Qube - cobot welding cell - Omron

Transcript of Qube - cobot welding cell - Omron

2

Qube - cobot welding cellThe golden link between small and large series production.

+52 1 442 628 2286 [email protected]

+44 23 8077 2711 [email protected]

+1 864 541 0521 [email protected]

+31 341 411 811 [email protected]

+420 577 112 789 [email protected]

+86 510 8356 0058 [email protected]

Querétaro Mexico

SouthamptonUnited Kingdom

Spartanburg, SCUSA

AWL-Techniek B.V. AWL-Techniek CZ s.r.o.

AWL Automation Welding and Cutting Equipment (Wuxi) Co., Ltd.

AWL Automation S. de R.L. de C.V.

ICS Robotics and Automation Ltd

AWL Automation LLC

HarderwijkThe Netherlands

Napajedla Czech Republic

Wuxi, JiangsuChina

OUR PARTNERS

+31 341 277 070 [email protected]

+31 38 425 7680 [email protected]

HarderwijkThe Netherlands

ZwolleThe Netherlands

MechDes Engineering TT-Engineering

www.awl.nl

Strategic Program

WELDING SOURCES OF

YOUR DESIRE:

• MIG/MAG

• TIG

INTERCHANGEABLE

PANELS TO CUSTOMIZE

TO YOUR TASTE

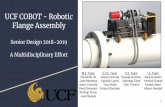

OMRON COBOT

MANUAL INDEXER

WITH SIEGMUND

TABLETOP

2 332

High qualityWhen it comes to product quality, AWL stands for a high standard. The total quality of Qube can only be as good as that of all the components combined. Therefore it is composed of the best components.

EfficientBesides the fencing, the most significant difference from a regular welding cobot is the double-sided indexer table, which boosts efficiency by up to 50%. While the operator is tending new parts, the cobot can simultaneously weld on the other side.

EconomicalEven though it’s designed with the smallest eye for details and made of the highest quality equipment, Qube is available for under €100,000. The price includes training, so you can immediately start welding with Qube. Although the cobot welding cell is 30% more expensive than a welding cobot, Qube can be up to twice as efficient and is inherently safe.

Collaboration with OMRONIn a market where there’s a great shortage of welding expertise and an increasing demand for flexible and safe welding machines, AWL and OMRON have joined forces to develop a solution that meets this need: Qube - the cobot welding cell. AWL has expertise in the field of process improvement and welding, while OMRON’s strength lies in automation solutions that empower people and machines. This collaboration has resulted in the development of this flexible new cell.

Your compact welding solutionAre you welding products of medium to high volumes with a high variety? Is a welding cobot interesting because of its ease of programming, but not fast enough for your production? Or do you doubt whether the product quality will be sufficient? Let us introduce to you Qube, our cobot welding cell. A true AWL machine with improved output – both in numbers and quality. Designed to be flexible, safe, efficient, of high quality, and economical.

Flexible solutionQube is flexible in many ways: reprogrammable for a variety of products, relocatable within your plant, but also reconfigurable as a cell.

ReprogrammableCobots have been conquering the traditional world of robotics for over a decade. They were initially designed to work alongside humans because they can detect collisions. Another benefit of the built-in sensors of cobots is that they can be programmed by hand-guidance: moving the cobot manually instead of by a joystick.

This easier handling also comes with a simple interface that is understandable for a wider public. In other words: the cobot can be programmed by your welders – without the help of a robot programmer

RelocatableDo you want to relocate the cobot welding cell to bring it in line with other cells? The small footprint makes it easy to squeeze it in. It weighs only 1,500 kg and the base frame is fitted with forklift slots and lifting eyes, so it is easily relocatable by forklift or overhead crane.

ReconfigurableThe cobot is placed inside fencing to protect you and your coworkers from the harmful heat, movements, and welding light produced by the cobot and the welding equipment. On the front, anyone working with the cobot welding cell is shielded by a fence mounted on the manual indexing table. This fence is fitted with welding glass, through which you can monitor the process safely.