamics of Pre-Breakdown Cavities in viscous Silicone Fluids in Negative Point-Plane Gaps", IEEE Trans. Electr. Insul., Vol. 23, pp, 729-738,1991.

[50] R. Kattan, A. Denat and 0. Lesaint, "Generation, Growth, and Collapse of Vapor Bubbles in Hydrocarbon Liquids under a High Divergent Electric Field", J. Appl. Phys., Vol. 66, pp, 40624066,1989.

[51] A. Bbroual, C. Marteau and R. Tobazkon, "Measurement of the Charge of a Single or of a Series of Streamers in Liquids Subjected to a Voltage Step", IEEE Trans. Electr. Insul., Vol. 23, pp. 427-431,1988.

[52] V D. Terasov, V A. Balakin and 0. P Pecherskii, "Electrical Breahdown in Water by 0.5-1. 7 MV Pulses 0.5-5 sec Long", Soviet Physics -Technical Physics, Vol. 16, pp. 1379-1380,1972,

1531 Katsumi Yoshino, Masazumi Shiraishi, Haruhisa Fujii and Yosino Inuishi, "Pressure Dependence of Polarity Effect of Dielectric Breakdown in liquid Nitrogen", Japan J. Appl. Phys., Vol. 19, pp. 997-999,1980,

[54] Y. Kamata and Y. Kaka, "Flashover Characteristics of Extremely Long Gaps In Trans- former Oil Under Non-Uniform Field Conditions", Trans. Electr. Insul., Vol. 15, pp. 1&26,1980.

[55] H. Yamada, T. Murakami, K. Kusano, T. Fujisawa and T. Sato, "Positive Streamer in Cyclohexane under Microsecond Pulse Voltage", IEEE Trans. Electr. Insul., Vol. 26, pp. 708-714,1991,

1561 Yu. V. Torshin, "On the Existence of Leader Discharges in Mineral Oil", IEEE Trans. Dielectr. Electr. Insul., Vol. 2, pp, 167-179,1995,

1571 J. K. Bragg, A. H. Sharbaugh and R. W. Crowe, "Cathode Effects in the Dielectric Breakdown of Liquids", J. Appl. Phys. Vol. 25, pp. 382-391,1954,

[58] V Ya. Ushakov, Pulsed Electric Brenkdozua ofliqirids, Tomsk University Press, Tomsk 1975 (in Russian).

1591 J. C. Devins, S. J. Rzad and R. J, Schwabe, "Breakdown and Prebreakdown Phenom- ena in Liquids", J. Appl. Phys., Vol. 52. pp. 4531-4545,1981.

[60] A. K. Sharma, B. R. Locke, I? Arce and W. C. Finney, "A Preliminary Study of Pulsed Streamer Corona Discharge for the Degradation of Phenol in Aqueous Solutions", Hazardous Waste &Hazardous Materials, Vol. 10, pp. 209-219,1993.

[61] D. M. Willberg, P. S. Lang, R. H. Hochemer, A. W. Kratel and M. R. Hoffmann, "Electrohydraulic Destruction of Hazardous Wastes", CHEMTECH. Vol. 26, pp, 52- 57,1996.

[62] M. R. Hoffmann, "Electrohydraulic Discharge, Cavitation and Sonolysis", Proc. 2nd lnt. Symp. on Environ. Appl. Adv. Oxidation Technol., Vol. 3, p. 28-45, San Fran- cisco, USA 1997.

[63] M. Sato, T. Ohgiyama, 1 and S. Clements, "Formation of Chemical Species and Their Effects on Microorganizms Using a Pulsed HV Discharge in Water", IEEE Trans, Industry Appl., Vol. 32, pp. 106-112,1996.

I641 M. Sato, B. Sun, T. Ohshima and Y. Sagi, "Characteristics of Active Species and Removal of Organic Compound by a Pulsed Corona Discharge in Water", J, Adv. Oxid. Technol., Vol. 4, pp. 339-342,1999.

1651 R. W. B. Pearse and A. G. Gaydon, The Idrtitijrotion ofMolecular Speclm, Chapman and Hill, London, pp. 264,1976.

[66] A. A. Joshi, B. R. Locke, I? Arce and W. C. Fiuney, "Formation of Hydroxvl Radicals, Hydrogen Peroxide and Aqueous Electrons by Pulsed Streamer Corona Discharge in Aqueous Solution", Hazardous Materials, Vol. 41, pp. 3-30 1995.

[67] N. J. Felici, "Blazing a Fiery Trail with the Hounds", IEEE Trans. Electr. Insul., Vol. 23, pp, 497-503,1988,

[68] J. C. Devins, S. J , Rzad and R. J. Schwabe, "Breakdown and Prebreakdown Phenom- ena in Liquids", J. Appl. Phys., Vol. 52, pp. 4531-4545,1981.

Manuscript was received on 29 May 2000, in final form 15 August 2000,