RANGE OF OUR PRODUCTION - DELGADO y … · RANGE OF OUR PRODUCTION FIRENZE SIENA COLLE DI VAL...

Transcript of RANGE OF OUR PRODUCTION - DELGADO y … · RANGE OF OUR PRODUCTION FIRENZE SIENA COLLE DI VAL...

RANGE OF OUR PRODUCTION

FIRENZE

SIENA

COLLE DIVAL D'ELSA

MILANO

ROMA

General :Nencini Co. since 45 years is a private manufacturer of special valves for hydraulic purposes, as drinking waterplants, irrigation, discharge of dams, hydraulic power plants, sea water plants and oil plants only for controlvalves.Nencini has proper design and technical department, quality control dept, production dept, Ansyscalculation dept, and a workshop with a big size of tools machines.

Experience:The experience of Nencini Co. since 40 years is supported from historical record of hydraulic tests carried outon site of works, in our workshop and with samples from Hydraulic University Laboratories, or hydraulicinternational laboratories ( as DELFT).

Special valves:Our valves are designed to resolve properly specific problems involved in the plants for every plant.These valves are special for type, size and working performances.

Technology:A lot of valves are supplied with control units for flow, pressure, level.These control units can have local electrical board with PLC and suitable for BUS connection fordistance control panel.The Engineering of HPU (Hydraulic Power Unit) and Electric Control Panel is made from ourCompany.

Machine Tools:The workshop of Nencini has big size of machine tools as vertical late, boring machine and weldingmachine with submerged arc with a rotating plate up to 5000 mm, in our workshop we are able to machine valvesup to 4500 mm of size.Two sister companies with bigger machine tools and a crane of 250 Tons are working with ourcompany under our design, our purchasing dept and our quality control dept, and are able to manifacture valvesup to 5500/6000 mm.

Workshop test.Our Company carries out workshop test of all valves manufactured from smaller sizes up to biggest.

Quality Control Dept:Nencini is qualified ISO 9001 : 2000 by DNV.

Materials and components:The materials used for the manufacture of valves are as follows:Ductile Cast Iron with proper wooden modelGrey Cast Iron with proper wooden modelCast Carbon Steel with proper wooden modelAluminium bronze with proper wooden modelStainless Steel with proper wooden modelStructural steel by welding systemStainless Steel by welding systemElectric Actuators Rotork - AumaHydraulic hoists Best International productionHPU Italian qualified suppliersElectronics CGE - FANUC - OTHERS

LocationColle Val D'Elsa is close to Florence and Siena.Distance from Milan 350 KmDistance from Rome 250 Km.

2

RANGE OF OUR PRODUCTION

Drive Unit: electric / hydraulic actuator / manual controlPressure Class: up to PN100 / ANSI 600End Flanges: as per UNI, ISO, DIN, BS, ANSI Standards

Ring FollowerRotative valve

DN 500 - DN 2500DN UP TO - DN 2000

Check Valves:Venturi nozzle typeButterfly type with counterweight

DN 50 - DN 1400DN 300 - DN 4000

Flow and Pressure Control Valves:Standard Needle valves L. Johnson typeMultijet Needle valve L. Johnson typeGlobe valvesHigh Pressure Sleeve valves

DN 50 - DN 3000DN 50 - DN 3000DN 50 - DN 1600DN 200 - DN 2500

Safety Valves for Hydropewer Plants:Butterfly valve with counterweight DN 50 - DN 4000

Air Valves:Air release valvesVacuum breaker valvesDouble air release valves

DN 50 - DN 800DN 50 - DN 800DN 50 - DN 800

Tank Level Control Valves:Sleeve valves with mechanical controlFloat valves with hydraulic control

DN 50 - DN 2000DN 50 - DN 2000

Discharge Valves:Spillway Radial GatesOutlet sluice valvesFixed cone valves Howell Bunger type

Required SizesRequired SizesDN 200 - DN 3500

Penstocks:Cast-iron sluice valves with round portCast-iron sluice valves with square portStructural Steel Sluice valves

DN 200 - DN 20002000 x 2000Required Sizes

On-Off Valves:Butterfly valvesGate valves

up to - DN 4000DN 1000 - DN 2000

Submerged vertical sleeve valves DN 200 - DN 3500

Ring follower gates up to - DN 2500

Automatic Control Valves DN 50 - DN 1600

3

ON - OFF VALVES

Butterfly valveDN 2400 PN 10

Butterfly valveDN 2000 PN 10

Butterfly valveDN 3500 PN 6

Butterfly valveDN 3600 PN 10

4

ON - OFF VALVES

Butterfly valveDN 1600 PN 10

Butterfly valveDN 600 ANSI 600

Gate valveDN 1500 PN 10

Butterfly valveDN 2400 PN 10

5

CHECK VALVES

Butterfly valveDN 2400 PN 6

Butterfly valveDN 1000 PN 16Aluminium bronze

Non return ValveVentury type

DN 600 PN 25

Non Return Valve Venturi typeDN 300 PN 25

6

FLOW AND PRESSURE CONTROLV VALVES

Needle ValveDN 3000 PN 10

Needle ValveDN 100 PN 16Cut a view

Needle ValvesDN 1400 PN 10

Needle ValvesDN 2000 PN 16

7

FLOW AND PRESSURE CONTROLV VALVES

Needle ValveDN 1800 PN 16

Needle ValveDN 200 ANSI 300Stainless Steel

Needle ValveDN 800 PN 16Stainless Steel

Needle ValveDN 600 PN 16Welded Stainless Steel

8

FLOW AND PRESSURE CONTROLV VALVES

Needle ValveDN 2400 PN 10

Needle ValvesDN 200 PN 16Stainless Steel

Needle ValveDN 1400 PN 10Body pressure test

9

PRESSURE AND FLOW CONTROLV VALVES

Double flangedsleeve valvesDN 400 PN 16

Globe valveDN 600 PN 40

Double flangedsleeve valvesDN 800 PN 25

Double flangedsleeve valve

DN 600 ANSI 600

Double flangedsleeve valveDN 300 ANSI 600

10

AUTOMATIC CONTROLS VALVES

Automatic pressurecontrol valveself - actuatedDN 1500 PN 10 Automatic pressure

control valveself - actuatedDN 800 PN 16

Automatic pressurecontrol valve

self - actuatedDN 600 PN 25

Automatic pressurecontrol valveself - actuatedDN 1200 PN 10

11

SAFETY VALVES FOR HYDROPOWER PLANTS

Counterweight Butterfly ValveDN 2000 ANSI 400

for Hydropower by-pass

Butterfly valvewith counterweightDN 3500 PN 10

Butterfly valvewith counterweight

DN 1200 PN 16

Butterfly valvewith counterweightDN 3500 PN 10

Counterweight Butterfly ValveDN 2000 PN 16for Hydropower by-pass

12

SAFETY VALVES FOR HYDROPOWER PLANTS

Safety Valve. Butterfly Type.DN 600 PN 16Aluminium bronze

Safety Counterweight Butterfly ValveDN 2500 PN 25Welded carbon steel

Counterweight Butterfly ValveDN 2000 ANSI 400

for Hydropower by-pass

13

AIR VALVES

Double actionair valveDN 150 PN 16

Air vacuum valveDN 700 PN 10

Double actingair valve AL-BZDN 100 PN 16

Double actingair valve

with release deviceand antislam unit

AL-BZDN 500 PN 10

14

AIR VALVES

Double actingand release air valve AL-BZ

DN 200 PN 10

Double actingand release air valvewith shut-off valveDN 100 PN 16

Anti vacuumair valve

DN 400 PN 10

15

TANK LEVEL CONTROLS VALVES

Tank Level Control ValveDN 500 PN 16Ductile cast iron

Outlet Folw Control ValveSleeve type

DN 500 PN 25Welded carbon steel

Capitanata Plant (Italy)Tank level control valves

Tank Level Control ValveDN 600 PN 10Welded carbon steel

16

DISCHARGE VALVES

Submerged sleeve valveDN 2000 PN 16

Hight Pressure Control ValveDN 400 PN 25Welded carbon steel

Submerged verticalsleeve valve

DN 2000 PN 16

17

DISCHARGE VALVES

Fixed cone valveHowell-Bunger type

DN 500 PN 25

Discharge ValveSleeve typeDN 1200 PN 25Welded carbon steel

Submerged discharge valve,Vertical Sleeve type

DN 600 PN 25Welded carbon steel

Fixed cone valveHowell-Bunger type with hoodDN 600 PN 16

18

DISCHARGE VALVES

Fixed cone valveHowell-Bunger type

DN 2400 PN 10

Fixed cone valveHowell-Bunger typeDN 1000 PN 25

Fixed cone valveHowell-Bunger typeDN 2400 PN 10

Fixed cone valveHowell-Bunger typeDN 600 PN 16

Fixed cone valveHowell-Bunger type

DN 800 PN 16

19

Penstock - 2000x2000 mmWelded carbon steel

High Pressure Outlet Slide Gate3000x3000 mm Head 45 m.w.c.Welded carbon steel

High Pressure Outlet Slide Gates2550x2500 mm. Head 30 m.w.c.Welded carbon steel

On-OffPenstock for basin

2500x2500 mmWelded Carbon steel

PENSTOCKS

High Pressure OutletRadial Gate

3000x3000 mmHead 45 m.w.c.

Welded carbon steel

20

Needle valve bodyafter welding process

DN 3000 PN 10

Dissipating energychamber for Howell-BungerDN 1200 PN 40

FROM THE WORKSHOP

Submerged arcwelding process forButterfly valve body

21

ST ST Shafts forButterfly valves

Autolubrificating bearingsfor Butterfly valveAL-BZ

FROM THE WORKSHOP

Butterfly valve bodyDN 3550 PN 12

Butterfly valve discDN 3550 PN 12

22

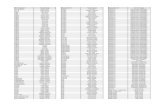

295

354

184

626

656

14

17

23

19

19

39

20

0

26

6

34

0

20

0

26

6

34

0 E

1 3173124 2522153727307389365463435 8

29

32

33

40

28

20

2

2116

10

13

18

FLO

WD

IREC

TION

SECT. A-AOPEN POSITION

26

1211

N.3 Concentric Groovesfor GasketcPurpose

N.3 Concentric Groovesfor GasketcPurpose

2

24

2

24

495

C

295

N.12 Fori Ø22

VIEW CSCALE 1:3

4142

43

CLOSED POSITION

DETAIL ESCALE 5 : 1

DETAIL DSCALE 5 : 1

DETAIL FSCALE 3 : 1

DETAIL GSCALE 5 : 1

Item Codex Article Material Q.ty

The above cited materials could be changed with equivalent or better materials because manufacturing requirements

43 ____ Protection Plexiglass 1

42 FR_02 Flow Direction Tag Aluminum 1

41 OT_01 Identification Tag Brass 1

40 IN_200 Position Indication Tag Brass 1

39 IQM10 Electric actuator Rotork mod. IQM10; 18rpm; Folomatic+CPT; 415V/3PH/50HZ 1

38 7_Øe220_Øi211 Gasket H-ECOPUR - K35-P Øe220 Øi211 L=7 2

37 K35P-92_4.5-DG Gasket H-ECOPUR - K35-P Øe60 Øi54.2 L=4.5 1

36 S35P-30_3.5-DG Gasket H-ECOPUR - S35/P Øe35.8 Øi30 L=4.5 2

35 OR6870-DC Gasket Certified Rubber For Potable Water - OR6870 AS-568 A 1

34 OR4850-DC Gasket Certified Rubber For Potable Water - OR 4850 AS-568 A 1

33 OR4187-DC Gasket Certified Rubber For Potable Water - OR4187 AS-568 A 1

32 OR4118-DC Gasket Certified Rubber For Potable Water - OR 4118 AS-568 A 1

31 OR3625-DC Gasket Certified Rubber For Potable Water - OR3625 AS-568 A 1

30 UM9070-DC Gasket Certified Rubber For Potable Water - UM 9070 1

29 JA021601 Trust ring Nylatron GSM 1

28 JA021501 Trust ring Nylatron GSM 1

27 K1_4-M Plug AISI 316 - 1/4" G 1

26 G10-J Lifting Eye Class 4A Galvanized - M10 DIN 580 2

25 J640-P Spring Pin Class R150 - Ø6x40 ISO 8752 1

24 I14930-O Parallel Key Class C40 - 14x9x30 1

23 I5530-O Parallel Key Class C40 - 5x5x30 1

22 R40-T Self Locking Ring Nut Class "R50" Galvanized - M40X1.5 1

21 L24-L Self Looking Nut Class A2 - M24 DIN982 1

20 R25-T Self Locking Ring Nut Class R50 Galvanized - M25x1.5 1

19 E1025-M Bolt Class A4 Gr. 70 - M10x25 ISO 4017 8

18 D1035-M Bolt Class A4 Gr. 70 - M10x35 ISO 4762 3

17 D614-M Bolt Class A4 Gr. 70 - M6x14 ISO 4762 9

16 F825-M Bolt Class A4 Gr. 70 - M8x25 DIN 7991 4

15 JA021400 Bevel Gear Materiale <non specificato>Steel DIN C45 1

14 JA021201-CN Position Indicator Brass CuZn40Pb2 (CW617N) 1

13 JA021001-CM Bearing G-CuSn5Zn5Pb5-C EN 1982 1

12 JA020901-CM Stem Nut G-CuSn5Zn5Pb5-C EN 1982 1

11 JA020901-CG Antirotation Pin X5CrNiMo17-12-2 EN 10088 (AISI 316) 1

10 JBP80901-CG Driving Stem X5CrNiMo17-12-2 EN 10088 (AISI 316) 1

9 JA020801-CG Stem Nut X5CrNiMo17-12-2 EN 10088 (AISI 316) 1

8 JA020701-BA Seat ASTM A351 CF8M 1

7 JA020601-BA Stem Nut Flange ASTM A351 CF8M 1

6 JA020501-BA Ported ASTM A351 CF8M 1

5 JA020402-CH Shutter - Antirotation Pipe AISI 316 1

4 JA020401-BA Shutter - Body ASTM A351 CF8M 1

3 JA020301-BA Inlet Needle ASTM A351 CF8M 1

2 JA030201-BA Bonnet 1

1 JB020101-BA Body ASTM A351 CF8M 1

Required Quantity Q.ty =

Approximated Weight 144 Kg/each

HYDRAULIC PRESSURE TESTFOR BODY 24 Bar for 10 minutes

FOR SEAT 17.6 Bar for 10 minutes

FOR SHUTTER 16 Bar

Compiled Approved Description Date Rev.

M. Pianigiani L. Folini For Constructor 18/04/2014 00

A

1 2 3 4 5 7 8 9 10 11 12 13 14 15 16

B

C

6

D

E

F

G

H

I

J

K

D

E

J

K

A

B

C

5 6

F

G

H

I

12

L

1 2 3 4 7 8 9 10 11 13 14 15 16

L

Con

fiden

tial i

nfor

mat

ion,

pro

perty

of N

EN

CIN

I S.p

.A N

ot b

e us

ed fo

r any

pur

pose

oth

er th

an th

at fo

r whi

ch it

is s

uppl

ied.

A01:2

1/1

JB020000----S.p.A.Colle di Val D'Elsa (SI) ITALY

Sheet

Drawing

Client:

Order

Project:

ScaleDescription:

00

Rev.

----

----

FLOW CONTROL VALVE

DN200 PN16

ASSEMBLY DRAWING