RANGE OF PRODUCTS OVERVIEW - Hydrolico...

Transcript of RANGE OF PRODUCTS OVERVIEW - Hydrolico...

RANGE OF PRODUCTS OVERVIEWDetailed release

E0.

00.1

013.

03.0

0

SALAMI SPAvia Emilia Ovest 100641123 Modena Italytelefono +39-059-387411telefax [email protected] - www.salami.it

TM

SALAMI ESPAÑAPoligono Industrial ArmenteresC/Primer de Maig, 18, Nave 408980 San Feliu de LlobregatBarcelonatelefono +34-93-6327288telefax [email protected]

SALAMI FRANCE22, rue Louis Saillant69120 Vaulx en VelinLyontelefono +33-04-78809941telefax [email protected]

SALAMI HYDRAULICS N.A INCLoop RoadBaldwinsvilleNY 13027 - USATel.: +1-315-295-2363Fax.: [email protected]

www.salami.it our official channels

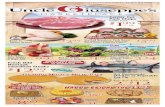

Salami Spa is one of the best Italian engineering Company in the field of hydraulic power applied

to mobile applications.

It was founded in 1956 with specific guidelines that have led the brand to identify

Salami Spa as a symbol of Warranty and Reliability in its sector in Italy and in the World.

Salami Spa Hydraulics has remained loyal in time to its three strengths dictated by its founder:

Quality, Innovation and Customer Service.

These are the Salami’s Values, into the present and to the future.

The head office and establishment of production are situated in Modena, Italy.

Through its offices in USA, Canada, Spain, France, together with its business partners, Salami Spa

distributes its own products by putting the excellence of Italian engineering at the service of the whole world.

DIRECTIONAL CONTROL VALVES MONOBLOCK TYPE

GEAR PUMPS AND MOTORS

DIRECTIONAL CONTROL VALVES ESPECIALLY DESIGNED FOR OEMS

PRESSURE COMPENSATED LOAD SENSING VALVE

pag 1

pag 3

pag 2

pag 7

pag 6

pag 5

DIRECTIONAL CONTROL VALVES SECTIONAL TYPE

GEAR FLOW DIVIDERSpag 13

E0.00.1013.03.00

CUSTOMIZED GEAR MOTORS AND PUMPS - ACCESSORIESpag 14

1

MONOBLOCK TYPE

VDM6

VDM6A

VDM8

- cast-iron monoblock construction. - parallel circuit, load check valve protection on down-stream of the pressure "P" line.

- tandem circuit, only the first working section,

- possibility of power beyond.

- spool construction in steel, hardened and nichel-plated to obtain a higher surface hardness and a better corrosion resistance.

- several types of spool: double, single acting, spool motor, float position, regenerative position etc.

- minimum tolerance between the spools and the body to obtain a minimum internal leakage. - interchangeabilty of all the spools.

- several spool control devices and spool positioning devices.

l.c.v. protection + l.c.v. protection on down-stream of the "P" line.

- available spool with overcenter valve built-in, available spool with hydraulic kick-out built-in.

- cast-iron monoblock construction. - parallel circuit, load check valve protection on each section. - possibility of power beyond configuration. - spool construction in steel, hardened and chromium-plated

to obtain a higher surface hardness and a better corrosion resistance. - several types of spool: double, single acting, spool motor, float position, regenerative position etc.

- minimum tolerance between the spools and the body to obtain a minimum internal leakage. - interchangeability of all the spools.

- possibility of auxiliary valve either on port A or B or on both. - several spool control devices and spool positioning devices.

- available spool with overcenter valve built-in, available spool with hydraulic kick-out built-in.

E0.00.1013.03.00

- cast-iron monoblock construction. - parallel circuit, load check valve protection on each section. - possibility of power beyond configuration. - spool construction in steel, hardened and chromium-plated

to obtain a higher surface hardness and a better corrosion resistance. - several types of spool: double, single acting, spool motor, float position, regenerative position etc.

- minimum tolerance between the spools and the body to obtain a minimum internal leakage. - interchangeability of all the spools.

- possibility of auxiliary valve either on port A or B or on both. - several spool control devices and spool positioning devices.

- available spool with overcenter valve built-in, available spool with hydraulic kick-out built-in.

VDM09

- parallel circuit, load check valve protection on down-stream of the pressure "P" line. - cast-iron monoblock construction.

- possibility of power beyond. - spool construction in steel, hardened and nichel-plated

to obtain a higher surface hardness and a better corrosion resistance. - types of spool: double, single acting, spool motor, float position, regenerative position etc.

- minimum tolerance between the spools and the body to obtain a minimum internal leakage. - several spool control devices and spool positioning devices.

- available spool with overcenter valve built-in, available spool with hydraulic kick-out built-in.

2

MONOBLOCK TYPE

E0.00.1013.03.00

VDM6

Mechanical

VDM6A VDM09 VDM8

Hydraulic

Pneumatic

Direct electric

Electro-hydraulic

Electro-pneumatic

On ports

Unloader valve

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

CONTROLS

AUXILIARY VALVES

•

•

•

•

Configuration

•

•

(*) P=parallel / S=series / T=tandem(1) Tandem circuit available only on the first working section of the 4, 5 and 6 working sections monoblocks.(2) G1/2 ports also available, for other size ports please get in touch with our sales dept.(3) 6 and 7 working sections monoblocks are still work in progress.

Main characteristics

TYPE

BSP UN-UNF METRIC METRIC

(l/min - US gpm) (bar - psi) (mm - in) (ISO 228/1) (ISO 11926-1) (ISO 262) (ISO 6149-1)

45 - 12

45 - 12

75 - 20

315 - 4600 1 ÷ 7 P/T 32 - 1,26 G3/8 SAE 8 M18x1.5 M18x1.5

M18x1.5

M22x1.5

M22x1.5

M18x1.5

M22x1.5

M22x1.5

SAE 8

SAE 10

SAE 10

G3/8

G1/2

G1/2

36 - 1,42

38 - 1,50

40 - 1,57

P

P

P

1 ÷ 7

1 ÷ 6

1 ÷ 7

315 - 4600

315 - 4600

NOMINALFLOW

OPERATINGPRESSURE

NR.OFSECTION

CIRCUIT* SECTIONDISTANCE

STANDARD THREADS(referred to ports)

280 - 4000

75 - 20

(1)

(3)

(2)

VDM6

VDM6A

VDM09

VDM8

3

SECTIONAL TYPE

VD6A

VD8A

VD10A

VD12A

- cast-iron made (inlet section, working section, outlet section). - parallel circuit, load check valve protection on each section. - series circuit, load check valve protection on each section (possibility of 2nd load check valve on series line) - tandem circuit, load check valve protection on each section.

- possibility of power beyond configuration and possibility of closed center. - spool construction in steel, hardened and nichel-plated

to obtain a higher surface hardness and a better corrosion resistance. - several types of spool: double, single acting, spool motor, float position, regenerative position etc.

- minimum tolerance between the spools and the body to obtain a minimum internal leakage. - interchangeabilty of all the spools.- several spool positioning devices.

- available spool with overcenter valve built-in, available spool with hydraulic kick-out built-in.

- inlet with adjustable pressure compensated priority flow valve built-in available.

- cast-iron made (inlet section, working section, outlet section). - parallel circuit, load check valve protection on each section. - series circuit, load check valve protection on each section (possibility of 2nd load check valve on series line) - tandem circuit, load check valve protection on each section.

- possibility of power beyond configuration and possibility of closed center. - spool construction in steel, hardened and nichel-plated

to obtain a higher surface hardness and a better corrosion resistance. - several types of spool: double, single acting, spool motor, float position, regenerative position etc.

- minimum tolerance between the spools and the body to obtain a minimum internal leakage. - interchangeabilty of all the spools.- several spool positioning devices.

- available spool with overcenter valve built-in, available spool with hydraulic kick-out built-in.

- working section with pressure compensated priority flow valve built-in available.

- cast-iron made (inlet plus working module, single working module, outlet module). - parallel circuit, load check valve protection on each section. - series circuit, load check valve protection on each section. (series line realized inside of the spool with dedicated lcv.). - tandem circuit, load check valve protection on each section. - possibility of power beyond configuration. - spool construction in steel, nickel plated to obtain a higher surface hardness

and a better corrosion resistance. - several types of spool: double, single acting, spool motor, float position etc.

- minimum tolerance between the spools and the body to obtain a minimum internal leakage. - interchangeabilty of all the spools. - several spool positioning devices.

- available spool with hydraulic kick-out built-in.

- cast-iron made (inlet module or inlet plus working module, single working module, outlet module). - parallel circuit, load check valve protection on each section. - series circuit, load check valve protection on each section. (series line realized inside of the spool with dedicated lcv.). - tandem circuit, load check valve protection on each section. - possibility of power beyond configuration. - spool construction in steel, nickel plated to obtain a higher surface hardness

and a better corrosion resistance. - several types of spool: double, single acting, spool motor, float position etc.

- minimum tolerance between the spools and the body to obtain a minimum internal leakage. - interchangeabilty of all the spools. - several spool positioning devices.

- available spool with overcenter valve built-in, available spool with hydraulic kick-out built-in.

E0.00.1013.03.00

4

SECTIONAL TYPE

Configuration

VD6A

Mechanical

VD8A VD10A VD12A

Hydraulic

Pneumatic

Direct electric

Electro-hydraulic

Mid return manifold

With secondary inlet

With service relief valve

With flow control

With priority flow valve

Elettro-pneumatic

On ports

Unloader valve

•

•

•

••

•

•

•

•

••

•

•

•

•

•

•

•

•

•

••

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Controls

Auxiliary valves

Intermediate sections

•

•

•

•

• •

•

•

E0.00.1013.03.00

• •

TYPE

BSP UN-UNF METRIC METRIC

(l/min - US gpm) (bar - psi) (mm - in) (ISO 228/1) (ISO 11926-1) (ISO 262) (ISO 6149-1)

45 - 12

75 - 20

120 - 32

180 - 48

315 - 4600 1 ÷ 8 P/S/T 35.5 - 1.40 G3/8 SAE 8 M18x1.5 M18x1.5

M22x1.5M22x1.5SAE 10

SAE 12

SAE 16

G1/2

G3/4

G1

40 - 1.57

46 - 1.81

52 - 2.05

P/S/T

P/S/T

P/S/T

315 - 4600

280 - 4000

280 - 4000

NOMINALFLOW

OPERATINGPRESSURE

NR. OFSECTIONS

CIRCUIT* SECTIONDISTANCE

STANDARD THREADS(referred to ports)

1 ÷ 8

(1)

(1)

G3/4(2)

1 ÷ 8(1)

1 ÷ 8(1)

(*) P=parallel / S=series / T=tandem(1) For more working sections, please contact our sales department.(2) These threads are available only on body without auxiliary valve seat.

Main characteristics

VD6A

VD8A

VD10A

VD12A

5

DIRECTIONAL CONTROL VALVESe x p e c i a l l y d e s i g n e d f o r O E M S

VDM071/VDM091/VD6A

VDM07

- especially designed for tractor.- cast-iron monoblock construction available with 3 and/or 4 spools.- tandem circuit first working section with load check valve protection on down-stream of the "P" line and priority flow valve to adjust the flow required(only on the 4 sections monoblock).- parallel circuit, load check valve protection on down-stream of the pressure "P" line.- possibility of power beyond.- spool construction in steel, hardened and nichel-plated to obtain a higher surface hardness and a better corrosion resistance.- several types of spool: double, single acting, spool motor, float position.- available spool with hydraulic kick-out built-in.- minimum tolerance between the spools and the body to obtain a minimum internal leakage.- possibility of auxiliary valve only on B port, included valve to shift from double acting to single acting spool.- load check valve mechanical operated on A port available.- several spool control devices and spool positioning devices.

VD8A- especially designed for Diesel engine fork-lift truck- cast-iron made, inlet module with priority flow valve adjustable by a pressure signal.- priority flow available to supply a power steering unit.- two double working modules.- load check valve protection on down-stream of the pressure "P" line, on every sections.- overcenter valve built-into the spool to control the tilt function.- spool construction in steel, hardened and nichel-plated to obtain a higher surface hardness and a better corrosion resistance.- double and single acting spool circuit.- minimum tolerance between the spools and the body to obtain a minimum internal leakage.- possibility of auxiliary valve only on B port.- several spool control devices and spool positioning devices.

E0.00.1013.03.00

- parallel circuit, load check valve protection on down-stream of the pressure "P" line. - cast-iron monoblock construction.

- possibility of power beyond. - spool construction in steel, hardened and nichel-plated

to obtain a higher surface hardness and a better corrosion resistance. - types of spool: double, single acting, spool motor, float position, regenerative position etc.

- minimum tolerance between the spools and the body to obtain a minimum internal leakage.

- several spool control devices and spool positioning devices.

- possibility of auxiliary valve on B port or relief valve on neutral line that can unload both the ports.

- available spool with overcenter valve built-in, available spool with hydraulic kick-out built-in.

- especially designed for truck crane stabilizers.

VD4E100

- especially designed for multiutility vehicles.- 4/3 Directional Control Valve- 5-chambers model with good spool guidance- Parallel connection (adding more working sections)- Cast-iron body (inlet/outlet and working sections)- Inlet port with Venting Valve- Main Relief Valve (direct operated or pilot operated)- Check valve on inlet port (optional)- Auxiliary inlet port (P2) for second pump with combining flows (optional)- Direct operation with wet pin solenoid- Coils can be changed without having to open the pressure-tight chamber- Manual override, optional- Open Center and Closed Center spool types

6

LOAD SENSING VALVES

VDP08 and JOYSTICK- load sensing directional control valve.- made on cast-iron(inlet section, working section, end section).- available with inlet module for fixed or variable displacement pump.- inlet module with pressure compensator built-in.- working modules with pressure compensator built-in.- possibility of venting valve.- spool construction in steel, nichel-plated to obtain a higher surface hardness and a better corrosion resistance.- different choices of working flows, choosing the proper spool.- several types of spool: double, single acting, spool motor etc.- minimum tolerance between the spools and the body to obtain a minimum internal leakage.- interchangeability of all the spools.- possibility of auxiliary valve either on port A or B or on both.- possibility of pressure relief valve on the LS line coming from the ports.- handle control also with friction to look the spool in every intermediate position.- pneumatic proportional control available.- hydraulic proportional control available.- open loop electro-hydraulic proportional control available 12 or 24 Vdc(picture beside).- closed loop electro-hydraulic proportional control available analog or CANBUS (picture beside).- on-off electro-hydraulic control available 12 or 24 Vdc(picture beside).- possibility to control VDP08 using of electronic Joysticks (PWM, analog and CANBUS controls).

(*) with compensator(**) FDC = fixed displacement circuit / VDC = variable displacement circuit

TYPE

BSP UN-UNF

on inlet(l/min - US gpm)

(bar - psi) (mm - in) (ISO 228/1) (ISO 11926-1)

130 - 34 315 - 4600 1 ÷ 8 FDC / VDC 48 - 1,89 G1/2 SAE 10

NOMINALFLOW

OPERATINGPRESSURE

NR. OFSECTION

CIRCUIT* SECTIONDISTANCE

STANDARD THREADS(referred to ports)

Main characteristics

on ports(l/min - US gpm)

95* - 25*

E0.00.1013.03.00

VDP08

VD8ALS- load sensing directional control valve.- made on cast-iron(inlet section, working section, end section).- available with inlet module for fixed or variable displacement pump.- inlet module with pressure compensator built-in.- possibility of venting valve.- spool construction in steel, nichel-plated to obtain a higher surface hardness and a bettercorrosion resistance.- several types of spool: double, single acting, spool motor, float position etc.- minimum tolerance between the spools and the body to obtain a minimum internal leakage.- interchangeability of all the spools.- possibility of auxiliary valve either on port A or B or on both.- handle control- pneumatic proportional control available.- hydraulic proportional control available.- open loop electro-hydraulic proportional control available 12 or 24Vdc(picture beside).- on-off electro-hydraulic control available 12 or 24 Vdc(picture beside).

TYPE

BSP UN-UNF

on inlet(l/min - US gpm)

(bar - psi) (mm - in) (ISO 228/1) (ISO 11926-1)

100 - 26 315 - 4600 1 ÷ 8 FDC / VDC 40 - 1,57 G1/2 SAE 10

NOMINALFLOW

OPERATINGPRESSURE

NR. OFSECTION

CIRCUIT SECTIONDISTANCE

STANDARD THREADS(referred to ports)

Main characteristics

on ports(l/min - US gpm)

90 - 24VD8ALS

7

GEAR PUMPS

1PE- Gear pumps and motors made with alluminium alloy body, flanges and rear covers

- High volumetric efficiency by innovative design and accurate control of machining tolerances.

- Axial compensation is achieved by using floating bushes that allow high volumetric efficiency

througout the pressure range.

- DU bearings ensure high pressure capability.

- Nitrile seals as standard and viton seals in high temperature range.

- Available with flanges, shafts and ports for the main European and German standards.

- Assembling on multiple stage pump available.

- All pumps and motors are tested after assembly and run-in to ensure the high standard required

by Salami engineers.

E0.00.1013.03.00

1.6PE

TYPE 0.8 1.1 1.3 1.6 1.8 2.1 2.7

0.80.004

3.2 3.7 4.2 4.8

1.10.067

2303340

1.30.079

1.60.097

1.80.109

2.10.128

2.70.164

3.20.195

3.70.225

4.20.256

4.80.292

1902750

2103050

2303330

1000

- Gear pumps and motors made with alluminium alloy body, flanges and rear covers

- High volumetric efficiency by innovative design and accurate control of machining tolerances.

- Axial compensation is achieved by using floating bushes that allow high volumetric efficiency

througout the pressure range.

- DU bearings ensure high pressure capability.

- Nitrile seals as standard and viton seals in high temperature range.

- Available with flanges, shafts and ports for the main SAE standards.

- Assembling on multiple stage pump available.

- All pumps and motors are tested after assembly and run-in to ensure the high standard required

by Salami engineers.

Displacement

Working pressure

Intermittent pressure

Peak pressure

Max speed

Min speed

cu.in./rev

barpsi

barpsi

barpsi

rpm

rpm

p3

p2

p1

TYPE 1.4 2.1 3.5 4.1 5.2 6.2 7.6

3.50.213

4.10.250

5.20.317

6.20.378

7.60.463

2503600

2303330

2703900

2904200

6000

Displacement

Working pressure

Intermittent pressure

Peak pressure

Max speed

Min speed

cu.in./rev

barpsi

barpsi

barpsi

rpm

rpm

p3

p2

p1

2.8

2.80.170

2.10.128

1.40.085

2453550

2603770

2002900

2153120

2303330

5000 4000 3500 3000

800 800 800 600

5.8

5.80.353

3000

2503620

2703910

2103050

2303330

2503620

6000 5000 4500

800

4000 3500

600

8E0.00.1013.03.00

2PE

* Available only as rear pump

TYPE 3.2* 4.5 6.2 8.3 11.3 13.8

3.20.19

16 19 22.5 26

4.60.27

6.50.40

8.20.50

11.50.68

13.80.84

16.61.01

19..41.15

22.91.37

25.81.58

2503600

2804000

3004300

4000

600

3500

500

3000

400

2750

400

2500

300

2203140

2002900

1802600

2403450

2203140

2002900

2603750

2403450

2203140

Displacement

Working pressure

Intermittent pressure

Peak pressure

Max speed

Min speed

cu.in./rev

barpsi

barpsi

barpsi

rpm

rpm

p3

p2

p1

- Gear pumps and motors made with alluminium alloy body and cast iron flanges and rear covers.- High volumetric efficiency by innovative design and accurate control of machining tolerances.- Axial compensation is achieved by using floating bushes that allow high volumetric efficiency througout the pressure range.- DU bearings ensure high pressure capability.- 12 teeth integral one-piece gear and shaft.- Double shaft seals.- Nitrile seals as standard and viton seals in high temperature range.- Available with flanges, shafts and ports for the main European, German and SAE standards.- Outrigger bearing available.- Available with several rear covers with valves built-in.- Assembling on multiple stage pump available on both 2PB and 2PE types.- Extremely compact design on the multiple assembling pump for the 2PE type.- All pumps and motors are tested after assembly and run-in to ensure the high standard required by Salami engineers.

GEAR PUMPS AND MOTORS

2ME

- Gear motors made with alluminium alloy body and cast iron flanges and rear covers.- High volumetric efficiency by innovative design and accurate control of machining tolerances.- Axial compensation is achieved by using floating bushes that allow high volumetric efficiency througout the pressure range.- DU bearings ensure high pressure capability.- 12 teeth integral one-piece gear and shaft.- Double shaft seals.- Nitrile seals as standard and viton seals in high temperature range.- Available with flanges, shafts and ports for the main European, German and SAE standards.- Outrigger bearing available.- Available with several rear covers with valves built-in.- All motors are tested after assembly and run-in to ensure the high standard required by Salami engineers.

TYPE 4.5 6.2 8.3 13.8 16 19 22.5 26

4.60.27

6.50.40

8.20.50

13.80.84

16.61.01

19..41.15

22.91.37

25.81.58Displacement cu.in./rev

rpm

11.3

11.50.68

10.5

10.60.65

12.5

12.70.77

max. continuous pressure P1 bar( )psi ( )3140 ( )2900 ( )2600

220 200 180

max. starting pressure P2

250( )3600280

( )4000 ( )3450 ( )3140 ( )2900240 220 200

min. rotational speed 600 500 450max. rotational speed P1 4000 3500 34003600 3200 3000 2850Motor outlet pressure Pout bar ( )psiLeakage-oil line pressure Pdrain

Pin

Pout 5 bar)( )43 psi

Pin

Pdrain

( )43 psi< 5 bar)

Pout 120 bar( )1740 psi

9

GEAR PUMPS AND MOTORS

2,5PB - 2,5MB- Gear pumps and motors made with alluminium alloy body and flanges, cast iron rear covers.- High volumetric efficiency by innovative design and accurate control of machining tolerances.- Axial compensation is achieved by using floating bushes that allow high volumetric efficiency througout the pressure range.- DU bearings ensure high pressure capability.- 12 teeth integral one-piece gear and shaft.- Double shaft seals.- Nitrile seals as standard and viton seals in high temperature range.- Available with flanges, shafts and ports for the main European, German and SAE standards.- Available with several rear covers with valves built-in.- Extremely compact design on the multiple assembling pump 2.5PB/2.5PB.- Assembling on multiple stage pump also available in combination with 2PE or 1.5PB types.- All pumps and motors are tested after assembly and run-in to ensure the high standard required by Salami engineers.

TYPE 5.5* 8.3 11.5 13.8 16 19 22

rpm

25 28 32 38 44

5.970.36

8.290.50

11,760.72

14.070.86

160.97

19.31.17

22.21.35

25.21.53

27.61.68

32.41.97

38.12.32

44.22.69

2303300

2002900

1702465

2503600

2203140

1902700

2603750

2403450

2103000

2503600

2804000

3004300

3000

600 500 400

25002750

* Available only as rear pump

E0.00.1013.03.00

Displacement

Working pressure

Intermittent pressure

Peak pressure

Max speed

Min speed

barpsi

barpsi

barpsi

rpm

p3

p2

p1

cm3/rev.cu.in./rev.

3PE - 3ME

TYPE 21* 27 33 38 46 55 65

2503600

75*

271.65

33.52.04

38.72.36

46.92.86

54.13.30

63.13.85

73.44.48

2804000

3004300

3000

2453500

2203190

2002900

1802600

2653840

2403480

2203140

2002900

2753950

2503600

2403450

2203190

600 500 400

25002750

20.61.26Displacement

Working pressure

Intermittent pressure

Peak pressure

Max speed

Min speed

cu.in./rev

barpsi

barpsi

barpsi

rpm

rpm

p3

p2

p1

- Gear pumps and motors made with alluminium alloy body and flanges, cast iron rear covers.- High volumetric efficiency by innovative design and accurate control of machining tolerances.- Axial compensation is achieved by using floating bushes that allow high volumetric efficiency througout the pressure range.- DU bearings ensure high pressure capability.- 12 teeth integral one-piece gear and shaft.- Double shaft seals.- Nitrile seals as standard and viton seals in high temperature range.- Available just with European and SAE flanges, shafts and ports.- Extremely compact design on the multiple assembling pump 3PE/3PE.- All pumps and motors are tested after assembly and run-in to ensure the high standard required by Salami engineers.

*Available for quantity, please contact our sales department.

10

GEAR PUMPS AND MOTORS

E0.00.1013.03.00

- Gear pumps and motors made with alluminium alloy body, flanges and rear covers.- High volumetric efficiency by innovative design and accurate control of machining tolerances.- Axial compensation is achieved by using floating bushes that allow high volumetric efficiency througout the pressure range.- DU bearings ensure high pressure capability.- 12 teeth integral one-piece gear and shaft.- Double shaft seals.- Nitrile seals as standard and Viton seals in high temperature range.- Available with flanges, shafts and ports for the main European, German and SAE standards.- Outrigger bearing available.- Available with several rear covers with valves built-in.- Assembling on multiple stage pump 3PB/3PB available.- Assembling on multiple stage pump also available in combination with 2PE or 2PB types.- All pumps and motors are tested after assembly and run-in to ensure the high standard required by Salami engineers.

3PB - 3MB

TYPE 21* 27 33 38 46 55 65

2503600

75*

271.65

33.52.04

38.72.36

46.92.86

54.13.30

63.13.85

73.44.48

2804000

3004300

3000

2453500

2203190

2002900

1802600

2653840

2403480

2203140

2002900

2753950

2503600

2403450

2203190

600 500 400

25002750

20.61.26Displacement

Working pressure

Intermittent pressure

Peak pressure

Max speed

Min speed

cu.in./rev

barpsi

barpsi

barpsi

rpm

rpm

p3

p2

p1

- Gear pumps and motors made with alluminium alloy body, flanges and rear covers.- High volumetric efficiency by innovative design and accurate control of machining tolerances.- Axial compensation is achieved by using floating thrust plates that allow high volumetric efficiency througout the pressure range.- DU bearings ensure high pressure capability.- 12 teeth integral one-piece gear and shaft.- Double shaft seals.- Nitrile seals as standard and Viton seals in high temperature range.- Available with flanges, shafts and ports for the main European, German and SAE standards.- Outrigger bearing available.- Assembling on multiple stage pump 3,5PB/3,5PB available.- Assembling on multiple stage pump also available in combination with 2PE, 2PB or 3PB types.- All pumps and motors are tested after assembly and run-in to ensure the high standard required by Salami engineers.

3,5PB

TYPE 55 64 75 87 98*

54.83.34

63.23.85

74.74.55

885.36

996.03

2503600

2804000

3004300

2750

2303300

2103000

2002900

2503600

2303300

2203140

2804000

2603750

2503600

2500 2250 2000

300400 350

Displacement

Working pressure

Intermittent pressure

Peak pressure

Max speed

Min speed

cu.in./rev

barpsi

barpsi

barpsi

rpm

rpm

p3

p2

p1

*Available for quantity, please contact our sales department.

*Available for quantity, please contact our sales dept.

11 E0.00.1013.03.00

GEAR PUMPS

- Gear pumps made with alluminium alloy body and cast iron flanges and rear cov- 12 teeth double gear staggered assembling construction, to double the flow pulsations in order to reduce the instantaneous flow amplitude, that is the noise level generator.- High volumetric efficiency by innovative design and accurate control of machining tolerances.- Axial compensation is achieved by using floating bushes that allow high volumetric efficiency througout the pressure range.- DU bearings ensure high pressure capability.- Double shaft seals.- Nitrile seals as standard and viton seals in high temperature range.- Available with flanges, shafts and ports for the main European, German and SAE standards.- Outrigger bearing available.- Available with several rear covers with valves built-in.- Assembling on multiple stage pump available. .- All pumps and motors are tested after assembly and run-in to ensure the high standard required by Salami engineers.

2PZ

DOUBLE GEARCONSTRUCTION

SALAMI STANDARDCONSTRUCTION

TYPE 5 8 11 14 16 19 22,5*

50.30

80.49

2203140

2103000

1902700

1802600

2303300

2103000

2002900

2503600

3000 2750

2303300

400

2203140

2503600

2753950

4000

600

3500

500

10.90.66

13.90.85

160.98

191.16

22.51.37Displacement

Working pressure

Intermittent pressure

Peak pressure

Max speed

Min speed

cu.in./rev

barpsi

barpsi

barpsi

rpm

p3

p2

p1

rpm

2PW - 2MW (displacements, flages and shafts are the same available for 2PE - 2ME)

The geometry of the displacement gearing, matchedin form by the rotation of the drive shaft, results in theparabolic flow characteristic shown here onthe left. In a standard pump, this characteristic isrepeated each time a gear tooth meshes.With their dual-flank system, the flow pulsation of 2PWpumps is reduced by 75 % – with correspondinglylower excitation of downstream system components– at double the fundamental frequency.

Standard construction

W type construction

O E M S o r i e n t e d l o w n o i s e r e l e a s e s

COMPARISON DIAGRAM OF FLOW AMPLITUDE

Flow

am

plitu

de

Rotation degrees

0° 90° 180° 270° 360° 90° 180° 270° 360° 90° 180° 270° 360° 90° 180° 270°270° 360°

12E0.00.1013.03.00

PG330 - MG330 - OEMS ORIENTED RELEASE

- Cast iron front flanges and rear bodies.

- High volumetric efficiency throughout the full pressure range, by

narrow machining tolerance range and by floating thrust plates,

that ensure axial compensation too.

- High pressure capability by DU bearings

- 12-Teeth gear with shaft (one-piece construction)- Double shaftseals

- Double shaft seals

- NBR Seals as Standard, Viton seals for high temperature range

- Flanges: European, SAE B, SAE C, ISO (for PTO designs)

- Ports: European and SAE Standards

- Multiple pumps: max. 3 cast iron PG330 stages, with additional aluminium 2PE stages

GEAR PUMPS AND MOTORS

PG331 - DISTRIBUTORS RELEASE

- Easy 2-Stage Pump assembling, with/w-out common Inlet Port

- Fast assembling of Standard Aluminium 2PE as Rear Pump, on Single PG331 Stage

- Only two Assembling Kits for all possible 2-Stage PG and PG/2PE combinations

P/MG330 - PG331 TYPES 23 28 34 40

2804000

28.61.74

34.42.1

40.32.46

3004350

3405000

3000

2603800

2804000

3004350

400

23.41.43Displacement

Working pressure

Intermittent pressure

Peak pressure

Max speed

Min speed

cu.in./rev

barpsi

barpsi

bar

rpm

rpm

p3

p2

p1

psi

47 55 64 72

55.23.37

64.33.92

73.44.48

2203200

2403500

2603800

2700

47.42.89

2500

350

80

80.64.91

2002900

2203200

2403500

2403500

2603800

2804000

2804000

3004350

3204650

2603800

2804000

3004350

2804000

3004350

3204650

2603800

2804000

3004350

Sharing the same features of PG330 Series, in terms of dimensions and working conditions, this version has been created for Distributors Management,and offers the following possibilities:

This new series of cast iron pumps and motors has been designed for two-piece construction, to grant as much compactness as possible.

Two sizes of Front Flange cover the complete range of PG Series, from 23 to 80 cc.

GEAR FLOW DIVIDERS

E0.00.1013.03.0013

2DRE - 2DRE-AR - 2DRE-VA

2DRE

2DRE-AR

2DRE-VA

max. max. max.

bar bar psi psi bar psi

2DRE - 4,5 4,60 0,27 250 280 3600 4000 50 725 1250 3900 6,05 18,88 1,59 4,97

2DRE - 6,2 6,50 0,40 250 280 3600 4000 50 725 1250 3750 8,55 25,66 2,25 6,75

2DRE - 8,3 8,20 0,50 250 280 3600 4000 50 725 1200 3600 10,36 31,07 2,73 8,18

2DRE - 10,5 10,60 0,65 250 280 3600 4000 50 725 1200 3500 13,39 39,05 3,52 10,28

2DRE - 11,3 11,50 0,68 250 280 3600 4000 50 725 1200 3500 14,53 42,37 3,82 11,15

2DRE - 12,5 12,70 0,77 250 280 3600 4000 50 725 1200 3400 16,04 45,45 4,22 11,96

2DRE - 13,8 13,80 0,84 250 280 3600 4000 50 725 1200 3400 17,43 49,39 4,59 13,00

2DRE - 16 16,60 1,01 250 280 3600 4000 50 725 1100 3200 19,22 55,92 5,06 14,71

2DRE - 19 19,40 1,15 220 240 3150 3450 50 725 1100 3200 22,46 65,35 5,91 17,20

2DRE - 22,5 22,90 1,37 220 240 3150 3450 50 725 1100 3000 26,52 72,32 6,98 19,03

2DRE - 26 25,80 1,58 200 220 2900 3150 50 725 1100 2850 29,87 77,40 7,86 20,37

2DRE - 30 30,10 1,84 200 220 2900 3150 50 725 1100 2700 34,85 85,55 9,17 22,51

Ty peDisplacement

Max. outlet pressure Max. outlet p Speed Flow per section Flow per section

p1 p2 p1 p2 between sections min. min. min.

cm3/rev cu.in./rev min-1 l/min gpm

Designed to be easily managed by Distributors, these gear flow dividers require a minimum stock investment, to allow the assembling of every possibleconfiguration, including cylinder realignment function, during extension and re-entry. All flow dividers are 100% tested, with high pressure run-in.

- Aluminium alloy bodies, cast iron side-covers

- High volumetric efficiency throughout the full pressure range, by narrow machining tolerancerange and by floating bushes, that ensure axial compensation too

- High pressure capability by DU bearings

- 12-Teeth gear with shaft (one-piece construction)

- NBR Seals as Standard, Viton seals for high temperature range

- Ports: European, German and SAE Standards

- All bodies pre-arranged for assembling of AR cylinder realignment valves

- Common Inlet Port available also on the side-cover

- Assembling up to 6 Stages possible

- 2DRE-VA: cylinder realignment function

- 2DRE-AR: for cylinder realignment in both directions (additional Tank connection required)

ACCESSORIES

PRIORITY FLOW VALVE

FLOW DIVERTER VALVES

PUMPS AND MOTORS SPECIAL APPLICATION

HYDRAULIC REMOTE CONTROLS AND POWER SUPPLY UNITS

CABLES AND

CABLE REMOTE CONTROLS

E0.00.1013.03.00 14

GEAR PUMPS AND MOTORS

AIR COMPRESSOR MOTORS

FAN DRIVE MOTORS

HI-LOW PUMP - GROUP 2The perfect compromise between speed

and pressure, when the available power

is limited (presses, log splitter, power

packs, etc.)

Electro-proportional Fan speed control,

with electrical Inversion Function.

electrical/manual flow regulator, with

electric unloading valve.

NOTE

You can find our most up to date “STANDARD SALES CONDITIONS” on our website

www.salami.itph. +39 059 387 411

www.salami.it

You can watch our tutorials on youtube channel

You can fi nd our most up to date “STANDARD SALES CONDITIONS” on our website

Potete trovare le nostre più aggiornate “CONDIZIONI DI VENDITA STANDARD” sul nostro sito

ph. +39 059 387 411

Salami Fluid PowerSalami Fluid Power WorldSalami Fluid Power FranceSalami Fluid Power EspañolSalami Fluid Power Deutsch

watch our tutorials on our official youtube channels

RANGE OF PRODUCTS OVERVIEWDetailed release

E0.

00.1

013.

03.0

0

SALAMI SPAvia Emilia Ovest 100641123 Modena Italytelefono +39-059-387411telefax [email protected] - www.salami.it

TM

SALAMI ESPAÑAPoligono Industrial ArmenteresC/Primer de Maig, 18, Nave 408980 San Feliu de LlobregatBarcelonatelefono +34-93-6327288telefax [email protected]

SALAMI FRANCE22, rue Louis Saillant69120 Vaulx en VelinLyontelefono +33-04-78809941telefax [email protected]

SALAMI HYDRAULICS N.A INCLoop RoadBaldwinsvilleNY 13027 - USATel.: +1-315-295-2363Fax.: [email protected]

www.salami.it our official channels