Reckli Concrete Finish

-

Upload

anthonyquinn500 -

Category

Documents

-

view

27 -

download

3

description

Transcript of Reckli Concrete Finish

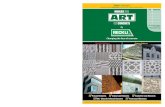

Application Guide Line for RECKLI-Formliners

2

1. Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4. Delivery Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5. Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

6. Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

7. Heat Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

8. Pattern Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

9. Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

10. Application for Pre-cast Concrete Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

11. Application for In-situ Concrete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

12. Adhering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

13. Release Agents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

14. Spacers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

15. Concrete Casting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

16. Striking/Release. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

17. Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

18. Joints/Corners/Edges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

19. ‘Stop-offs’. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

20. Repairing of Formliners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

21. Waste Declaration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

22. Consumption and Requirement Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table of Contents

3

1. ClassificationWe distinguish our formliners with the prefixnumbers 1/.. and 2/.. The most importantdistinguishing features are listed in table 1.There is also available another type of form-liner with the prefix number 3/.. These form-liners are for one use only. This workingguide applies only to the formliners with thepre fix1/.. and 2/.. For the OneTimerFormliners prefix number 3/.. there is aseparate catalogue with the relevant guide.

2. MaterialThe formliners consist of rubber-likePolyurethane Elastomers. The high flexibilityand elasticity allow a damage-free releaseof the concrete and exact reproduction ofthe pattern and allowing for undercuts andshallow grooves.

3. DeliveryFor the formliners with the index 1/.. wedeliver them flat on pallets or in chipboardboxes. The formliners 2/.. are rolled up on heavyduty cardboard rolls for transport and stor-age and wrapped in heavy brown kraftpaper and/or polyethylene for extra protec-tion against dirt. Depending on the size andweight they are additionally strapped tonon-returnable pallets. (Picture 1)

4. Delivery Check Upon delivery please check your consign-ment immediately for any damage sustai-ned in transport. If you note any damage toyour consignment you must describe it indetail on the delivery note and get the driverto countersign your comments. Beforeusing the formliners first check the requireddimensions as detailed on the packageespecially to the longitudinal direction (ld)of the pattern if there is one.

5. StorageBefore fixing all formliners must be storeddry and level to avoid deformation of thepattern. If using the 2/.. formliners loosely(not adhered) they can be rolled up tightlyagain onto the cardboard rolls after use.Make sure the formliners rolls do not haveany heavy or sharp objects stored on top ofthem as this would lead to permanentdeformation. The formliners must be protected againstintensive weathering such as UV light, rain,frost and any other aggressive conditions.This is best accomplished by covering withdark or black polyethylene or other water-proof sheets. (Picture 2)

6. Transport6.1 Boxes and palletsThe boxes and pallets with the formliners1/.. can usually be transported and movedby fork-lift or crane. The pallets with theformliner rolls can also be transported andmoved by fork-lifts or cranes.

6.2 Single formliner rollsUp to a length of approx. 1.50 m the card-board rolls can be lifted by placing the forkor forks of the fork-lift into the cardboardtube. For rolls of formliner in excess of 1.5 m it is necessary to use extension forksor a carpet ‘spike’ as otherwise the forkswould pierce the cardboard roll and proba-bly the liner as well. If using a crane for lif-ting make sure you use wide nylon liftingstraps evenly distributed along the length ofthe roll. Do not use wires ropes or chains.For large size formliners it can be useful toplace a steel tube through the cardboardroll, make sure you use separate liftingstraps from each pole end to crane hook toensure even lifting. (Picture 3)

7. Heat ResistanceThe formliners can used in temperatures upto + 65° C. Temperatures which exceed thisvalue will damage the material. Should youexpect a concrete temperature on the inter-face to the formliner of more than + 65° Cdue to the concrete mass or other circum-stances the mix design or other suitableactions should be adjusted to allow for thesafe use of the formliner within its tempera-ture constraints.

2 31

Formliners 1 / .. Formliners 2 / ..Depth of structure*Maximum size*Type of elastomerRe-usesKind of delivery

> 25 mmapprox. 1.00 m x 5.00 mlight c = 0,950 timesPacked flat

1 - 25 mmapprox. 4.00 m x 10.00 mnormal c = 1,4100 timesRolls

* The exact sizes you find in our catalogue under the photos of the pattern.

Table 1

4

8. Pattern Design There is no intended repeatability (with theexception of any of the rib type patterns) inthe formliner patterns within the maximummould size as compared to wallpapers. Anumber of patterns are designed in a waythat they can be placed together side byside continuously. With a little care the jointsin the patterns can be made almost invisi-ble. (Picture 4+5)For the building of our master moulds weuse a combination of natural and man madematerials of commercial grade quality whichare formed using current standard workingpractices. Unavoidable tolerances, discre-pancies and imperfections caused by theuse of these materials can and will bereflected in the patterns of the formliners.The measurements shown in the sectionaldrawings under and beside the patternphotos in our pattern book are averagevalues and nominal dimensions which havethe stated tolerances. In using these sizesfor the calculation of your requirements youshould not expect that there is an equalrepetition of measurements within the sameformliner. The same criteria will applywhether you place two full sizes sheet form-liners together or two or more ‘made tomeasure’ (smaller) formliners.Therefore it is possible that you will have tostretch or compress the formliners to adaptthem to the required pattern format or shut-ter/mould measurements. This may berequired especially for patterns and textu-res for formliners of bricks, blocks, boards,ribs etc.It is essential that attention be paid to bothpattern sequence and direction of all de-signs; especially when concrete elementsare to be arranged side by side or one uponanother and are to appear seamless.Unintentional rotation of the formliners by180° for example can lead to conflictingpattern effects.

9. Cutting9.1 Oversize and tolerancesDue to their high elasticity the formliners willbe stretched or compressed during packingand transport which can lead to dimensio-nal tolerances. Therefore, to protect theliner edges against damage we always sup-ply the formliners oversized. They must becut to their final dimension on site. It isalways advisable to cut formliners a coupleof millimetres longer than required for atight fit against the formwork guide battens.(see 10.1)The formliners should be cut to their finalsize directly before adhering to avoid sizechanges by stretching or shrinking due totemperature differences.As with all highly elastic rubber-like materi-als the formliners are subjected to stret-ching after a long period of use. Therefore itmay be necessary to re-cut the formlinersto their original dimension from time to time.This of course will only apply if the formli-ners are not fixed by gluing. Despite the most carefully controlled pro-duction process, dimensional tolerances ofsome mm in the rear wall thickness of theformliners is unavoidable. This is due tomaterial and production factors which weare unable to negate. These dimensionaldifferences are unavoidable whether youhave a formliner produced in its maximumsize or a smaller ‘made to measure’ formli-

ner within the maximum size of the sameformliner. Therefore it may be necessary togrind the formliners edges to even and levelthem or to thicken the seam area withRECKLI-Formliner Adhesive or RECKLI-Elasto Filler when required to place themhorizontally next to another formliner. (see20.2)

9.2 Formliners with prefix number 1/..These formliners are normally supplied infixed widths whereas the length/height (ld)is variable. If you have to put 2 or more form-liners together (side by side) to reach a totalarea for the shutter or mould, cutting willprobably be necessary. To make perfectcuts lay the formliners onto a flat, clean evensurface and cut them using a suitable handpanel or circular power saw. (Picture 6) Ifusing a power saw it is most important toallow the saw blade to rotate freely into thecut and during the cut. Keep the sawn mate-rial (waste part) pulled away from the bladeto avoid it flapping against the rotating sawblade, otherwise heat will be generated andthe formliner can burn. On long cuts it is agood idea to pull the power saw away fromthe cut and let the saw spin under power todissipate any build-up of heat.

9.3 Formliners with prefix number 2/..Roll out these formliners onto a flat, cleaneven surface and cut them with the

4 5

6 7

5

RECKLI- Formliner Knife. For a straight cutline please use a metal or timber straightedge. (Picture 7)When cutting thicker pattern formliners donot try and make the cut ‘in one’ place theknife in the first cut and draw through theformliner gently as many times as required,do not use excessive force as this will leadto crooked cuts. We do not advise cuttingthese formliners with a circular power saw. Note: It is very difficult to make mitred, bevelcuts with a knife to an unfixed formliner.When such bevels are required we can sug-gest two methods: a) place the area to bemitred onto a board, place another boardabove the formliner and fix thereby com-pressing the formliner. Set the power saw tothe required angle and depth and cut theboard and the formliner together. (Picture8+9) b) Perform this task with a power sawmin. 24 hours after the formliner has beenadhered. Cutting the fixed formliner and theplywood will give a more precise finish. Wealso advise the 24 hour delay for the drillingof any ‘tie-bolt’ holes.

10. Application in Pre-cast Concrete

10.1 Fitting the formliner to the formwork or mould

After cutting the liner lay it loose into theformwork/mould frame. The formliners withprefix number 1/.. should have been cut

with an over-size of 1-2 mm. So that youcan compress them into the dimensionframe for getting a tight compressive fit allround.The liners with prefix number 2/.. shouldalso be cut to an oversize of 1-2 mm. It iseasy to compress them so that they will bea tight fit around the edges of the form-work/mould. Please Note: When you allowtoo much oversize, the formliner will ‘bowup’ at the edge and form an ‘air cushion’which even the pressure of the concrete willnot flatten. These ‘air cushions’ will lead toindentations in the concrete surface.

10.2 Fixing by adheringLoose formliners have to be refitted into themould after every cast. To avoid this youcan glue the formliner on to the ‘tilt-up’ orvibrating tables (see 12.) This is always anadvantage when you have to produce aseries of elements of the same size. Looseformliners will also be more prone tostretching from their constant handling.

10.3 Setting & Placing theformwork/mould edges

You can of course place your form-work/mould dimension frame directly on tothe formliners which have shallow patternsor textures of approx. 1-2 mm. Patterns witha depth of up to 5 mm can be sealed suffi-ciently by a compression band. For deeper

patterns we suggest you make ‘patternstop-offs’ (see 19.2) or in symmetrical pat-terns (ribs or waves) you can use the sameformliner piece inverted. (Picture 10)Please Note: If the frame is pressed toofirmly on to the formliner for too long, therewill be a permanent depression in the form-liner giving a noticeable difference to thepattern if and when the frame has to bemoved to a different part of the formliner.

10.4 VibrationIt is possible that the frequencies of anexternal vibrator can make the formliner‘flutter’ and draw air under the formliner.This can result in air ‘cushions’ or ‘bubbles’in the formliner which can lead to indentati-ons in the concrete surface. Therefore thevibrator and its vibration frequency must bechecked and adjusted correctly.

10.5 Stripping/StrikingFormliners that are laid loose in the mouldare generally removed from the concreteelements and replaced back into themoulds ready for reuse. Care should betaken during the stripping/striking processthat the formliner will not fall off the concre-te element when the tilting table is in thevertical. The formliner would almost certain-ly be damaged. (Picture 11-13) To avoid thishappening you can glue the liners onto theformwork/tilting table. (see 12.)

10

11

8 9

12 13

X

6

11. Application for In-situ Concrete

11.1. Fixing by adheringWhen used for in-situ concrete the form-liners must be glued down. (see 12.)

11.2 Fixing by nailsFor minimum use or the immediate changeof shutter sizes after the first pour, the form-liners with prefix number 1/.. can be nailedonto the formwork. The nail centres shouldbe approx. 20-25 cm. Use ‘lost heads’ or‘ovals’ nails so that it is possible to pull thenail heads through the formliner duringstripping/striking. Depending on the patternor texture always nail through the highpoints of the pattern. This will ensure thatnail holes are in the negative part of theconcrete and not so easily noticed.The formliners with prefix number 2/..should not be nailed to the formwork. Dueto the weight of the formliners there wouldbe too much weight placed on the nailswhen lifted into the vertical position and thiscan result in the formliner tearing.

12. AdheringPlease Note: It can be to your advantage toglue the formliners onto plywood sheetsand use these sheets as auxiliary/’slave’formwork which you can then fix onto yourload bearing formwork or casting table. Theplywood can be fixed from the rear usingwood screws. The plywood can easily beremoved from the load bearing formworkafter use. It will also be easier to store anddispose of the formliners when they areglued to plywood.

12.1 Principles of fixingRECKLI-Formliners must adhered comple-tely. Point or spot gluing will lead to stret-ching of the formliners during stripping/stri-king. This type of stretching will lead to rai-sed round areas in the formliner which willshow itself as dents in the concrete. It is possible to glue on to steel as well ason timber. Note: For adhering to steel useour RECKLI-Primer MK. (see 12.3.2.1)

The easiest surface to glue on to is the hori-zontal surface. Other shutter/mould appli-cations which you might encounter mightbe inclined, (Picture 17) half or quartercolumns etc. On vertical or rounded surfa-ces the adhesive would flow down to thelowest point leaving insufficient adhesive fora complete fixing. In these applications theFormliner Adhesive should be thickenedwith our RECKLI-Standardiser 100 to makeit more ‘pasty’. Please ask for our specialadvice.On inclined or vaulted surfaces the formli-ners can slide on the adhesive because oftheir weight and the adhesive is not acontact adhesive. Therefore the formlinermust be clamped, propped or pinned withlaths to the formwork/mould until the adhe-sive has cured. It is easier to add theclamps and laths incrementally as you workround the curve or radius. You should not walk on or kneel on a fresh-ly adhered formliner as this will push awaythe adhesive under the formliner and canresult in dents in the formliner and show it-self as circular raised areas in the concrete.

12.2 AdhesiveRECKLI-Formliner Adhesive is not a contactadhesive. It is a 2-component adhesive. Themixing ratio is 8:1 by weight. If it is neces-sary to weigh out smaller quantities ofadhesive this must be done by weight. For

mixing the adhesive a slow speed electricdrill with the correct mixing paddle shouldbe used. (Picture 14) The base solution mustbe mixed first. The hardener is then addedto the base solution and mixed thoroughly.To avoid any ‘soft spots’ or uncured materi-al the adhesive must be placed into anotherempty, clean container and mixed again.(Picture 15+16) You should use only asmuch adhesive as you can work with withinthe pot-life. The pot-life depends on theambient temperature but as a rough guideyou will have approximately 10-15 minutesat 18-20° C. Adhesive consumption isapprox. 750-1000 g/m2. After 24 hours theadhesive is cured. You should give a longercuring time during winter periods with lowertemperatures. The formwork, mould or thetilting table can now be used.

12.3 Surface / Formliner rearsAll surfaces that you wish to adhere to mustbe even, clean and dry. Any grease, oil ormud should be sanded off the shutter notwashed off. A superior bonding of the form-liner to the shutter will be achieved if yousand the rear of the formliners. (Picture 18)A light sanding which will roughen the sur-face will be sufficient. In every case theformliner backs must be cleaned by wash-ing with RECKLI-Formliner Cleanser beforegluing. (see 12.4.1.1 and 12.4.2.1)

1514 16

1817

7

12.3.1 TimberThe most suitable foundation for RECKLI-Formliners are new clean untreatedplywood sheets designated as suitable forshuttering. (Picture 19) With coated ply-wood’s such as EVANS Pourform andWYSEFORM please refer to RECKLI foradvice.

12.3.2 SteelSteel must be rust free and the work willbenefit from a light sand-blast. If this is notpossible the minimum should be the use ofan angle grinder to the surface. In any casesteel must be primed with RECKLI-PrimerMK.

12.3.2.1 PrimingWhen adhering/gluing onto steel surfacesRECKLI-Primer MK must be used. It can bebrushed or rolled on to the steel surface.Allow approx. 30-60 minutes drying timedepending on ambient temperature and aircirculation before mixing and applyingRECKLI-Formliner Adhesive. A practicalindication of when the Primer MK is readyfor use is to test for ‘tack’ with your fingers,if the Primer MK shows ‘tackiness’ and doesnot disturb the film of primer on the steelsurface then it is safe to apply FormlinerAdhesive. If you exceed the drying time you

will have to wait approx. 24 hours for thePrimer MK to dry properly then you willhave to sand the dried Primer MK to rough-en its surface.

12.3.2.1 Properties of RECKLI-Primer MK

Primer MK is a 2-component material. Themixing ration is 4:1 by weight. If you need tomix smaller quantities from the drum or canyou must weigh out the quantities. Youshould never portion out the material byvolume. Add the hardener to the base mate-rial and mix thoroughly. To ensure completemixing pour the Primer MK into anotherempty container and mix again briefly. Youcan now apply the primer onto the steelsurface with brush or roller. The pot-life isapprox. 24 hours. The consumption rate isapprox. 150 g/m2.

12.4 Adhering12.4.1 Formliners with prefix number 1/..12.4.1.1 CleaningLay the formliners onto their patterned sur-face for cleaning the rear. Take a clean cot-ton rag and soak it with RECKLI-FormlinerCleanser to clean the rear of the liner. Toobtain a thorough cleaning of the formlinerdo not reuse dirty rags. When the cleanserhas evaporated (approx. 15 minutes depen-ding on temperature and air circulation) youcan start the adhering. You can hasten thedrying time by wiping the rear with a cleandry cotton rag.

12.4.1.2 Checking dimensions with a‘Dry run’

Lay the liners loosely onto the surface to beadhered, adjust them and check againstyour measurements. Lay out a temporaryright angle on to your shutter/mould and laythe liners against this frame. Remove andstack the formliners onto a clean surface.

12.4.1.3 Adhering/GluingAfter mixing the RECKLI-FormlinerAdhesive (see 12.2) pour it onto the surfaceto be glued and spread the adhesive even-ly over the surface using the supplied ser-rated trowel. (Picture 19+20) Take care thatyou spread the adhesive equally. Spreadonly so much adhesive over the formworksurface as you need for the gluing of oneformliner or that you can work with withinthe adhesive’s pot life. Make sure that theedges of the formliner have sufficient adhe-sive as this is the most critical area of stresswhen stripping and concrete will always tryto enter at the edge of the glue line and getbehind the formliners. Lay the formlineronto the fresh adhesive along the tempor-ary right angle. (Picture 21) Please take carethat there are no air bubbles under the liner.The best way to avoid this is by sliding theformliner backwards and forwards on theadhesive. Then apply the adhesive for thenext liner. Press the liner against the firstone making sure you coat the vertical sur-face of the first formliner with adhesive togive a grout free join. (Picture 22) Any surp-lus that has been squeezed out can bewiped off after fixing or left to dry and san-ded down. Carry on in this order until youreach your total shutter requirement. Whenfixing the formliner onto the shutter checkthat the formliners will reach the requiredpoint on the shutter/mould. Use rips ofplywood / wood and pin down edges ofliner to prevent them from lifting. You needgentle pressure on the edges for 24 hrs.minimum. Nail through the liner into theplywood. Note: Do not drive the nails home,excessive pressure will raise the edge ofthe formliner and take it out of contact withthe shutter. If using steel shutters useweight on the timber/ply rips.

20 21

22

19

8

12.4.1.4 Gluing onto vaulted or curvedsurfaces

The formliners 1/.. are flexible and can bedeformed to various degrees to accommo-date shutter and mould shapes but becau-se they are flexible and have a ‘spring‘value you will have to support/contain theformliners to the shutter/mould profile untilthe adhesive cures. To reduce the ‘spring’ inthe formliner you can cut kerfs in the rear ofthe formliner which makes curving the form-liner easier, on extreme curves you can cutV’s in the back of the liner. The depth ofthese cuts will depend on the thickness ofthe formliner. Cut only into the rear thick-ness of the formliner do not cut near thepattern thickness. (Picture 23+24)

12.4.2 Formliners with prefix number 2/..

12.4.2.1 CleaningBefore gluing/adhering the rear of the form-liner must be cleaned. Lay the formlinersonto their patterned surface for cleaning therear. Take a clean cotton rag and soak itwith RECKLI-Formliner Cleanser to cleanthe rear of the liner. To obtain a thoroughcleaning of the formliner do not reuse dirtyrags. When the cleanser has evaporated(approx. 15-30 minutes depending on tem-perature and air circulation) you can startthe gluing/adhering. You can hasten thedrying time by wiping the rear with a cleandry cotton rag. When the formlineris dryturn the formliner back onto its rear sideand roll it up again on to the ‘transportjacket’ (cardboard roll) making sure thatformliner is in the right position to be rolledout on to the Formliner Adhesive and shutter. The use of the stripping jackets will make it easier to move the formliners around the working area.

12.4.2.2 Checking dimensions with a‘Dry run’

Roll the liner loosely onto the surface to beadhered, adjust and check against yourmeasurements. If necessary mark referencepoints on the shutter/mould. Lay out a tem-

porary right angle on to your shutter/mouldand lay the liner against this frame. Roll theliner loose onto the surface to be adheredand straight and fit it exactly. Take note of anypattern that has parallel ribs or grid details.

12.4.2.3 Adhering/GluingMix the adhesive (see 12.2) pour it onto theshutter/mould surface, spread the adhesivewith a serrated trowel. Lifting the formlinerby its stripping jacket, place it next to thestart of the vertical part of the right angle‘setting out’ frame roll the liner slowly ontothe fresh adhesive. Make sure that the edges of the formlinerhave sufficient adhesive as this is the mostcritical area of stress when stripping andconcrete will always try to enter at the edgeof the glue line and get behind the formli-ners. Please take care that there are no airbubbles under the formliner. For the fixing of large formliners or whenthere is a shortage of manpower an alterna-tive method of fixing you might employcould be this. After the ‘Dry-run’ roll up theformliner again with the cardboard roll untilin the middle of the shutter. Then mix theformliner adhesive (see 12.2) and pour it infront of the rolled up half of the formlinerand spread it equally over a strip of approx.75-100 cm along the length of the liner.(Picture 25+26) An even and uniformthickness of the adhesive is most important.Check against excess adhesive which canlay in pools. In moving the adhesive with theserrated trowel you should look for thedistinctive ‘tram-line’ effect on the adhesivethe shutter/mould surface should be clear-ly visible. Now roll the liner onto the freshadhesive and repeat the pouring, spreadingand rolling the liner along the shutter/mouldstrip by strip until you reach the end of thefirst liner half. Make sure that there are noair bubbles under the formliner. Press outthe air to the front and the sides. Duringfixing check that you are reaching yourdatum/pattern points on the formliner or theparallel running of ribs or joints if there areany in the patterns.

Now roll up the second half of the liner to itsmiddle until you reach where you have star-ted spreading the adhesive for the first halfand repeat the first half procedure until youreach the end of the second formliner half.

12.5 Removal of glued formlinersWhen the formliner adhesive has beenmixed and applied correctly the fixingshould be considered permanent. Theremoval of glued formliners should be con-sidered a major task and would be very dif-ficult to remove them from theshutter/mould without damage to the form-liner. Therefore it can be an advantage notto glue the formliner directly onto the struc-tural formwork but onto separate plywoodsheets as ‘slave’ formwork and then to fixthese to the structural formwork.If it is absolutely necessary to remove form-liners from the shutter/mould you can usethe peel-off method. Cut in at the glue lineon one corner pulling the formliner up andcutting away at the glue line carry on untilyou have a large enough piece of formlinerto attach a clamp to which can be attachedto a crane, fork lift etc. to apply more forcewhile cutting away at the glue line. Any resi-due can be sanded off the shutter andformliner with a belt sander.

23 24 25

26

9

13. Release Agents13.1 Choice of release agent The choice and application of the correctrelease agent is most important to obtain anefficient release and high a quality concre-te finish. We supply three different releaseagents depending on the application.RECKLI-Stripping Wax TL contains sol-vents. RECKLI-Stripping Wax TL-W iswater-based. These two release agents aremore suited to pre-cast concrete. RECKLI-Stripping Wax TL-SO also contains solventsand is especially designed for in-situ concrete. (Table 2)

13.2. ApplicationThe stripping wax must be brushed orsprayed on a minimum two times. (Picture 27) The release agent should beapplied laterally and longitudinally. It is mostimportant that in any rib patterns the vertical part of the ribs should be sprayed at45° from both sides of the formliner to en-sure correct coverage. Surplus wax mustbe removed by a brush or clean cloth. Youcan also blow it off with compressed air.

13.3 Protection of the wax film againstweathering

After evaporation of the solvents inStripping Wax TL and TL-SO or the dryingof the water-based Wax TL-W you can usethe formliner/mould. To avoid any damageby rain and weather to the wax film youshould protect the liners with polyethyleneor any light plastic covers. (Picture 28) If thewax film has been reduced or damaged itshould be reapplied. Note: You will find that a ‘fan’ spray will givethe best and most even application of theStripping Wax’s TL and TL-SO. Make surethat your sprayer has solvent resistant gas-kets.

14. Bar spacersBar spacers that offer the largest contactareas should be used. Chair type spacersgive a point loading and will press into theformliner (Picture 29) and will thereforeshow through the concrete. The minimumconcrete covering over the reinforcement isalways measured from the deepest point inthe concrete surface. Therefore the barspacers must be set onto the highest pointsof the formliner pattern.It is of great advantage to hang up the rein-forcement for avoiding a loading of theliners. (Picture 30)

15. Concrete CastingRECKLI-Formliners allow the use of alltypes of cement based concrete. Whenusing external vibrators you should notethat some of the vibration frequencies willby absorbed by the elasticity of the formli-ner. This can be compensated for by a lon-ger vibration time.

27 28 29

30

Application Type Consumption per coatPre-cast concrete

Pre-cast concrete

In-situ concrete

RECKLI-Stripping Wax TLcontains solventsRECKLI-Stripping Wax TL-Wwater-basedRECKLI-Stripping Wax TL-SOcontains solvents

50 -100 g/m2

2 coats required50 -100 g/m2

2 coats required50 -100 g/m2

2 coats required

Table 2

X

10

16. Striking / Stripping 16.1 Striking / Stripping timingIt is easier to release RECKLI-Formlinerswithin 24 hrs of casting. Specification andstriking times for your particular applicationshould overrule RECKLI`s suggestion.

16.2 Unfixed formliners Formliners that are laid loosely in the mouldwill peel off of the concrete during strippingdue to their weight. (Picture 11-13) If thisshould not happen due to the depth of pattern, peel off the liners carefully startingfrom a corner. Do not tear at the formliner,doing so could exceed its stretching capacity

16.3. Adhered formlinersRelease the pre-cast concrete elementsfrom their moulds or the shutter from theconcrete. The releasing of the element fromthe mould or the shutters from the concreteshould be done slowly and carefully. Youmust allow the formliners time to stretch andrelease themselves from the concrete theyshould need the minimum effort from you.(Picture 31-35) In every instance avoid theuse of sharp or edged tools to hasten thestripping process as damage will be doneto the formliners.

17. Cleaning17.1 Formliner surfacesWhen the formliners are provided with thecorrect amount of Stripping Wax the formli-ner will be clean and ready for reuse afterstriking/stripping, reapply more StrippingWax ready for the next cast. If, for any rea-son it becomes necessary to clean theformliner, take a dry, clean rag and soak itwith the relevant Stripping Wax and cleanoff any cement splashes or dirt on the form-liner. Please do not use RECKLI-FormlinerCleanser for this work. RECKLI-FormlinerCleanser is only suitable for cleaning therear (fixing side) of the formliners beforegluing.

17.2 Tools and equipmentFor cleaning tools and equipment after use, use RECKLI-EK-PU Thinner. Cleanthoroughly while the formliner adhesive is fresh. Use a brush, it is not sufficient tolay the tools in the thinner. You will not beable to remove the cured 2-componentmaterial once it has hardened. For cleaningtools you can also use RECKLI-FormlinerCleanser. But this cleanser is not so effec-tive as RECKLI-EK-PU Thinner.

31 32 33

34 35

11

18. Joints / Corners / Edges18.1. Use of profiled filletsProfiled fillets for shaping corners, edgesand joints should be considered. You mustcalculate the thickness of the profile as towhat part of the pattern it is required to bealigned to i.e., top, middle or bottom. Thethickness of the formliner back must also be considered. (see sketch 1-5) (Picture 36-39)

Sketch 3

36 37 38

Butt joint

formliner

Sketch 4

Smooth frame with chamfer deep in concrete

Sketch 5

Smooth frame with chamfer high in concrete

Sketch 1

Chamfered cove, high in concrete

Sketch 2

Chamfered cove, deep in concrete

formliner

formlinerformliner

formliner

12

39 40 41

18.2 Formliner jointsWhen placing formliners with coarse orrank patterns side by side care must betaken to see that the joints from this opera-tion are sealed correctly. RECKLI-FormlinerAdhesive can be used after you have gluedthe formliner down. You can also use standard building One Component Siliconeapplied to the formliner when the adhesivehas cured. We do not advise butting or mitring formliners together for 90° cornersfor such kind of patterns. They will neverlook good. Make a feature at the corners byintroducing a plain band to the pattern, thecorner will look sharper and straighter. Theformliner will also have a straight line tofinish to. (see sketch 6-9)Of course for patterns with straight lines like ribs and waves it is of advantage to cut the liners mitred for 90° corners.(Picture 40+41)

Sketch 7

Cove with chamfer, high in concrete

Sketch 8

Cove with chamfer, middle in concrete

Sketch 9

Cove with chamfer, deep in concrete

Sketch 6

Chamfer in formliner

formliner

formliner

formlinerformliner

13

19. Stop-offs / Counter impressions

19.1 Cuts outPattern stop-offs for i.e. windows, doors orlighting can be formed by cutting out theshapes in the formliners and inserting aframe. This is suitable if the same openingsare to be used in the same position forevery use of the formliner. (Picture 42)

19.2 Pattern stop-offs using RECKLI-Mould Paste PU

If they are to be used once or twice or theformliner needs to be used in a differentposition then RECKLI-Mould Paste PUshould be used. (Picture 43+44) Select thearea for the pattern stop-off and paint onRECKLI-Mould Wax exceeding the area byat least 100 mm all round. On textures, shal-low patterns deep ribs place a frame largerthan the required stop-off. Use clay orPlastercine to fill in the space between thebottom of the frame and the pattern detail.On deep rib patterns, to save material blockoff with timber pieces. Paint the frame, clay,Plastercine with a coat of Mould Wax. Mixand pour the Mould Paste PU inside theframe forcing the material into the patterndetail with a spatula. You can mix and pourwet on wet material to reach the requiredlevel which should be approx. 6mm higherthan the highest part of the pattern. Place aclean dry board onto the fresh Mould PastePU making sure it is level. Leave to harden.When hardened remove from formliner andtrim off surplus material for sharp square orcut bevelled edges.

19.2.1 Properties of RECKLI-Mould Paste PU

RECKLI-Mould-Paste PU is a pasty elastic2-component material. The mixing ration is10:1 by weight. If using only part quantitiesfrom a drum the amounts of base solutionand hardener must be weighed out, nevermix by volume. For mixing use a slow speedelectric drill with the correct mixing agitator.Mix only so much paste as you can workwith within the pot-life. The pot-life isapprox. 10-15 minutes depending on tem-perature. The curing time is approx. 1 hour.The consumption depends on the type ofpattern. The specific weight is approx. 1.4 g/cm3.

19.2.2 Removing of mould wax residuesTo avoid different colours in the finishedconcrete, the area treated with RECKLI-Mould Wax must be removed and cleanedby using RECKLI-Stripping Wax. Soak aclean cloth with RECKLI-Stripping Wax TL,TL-SO or TL/W and wash and clean off theareas where the Mould Wax remains. If thisprocedure is not carried out carefully,colour differences in the finished concretesurface should be expected.

19.3 Inverted formlinersFor symmetrical patterns (ribs or waves)you can use the same formliner piecesinverted for stop-offs. (Picture 10)

20. Repairing / Patching &Equalizing of Formliners

20.1 RepairWith RECKLI-Elasto Filler you can patchand repair damaged or torn formliners. Toget a correct bonding of the Elasto Filler tothe formliner the damaged area holes ortears must be clean, dry, dust, oil, wax andgrease free. The area to be repaired or filledmust be roughened by sand paper. The fil-ler must be applied quickly and within thepot life time. Surplus material must beremoved while the material is still fresh.Texture and shape modelling must be donealso within the pot-life. Any hardened resi-due can be ground off after approx. 2-3hours. After 4-5 hours you can load therepaired area. Tears and splits: Carefully clean and pre-treat the sides of the split or tear as abovementioned. Under the tear lay a piece ofpolyethylene to avoid unwanted bonding ofthe paste. Apply RECKLI-Elasto Filler to thesides of the tear and press the tear together.Surplus filler can be removed with cloth orspatula and is best removed while fresh.Cured filler you can only remove by sandingor cutting. After curing turn the liner on to itsfront side. Grind out 3-5 cm left and to theright of the tear line and approx. 3 mmdeep. Fill this recess with the Elasto Fillerand smooth it. After 2-3 hours hardening itcan be ground level. Turn the formliner backonto its rear and apply RECKLI-StrippingWax to the repaired area. Note: We must categorically point out that a repaired seam cannot possibly give thesame result as an undamaged formliner.There is always the possibility of the repaired formliner tear showing through inthe patterned surface even when the repairhas been carried out extremely careful.

42 43 44

14

20.1.2 Properties of RECKLI-Elasto Filler

RECKLI-Elasto Filler is composed of 2 liquid components. The mixing ratio is 8:1 by weight. After mixing the hardenerwith the base component a thixotropicaction will take effect after about 2-3 minu-tes. The thixotropic effect increases until theend of the materials workable time. In thistime RECKLI-Elasto Filler can be used as apourable material and as a filler. The pot-lifetakes approx. 10 minutes at + 18° C. Thelayer thickness can be up to 10 mm in oneapplication. Consumption depends on thearea to be repaired. The specific weight isapprox. 1.4 g/cm3. Note: To extend the workable time of ElastoFiller spread the mixed filler onto a board asa thin coat.

20.2 Equalizing of formliner rearsAs already mentioned (see 9.) dimensionaltolerances of some mm in the rear wallthickness of the formliners is unavoidable.(Picture 45) Therefore, sometimes it isnecessary to adjust the thickness of theformliner rear. This you can do by grindingdown the thicker one or by increasing thethickness of the thinner one. Turn the linerson to their pattern sides put them togetherand grind or sand down the thicker partsalong the edges in a flat strip until you havereached the thickness of the thinner formli-ner. (Picture 46) Be sure to 'feather' awaythe grinding or sanding to the centre of theformliner so that you do not leave a step.When the difference of the rear thickness’ istoo big, it could be easier not to grind theformliner down but to increase the thick-ness of the thinner one. Turn the liners on totheir pattern side. Clean the area to belevelled by grinding or sanding this alsoacts as preparing the foundation. Place apiece of timber along the edge to be level-led to the required height. Paint the boardwith RECKLI-Mould Wax allow to dry and fixalong the formliner edge which you wish tofill level. Mix the RECKLI-FormlinerAdhesive (see 12.2) and pour it onto theroughened rear part of the formliner.

(Picture 47) Being a liquid it should find itsown level. Take RECKLI-Elasto Filler (see20.1.2) for the levelling material when thearea to be levelled is not too large. (Picture48) After the Formliner Adhesive or theElasto Filler has cured remove the boardalong the formliner edge. If necessarygrade the repair into the formliner by grin-ding or sanding which will also remove anyhigh spots. The formliner is now ready foruse. (Picture 49)

21. Waste disposalRECKLI-Formliners are made from Poly-urethane Elastomers. The code of theEuropean Waste Register is 12 01 05.

45 46 47

48

49

15

Material Application ConsumptionRECKLI-EK-PU ThinnerRECKLI-Elasto Filler

RECKLI-Formliner Adhesive

RECKLI-Formliner Cleanser

RECKLI-Mould Paste PURECKLI-Mould Wax

RECKLI-Primer MKRECKLI-Standardiser 100

RECKLI-Stripping Wax TL

RECKLI-Stripping Wax TL-SO

RECKLI-Stripping Wax TL-W

Cleaning of tools and equipmentRepair of damaged formliners and equalizing of formliner rearsAdhesive for full entire surfaces on steel or timber and equalizing of formliner rearsCleaning of formliner rears or damaged spots or fractures and toolsFor making pattern stop-offsRelease agent for RECKLI-Mould Paste PU and for steel or timber gauges while equalizing of formliner rearsPrimer before gluing on to steelThickener for Formliner Adhesive for gluing on vaulted or curved surfacesRelease agent for pre-cast concrete, contains solventRelease agent for in-situ concrete, contains solventRelease agent for pre-cast concrete, water-based

Depending on the degree of contaminationdepending on the volume of damage or filling, c = 1.4Approx. 750-1000 g/m2

Approx. 100-200 g/m2 or depending on the degree of contaminationDepending on the pattern, c = 1.4Approx. 150-200 g/m2

Approx. 100-200 g/m2

1-5 %

Approx. 100-150 g/m2

depending on the patternApprox. 100-150 g/m2

depending on the patternApprox. 100-200 g/m2

depending on the pattern

22. Product & Consumption Table22.1 Material – Please refer to the relevant technical pamphlets, too.

22.2 Tools / Equipment

Tool / Equipment Application / UseBoards / rips / laths

Brush / rollerBucketsCircular grinder / belt grinder

Cloth / rags

Gauging/pointing trowelHand circular sawMarker-pencilMetal / wood straight edgesMixing paddlePolyethyleneRECKLI-Formliner Knife / hand panel sawsSandpaper

Screw clamps

Serrated trowelSlow speed electric hand drillSpatula

SprayStanley or RECKLI-Formliner KnifeTape measureWeighing scales

Restraining of formliner during and after adhering, boards for pressing into Mould Paste PU for stop-offsApplication of Primer MK / Cleaning toolsTo decant after mixing 2-component material in original containerRemoving residue of adhesive film / grinding rear of formliner for better bonding / grinding of recesses for strengthening of repaired tears / equalizing of formliner rearCleaning the rear of formliners / removing of Mould Wax residues while using Mould Paste PU Scraping material from pails or drumsCutting of formliners index 1/.. and pattern stop-offsMarking of stop-off lines Straight edges for cutting liner index 2/..For electric hand drilling machine for mixing 2-component materialProtection of formliners and Stripping Wax application against weatheringCutting of formliner index 2/..Cleaning and sanding of formliners / removal of surplus Elasto Filler and levelling of repaired areasTo apply pressure to boards while Formliner Adhesive cures / clamp preparation for peeling off of glued formlinersSpreading of Formliner AdhesiveMixing of 2-component materialMixing and application of Elasto Filler, cleaning and pointing joint lines and smaller quantities of Formliner AdhesiveApplication of Stripping WaxPeel off of adhered liners from form-workChecking of formliner measurementsWeighing out of smaller quantities of 2-component materials

1111

/ 1

0/03

/R

WRECKLI-Chemiewerkstoff GmbHAdresse/Address: Eschstraße 30 D-44629 Herne Germany Tel. ++49/(0)2323/1706-0 [email protected]/Mailing Address: Postfach 1013 29 D-44603 Herne Germany Fax ++49/(0)2323/1706-50 http://www.reckli.de

StrukturmatrizenAbformtechnikFormen- undModellbauharze