Reburning Treatment of the Froths Obtained after the ... · sanitation standard for incineration of...

Transcript of Reburning Treatment of the Froths Obtained after the ... · sanitation standard for incineration of...

Aerosol and Air Quality Research, 17: 1084–1096, 2017 Copyright © Taiwan Association for Aerosol Research ISSN: 1680-8584 print / 2071-1409 online doi: 10.4209/aaqr.2016.12.0535

Reburning Treatment of the Froths Obtained after the Flotation of Incinerator Fly Ash Guo-Xia Wei1, Han-Qiao Liu2,3*, Fang Liu2, Rui Zhang2, Yu-Wen Zhu2, Si-Yu Gao2 1 School of Science, Tianjin Chengjian University, Tianjin 300384, China 2 School of Energy and Safety Engineering, Tianjin Chengjian University, Tianjin 300384, China 3 Tianjin Key Laboratory of Soft Soil Characteristics and Engineering Environment, Tianjin 300384, China

ABSTRACT

Flotation has been proven to successfully remove most polychlorinated dibenzo-p-dioxins and polychlorinated

dibenzofurans (PCDD/Fs) and carbon constituents from hospital solid waste incinerator (HSWI) fly ash. The resultant froths contain large quantities of carbon constituents that can reburn in the incinerator. In this paper, the reburning behavior of froths at temperatures from 800°C to 1200°C was compared with that of HSWI fly ash. Results showed that the destruction efficiency of PCDD/Fs was higher in the froths than in the fly ash at the same reburning temperature. The destruction efficiencies of PCDD/Fs in the froths exceeded 98% at temperatures higher than 1000°C. The volatilization ratio of Pb, Zn, and Cu was lower in the froths than in the fly ash. Furthermore, reburning of the froths can achieve energy recovery of the carbon constituents. Therefore, flotation followed by reburning treatment in a combustion chamber could be a suitable process for the detoxification and reutilization of HSWI fly ash.

Keywords: HSWI fly ash; Reburning; Flotation; Heavy metals; PCDD/Fs. INTRODUCTION

The centralized incineration treatment of hospital solid waste is prominent in China. Due to small-scale incinerator, incomplete incineration and high chlorine content in the waste feed, some toxic persistent organic pollutants are generated such as polychlorinated dibenzo-p-dioxins and polychlorinated dibenzofurans (PCDD/Fs), polycyclic aromatic hydrocarbons (PAHs), chlorobenzenes (CBs), chlorophenols (CPs) and polychlorinated biphenyls (PCBs), etc. (Lee et al., 2003; Chen et al., 2013; Cheruiyot et al., 2015; Lee et al., 2016). The PCDD/F emission factors of hospital solid waste incinerator (HSWI) were about 1–2 orders higher than those of municipal solid waste incinerator (MSWI) (Lee et al., 2003; Cheruiyot et al., 2016).

A rotary kiln is the main type of incinerator used because it has the advantages of adequate mixing and continuous operation. In facilities that use rotary kilns, the primary and secondary combustion chambers are operated at temperatures of 800°C and 1200°C, respectively (Gao et al., 2009). At the end of the incinerator, a large amount of powder activated carbon (PAC) is injected into the exhaust gas to ensure that the concentration of PCDD/Fs in the flue gas remains lower * Corresponding author.

E-mail address: [email protected]

than that specified by the new Chinese emission standards [0.1 toxicity equivalent quantity (TEQ) in ng m−3] (Chang et al., 2009; Wei et al., 2016a). Thus, PCDD/Fs and other organic pollutants such as PAHs, CBs, CPs and PCBs, in the flue gas are transferred to HSWI fly ash (Lee et al., 2004; Wang et al., 2006a; Cheruiyot et al., 2016).

Because PCDD/Fs are much more toxic than other organic pollutants, the control index regulated by “Environmental sanitation standard for incineration of medical treatment wastes” enacted in China is confined to PCDD/Fs (Chen et al., 2013). HSWI fly ash is classified as hazardous waste because of its high concentrations of PCDD/Fs and toxic heavy metals (Bo et al., 2009). It also has high content of carbon constituents, including PAC and unburned carbon. In China, MSWI fly ash is generally landfilled either directly or after cement solidification treatment (Wu et al., 2011). However, because of the high chloride and PAC content in HSWI fly ash, this conventional solidification method has many disadvantages.

Flotation is widely used and effective method in separation of fine materials. The principle of flotation is based on the differences in surface hydrophobicity between the particles. The hydrophobicity and lipophilicity nature of PCDD/Fs and other organic contaminants such as PAHs, CBs, CPs and PCBs makes them easy to float into the froths after flotation (Cheruiyot et al., 2015; Lee et al., 2016). The previous report indicated that the flotation process could be successfully applied to substantially decrease the amount of carbon

Wei et al., Aerosol and Air Quality Research, 17: 1084–1096, 2017 1085

constituents and PCDD/Fs in HSWI fly ash (Liu et al., 2013). In that study, the removal efficiency was more than 96% for PCDD/Fs and 92% for carbon constituents. Accordingly, most PCDD/Fs and carbon constituents were removed from the fly ash and were concentrated into the froths (Liu et al., 2014). However, detoxification of the froths is necessary to reduce PCDD/F emissions into the environment; otherwise, complete disposal of HSWI fly ash cannot be achieved.

Because PCDD/Fs do not have high thermal stability, thermal treatment is a viable method for decomposing PCDD/Fs. The melting process of fly ash can easily decompose PCDD/Fs by exposing them to a very high temperatures such as 1300°C (Vehlow et al., 2006; Lin et al., 2011). Pan (2013) indicated that the decomposition efficiency of PCDD/Fs was more than 99% on TEQ screening after the plasma melting process. Despite the high detoxification efficiency of PCDD/Fs, several disadvantages, such as high energy consumption, the requirement of extensive equipment, and the retreatment of vaporized metals, have been noted (Okada et al., 2013).

Ash reburning in a combustion chamber, which is relatively easier and more inexpensive than melting, may be a feasible option (Okada et al., 2013). The reburning treatment of fly ash in the combustion chamber of an incinerator can decompose more than 99% of the PCDD/Fs in the fly ash (Rafalp et al., 2001). However, if the HSWI fly ash is directly fed into the incinerator, a considerable amount of the volatile components, such as chlorine, alkali metals and sulfates, in the fly ash would be recirculated, leading to enhancement of the corrosion processes in the plant installations (Streibel et al., 2007; Vehlow et al., 2012). After flotation treatment, the chlorine content in the froths is obviously lower than that in the fly ash because most of the inorganic compounds, such as sodium chloride (NaCl), in the fly ash have been dissolved and removed, thus reducing the undesirable effects. Furthermore, the froths have approximately 56% loss on ignition (LOI), which might make them suitable for reburning as an additional fuel for the incinerator (Liu et al., 2013).The altered characteristics of fly ash after flotation might influence the decomposition effect of the PCDD/Fs. However, no study has compared the destruction efficiency of PCDD/Fs between fly ash and froth products.

In addition to PCDD/Fs, the change in the fly ash components also affects the partitioning of heavy metals. Heavy metals cannot be destroyed but can be partially or completely vaporized at high temperatures. Differences in the volatilization process of heavy metals can result from differences in their chemical composition (Wey et al., 2006). Previous studies have indicated that removing chlorine from the fly ash through the water-washing method can reduce the emission of metallic chlorides during subsequent melting treatment and can improve the efficacy of melting or sintering treatment (Wey et al., 2006; Chiang et al., 2010). During the reburning process, a part of the heavy metals invariably remains in the exhaust gas of the combustion chamber. Therefore, the partitioning of heavy metals between the fired product and exhaust gas must be understood.

This study mainly investigated the effect of flotation on HSWI fly ash characteristics, PCDD/F decomposition, and

the volatilization behavior of heavy metals during reburning. The research objectives were (1) to examine the influence of ash composition and temperature on the destruction efficiency of PCDD/Fs and volatilization of heavy metals and (2) to investigate the feasibility of integrating the flotation and reburning techniques for the detoxification of HSWI fly ash.

MATERIALS AND METHODS Materials

The fly ash sample used in this study was obtained from a 20t d–1 gyration kiln incinerator at a HSWI centre in northern China. The incinerator was equipped with a PAC sprayer device and bag filters as air pollution control devices for managing PCDD/Fs. The fresh, dry fly ash sample was collected from the hopper of a bag filter; it thus contained PAC that had been injected into a flue gas duct before entering the bag filter. The ash sample was dried at 110°C for 24 h.

Fly ash was treated with column flotation, and the experimental flotation apparatus and operating conditions were the same as those in our previous study (Liu et al., 2013). After flotation, the froth products were carefully vacuum-filtered, dried. Chemical composition, loss on ignition (LOI) and the content of heavy metals in the raw fly ash and the froth product are shown in Table 1. Methods

In this investigation, samples of fly ash and froths were subjected to thermal treatment in a static-bed reactor at 800°C–1200°C, which are typical temperatures in a combustion chamber. A flow chart of the experimental apparatus was shown in Fig. 1. The reactor was 800 mm in length and had an inner diameter of 70 mm and maximum temperature of 1500°C. When the furnace was preheated to 800°C–1200°C, the aluminum oxide (Al2O3) crucible was filled with (3.00 ± 0.01 g) samples of fly ash or froths and was introduced to the center of the furnace on a quartz boat. Air (50 mL min–1) was simultaneously introduced into the tube furnace to stimulate the combustion atmosphere. The heating time was set to 30 min, which is equivalent to half of the retention time in the heating zone of a practical rotary kiln (Kakuta et al., 2005). In each test run, the samples were collected in the Al2O3 crucible and were thoroughly mixed after cooling. The collected samples were stored in a refrigerator before the analysis and were assessed before and after treatment. Two groups of experiments were performed to analyze the destruction efficiency of PCDD/Fs and migration of heavy metals during the reburning process.

In the experiment for estimating the destruction efficiency of PCDD/Fs, the generated exhaust gas was introduced into XAD-2 polymeric resin and two toluene absorber bottles to examine the evaporation of the PCDD/Fs. After each test run, XAD-2, toluene, and rinsed solvent (obtained by flushing the reactor and tube with toluene) were collected and mixed in one sample, according to standard PCDD/Fs analysis procedures. The concentrations of 17 toxic PCDD/Fs congeners (2,3,7,8-substituted) were analyzed

Wei et al., Aerosol and Air Quality Research, 17: 1084–1096, 2017 1086

Table 1. Chemical composition, LOI and the content of heavy metals of the fly ash and the froths.

Major components Mass fraction (%) Heavy metals Content (mg kg–1) Fly ash Froths Fly ash Froths

SiO2 17.1 32.5 Pb 1410 2125 CaO 24.4 38.6 Zn 5235 9286 Al2O3 2.9 5.3 Cu 1022 2158 Fe2O3 1.8 3.4 Cd 88 119 MgO 1.8 3.3 Cr 112 174 K2O 2.8 1.1 Na2O 15.2 0.1 SO3 6.4 6.1 Cl 20.4 2.9 P2O5 1.1 1.4 TiO2 1.3 2.2 F 2.6 0.8 LOI 11.1 56.4

1, gas cylinder; 2, rotameter;3, reactor; 4, Al2O3 crucible; 5, sample; 6, electric furnace; 7, thermocouple, 8, XAD-2 resin; 9, toluene absorber bottle; 10, silica gel bottle; 11, vacuum pump; 12, 5%HNO3absorber bottle

1

Or2

3

5

6

4 8

99

11

1112 12

7

10

10

Fig. 1. Flowchart of the experimental apparatus.

using isotope dilution high-resolution gas chromatography–mass spectrometry. Our PCDD/F analysis method was described in a previous study (Wei et al., 2016a). The destruction efficiency of PCDD/Fs were calculated for both gaseous PCDD/Fs vaporized or desorbed from the samples during reburning treatment and adsorbed by XAD-2 resin, and for solid-phase PCDD/Fs remained on the fired product. The destruction efficiency was defined as the ratio of total PCDD/Fs concentration reduction by reburning treatment to total mass PCDD/Fs concentrations in the untreated samples, and it was calculated as shown in Eq. (1). Destruction efficiency = [1 – (Amount of PCDD/Fs adsorbed by XAD-2 resin + Amount of PCDD/Ds in the fired product)/(Amount of PCDD/Ds in the unfired product)] × 100 (1)

The experimental process for assessing the migration of heavy metals was identical to that performed for assessing the PCDD/Fs. In this experiment, the concentration of heavy metals in the gas phase was sampled using an adsorption liquid in two 5% nitric acid (HNO3) absorber bottles. Solid samples of the fly ash, froth product and fired product were dissolved in aqua regia. The obtained solution was

then analyzed in an AA800 atomic absorption spectrometer to determine the heavy metal content. The characteristics of heavy metal emissions from the fly ash and froths were evaluated using the volatilization ratio as an index and defined as shown in Eq. (2). Volatilization ratio (%) = [1 – (Amount of heavy metals in the fired product/Amount heavy metals in the untreated sample)] × 100 (2)

A modified version of the sequential extraction procedure developed by Tessier was used for the partitioning of heavy metals (Liu et al., 2014).The speciation of heavy metals was divided into exchangeable fraction (F1), carbonate fraction (F2), Fe–Mn oxide fraction (F3), organic matter fraction (F4), and residue fraction (F5).

The LOI for the sample was determined as the weight loss when the subsample was kept at 600 ± 25°C for 3 h, in accordance with the standard for pollution control (GB18485-2014). The thermal property of the samples was evaluated using a thermogravimetry/differential thermal analyzer (TG/DTA) by heating ash samples in a Pt-crucible up to a temperature of 1200°C at a heating rate of 10 °C min–1. Al2O3 was used as the reference material. Scanning electron

Wei et al., Aerosol and Air Quality Research, 17: 1084–1096, 2017 1087

microscopy–energy dispersive spectroscopy (SEM–EDS) was employed to provide imaging information regarding the morphology and composition of the samples by using an FEI NANOSEM 430 apparatus. X-ray diffraction (XRD) analysis was conducted using a Rigaku Ultima IV diffractometer. RESULTS AND DISCUSSION Effect of Flotation on the Characteristics of the Fly Ash

Table 1 shows the chemical composition and heavy metal speciation of the fly ash and froth products. Results indicated that the major components in the received fly ash were silicon dioxide (SiO2), calcium oxide (CaO), sodium oxide (Na2O), and chlorine, and the chlorine content was remarkably high (up to 20.43%). Through the flotation process, approximately 64% weight loss occurred in the fly ash because of the solubilization of soluble compounds such as alkali metals and chlorides. By contrast, SiO2 and CaO emerged as major components in the froth products, which had an LOI of 56.1%. The calorific value of the froths was 12.3 MJ kg–1 and exceeded a low heat value of 10.5 MJ kg–1, which is typical of hospital solid waste (Liu et al., 2013). Thus, reburning treatment of the froths in the combustion chamber of incinerators may achieve energy recovery of the carbon constituents.

The predominant heavy metals in the fly ash were Zn (up to 5235 mg kg–1) and Pb, accompanied by lesser amounts of Cu, Cd, and Cr. The content of heavy metals in the froths is higher than that of fly ash. This is because flotation is similar to the water-washing process and increases the concentration of heavy metals in the ash because of the removal of soluble chlorides (Wang et al., 2015). This is also likely related to the high PAC content in the froth products (Wei et al., 2016b). PAC has high adsorption capacity because of its large surface area and microporous structure (Cheruiyot et al., 2016). Heavy metals such as Pb, Zn, and Cd, can be extracted from the fly ash in the water phase during the flotation process. Some of these dissolved heavy metals can interact with PAC and finally become concentrated in the froth products. Effect of Flotation on the Thermal Behavior of the Fly Ash

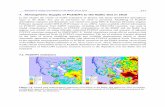

Thermogravimetric experiments describing the evolution of each sample were performed using air as a purge gas. Fig. 2 shows TG/DTA thermograms of the fly ash and froth products. TG results indicated an initial weight loss of approximately 4.3%, which was related to the evaporation of moisture from the sample, when the fly ash was heated from an ambient temperature to 200°C [Fig. 2(a)]. DTA showed a large exothermic peak at 456°C, corresponding to a weight loss of 11.9% between 300°C and 600°C, which indicated the exothermic curves of carbonaceous matter combustion (including PAC) in the fly ash. Significant weight loss, which was partially related to the volatilization of alkali metal chloride compounds, was observed again at approximately 760°C. Further weight loss was observed between approximately 1000°C and 1100°C because of the evolution of gaseous sulfur dioxide (SO2) from the partial

decomposition of alkali metal sulfates. In the froth products, the exothermic peak became sharper

at 548°C [Fig. 2(b)] with simultaneous weight loss over a wide temperature range (300°C–600°C); the total weight loss was approximately 61.5%. These results are consistent with the high LOI findings for the froth products (Liu et al., 2013). Because the carbon content of the froths is higher than that of the fly ash, the heat release peak was relatively high. Moreover, the weight loss at approximately 760°C was not so obvious because of the solubilization of the alkali metal chlorides after flotation.

Effect of Flotation on the Microstructure of the Fly Ash

The XRD patterns of the fly ash as well as the froths and fired products obtained after thermal treatment at 1100°C are shown in Fig. 3. The major crystalline phases of the fly ash were NaCl accompanied by lesser amounts of calcium sulfate (CaSO4), SiO2, and complex silicates. The XRD pattern of the froths showed markedly reduced peaks at 2θ = 31.6°and 2θ = 45.4°, indicating a significant reduction of NaCl as a soluble salt. No newly formed crystalline phases were detected.

The XRD pattern of two types of fired product showed no peaks for NaCl (which had predominant crystalline phases in the fly ash), indicating almost complete volatilization of the compounds after reburning. The patterns of the two types of fired product were characterized by almost the same crystalline phase, and monticellite (CaMgSi2O4) and kirschsteinite (CaSiO3) were the major phases. Their diffraction peak at 2θ = 25.5° was relatively low because of the decomposition of CaSO4 at high temperatures. These results were consistent with the TG/DTA thermograms of the fly ash and froths.

Fig. 4 illustrates the representative SEM/EDX observations for the fly ash as well as the froths and fired products after reburning treatment at 1100°C. Fig. 4(a) shows that the fly ash was composed of noncontinuous, loose particles and some spherical particles covered by cubic crystals. EDS analysis of the cubic crystals indicated the presence of Cl and Na, which may bein the form of NaCl. This finding was in agreement with the chemical composition and XRD results. In the froth products, large, porous, sponge-like particles with many open pores were observed (Fig. 4(b)). EDS analysis showed that carbon was the predominant constituent of these particles, and this may have been PAC. The froths were found to have high PAC content. Compared with the SEM analysis of the fly ash (Fig. 4(a)), NaCl crystals were no longer detected in the froth products. These observations were in agreement with the LOI values and chemical compositions described in Table 1. Meanwhile, a high number of crumbled particles were observed in the SEM images of the froth products, possibly because the flotation process caused some loosely agglomerated fly ash particles to break up. The different microstructures of the fly ash and froths may affect the evaporation process of volatile heavy metals (Nowak et al., 2015).

SEM images of the fired products of the fly ash and froths (Figs. 4(a)–4(d)) revealed the presence of large amounts of the nonporous spheroidal particles such as coal fly ash

Wei et al., Aerosol and Air Quality Research, 17: 1084–1096, 2017 1088

0 200 400 600 800 1000 1200

-60

-40

-20

0

20

40

60 DTA TG

50

60

70

80

90

100

dH/d

t (μV

)

Temperature (℃)

TG

(%

)

0 200 400 600 800 1000 1200-20

0

20

40

60

80

DTA TG

20

30

40

50

60

70

80

90

100

TG

(%

)

dH/d

t (μV

)

Temperature (℃) (a) the fly ash (b) the froths

Fig. 2. TG/DTA thermograms of the fly ash and the froths.

1 0 1 5 2 0 2 5 3 0 3 5 4 0 4 5 5 0 5 5 6 0 6 5 7 0

6 - C a2

A l2

S i O7

- C a S i O3

- C a S O4

- N a C l

4 - C a M g S i2

O6

- S i O2

(a) raw fly ash, (b) the froths, (c) fired product of fly ash, and (d) fired product of the froths

2θ(°)

Intensity(a.

(d)

(b)

(c)

(a)

Fig. 3. The XRD pattern of fly ash, the froths and their fired product after treatment at 1100°C.

(Duchesne et al., 1999). EDS identified the major elements as oxygen, Si, Al, Ca, and Na, which may be silicates, quartz, and alkali metal salt. SEM images of the fired products differed completely from those of the original samples. Effect of Flotation on the Distribution and Decomposition Efficiency of PCDD/Fs

The PCDD/F homolog concentrations in the fly ash, froth products, and their fired products are shown in Table 2. The total concentrations of PCDD/Fs in the fly ash and froths was 78.8 and 403.8 ng g–1 which were equivalent to 5.61 and 29.6 ng I-TEQ g–1, respectively. The TEQ of PCDD/Fs in the froths was more than five times that in the fly ash. Through flotation; a large amount of PCDD/Fs were enriched and separated onto the sides of the froth products. HpCDD, OCDD, TeCDF, 1,2,3,4,7,8-HxCDF, 2,3,4,6,7,8-HxCDF;

1,2,3,4,6,7,8-HpCDF and OCDF were the primary congeners in the fly ash.The predominant congeners in the froths were similar to those in the fly ash, with the first two predominant congeners being HpCDD and 1,2,3,4,7,8-HxCDF. The migration of other organic toxicants such as PAHs, CBs, CPs and PCBs might be similar to that of PCDD/Fs, their concentration in the froths should be much higher than that in the fly ash. Further study is required to investigate the distribution of these organic pollutants in the fly ash and the froths.

Fig. 5 shows the total mass destruction efficiency of PCDD/Fs after the reburning of the fly ash and froth products at different temperatures. For the fly ash, the destruction efficiency of PCDD/Fs increased approximately linearly with the temperature. The destruction efficiencies of the fly ash were only 75.0 wt% at 800°C but reached 97.6 wt%

Wei et al., Aerosol and Air Quality Research, 17: 1084–1096, 2017 1089

(a) the fly ash (b) the froths

(c) fired product of fly ash at 1100°C (d) fired product of the froths at 1100°C Fig. 4. SEM and EDS images of fly ash, the froths and their fired product after treatment at 1100°C.

at 1200°C. According to Rafal, the reduction efficiency of PCDD/Fs in a fluidized bed furnaceis proportional to the temperature during the pelletizing and reburning of MSWI fly ash (Rafalp et al., 2001). However, Wang stated that the PCDD/F content in HSWI fly ash increases from 6.20

to 401 ng I-TEQ g–1 and does not appear to be destroyed at a treatment temperature of 850°C without addition of CaO. This finding is related to the fact that de novo synthesis leads to the reformation of PCDD/Fs during the natural cooling process in the furnace (Wang et al., 2012).

Wei et al., Aerosol and Air Quality Research, 17: 1084–1096, 2017 1090

Table 2. Concentration of each PCDD/Fs congener in the fly ash and the froths.

Congeners TEF Fly ash Froths ng g–1 ng I-TEQ g–1 ng g–1 ng I-TEQ g–1

2,3,7,8-TeCDD 1.0 0.2 0.2 1.0 1.0 1,2,3,7,8-PeCDD 0.5 0.5 0.3 2.2 1.1 1,2,3,4,7,8-HxCDD 0.1 0.8 0.1 2.8 0.3 1,2,3,6,7,8-HxCDD 0.1 1.2 0.1 7.0 0.7 1,2,3,7,8,9-HxCDD 0.1 2.3 0.2 14.0 1.4 1,2,3,4,6,7,8-HpCDD 0.01 10.5 0.1 46.9 0.5 OCDD 0.001 13.3 0.01 55.7 0.1 2,3,7,8-TeCDF 0.1 6.6 0.7 29.2 2.9 1,2,3,7,8-PeCDF 0.1 1.2 0.1 5.5 0.3 2,3,4,7,8-PeCDF 0.5 3.5 1.8 15.1 7.6 1,2,3,4,7,8-HxCDF 0.1 9.4 0.9 56.7 5.7 1,2,3,6,7,8-HxCDF 0.1 3.8 0.4 24.8 2.5 2,3,4,6,7,8-HxCDF 0.1 6.4 0.6 40.3 4.0 1,2,3,7,8,9-HxCDF 0.1 0.6 0.06 4.3 0.4 1,2,3,4,6,7,8-HpCDF 0.01 8.1 0.08 36.0 0.4 1,2,3,4,7,8,9-HpCDF 0.01 3.9 0.04 25.7 0.3 OCDF 0.001 6.5 0.01 36.5 0.04 Total 78.8 5.6 403.8 29.0

800 900 1000 1100 120070

75

80

85

90

95

100

Des

truc

tion

eff

icie

ncy

of P

CD

D/F

s (%

)

Temperature(℃)

Raw fly ash The froths

Fig. 5. Destruction efficiency of PCDD/Fs in the fly ash and the froths at temperature of 800°C to 1200°C.

For the froths in the present study, the destruction efficiency of PCDD/Fs increased rapidly with the temperature while below 1000°C; subsequently, the efficiency remained higher than 98%. These results indicated that at high temperatures (≥ 1000°C), most PCDD/Fs in the froth products could be decomposed, and the detoxification efficiency approximates that of melting (Kim et al., 2005; Wang et al., 2009a).

The froths had a high initial concentration of PCDD/Fs, but the destruction efficiency of PCDD/Fs in the froths was higher than that in the fly ash at the same reburning temperature. The froths were relatively high in carbon constituents, organic pollutants such as PAHs, CBs, CPs and PCBs and low in chlorine, which might explain this

discrepancy. The carbon constituents in the samples combusted easily in the oxygen atmosphere because their ignition point was 400°C–500°C (Fig. 2). Furthermore, PCDD/Fs are prone to decomposition at 850°C under combustion conditions (i.e., the presence of oxygen, mixing, and flow) (Wielgosinski et al., 2011). Thus, the PCDD/Fs adsorbed on PAC pores might be rapidly and efficiently decomposed after the complete combustion of the carbon constituents.Thus, the high content of the carbon constituents in the froths contributed to the high destruction efficiency of PCDD/Fs in the froths. In contrast, high content of PAHs, CBs, CPs and PCBs in the froths might lead to the formation of PCDD/Fs. PAHs are a kind of precursor or important basic reactive substance in the generation of

Wei et al., Aerosol and Air Quality Research, 17: 1084–1096, 2017 1091

PCDD/Fs (Chen et al., 2013). It is acknowledged that PAHs are most easily catalyzed to form PCDFs by de novo synthesis reactions in low-temperature zone (200–450°C) and in the presence of oxygen, when CuCl2 exists in the fly ash (Chin et al., 2012; Chen et al., 2013; Cheruiyot et al., 2016). On the other hand, PCDD/Fs might be produced by a precursor condensation pathway via condensation reactions of precursors such as CBs, CPs and PCBs at 250–650°C (Lin et al., 2014). However, it is expected that de novo synthesis and heterogeneous precursor condensation of PCDD/Fs might be avoided in the reburning process, if the reburning temperature is above the two temperature windows. In addation, chloride is an essential constituent of PCDD/Fs, especially metal chlorides that catalyze the de novo synthesis of PCDD/Fs at 250°C–450°C in the presence of oxygen (Wang et al., 2006b; Chen et al., 2013). Low chloride content in the froths would decrease the possibility of PCDD/Fs through de novo synthesis during the cooling process (Lin et al., 2008). Moreover, high chlorine content in the fly ash might also increase the possibility to form precursors such as CBs and CPs during reburning, and then promoted the PCDD/F formation (Wang et al., 2006b). We inferred that in industrial applications, the de novo synthesis of PCDD/Fs should be avoidable because incinerators are operated at high temperatures, and the gradual cooling process does not occur in the furnace. Therefore, in the present study, the destruction efficiency of PCDD/Fs in the froths was higher than that in the fly ash.

Fig. 6 shows the TEQ concentration of PCDD/Fs in the fired products obtained after reburning of the fly ash and froths at different temperatures. The TEQ concentration of PCDD/Fs in the fired product decreased as the temperature increased. At 800°C, the TEQ concentration of PCDD/Fs in the fired products from the froths was 6.59 ng I-TEQ g–1, which was higher than that in the fired products from the fly ash (1.66 ng g–1). However, almost no difference was observed between the two samples at temperatures higher

than 900°C. The initial amount of PCDD/Fs in the two samples did not reflect the residual amount of PCDD/Fs in the fired product after treatment. The residual concentration of PCDD/Fs in the froths after heat treatment at 1200°C was only 0.38 ng I-TEQ g–1. In practice, if the duration of reburning treatment is sufficient, the PCDD/F decomposition in the froths would be higher.

Fig. 7 shows the effect of reburning temperature on the distribution profiles of 17 major PCDD/F congeners in the fly ash and froth products. After treatment, the dominant congeners in the fired products were similar to those in the fly ash and froth. Increasing the reburning temperature did not obviously change the PCDD/Fs congener profiles. In the froth products, the fractions of low-chlorinated compounds, such as 1,2,3,6,7,8-HxCDD, 2,3,4,7,8-PeCDF, 1,2,3,4,7,8-HxCDF, and 2,3,4,6,7,8-HxCDF, became low after the reburning treatment. The fractions of highly chlorinated congeners, such as OCDD and OCDF, in the two types of fired product increased with the reburning temperature, possibly because OCDD and OCDF are relatively more stable than are other congeners because of their more symmetrical molecular structure (Chang et al., 2011). Some research studies demonstrated after fly ash was subjected to melting treatment, the slag product was high in only OCDD and OCDF (Kim et al., 2005; Lin et al., 2011). By contrast, Chang (2013) reported a change in the content distribution profiles of 17 major PCDD/F congeners from before to after treatment with microwave peroxide oxidation in an H2SO4/HNO3 solution. In addition, metal chlorides such as CuCl2 in HSWI fly ash may also affect the species distribution of PCDD/Fs during thermal treatment at low temperature (Chin et al., 2012). The congener distribution of PCDD/Fs during reburning treatment require more intensive study in the future.

Effect of Flotation on the Phase Distribution and Volatilization Behavior of Heavy Metals

The phase distributions of heavy metals in the fly ash

untreated sample 800 900 1000 1100 12000

5

10

15

20

25

30

35

TE

Q c

once

ntra

tion

of

PC

DD

/Fs

(ng

I-T

EQ

g-1

)

Temperature(℃)

Raw fly ash The froths

Fig. 6. TEQ concentration of PCDD/Fs in the fly ash and the froths at the temperature of 800°C to 1200°C.

Wei et al., Aerosol and Air Quality Research, 17: 1084–1096, 2017 1092

2,3,7,8-TeCDD

1,2,3,7,8-PeCDD

1,2,3,4,7,8-HxCDD

1,2,3,6,7,8-HxCDD

1,2,3,7,8,9-HxCDD

1,2,3,4,6,7,8-HpCDDOCDD

2,3,7,8-TeCDF

1,2,3,7,8-PeCDF

2,3,4,7,8-PeCDF

1,2,3,4,7,8-HxCDF

1,2,3,6,7,8-HxCDF

2,3,4,6,7,8-HxCDF

1,2,3,7,8,9-HxCDF

1,2,3,4,6,7,8-HpCDF

1,2,3,4,7,8,9-HpCDFOCDF

0

5

10

15

20

25

30

Frac

tion

s (%

)

untreated froths 800 900 1000 1100 1200

2,3,7,8-TeCDD

1,2,3,7,8-PeCDD

1,2,3,4,7,8-HxCDD

1,2,3,6,7,8-HxCDD

1,2,3,7,8,9-HxCDD

1,2,3,4,6,7,8-HpCDDOCDD

2,3,7,8-TeCDF

1,2,3,7,8-PeCDF

2,3,4,7,8-PeCDF

1,2,3,4,7,8-HxCDF

1,2,3,6,7,8-HxCDF

2,3,4,6,7,8-HxCDF

1,2,3,7,8,9-HxCDF

1,2,3,4,6,7,8-HpCDF

1,2,3,4,7,8,9-HpCDFOCDF

0

5

10

15

20

25

Frac

tion

s (%

)

raw fly ash 800 900 1000 1100 1200

(a) Fractions of raw fly ash (b) Fraction of froths

Fig. 7. Effect of temperature on fractions of PCDD/Fs in the fly ash and the froths.

and froths are shown in Fig. 8. The fly ash had a relatively uniform distribution of Pb and a high carbonate fraction (25%). The exchangeable-associated Zn in the fly ash was high (18%). The dominant and secondary fractions of Cd were exchangeable (35%) and carbonate (19%), respectively. Both Cu and Cr had very low exchangeable fractions, and their residual speciation was the most dominant. Compared with the fly ash, the exchangeable speciation of Zn, Pb, and Cd was obviously decreased in the froth products. This is because that the exchangeable fraction of these heavy metals is mainly in the form of heavy metal chlorides, and they immediately dissolve during the flotation process.

When fly ash is subjected to reburning in a combustion chamber; the heavy metals might either volatilize or remain in the fired product. Therefore, exploring the volatilization behavior of heavy metals in fly ash before and after flotation is essential. Fig. 9 shows the volatilization characteristics of heavy metals in the fly ash and froths at temperatures ranging from 800°C to 1200°C.The volatilization ratios of heavy metals in the two samples increased with the temperature. The volatilization ratios of heavy metals, especially Pb, Zn, and Cu, were lower in the froth than in the fly ash, and this difference was more obvious at high temperatures. For example, at 1200°C, the volatilization ratios of Pb, Zn, and Cu in the fly ash were 93.2%, 68.5%, and 57.2%, respectively, which is obviously higher than the corresponding ratios (72.2%, 58.8%, and 23.2%) in the froth products. This difference is related to the high content of heavy metal chlorides in the fly ash, which in turn is related to the high NaCl content in the fly ash. NaCl promotes the transformation of heavy metals from a pure metal or metal oxide to its chloride (Casa et al., 2007). Metal chlorides tend to have lower boiling points than the respective pure metals or metal oxides, and the combustion temperature in the rotary kiln is sufficiently high to vaporize these metal chlorides. For example, cadmium oxide (CdO) is easily transferred to cadmium chloride (CdCl2) or to Cd and completely evaporated (i.e., 765°C and 960°C are the boiling points of

Cd and CdCl2, respectively) at high temperatures. Similarly, lead(II) oxide (PbO) is thought to react with NaCl to form lead(II) chloride (PbCl2;boiling point, 950°C). Cu has two main chloride forms: copper (II) chloride (CuCl2; boiling point, 993°C) and copper(i) chloride (CuCl; boiling point, 1366°C). CuCl2 is easy to evaporate, but it is also easily decomposed into nonvolatile CuCl. Notably, Cu has a high affinity for chlorine and plays a catalytic role, thus easily promoting the formation of PCDD/Fs through the de novo synthesis reactions (Wang et al., 2009b; Cheruiyot et al., 2016). In addition, copper chloride also affects the formation of PAHs during reburning (Chen et al., 2013). Therefore, the flotation process can wash out a lot of chloride and reduce the de novo synthesis of PCDD/Fs during the reburning process. The chlorination of Zn is relatively complex. Although Zn is a volatile heavy metal, the volatilization rates of Zn shows no obvious change when the heating temperature is increased. This is probably because Zn is simultaneously involved in two distinct competing reactions (Stucki et al., 1997; Nowak et al., 2013): (1) Zn oxides react with NaCl to form a volatile compound zinc chloride (ZnCl2) as a reaction, and (2) Zn oxides react with SiO2 and Al2O3 to form some more stable compounds such as willemite (Zn2SiO4) and zinc aluminate (ZnAl2O4). Wey (2006) revealed that the water-washing process could change the speciation of Cu and Pb and inhibit their emission during thermal treatment. In the present study, the volatilization ratio of Cr in the fly ash and froths was close because of high boiling points (Kuo et al., 2012). At temperatures lower than 900°C, almost no volatilization was observed, and the volatilization rates were approximately 10% at ≥ 1200°C, indicating that the flotation process had almost no effect on the volatilization of Cr. This finding is consistent with the high residual fraction of Cr.

In addition to the temperature and the presence of chlorine compounds, burning conditions involving a redox atmosphere and carbon constituents also affected both the volatilization and stabilization of heavy metals. For example, PAC acted as a reducing agent and readily reduced the Cu

Wei et al., Aerosol and Air Quality Research, 17: 1084–1096, 2017 1093

0%

20%

40%

60%

80%

100%

Pb Zn Cu Cd Cr

Phas

e di

strib

utio

ns

Heavy metals

F5

F4

F3

F2

F1

0%

20%

40%

60%

80%

100%

Pb Zn Cu Cd Cr

Phas

e di

strib

utio

ns

Heavy metals

F5

F4

F3

F2

F1

(a) the fly ash (b) the froths

Fig. 8. Phase distributions of heavy metals in the fly ash and the froths.

800 900 1000 1100 12000

10

20

30

40

50

60

70

80

90

100

Vol

atil

izat

ion

rati

o(%

)

Temperature(℃)

Cu Pb Zn Cd Cr

800 900 1000 1100 1200

0

20

40

60

80

100

Vol

atil

izat

ion

rati

o(%

)

Temperature(℃)

Cu Pb Zn Cd Cr

(a) the froths (b) the fly ash

Fig. 9. Effect of temperature on volatilization rate of heavy metals in the fly ash and the froths.

compounds in the fly ash and froths to elemental Cu (boiling point, 2573°C); thus, the evaporation of Cu may be suppressed under an inert or a reducing atmosphere. By contrast, PAC may also reduce oxidic Zn (such as pure ZnO or ZnO containing matrix compounds) to its metallic state (Ludwig et al., 2001). The boiling point of Zn0 is 907°C; thus, it might evaporate at temperatures higher than 900°C, thereby promoting the volatilization of Zn in fly ash and froth products. Froth products contain a large amount of PAC acting as a reducing agent, which has a positive effect on the volatilization of Zn and a negative effect on volatilization of Cu in an inert atmosphere. Therefore, the effect of a redox atmosphere on the volatility of heavy metals may be more obvious in the froth products than in the fly ash (Yang et al., 2009).

Proposed Procedure for Reburning Froths after the Flotation of HWSI Fly Ash

This study demonstrated that reburning is an effective destruction technology for PCDD/Fs in froth products. A simplified flow chart of the proposed procedure is shown

in Fig. 10. First, the flotation method was used to remove PCDD/Fs and carbon constituents from HSWI fly ash (Liu et al., 2013). This technique enabled the removal of most PCDD/Fs and carbon constituents from the fly ash, which were then concentrated into froth products. After the flotation of the fly ash, two types of solid product (including froth and tailings) and wastewater were produced.Under optimal flotation conditions, the PCDD/F content in the tailings could be decreased to less than 3 ng I-TEQ g–1; therefore, the tailings could be directly disposed of in landfill because the PCDD/Fs concentrations were below the upper limit specified in Chinese landfill site regulations (Liu et al., 2014). After drying, the froth products were fed into the feeding port of a rotary kiln incinerator. Reburning of the froths in the combustion chamber resulted in almost complete decomposition of the PCDD/Fs. Meanwhile, the froths with high carbon content could be reused as an auxiliary fuel in the incinerator, thereby achieving energy recovery. In industrial applications, the heavy metals in the froths might be present in the bottom ash or fly ash during reburning. The elimination of chlorides through flotation would reduce the

Wei et al., Aerosol and Air Quality Research, 17: 1084–1096, 2017 1094

Recombustionchamber

Hospital solid waste

Rotary kin

Water

Semi-dry scrubber

Bag filter Quench tower Stack

PAC injection

Induced fan

PAC

Fly ash

Agent

Water

SlurryingFroths

Drying

Solid/liquidseparation

Tailings

Waste water treatment

Landfill disposal

Reburning

Flotation column Flotation

column

Bottom ash

Fig. 10. Flowchart of the proposed procedure of incinerator for hospital solid waste.

volatilization of heavy metals and increase their percentage in the bottom ash. Even if a small amount of heavy metals are evaporated into the flue gas, they might be recollected or recaptured by the filter and might finally become a part of the fly ash (Jiang et al., 2007). In addition, removal of the chlorine would effectively avoid the problems of high temperature corrosion and deposition during the reburning of the froths (Buekens et al., 2011; Lundin et al., 2013). The production of waste water after the flotation of fly ash is undesirable. Some soluble heavy metal compounds, such as Cd or Zn compounds, showed a high release rate and were transferred into the wastewater.The waste water may be used for the neutralization of other waste streams or may be precipitated to form a solid and then separated by filtration (Chou et al., 2009). The next stage of this research will focus on the treatment and recirculation of effluents containing heavy metals after flotation. CONCLUSIONS

This study investigated the effect of flotation on the reburning behavior of fly ash. The thermal characteristics, decomposition effect of PCDD/Fs and volatilization behavior of heavy metals in the froths and fly ash were compared. Results showed that the high carbon content in the froth products rendered it suitable for recombustion in the feeding port of a rotary kiln incinerator. The crystalline phase of the fired product showed no change after flotation. The total mass destruction efficiencies of the PCDD/Fs in the two types of samples increased with the reburning

temperature. Reburning treatment exhibited a considerably high destruction efficiency of the PCDD/Fs in the froth products. The volatilization ratios of heavy metals such as Pb, Zn, and Cu in the froth were obviously less than those in the fly ash. The chlorine in the fly ash was washed out after flotation, so the metal chlorides were lightly vaporized, thereby avoiding fouling and corrosion. Overall, our results indicate that flotation treatment before reburning not only improves the decomposition of PCDD/Fs but also reduces the volatilization of heavy metals. We suggest that the combined use of flotation and reburning techniques could be an alternative for the detoxification and resource recovery of HSWI fly ash. ACKNOWLEDGMENTS

The authors gratefully acknowledge the National Natural Science Foundation of China under grant under the project number NSFC 51378332 and Tianjin science and technology correspondent project number16JCTPJC50300. REFERENCES Artha, A.A, Wu, E.M, Wang, L.C, Chen, C.H. and Chang-

Chien, G.P. (2011). Thermal formation of polybrominated diphenyl ethers in raw and water-washed fly ash. Aerosol Air Qual. Res. 11: 393–400.

Bo, D., Zhang, F.S. and Zhao, L.J. (2009). Influence of supercritical water treatment on heavy metals in medical waste incinerator fly ash. J. Hazard. Mater. 170: 66–71.

Wei et al., Aerosol and Air Quality Research, 17: 1084–1096, 2017 1095

Buekens, A. and Cen, K. (2011).Waste incineration, PVC, and dioxins. J. Mater. Cycles Waste Manage. 13: 190–197.

Chang, Y.M., Hung, C.Y., Chen, J.H., Chang, C.T. and Chen, C.H. (2009). Minimum feeding rate of activated carbon to control dioxin emissions from a large-scale municipal solid waste incinerator. J. Hazard. Mater. 161: 1436–1443.

Chang, Y.M., Fan, W.P., Dai, W.C., His, H.C., Wu, C.H. and Chen, C.H. (2011). Characteristics of PCDD/F content in fly ash discharged from municipal solid waste incinerators. J. Hazard. Mater. 192: 521–529.

Chang, Y.M., Dai, W.C., Tsai, K.S., Chen, S.S., Chen, J.H. and Kao, J.C.M. (2013). Reduction of PCDDs PCDFs in MSWI fly ash using microwave peroxide oxidation in H2SO4/HNO3 solution. Chemosphere 91: 864–868.

Chen, Y., Zhao, R.Z., Xue, J. and Li, J.H. (2013). Generation and distribution of PAHs in the process of medical waste incineration. Waste Manage. 33: 1165–1173.

Cheruiyot, N.K., Lee, W.J., Mwang, J.K., Wang, L.C., Lin, N.H., Lin, Y.C., Cao, J.J., Zhang, R.J., Chang-Chien, G.P. (2015). An overview: Polycyclic aromatic hydrocarbon emissions from the stationary and mobile sources and in the ambient. Aerosol Air Qual. Res. 15: 2730–2762.

Cheruiyot, N.K., Lee, W.J., Yan, P., Mwang, J.K., Wang, L.C., Gao, X., Lin, N.H. and Chang-Chien, G.P. (2016). An overview of PCDD/F inventories and emission factors from stationary and mobile sources: What we know and what is missing. Aerosol Air Qual. Res. 16: 2965–2988.

Chiang, K.Y. and Hu, Y.H. (2010). Water washing effects on metals emission reduction during municipal solid waste incinerator (MSWI) fly ash melting process. Waste Manage. 30: 831–838.

Chin, Y.T., Lin, C., Chang-Chien, G.P. and Wang, Y.M. (2012). PCDD/F formation catalyzed by the metal chlorides and chlorinated aromatic compounds in fly ash. Aerosol Air Qual. Res. 12: 228–236.

Chou, J.D., Wey, M.Y. and Chang, S.H. (2009). Evaluation of the distribution patterns of Pb, Cu and Cd from MSWI fly ash during thermal treatment by sequential extraction procedure. J. Hazard. Mater. 162: 1000–1006.

De, C.G., Mangialardi, T., Paolini, A.E. and Piga, L. (2007). Physical-mechanical and environmental properties of sintered municipal incinerator fly ash. Waste Manage. 27: 238–247.

Duchesne, J. and Reardon, E.J. (1999). Lime treatment of fly ash: Characterization of leachate composition and solid/water reactions. Waste Manage. 19: 221–231.

Gao, H.C., Ni, Y.W., Zhang, H.J., Zhao, L., Zhang, N., Zhang, X.P., Zhang, Q. and Chen, J.P. (2009). Stack gas emissions of PCDD/Fs from hospital waste incinerators in China. Chemosphere 77: 634–639.

Jiang, J.G., Xin, X.U., Wang, J., Yang, S.J. and Zhang, Y. (2007). Investigation of basic properties of fly ash from urban waste incinerators in China. J. Environ. Sci. 19: 458–463.

Kakuta, Y., Matsuto, T., Tanaka, N. and Masuda, T. (2005). Influence of residual carbon on the decomposition process of PCDD/Fs in MSWI fly ash. Chemosphere 58: 969–

975. Kim, K.H., Seo, Y.C., Nam, H. Joung, H.T., You, J.C.,

Kim, D.J. and Seo, Y.C. (2005). Characteristics of major dioxin/furan congeners in melted slag of ash from municipal solid waste incinerators. Microchem. J. 80: 171–181.

Kuo, Y.M., Huang, K.L. and Lin, C. (2012). Metal behavior during vitrification of municipal solid waste incinerator fly ash. Aerosol Air Qual. Res. 12: 1379–1385.

Lee, K.L., Lee, W.J., Mwangi, J.K., Wang, L.C., Gao, X. and Chang-Chien, G.P. (2016). Atmospheric PM2.5 and depositions of polychlorinated dibenzo-p-dioxins and dibenzofurans in Kaohsiung area, southern Taiwan. Aerosol Air Qual. Res. 16: 1775–1791.

Lee, W.S., Chang-Chien, G.P., Chen, S.J., Wang, L.C., Lee, W.J. and Wang, Y.H. (2004). Removal of polychlorinated dibenzo-p-dioxins and dibenzofurans in flue gases by venturi scrubber and bag filter. Aerosol Air Qual. Res. 4: 27–37.

Lee, W.S., Chang-Chien, G.P., Wang, L.C., Lee, W.J., Tsai, P.J. and Chen, C.K. (2003). Emissions of polychlorinated dibenzo-p-dioxins and dibenzofurans from the incinerations of both medical and municipal solid wastes. Aerosol Air Qual. Res. 3: 1–6.

Lin, X.Q., Huang, Q.X., Chen, T., Li, X.D., Lu, S.Y., Wu, H.L., Yan, J.H., Zhou, M.S. and Wang, H. (2014). PCDD/F and PCBz emissions during start-up and normal operation of a hazardous waste incinerator in China. Aerosol Air Qual. Res. 14: 1142–1151.

Lin, Y. M., Zhou, S.Q., Shih, S.I., Lin, S.L., Wang, L.C. and Wu, Z. S. (2011). Fate of polychlorinated dibenzo-p-dioxins and dibenzofurans during the thermal treatment of electric arc furnace fly ash. Aerosol Air Qual. Res. 11: 584–595.

Lin, Y.S., Chen, K.S., Lin, Y.C., Hung, C.H. and Chang-Chien, G.P. (2008). Polychlorinated dibenzo-p-dioxins/dibenzofurans distributions in ash from different units in a municipal solid waste incinerator. J. Hazard. Mater. 154: 954–962.

Liu, H.Q., Wei, G.X. and Zhang, R. (2013). Removal of carbon constituents from hospital solid waste incinerator fly ash by column flotation. Waste Manage. 33: 168–174.

Liu, H.Q., Wei, G.X., Zhang, R. and Liu, F.G. (2014). Simultaneous removal of heavy metals and PCDD/Fs from hospital waste incinerator fly ash by flotation assisted. Sep. Sci. Technol. 49: 1–10.

Ludwig, C. and Lutz, H. (2001). Studying the evaporation behavior of heavy metals by thermal-desorption spectrometry. Fresenius J. Anal. Chem. 371: 1057–1062.

Lundin, L., Gomez-Rico, M.F., Forsberg, C., Nordenskjöld, C. and Jansson, S. (2013). Reduction of PCDD, PCDF and PCB during co-combustion of biomass with waste products from pulp and paper industry. Chemosphere 91: 797–801.

Nowak, B., Aschenbrenner, P. and Winter, F. (2013). Heavy metal removal from sewage sludge ash and municipal solid waste fly ash — A comparison. Fuel Process. Technol. 105: 195–201.

Okada, T. and Tomikawa, H. (2013). Effects of chemical

Wei et al., Aerosol and Air Quality Research, 17: 1084–1096, 2017 1096

composition of fly ash on efficiency of metal separation in ash–melting of municipal solid waste. Waste Manage. 33: 605–614.

Pan, X.C., Yan, J.H. and Xie, Z.M. (2013). Detoxifying PCDD/Fs and heavy metals in fly ashes from medical waste incinerators with a DC double arcs plasma torch. J. Environ. Sci. 25: 1362–1367.

Rafalp, K., Kenji, O. and Ichiro, I. (2001). Dioxin and fly ash free incineration by ash pelletization and reburning. Environ. Sci. Technol. 35: 4313–4319.

Streibel, T., Nordsieck, H., Neuer-Etscheidt, K., Schnelle-Kreis, J. and Zimmermann, R. (2007). Experimental and statistical determination of indicator parameters for the evaluation of fly ash and boiler ash PCDD/PCDFs concentration from municipal solid waste incinerators. Chemosphere 67: 155–163.

Stucki, S. and Jakob, A. (1997). Thermal treatment of incinerator fly ash: Factors influencing the evaporation of ZnCl2. Energy Fuels 17: 231–236.

Vehlow, J., Bergfeldt, B. and Hunsinger, H. (2006). PCDD/F and related compounds in solid residues from municipal solid waste incineration – A literature review. Waste Manage. Res. 24: 404–420.

Vehlow, J. (2012). Reduction of dioxin emissions from thermal waste treatmentplants: A brief survey. Rev. Environ. Sci. Biotechnol. 11: 393–405.

Wang, M.S., Wang, L.C. and Chang-Chien, G.P. (2006a). Distribution of polychlorinated dibenzo-p-dioxins and dibenzofurans in the landfill site for solidified monoliths of fly ash. J. Hazard. Mater. 133: 177–182.

Wang, Q., Yan, J.H., Tu, X., Chi, Y., Li, X.D., Lu, S.Y. and Cen, K. (2009a). Thermal treatment of municipal solid waste incinerator fly ash using DC double arc argon plasma. Fuel 88: 955–958.

Wang, Q.H., Yang, J., Wang, Q. and Wu, T. (2009b). Effects of water-washing pretreatment on bioleaching of heavy metals from municipal solid waste incinerator fly ash. J. Hazard. Mater. 162: 812–818.

Wang, W., Gao, X.B., Zheng, L. and Lan, Y.X. (2006b). Reductive dechlorination of polychlorinated dibenzo-p-dioxins anddibenzofurans in MSWI fly ash by sodium hypophosphite. Sep. Purif. Technol. 52: 186–190.

Wang, Y., Pan, Y., Zhang, L., Yue, Y., Zhou, J. and Xu,

Y.F. (2015). Can washing-pretreatment eliminate the health risk of municipal solid waste incineration fly ash reuse. Ecotoxicol. Environ. Saf. 111: 177–184.

Wang, Y.F., Wang, L.C., Hsieh, L.T., Li, H.W., Jiang, H.C. and Tsai, C. H. (2012). Effect of temperature and CaO addition on the removal of polychlorinated dibenzo-p-dioxins and dibenzofurans in fly ash from a medical waste incinerator. Aerosol Air Qual. Res. 12: 191–199.

Wei, G.X., Liu, H.Q., Zhang, R. and Zhu, Y.W. (2016a). Application of microwave energy in the destruction of dioxins in the froth product after flotation of hospital solid waste incinerator fly ash. J. Hazard. Mater. 325: 230–238.

Wei, G.X., Liu, H.Q., Zhang, R., Zhu, Y.W. and Xu, X. (2016b). Mass concentrations of polychlorinated dibenzo-p-dioxins and dibenzofurans (PCDD/Fs) and heavy metals in different size fractions of hospital solid waste incinerator fly ash particles. Aerosol Air Qual. Res. 16: 1569–1578.

Wey, M.Y., Liu, K.Y., Tsai, T.H. and Chou, J.T. (2006). Thermal treatment of the fly ash from municipal solid waste incinerator with rotary kiln. J. Hazard. Mater. 137: 981–989.

Wielgosinski, G. (2011). The reduction of dioxin emissions from the processes of heat and power generation. J. Air Waste Manage. Assoc. 61:511–526.

Wu, H.L., Lu, S.Y., Yan, J.H., Li, X.D. and Chen, T. (2011). Thermal removal of PCDD/Fs from medical waste incineration fly ash – Effect of temperature and nitrogen flow rate. Chemosphere 84: 361–367.

Yang, Y., Xiao, Y., Wilson, N. and Voncken, J.H.L. (2009). Thermal behaviour of ESP ash from municipal solid waste incinerators. J. Hazard. Mater. 166: 567–575.

Yang, Z.J., Xia, C.H., Zhang, Q., Chen, J.P., and Liang, X.M. (2007). Catalytic detoxification of polychlorinated dibenzo-p-dioxins and polychlorinated dibenzofurans in fly ash. Waste Manage. 27: 588–592.

Received for review, December 29, 2016 Revised, February 17, 2017

Accepted, February 28, 2017