Quality, Durability, COMPANION EQUIPMENT Proven Performance · 2012-06-15 · exacting...

Transcript of Quality, Durability, COMPANION EQUIPMENT Proven Performance · 2012-06-15 · exacting...

Spout Truss KitsBUCKET ELEVATORS

SINCE1888

SINCESINCE18881888

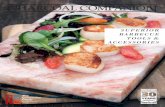

ACCESSORIES

COMPANION EQUIPMENT

Sudenga Industries, Inc.2002 Kingbird Avenue

George, IA 51237Toll-free: 1-888-783-3642

Phone: 1-712-475-3301Fax: 1-712-475-3320

E-mail: [email protected]: www.sudenga.com

German immigrant Folkert Sudenga opened the doors of his blacksmith shop in 1888. Calling his small business on main street George, IA, the George Iron and Woodworks, Sudenga provided area farm-ers with shoes for their horses and replacement parts for their wagons. George Iron and Woodworks became Sudenga Brothers, then Sudenga Ironworks and eventually Sudenga Industries, as subsequent generations of the Sudenga family expanded and diversified the business.

As the needs of the farmers who came to “Sudengas” for solutions grew, so did the product offerings. Able to draw on a well-estab-lished history of product development for the ag industry, Sudenga products became known for being innovative, extremely reliable, and above all, “delivering as promised”. Still known today for these traits, Sudenga products are at home on the farm or in the toughest commercial applications. Sudenga’s owners and employees proudly maintain standards, which reflect the qual-ity and innovation that comes with the experience of over 115 years of producing material handling equipment.

ABOUT US

. . . engineered, field tested and proven to meet,

and in many cases, exceed industry

standards.

Sudenga Bucket Elevators are available for farm or commercial applications in capacities to 40,000 bushels per hour and discharge heights of 200 plus feet. Capacities to 20,000 bushels per hour are standard. Capacities above 20,000 bph are quoted to specific application specifications. All systems are engineered, field tested and proven to meet, and in many cases, exceed industry standards. Sudenga Bucket Elevators deliver capacities as advertised. Components are manufactured to close tolerances for ease of con-struction and years of trouble free operation. Sudenga Industries offers a full line of complementary equipment for complete mate-rial handling systems.

200 ft & 40,000 BPH

Sudenga Industries is proud to be an industry leader in the design and manufacture of innovative handling systems for bulk mate-rial applications. Employing the latest advances in manufacturing technology and production methods to produce solid, reliable systems, Sudenga Bucket Elevators have many features that set them apart. Compare ours to others. Jigged and robotically welded com-ponents, pre-welded platforms for ease of assembly, high quality double-row spherical and tapered roller pillow block bearings, drum style slatted boot pul-leys, rubber leg belt and heavy gauge construction all come standard.

Quality, Durability, Proven Performance

View project photos and layout ideas:

www.sudenga.com

Look for theseother quality

Sudenga products....

· Horizontal and Incline Drag Chain Conveyors

· 2610 & 4012 Low-Profile Drive Over Conveyors

· Dump Pits· Catwalk Systems

· Leg Towers

A complete line of Stan-dard and Commercial Duty

Bin Unloading and Grain Handling Systems

Sudenga Industries offers a wide range of accessories for your next grain handling project....

Distributors

Valves

Spouting

Spout Truss Kits

Elbows

Moisture Dampers

Swivel Spouts

Bin Tops

Drives

Cups/Belting

Reducers/Adaptors

Slip Joints

Clamgates

Grain Retarders

Deadheads

Angle Rings

Rack & Pinion Gates

Sudenga Bucket Elevators have many features

that setthem apart.

2610 Low-Profile Drive Over Conveyor

Incline Drag Chain Conveyor

Industrial Bin Sweep& Sweep Sensor Control

Catwalk and Catwalk Support Towers

Distributed by:

. . . quality and innovation that comes with the

experience of over 115 years...

Distributors

Sudenga Industries offers a wide range of accessories

Adaptors

Open & Closed Bin Tops

DeadheadsRack & Pinion Gates

Valves

FEATURES

All Sudenga Bucket Elevator Systems are designed and built to exacting specifications, giving the owner a system that will provide more years of service, with less downtime and repair. The contractor is happy with the quality of fit and ease of construction. Sudenga Bucket Elevators deliver on all these points. Sudenga Elevators produce advertised capacities with extreme reliability. They offer

superior construction, and go up without problems.

Just started thinking about planning your grain handling system? Now is the time to call. Sudenga Industries can assist from the start with planning and layout

ideas. Our knowledgeable, experienced staff works with a qualified contractor or design firm to ensure proper utilization of equip-ment, matching design and capacity to the customer’s needs and application. Call today to discuss your ideas!

The difference is in the details. Sudenga Bucket Elevators offer the value added fea-tures that you and your operation demand. Our finish is an attrac-tive, durable blue enamel, with other colors available on request. Hot dipped galvanized finish is available for ultimate long term resistance to the elements.

Trunking sections are designed to provide superb dust and weather tight protection. Sections are jigged and continuous seam welded. Angle iron or plate flanges, depending on the series, are engineered for the job and minimize overlap to prevent the trapping of cor-rosive moisture or product. 14, 12, and 10 gauge trunking is avail-able. Reinforced inspection stations ensure trunk integrity when removable covers are off. Inspection ports can be positioned in four different locations by rotating the sec-tion and cover, allowing for easier ongoing inspection and maintenance.

Ladder and safety cage are standard galva-nized construction. Head service platforms, distributor service platforms and OSHA rest platforms are painted or hot dipped galva-nized and come assembled to save valuable time during installation.

All capacities are based on a 75% cup fill or water level plus 10%. Heavy duty polyethylene buckets resist bending, breaking and are lightweight. Bucket vents are standard. Standard SCOF (static con-

ducting, oil resistant, flame resistant) Goodyear Pathfinder “Su-preme” rubber belting is “the best there is”, and stays flexible in cold weather. PVC belting, belting for high oil exposure, and a variety of cup types are available upon request.

AA

B

C

WHY BUY SUDENGA

CALL TODAY!TOLL-FREE:

1-888-SUDENGA

CROWNED WING STYLE BOOT PULLEYS are standard in all sizes of legs. Pulleys ride on heavy duty shafts with heavy duty double tapered pillow block bearings*.

CROWNED DRUM STYLE PULLEYSwith SCOF vulcanized lagging are standard, pulleys with removable slide lagging (shown), are available. Head shafts are turned, ground and polished head shafts

PRESSURE-RELIEF PANELdesigned to meet NFPA standards

MULTIPLE PIECE HOOD ASSEMBLYallows for ease of maintenance

HEAVY DUTY POLYETHYLENE BUCKETSare lightweight, resist bending and breaking

RUBBER BELTINGstays flexible in cold weather

OVERSIZE INSPECTION PANELallows for easy inspection and maintenance

HEAD SECTION

GENTLE DISCHARGEdesigned for optimum discharge angle

BOOT SECTION

WEATHER TIGHT LIP SEALprovides protection from the elements

TORQUE ARM BRACKETheavy duty to ensure proper

speed reducer torque arm support

BEARING AND SHAFT SEALUHMW seal, internally mounted for weather tight seal. Bearing cover minimizes direct moisture access to bearing.

BEARING AND SHAFTHeavy duty double row pillow block bear-ings* with jacking bolts and gussets to ensure turned ground and polished head shaft runs true and level.

LADDER HANDLESconveniently located forentering head platform.

DISCHARGE LININGa variety of lining options available.Lined with 1/4” urethane backed by 16 ga. steel on Senior Series Legs.

HINGED INSPECTION DOORwith over center clamp

UPSIDE BOOT HOPPERdirects material flow for proper bucket fill

DOWN SIDE BOOT HOPPERsecondary hopper for additional fill option

HINGED INSPECTION DOORlocated for quick inspection of components.

Gasketed and sealed to prevent dust leaks.

BEARING AND SEALHeavy duty bearings* sized for the job. A UHMW seal eliminates dust leakage.

SCREW TAKE-UPgenerously sized for maximum pulleyadjustment. Designed for rugged duty.

ANGLED BOOT CLEANOUTangled to promote boot cleanout with cups.

Easily removed for clean out access.

VISIT US ONLINE:WWW.SUDENGA.COM D

D

C

INSPECTION SECTION AND TRUNKINGReinforced inspection stations ensure trunk integrity when removable cov-ers are off. Inspection ports can be positioned in four different locations by rotating the section and cover, al-lowing for easier ongoing inspection and maintenance.

SHAFT MOUNT SPEED REDUCERShaft mount torque arm speed reducer drives have easy-to-remove taper lock bushings. Class I and Class II arrangements are available.

*BEARINGS: Medium 24” Legs and larger have spherical double roller pillow block bearings. “C” and Junior Legs have sealed pillow block ball bearings.

B

MOTOR MOUNTS are located between the trunking sections to save space on the Head Ser-vice Platform while providing convenient access to the motor and drive. Channel irons provide mounts for pre-welded platforms for quick and easy installation.

PLATFORMS &MOTOR MOUNT

BOOT CONSTRUCTIONBoot specifications vary from 10 gauge to 7 gauge dependent on bucket elevator size.

Ordering an Elevator Leg

1. Choose an Elevator Leg based on capacity and discharge height required. Larger units available on special order.2. Select the Leg from pages 4-26. Select a drive unit from pages 27-30.3. Select optional components (spouting, deadheads, distributors, etc.) from pages 31-46.

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-20-08 SUDENGA INDUSTRIES, INC. • 1-888-SUDENGA (783-3642) • 1-712-475-3301Fax: 1-712-475-3320 • [email protected]

Page 3.0

Elevator Leg Dimensions (dimensions are in inches)

Series Capacity(BPH)

Cup Size Spacing

PulleyRPM

BeltFPM

PulleyDia.

TrunkDimen. A B C D E F G H I J K L M

175 78 122"C" 500 6 x 4 5 168 264 6 5½ x 8½ 21 8 21¾ 48 10 24 23 16 5½ 8 7 19 --

800 202 317

Junior

1000

9 x 6

8 45 140

12 9 x 13 34 14 41 72 16 38¾ 37 29½ 11 8 14½ 26¾ 13¾1250 14 122 3831500 12 122 3833000 7 138 433

DC 12" 2000 8 x 6 7 49 153 12 14 x 22 37¾ 19 47 72 16 38½ 36¾ 34½ 6¼ 8 18 29½ 13¾3000 73 2302600 9

Medium 24" 3000 9 x 6 8 80 500 24 9 x 13 39½ 20½ 53 72 16 44½ 42½ 41 23 8 22 28 14¼3500 74000 11

Medium 30" 4500 11 x 7 10 70 550 30 11 x 15 55 25½ 68 72 18 52 49¼ 51 29 10 24 36½ 23¾5000 9

Senior 36"

5000 12 x 7 10 60 565 12 246500 14 x 7 10 60 565 36 12 x 19 61 29 70 72 20 60 58½ 59 35 12 24 41¾ 247500 15 x 7 9 60 565 12 24

10,000 14 x 8 10 69 650 14 23

Senior 42"10,000 14 x 8 10 60 660 14 26½12,500 16 x 8 10 60 660 42 13 x 22 69 34 107 60 21 68¼ 66½ 66½ 40½ 16 23 48 25½15,000 18 x 8 9 60 660 18 24½

Senior 48" 12,500 16 x 8 10 52 654 48 13 x 22 84 37½ 117 60 21 72¼ 70 72½ 46½ 16 23 49 37½15,000 18 x 8 9 52 654 18 36½4300 12 x 6 8 10 12¾

Hi-Cap 24" 5200 12 x 7 9 81 500 24 12 x 16 44½ 24 55½ 72 16 44½ 42¼ 46 22 10 21¼ 25 12¾6000 12 x 7 8 12 11¾

Hi-Cap 30" 7500 15 x 7 9 70 550 30 12 x 19 60 29 82 60 24 60½ 59 52 28¼ 12 22¾ 43½ 24½17,500Hi-Cap 48" Contact Factory20,000

Capacity (75% bucket fill)

Model Sizes BPH CFPHTon/Hr60#/cf

Ton/Hr70#/cf

Max Disch,Height

"C" C-175-6-1.25 175 220 6.6 7.7 60 ft. C-500-6-1.25 500 630 18.9 22 60 ft. C-800-6-1.25 800 1000 30 35 60 ft.

Junior

JR-1000-12-1.75 Soft Dump 1000 1250 38 44 90 ft. JR-1250-12-1.75 1250 1565 47 55 90 ft. JR-1500-12-1.75 1500 1875 56 66 90 ft. JR-3000-12-1.75 3000 3750 113 131 90 ft.

DC 12" DC12-2000 2000 2500 75 87 100 ft. DC12-3000 3000 3750 113 131 100 ft.

Medium 24" M-2600-24-203 2600 3250 100 114 170 ft. M-3000-24-203 3000 3750 113 131 150 ft. M-3500-24-203 3500 4375 132 153 130 ft.

Medium 30" M-4000-30-203 4000 5000 150 175 196 ft. M-4500-30-203 4500 5625 169 200 174 ft. M-5000-30-203 5000 6250 188 219 158 ft.

Senior 36"

SR-5000-36-307 5000 6250 188 219 210 ft. SR-6500-36-307 6500 8125 245 284 210 ft. SR-7500-36-307 7500 9375 281 328 180 ft. SR-10000-36-307 10,000 12,500 375 437 160 ft.

Senior 42" SR-10000-42-307 10,000 12,500 375 437 198 ft. SR-12500-42-307 12,500 15,625 469 546 158 ft. SR-15000-42-307 15,000 18,750 563 656 132 ft.

Senior 48" SR-12500-48-307 12,500 15,625 469 546 210 ft. SR-15000-48-307 15,000 18,750 563 656 168 ft.

HI-CAP 24" HC-4300-24 4300 5375 162 189 152 ft. HC-5200-24 5200 6500 196 229 120 ft. HC-6000-24 6000 7250 219 256 110 ft.

HI-CAP 30” HC-7500-30 7500 9060 203 317 140 ft.

HI-CAP 48" HC48-17500 17,500 21,875

Contact Factory HC48-20000 20,000 25,000