RAPIDA/R - TooTools Μηχανήματα & Εργαλεία · RAPIDA/R. The base is made of highly...

Transcript of RAPIDA/R - TooTools Μηχανήματα & Εργαλεία · RAPIDA/R. The base is made of highly...

Top glue pot covered in teflon with quick release system for quick cleaning. Avoid any waste, encrustments and glue wastes.

Thanks to the high quality and sturdy mechanic components, the customer relies on a long lasting machine, which guarantees the quality of work.

Board load through track controlled by encoder with high grip rubber covered skids 1”. Cylinder for edge load with mechanic adjustment to minimize the edge waste and avoid any scratches on the board.

RAPIDA/R

The base is made of highly sturdy and stiff steel. Powder coating and galvanizing of all components. Electric and pneumatic plants fitted in the base and separated in compliance with the CE norms.

The skids slide on two steel guides (with high thickness – 15mm), one round and the other flat, which guarantee the linear transport of the piece and the resistance to the lateral loadings.

Telescopic support roller of the panel located outside the mat for the entire length of the machine.

GLUE UNITTop glue pot unit with top glue loading. Made with aluminium casting with internal Teflon coating, with no. 6 internal resistances, no. 1 temperature probe in the bottom.It is possible to work with the most common types of glue, including EVA and Polyolefin. As alternative, it is possible to work with Polyurethane glue, too, addying the proper accessory kit, which foresees a special treatment of the pot as well as of the pressure rollers.By means of thermofusible glue it glues automatically roll and strip edges on the straight side of the board.

Resistance power kW 4,0

Pot capacity

Roller diam.

l 0,8

mm 0,4-3

Recover of the glue of the glue spreading roller at the switch off of the machine.

The glue melts in the area near the gluing roller by means of a special positioning of the resistances as well as of the probe, keeping a temperature lower than the one present in the top side. This makes the glue to undergo the process of heating one time only thus guaranteeing the preservation of the technologic characteristics of the glue and avoiding the formation of encrustments with consequent less need of service and cleaning.

strenghts

The roller of the glue pot is supported by two airtight precision bearings for high temperature (250°) which guarantee gluing precision during the years, as they always keep the shaft at 90° in relation to the board.

The glue spreading roller has 34 mm diameter, which allows to spread the glue evenly.

This type of glue tank allows an easy cleanness and overhaul. To remove completely the glue tank it is enough to loosen the fixing screw. It is possible to remove easily the roller through the bottom fixing ring.

Quick start with glue heating in max 9 minutes.It is foreseen the stand-by function with automatic lowering of the temperature in case of temporary not use of the machine (after 6 minutes the machine doesn’t work, the temperature automatically goes down, remaining at 160°); this operation allows the glue to last.

Pneumatic glue pot locking in any passage to avoid the deposit of the glue on the back side of the board (option)

end cuttingunit

edge trimming

unit

gluescrapingunitbuffing

unit

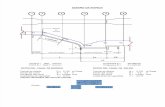

INTERNAL GROUPSINTERNAL GROUPS

pre millingunitglue unit

pressure unit (Example of configuration)

Positioning adjustment 0,4 ÷ 3 mm of the pressure unit through numerical decimal display.Adjustment through numeric indicator of the position in relation to the thickness of the edge.

cutterfor automatic cutting of roll edge

pressure unitmade up of 3 rollers:* 2 in neutral opposed and conical rollers (diam. 60 mm) * 1 motorized and rubbed roller (diam. 120 mm) Displayed mechanic adjustment of the pressure of the rollers.

PRE MILLING UNIT

Max removable thickness mm 3 Panel thickness mm 8/50Tool diameter mm 100Tool height mm 54Tool rotation speed rpm 15.0002 motors kW 1,1

Recommended the use of the accessory kit anti-adhesive spraying plant positioned before the pre-milling unit.It is important to avoid that the excess glue, after pressing the edge, settles on the top and bottom surfaces of the panel. It makes easier the finishing made by the glue scraper unit and the buffing unit. (Option – only for RAPIDA/R)

(standard on RAPIDA/R)

END CUTTING UNIT

It allows to cut the exceeding edge on the rear and front side of the panel.

- 1 high frequency passing through shaft motor- Unit sliding without play on ball screw skids- 2 independent copying devices for the setting of the cutting point of the cutters on the panel- Cutters included (diam. 100 mm)

Motors no. 1

Motor power

Cutters rotation speed

kW 0,22

rpm 12.000

(standard)

END CUTTING UNIT OPTION

Tilted cut to chamfer the boards with melamine edges (max thickness of the edge 0,8mm) on the 3rd and 4th passage.

EDGE TRIMMING UNIT

Motors no. 2Motor power (each) kW 0,33 Tools rotation speed rpm 15.000Min thickness of the panel mm 3Tools radius mm 2 (1-3 option)Vertical and front copying devices disc/skid

No. 4 interchangeable carbide plates

It is possible to equip the unit with the accessory kit for nesting working

(standard)

EDGE SCRAPING UNIT

It finishes the edge removing faults.The unit includes:- Copying devices for the setting of the working point of the tools on the panel- Handwheels and decimal numeric indicators for the execution of the adjustments- Complete with carbide knives radius 2 mm (option 1-3 mm)- Blower for cutters cleaning- Manual exclusion of the unit

Min thickness of the panel mm

Vertical and front copying devices

Tools radius

pattino/pattino

mm 2

8

pressure unitmade up of 3 rollers:* 2 in neutral opposed and conical rollers (diam. 60 mm) * 1 motorized and rubbed roller (diam. 120 mm) Displayed mechanic adjustment of the pressure of the rollers.

GLUESCRAPING UNIT

Remove the glue’ excess on the connecting point between panel and edge.

The unit is complete with:- Double, vertical copying device with bearings- Carbide cutters

BUFFING UNIT

2 indipendent motors for cleaning and polishing of the edge

Motors no. 2Motor power (each) kW 0,13Tools rotation speed rpm 1.400Tilted cloth brushes

Fibre brushes for pre-polishing and removal of any remaining wastes of glue (option).

The use of the accessory kit spreading plant of the cleansing detergent.

MODELSRAPIDA

EDGE SCRAPING UNIT

GLUESCRAPINGUNIT

the additional housing of up to two groups (1-2) selected from the following:

END CUTTINGUNIT

EDGE TRIMMINGUNIT

1 2

The machine, on both versions, should be completed with

MODELS

It is possible to equip the unit with the accessory kit for nesting working

BUFFING UNIT

RAPIDA/R

PRE MILLINGUNIT

END CUTTINGUNIT

EDGE TRIMMINGUNIT

the additional housing of up to two groups (1-2) selected from the following:

1 2

Siemens Electronic control system with Touch screen 4”, complete with:

Languages selection“soft touch” keyboard and lighting led for thesoftware selectionFull setting of the machine by means of PLC andencoder placed on the pinion of the panel moving carpetGlue pot temperature settingSimple and guided diagnosis for the solving ofeventual errors

Ergonomic position in the machine input for easy operation from the workstation

option

the additional housing of up to two groups (1-2) selected from the following:

Feed speed m/1’ 10

Panel’s thickness (min/max)

Edge thickness (strips)Edge thickness (roll)Roll edge max section

Roll maximum diam.

Edge excess in comparison to the panel’s thickness

MInimum distance to load panels

Min length of the panel with edge in roll (min width 100 mm)Min length of the panel with edge in strips (min width 100 mm)Min length of the edge in roll

Min length of the edge in stripsMin width of the panel (min length 400 mm)

Height of the working areaWidth of the panels’ support roller

mm 8/50

mm 0,4-3mm 0,4-3mm2 160

mm 780

mm 2+2

mm 800

mm 140

mm 250

mm 260mm 260mm 60mm 900mm 400

Net weight Rapida kg 1190

3350 mm 785 mm

1450 mm

Gross weight Rapida kg

RAPIDA

3500x1100x1750 mm

kg 1420

Net weight Rapida/R kg 12001195

Gross weight Rapida/R kg 1205

3600 mm785 mm

1450 mm

RAPIDA/R

3700x1100x1750 mm

kg 1440

TECHNICAL DATATECHNICAL DATA

Griggio Srl

Via Ca’ Brion 40 - 35011 Reschigliano (PD) - [email protected]. +39 049 9299711 Fax +39 049 9201433