QATAR QUARRY CO. W.L Quarry Company Profile.pdf · Page 7 of 7 Specification limits for Sub-bases...

Transcript of QATAR QUARRY CO. W.L Quarry Company Profile.pdf · Page 7 of 7 Specification limits for Sub-bases...

Page 1 of 7

QATAR QUARRY CO. W.L.L.

P.O. Box : 5007 DOHA - QATAR Tel. : 4653070/71/72 Telex : 4668 RMQ DH Telefax : 4651534 C.R. No. : 14678

COMPANY FOREWORD Qatar Quarry Co. is a Joint Venture Company between Lafarge Middle East and local partner HE Sheikh Hamad Bin Abdulla Al Thani, which has been in operation in Qatar since 1983. Currently one quarry is in operation in Simsimah area within 25 Kms. from Ras Laffan producing materials for unbound pavement, shoreline protection, breakwaters, berths, cable/pipe surround etc. Depending on demand & availability of reserves, the production capacity can be adjusted between 6 million tonnes per annum to 20 million tpa. Since 1993 the company has also been market leader in the importation of gabbro/imported limestone aggregates for supply to the Qatar market. Currently over 3,000,000 tonnes per year is being transported by sea through Mesaieed Port. In addition to this, we also deliver aggregate and rock products directly to customers who have temporary jetty facilities in Ras Laffan & New Doha International Airport sites. Qatar Quarry currently supplies many of the major projects in Qatar. Major contracts carried out during the last 20 years are :

YEAR CONTRACTOR PROJECT TONNES 1992-1995 Condotte & GLF JV Ras Laffan Port 3,000,000 1993-1994 GCC/KBAS/Al Sarh Module Corridor Road 200,000 1994-1995 Midmac/RMQ Qatar Gas LNG Tanks 250,000 1995-1996 Besix/Six Construct Doha Port – Quay Wall 300,000 1996-1999 BNI/Midmac/RMQ Al Udeid Military Base 200,000 1998-1999 Grandi Lavori Fincosit Qafac Berth - Mesaieed 350,000 1999-2000 Galfar Al Misnad Dual Carriage Way Ras Laffan 250,000 2000-2001 STFA New Service Berth Ras Laffan 800,000 2001-2003 Grandi Lavori Fincosit Multi-products & Small Craft Berth – Mesaieed 300,000 2002-2003 Grandi Lavori Fincosit Land Reclamation at LPG Tankage area – Ras

Laffan 2,500,000

2002-2004 Grandi Lavori Fincosit Crushed Stone Import Facilities - Mesaieed 800,000 2002-2004 ALEC/Darwish Eng. Power Station & Desalination Plant – Ras

Laffan 500,000

2002-2004 CCIC/GLF Common Cooling Water System 900,000 2003-2005 Archirodon

Construction LP Berth 1A/1B & 3A/3B – Ras Laffan 800,000

2003-2006 UEM Berhad Salwa International Highway 2,000,000

Page 2 of 7

2004-2005 Daewoo Eng/AGWED Laffan Refinery – Ras Laffan 2,000,000 2003-2006 Darwish/Midmac/J&P Education City 1,000,000 2005-2006 VanOord/Saipem Dolphin Offshore Pipeline – Ras Laffan 500,000 2006-2006 IHI/Ammico QG LNG Tanks & Plant – Ras Laffan 1,000,000 2005-2007 QDC NDIA – Shoreline Protection 1,000,000 2005-2007 QDC The Pearl Qatar 750,000 2005-2008 Gamuda (SGW) New Doha International Airport Pavement 3,500,000 2007-2008 STFA LNG Berth 6 Ras Laffan 1,500,000 2007-2009 JDN/Boskalis JV Ras Laffan Port Expansion – Phase I 31,500,000 2008-2009 CCIC (Ongoing) Ras Laffan Port Expansion – Phase II 3,500,000

Our present operation has a labour force of 400 people with 4 European Supervisors. During 2007-2008 period, our local quarry production was 35 million tonnes. To control the Quality of our product, we have established our own fully equipped Laboratory at the Simsimah Quarry. This Laboratory is capable of carrying out a full range of tests to both European & American Standards.

Qatar Quarry Co. received ISO 9002:1994 quality management certification in 1997, which was later upgraded to ISO 9001:2000 standard & subsequently to ISO 9001:2008 (copy attached).

Page 3 of 7

Page 4 of 7

•Simsimah Quarry •Imported Aggregates Depot in Mesaieed

SITE LOCATION

Page 5 of 7

GEOTECHNICAL CHARACTERISTICS The rock quarried at Qatar Quarry sites are found to contain a superficial mantle of recent carbonate sand and gravel which is underlain by a limestone bedrock of Simsima member of Upper Dammam Formation which is of Middle Eocene Age. The thickness of overburden varies from 30-60 cms. Below this lies the usable micro-crystalline limestone followed by unsuitable chalky limestone. The thickness of usable rock generally varies from 7 meters to 10 meters although it may contain pockets or bands of weak rock i.e. partially crystalline limestone, clayey limestone and marl. It is therefore important that the quarry faces are visually inspected regularly during the development of the quarries. The rock cores have been subjected to the following tests: Visual analysis, Specific Gravity, Water Absorption, Point Load Index, Sulphate & Chloride contents, Magnesium Sulphate Soundness, Petrographic examination, Chemical analysis, Mineral composition, Alkali Reactivity, Gel-Pat test etc. Based on the above test results it was concluded that the rock is suitable for producing aggregates for concrete, asphalt, road-base, structural fill; armour rock, underlayer and core rock for construction of breakwaters and shoreline protection works; rockfill, filter layer, rubble layer, bedding layer behind & under quay wall; reclamation fill, pipe surround and cable surround fill etc. provided that adequate quality control measures are taken during the processing of rock. TECHNICAL COMPLIANCE Quality requirements are laid down by the client based on the in-situ conditions, which the quarry products can be subjected to and with view to minimize the undesirable impact of the quarry products on its surroundings and vice-versa. Quality control methods employed at Qatar Quarry Co. also therefore depend on the end use of the product. Customers can be broadly classified into following categories as shown in the table below: Ser. No.

Customer Category Product Application Product Type

1. Concrete Producers Readymix Concrete, Precast Concrete, Hollow Blocks, Screed etc.

Coarse Aggregates

2. Pavement Contractors

Asphalt & Unbound pavement construction

Coarse & Fine aggregates, Sub-bases, Structural Fill, Sub-grade, Soakaway etc.

3. Marine Contractors Constuction of Breakwaters, Quay walls, Shoreline protection, Reclamation etc.

Armour rock, Underlayer, Filter layer, Bedding layer, Rockfill, Reclamation fill

4. Others including Drainage/Severage & Electrical Contractors

Pipe surround material, Cable surround fill etc.

Pipe Bedding, 5-0 mm Fill etc.

Page 6 of 7

Appendices attached herewith provide details of the general quality requirements that QQC products comply to : Specification limits for aggregates used in the manufacture of Concrete & Asphalt : 1. Sieve Analysis

% Passing

Graded Aggregates (mm) Single Sized Aggregates (mm)

Sieve Size

(mm) 40-5 20-5 14-5 40 20 14 10 5

50 100 - - 100 - - - - 37.5 90-100 100 - 85-100 100 - - - 20 35-70 90-100 100 0-25 85-100 100 - - 14 25-35 40-80 90-100 - 0-70 85-100 100 - 10 10-40 30-60 50-85 0-5 0-25 0-50 85-100 100 5 0-5 0-10 0-10 - 0-5 0-10 0-25 45-100

2.36 - - - - - - 0-5 0-30 2. Elongation Index (BS-812) - 30% max. 3. Flakiness Index (BS-812) - 25% max. 4. Clay, Silt & Dust content (BS-812) - 2% max. 5. Specific Gravity (SSD Basis) (BS-812) - 2.6 min. 6. Water Absorption (BS-812) - 2.0% max. 7. Aggregate Impact Value (BS-812) - 25% max. 8. Los Angeles Abrasion Value (ASTM C131) - 30% max 9. 10% Fines Value (BS-812) - 150 kN min. 10. Acid Soluble Sulphate Content (BS-812) - 0.4% max. 11. Acid Soluble Chloride Content (BS-812) - 0.030% max. 12. MgSO4 Soundness Loss (ASTM C88) - 15% max 13. Alkali Reactivity (ASTM C289) - Non-reactive

Page 7 of 7

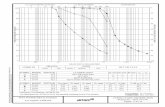

Specification limits for Sub-bases used in the construction of unbound pavement: 1. Sieve Analysis

% Passing Sieve Size (mm) Class-A Class-B Class-C

63.0 100 - - 50.0 90-100 100 - 37.5 60-90 70-100 - 25.0 42-77 55-85 100 20.0 35-70 50-80 90-100 10.0 25-60 40-70 50-85 5.0 15-40 30-60 35-65 2.36 10-26 20-50 25-50 0.425 5-15 10-30 15-30 0.075 2-9 5-15 5-15

2. Liquid Limit (BS 1377) - 25% max. 3. Plasticity Index (BS 1377) - 6% max 4. Flakiness Index (BS 812) - 35% max. 5. Los Angeles Abrasion Value (ASTM C131) - 40% max. 6. MgSO4 Soundness Loss (ASTM C88) - 18% max. 7. California Bearing Ratio (BS 1377) - 60 min. Specifications for shoreline protection materials ; 1. Weight distribution/Particle size distribution - Based on CIRIA SP-83 2. Specific Gravity (SSD Basis) - armour/underlayer 2.65 min. other rock grades 2.60 min 3. Water Absorption - armour/underlayer 2.0 max. other rock grades 3.0 max. 4. Franklin Point Load Index - armour/under. 3.5N/mm2 min others 2.3 N/mm2 min. 5. MgSO4 Soundness - 12% max. 6. Aggregate Impact Value - 30% max.

END