PXL System Hardware Architecture

description

Transcript of PXL System Hardware Architecture

L. Greiner 1PXL Sensor and RDO review – 06/23/2010

STAR

PXL System Hardware Architecture

L. Greiner 2PXL Sensor and RDO review – 06/23/2010

STARTalk Outline

• Revisit Requirements.• Overall Architecture.• Design Choices.• Summary.

L. Greiner 3PXL Sensor and RDO review – 06/23/2010

STAR PXL System Requirements

• Interface to the sensors for readout and control.

• Triggered detector system fitting into existing STAR infrastructure (Trigger, DAQ, etc.)

• Deliver full frame events to STAR DAQ for event building at approximately the same rate as the TPC (1 kHz for DAQ1000).

• Have live time characteristics such that the Pixel detector is live whenever the TPC is live. (PXL adds ≤ 5% additional dead time)

• Reduce the total data rate of the detector to a manageable level (< TPC rate of ~1MB / event).

• Reliable, cost effective, etc.

• Provide additional functionality for sensor testing including production probe testing.

L. Greiner 4PXL Sensor and RDO review – 06/23/2010

STARPixel Detector Characteristics

• Two concentric layers at 2.5 & 8 cm radii• 10 sensors/ladder, 4 ladders/module (arm), 10 modules/detector.• MAPS Pixel technology• Sensor spatial resolution < 10 μm • Coverage 2π in φ and |η|<1• Over 400 M pixels on ~0.16 m2 of Silicon• 0.37 % radiation length/layer • MCS limited resolution • Thinned silicon sensors (50 μm thickness)• Air cooled• Sensor power dissipation ~170 mW/cm2

• Quick extraction and detector replacement• Mechanical stability and insertion reproducibility within a 20 μm

window• Integration time <200 μs (L=8×1027)• Radiation environment at the level of up to 20k – 90k rad/year and

1011 -1012/cm2 Neq /year

L. Greiner 5PXL Sensor and RDO review – 06/23/2010

STAR System Constraints

• We need FPGA processing to do zero suppression (Phase-2) and event building. This necessitates moving the processing out of the high radiation area. (SEU)

• The constraint of locating the event fast pre-processing hardware ~7m from the sensors (in a lower radiation area) requires a driver/mass termination board located between the sensors and the processing hardware. This is required for mechanical and signal integrity reasons.

• This provides additional benefit that the main part of the electronics is in an area that is serviceable during a cave access.

• This leads to a 3 main component architecture.

L. Greiner 6PXL Sensor and RDO review – 06/23/2010

STAR PXL Hardware Architecture

80sensor data

5JTAG, RSTB

clk, START, SPEAK, marker8

LADDERMass Termination Board

LU Power Regulation

V5 Interface Motherboard

Temp diode2

Analog, Dig power, GND3

1 of 4

1 of 4

ana, dig, bufpower, gnd

4 3

320 sensor data

40JTAG, RSTB

clk, STARTSPEAK, marker8

Temp diode (I2C)4

LU senseand reset

LU sense and reset12

SIU

Fib

ers

gnd1

STA

R T

CD pw

r, g

nd

2

CM

OS

i/o

LVD

S i/

o

diff

anal

og in

pwr,

gnd

US

B

pwr,

gnd

in

Buf pwr2

clk returnclk return22

RDO motherboard Mass Termination Board

Ladder

L. Greiner 7PXL Sensor and RDO review – 06/23/2010

STARLadder1 of 4

80se

nsor

dat

a

5JT

AG

, RS

TB

STA

RT

, SP

EA

K, m

arke

r3

Tem

p di

ode

Ana

log,

Dig

pow

er, G

ND

3

sensors

clk,

clk

retu

rn

sensor data

clk, clk returnbu

f pow

er, G

ND

2LVDSbuffer

4

LVDS=>TTL

2 2

PXL Hardware Architecture

L. Greiner 8PXL Sensor and RDO review – 06/23/2010

STAR

80sensor data

5JTAG, RSTB

clk, START, SPEAK,clk return8

Mass Termination Board

Temp diode2

Analog, Dig, buf power, GND5

ana, dig, bufpower, gnd

53

320 sensor data

40JTAG, RSTB

clk, START, SPEAK,clk return

8

Temp diode4

LU senseand reset

LU sense and reset12

gnd1

pwr, gnd 2

pwr,

gnd

in

LVDSbuffer

LVDS=>TTL

marker

ADC

8 marker

x4

x4

x4

x4

x4

x4x4

2LVDSbuffer

LVDSbuffer

PXL Hardware Architecture

L. Greiner 9PXL Sensor and RDO review – 06/23/2010

STAR

V5 Interface Motherboard320 sensor data

40JTAG, RSTB

clk, START, SPEAK, marker, clk return

16

Temp diode4S

IU F

iber

s

gnd1

STA

R T

CD

CM

OS

i/o

LVD

S i/

o

diff

anal

og in

pwr,

gnd

US

B

Virtex-5LVDSbuffer

PMC

Busswitch

LU s

ense

and

res

et

12

TTL =>PECL ADC

QuickUSB

SRAM

Busswitch

PXL Hardware Architecture

L. Greiner 10PXL Sensor and RDO review – 06/23/2010

STARFunctional Data Path – One Ladder

buffer

JTAG, CLK, CTL, markers

buffer

LU protected power

Digital hit data

10 sensors

• After power-on and configuration, the sensors are run continuously. • Triggering is handled in the next stage of the RDO.

1 Ladder

Develop readout electronics (WBS 1.2.2.5)

L. Greiner 11PXL Sensor and RDO review – 06/23/2010

STARFunctional Data Path – Phase-1

• Each received trigger enables an event buffer for one frame.

• The system is dead-time free up to the hardware buffering limit.

Highly Parallel FPGA based RDO system

• 40 sensor outputs/ladder

• 1 sector / RDO board EventBuffer

EventBuffer

1

2

EventBuilder

RDOBuffer

SIU

DAQPC

Disk

80 independent sensor data chains

One per RDO board

address counter (zero suppression)

160 MHzbinary data

160 independent sensor data chains

L. Greiner 12PXL Sensor and RDO review – 06/23/2010

STARFunctional Data Path – PXL Sensor

• 20 sensor outputs/ladder

• 1 sector / RDO board

Highly Parallel FPGA based RDO system

• Same hardware with reconfigured firmware

EventBuffer

EventBuffer

1

2

EventBuilder

RDOBuffer

SIU

DAQPC

Disk

160 MHz Address only data

80 independent sensor data chains

One per RDO board

L. Greiner 13PXL Sensor and RDO review – 06/23/2010

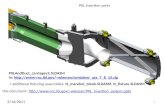

STARRDO System Design – Physical Layout

1-2 mLow mass twisted pair

6 m - twisted pair

Sensors / Ladders / Sectors(interaction point)

LU Protected Regulators,Mass cable termination

RDO Boards

DAQ PCs(Low Rad Area)

DAQ Room

PowerSupplies

Platform 30 m

100 m - Fiber optic30 mControl

PCs

30 m

L. Greiner 14PXL Sensor and RDO review – 06/23/2010

STARPXL RDO Basic Unit

2m6m

RDO PC100m

• 4 ladders per sector• 1 Mass Termination Board (MTB) per sector• 1 sector per RDO board• 10 RDO boards in the PXL system

Develop readout electronics (WBS 1.2.2.5)

L. Greiner 15PXL Sensor and RDO review – 06/23/2010

STAR Ladder Constraints

• 10 sensors to give required eta coverage

• Radiation length budget dedicated to cable/sensor assembly (0.17%) in low mass region.– Sensors thinned to 50 µm (X/X0 ~0.053%)– Al conductor 2 sided cable (X/X0 ~0.08%)

• Mechanical stiffener between cable and sector tube.

• Buffering for all signals to/from ladder.

• Fine twisted pair wire interface to ladders.

L. Greiner 16PXL Sensor and RDO review – 06/23/2010

STAR Ladder Design

The ladder consists of three main elements

10 x sensors

adhesive

Kapton flex cable

adhesive

Carbon fiber stiffener plate

• Thinning sensors to 50 µm is a standard commercial process.• The adhesive is a 50 µm acrylic film adhesive.• The carbon fiber stiffener plate is a basket weave 90º prepreg.• The flex cable is the component that requires a significant

development effort.

L. Greiner 17PXL Sensor and RDO review – 06/23/2010

STAR Flex Cable Development

There are 4 stages to the development process• Stage1 – Infrastructure Testing Board - evaluate the general design

of running 10 sensors on a ladder and find and test the working envelope of bypass capacitance and power supply and ground connection

• Stage 2 – FR-4 ladder cable prototype with Cu - Taking the knowledge gained in the Infrastructure Test Phase, we now attempt to fit the readout cable traces into the required size of the ladder readout cable.

• Stage 3 – Kapton ladder cable prototype with Cu – Translate above design to kapton flex.

• Stage 4 – Kapton ladder cable with Al – production prototype for the final ladder cable.

http://rnc.lbl.gov/hft/hardware/docs/cd1/PXL_flex_cable_and_sys_test_v2.doc

L. Greiner 18PXL Sensor and RDO review – 06/23/2010

STARFlex Cable Development

Low mass Sensor regionDriver region

Side view (exaggerated vertical scale)

Top View

• 2 layer Al conductor cable in low mass region• 0.004” (100 µm) traces and 0.004” (100 µm) spaces• 70% fill factor• Conductor thickness in low mass region is 21 µm (Cu) or 32 µm (Al)• Minimum required conductor trace width 1.325” (33.65 mm) of 46.16 mm available. • Bond wire connection between Al and Cu cable sections.

Low mass region calculated X0 for Al conductor = 0.073 %Low mass region calculated X0 for Cu conductor = 0.232 %

Preliminary Design: Hybrid Copper / Aluminum conductor flex cable

L. Greiner 19PXL Sensor and RDO review – 06/23/2010

STAR MTB Design

• Services 1 sector (4 ladders)• Buffers for all signals to and from ladders• ADC for temperature measurement of sensors• LU protected power daughter-card for each ladder• PLL to regenerate 50% duty cycle clock

L. Greiner 20PXL Sensor and RDO review – 06/23/2010

STARRDO motherboard design constraints

• 320 input data pins for Phase-1/2 sensor data / sector.• 160 input data pins for Final sensor data / sector.• JTAG, sensor CLK, etc. generation.• IODELAY function (Xilinx Virtex).• ALICE DDL interface to STAR DAQ.• STAR trigger interface.• USB interface• Sensor testing capabilities (one development platform)

– 8 ch ADC (50 MHz)– Fast SRAM for full frame event capture– Misc logic inputs for control / triggering (beam tests)

L. Greiner 21PXL Sensor and RDO review – 06/23/2010

STAR RDO motherboard designThe RDO board is a 2 board design

Virtex-5Daughtercard

JTAG interfaceRDO MB int.

RDO Motherboard

Sensor data interfaceSensor control interface

Virtex-5 interfaceSTAR Trigger interface

QuickUSB interfacePMC interface (DDL)

8 ch 50 MHz 12b ADC144Mb SRAM

Auxiliary logic interface

L. Greiner 22PXL Sensor and RDO review – 06/23/2010

STAR RDO motherboard designThe RDO board is a 2 board design

XilinxAFX-FF1760-500

Xilinx XC5VLX330

10,638 Kb block RAM1200 i/o

Custom Motherboard

6 layerStandard PCB “5 on 5”No BGA

L. Greiner 23PXL Sensor and RDO review – 06/23/2010

STARRDO motherboard design comments

• The complete RDO system for PXL consists of 10 RDO motherboard assemblies.

• Investment in a ≥ 16 layer custom RDO motherboard with BGA Xilinx V-5 is not warranted for this quantity.

• Additional testing functionality need not be loaded for production RDO boards.

• This design allows for a single development platform through the full project life cycle.

L. Greiner 24PXL Sensor and RDO review – 06/23/2010

STAR Parts Specifications

MAPS sensorFIN1108 Fairchild LVDS 8 Port RepeaterSN74LVC126A TI Quad Bus buffer gateSN65LVDS2 TI Single LVDS receiver

FIN1108 Fairchild LVDS 8 Port RepeaterSN65LVDT14 TI Interconnect Extender Chipset w/ LVDSSN65LVDT41 TI Interconnect Extender Chipset w/ LVDSAD7997 Analog Devices 8-ch, 10-bit I2C ADCCY7B9950 Cypress 200MHz PLL Clock BufferMIC37152 MICREL 1.5A LDO Voltage RegulatorAD626 Analog Devices single supply diff. amplifierAD8611 Analog Devices single supply comparatorpolyfuses

Ladder components

MTB components

Highradiation

area

Moderateradiation

area

L. Greiner 25PXL Sensor and RDO review – 06/23/2010

STAR Simple Data Rates

Item Number

Bits/address 20

Integration time 200 µs

Luminosity 8 × 1027

Hits / frame on Inner sensors (r=2.5 cm) 246

Hits / frame on Outer sensors (r=8.0 cm) 24

Final sensors (Inner ladders) 100

Final sensors (Outer ladders) 300

Event format overhead TBD

Average Pixels / Cluster 2.5

Average Trigger rate 1 kHz

Item Number

Bits/address 20

Integration time 640 µs

Luminosity 3 × 1027

Hits / frame on Inner sensors (r=2.5 cm) 295

Hits / frame on Outer sensors (r=8.0 cm) 29

Phase-1 sensors (Inner ladders) 100

Phase-1 sensors (Outer ladders) 300

Event format overhead TBD

Average Pixels / Cluster 2.5

Average Trigger rate 1 kHz

Phase-1/2 Final (Ultimate)

Raw data rate from sensors = 32 GB/secData rate to storage = 237 MB/sec Data rate to storage = 199 MB/sec(Scaled to full size detector) (199 kB/event)Note: Data rates for hit data only for Au-Au central collisions including peripheral collision electrons. Sensor noise is not included.

Item Number

Bits/address 20

Integration time 640 µs

Luminosity 3 × 1027

Hits / frame on Inner sensors (r=2.5 cm) 295

Hits / frame on Outer sensors (r=8.0 cm) 29

Phase-1 sensors (Inner ladders) 100

Phase-1 sensors (Outer ladders) 300

Event format overhead TBD

Average Pixels / Cluster 2.5

Average Trigger rate 1 kHz

Item Number

Bits/address 20

Integration time 200 µs

Luminosity 8 × 1027

Hits / frame on Inner sensors (r=2.5 cm) 246

Hits / frame on Outer sensors (r=8.0 cm) 24

Final sensors (Inner ladders) 100

Final sensors (Outer ladders) 300

Event format overhead TBD

Average Pixels / Cluster 2.5

Average Trigger rate 1 kHz

L. Greiner 26PXL Sensor and RDO review – 06/23/2010

STARSummary

• We have a well developed system architecture that is driven by the tracking, mechanical and testing constraints.

• Highly parallel system based on ladder and sector units.

• FPGA based data receiver and processing.

• Leverages commercial Xilinx development boards mated to a custom motherboard.

• Single architectural unit to provide for all required development and testing.

L. Greiner 27PXL Sensor and RDO review – 06/23/2010

STARBackup

L. Greiner 28PXL Sensor and RDO review – 06/23/2010

STARPXL Detector Design

Ladder with 10 MAPS sensors (~ 2×2 cm each)

MAPSRDObuffers/drivers

4-layer kapton cable with aluminium traces

Mechanical support with kinematic mounts

Cabling and cooling infrastructure

Detector extraction at one end of the cone

New beryllium beam pipe (800 µm thick, r = 2.5 cm)

2 layers10 modules4 ladders/module

L. Greiner 29PXL Sensor and RDO review – 06/23/2010

STARSensor Generation and RDO Attributes

Mimostar–2 30 µm pixel, 128 x 128 array1.7 ms integration time1 analog outputMimostar–330 µm pixel, 320 x 640 array2.0 ms integration time2 analog outputsPhase–130 µm pixel, 640 x 640 array640 µs integration time, CDS4 binary digital outputsPXL Sensor (Ultimate)18.4 µm pixel, 1024 x 1088 array≤ 200 µs integration time, CDS,zero suppression2 digital outputs (addresses)

Sensor Sensor RDO

50 MHz readout clockJTAG interface, control infrastructureADCs, FPGA CDS & cluster findingzero suppression ≤ 4 sensor simultaneous readout

160 MHz readout clockJTAG interface, control infrastructurezero suppression40 sensor simultaneous readout

160 MHz readout clockJTAG interface, control infrastructure400 sensor simultaneous readout(full system)

DO

NE

PR

OTO

TYP

ED

Gen

1

1

2

3

L. Greiner 30PXL Sensor and RDO review – 06/23/2010

STARSensor / RDO Services (preliminary)

240 W 180W 300W

1350W (AC)

1100W (AC)

LaddersMTB

Platform(racks)

RDOCrate

DAQ Room

4800 × 42 AWG (TP)160 × 24 AWG (TP)

40 × 0.42” dia. (50 TP cable)20 × 16 AWG

10 × fiber optic cable pair

10 × USB2 × TCD (10 TP)28 × 12 AWG

2m

6m

~100m

PP

~30m